444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2750

The North America drilling completion fluids market represents a critical segment of the oil and gas industry, encompassing specialized chemical formulations essential for well completion operations. This dynamic market serves the extensive drilling activities across the United States, Canada, and Mexico, supporting both conventional and unconventional hydrocarbon extraction processes. Market dynamics indicate robust growth driven by increasing shale gas exploration, enhanced oil recovery techniques, and technological advancements in drilling fluid formulations.

Regional distribution shows the United States commanding approximately 78% market share, with Texas, North Dakota, and Pennsylvania leading in drilling activities. Canada contributes significantly through its oil sands operations and conventional drilling programs, while Mexico’s energy sector reforms have opened new opportunities for completion fluid applications. The market demonstrates strong correlation with regional drilling rig counts and completion activities.

Technology integration has revolutionized completion fluid applications, with smart fluids and environmentally sustainable formulations gaining prominence. The market experiences seasonal variations aligned with drilling campaigns, weather conditions, and commodity price fluctuations. Growth projections indicate the market expanding at a 6.2% CAGR through the forecast period, supported by increasing horizontal drilling activities and multi-stage hydraulic fracturing operations.

The North America drilling completion fluids market refers to the comprehensive ecosystem of specialized chemical solutions, additives, and fluid systems used during the completion phase of oil and gas wells across the North American region. These fluids serve multiple critical functions including wellbore stability, formation damage prevention, and optimal hydrocarbon production facilitation.

Completion fluids encompass various formulations including clear brines, weighted completion fluids, and specialized chemical systems designed to maintain wellbore integrity during completion operations. These fluids must possess specific properties such as appropriate density, low formation damage potential, thermal stability, and compatibility with downhole equipment and formation characteristics.

Market scope includes fluid manufacturing, distribution, technical services, and recycling operations supporting drilling completion activities. The market serves diverse applications from conventional vertical wells to complex horizontal multi-lateral completions, each requiring tailored fluid solutions to optimize production outcomes and minimize operational risks.

Market leadership in North America’s drilling completion fluids sector reflects the region’s position as a global energy production hub, with sophisticated completion technologies driving demand for advanced fluid solutions. The market benefits from established infrastructure, technological innovation, and extensive unconventional resource development programs across major shale formations.

Key growth drivers include increasing horizontal drilling activities, which account for approximately 85% of new well completions, and the rising adoption of multi-stage hydraulic fracturing techniques. Environmental regulations have accelerated development of eco-friendly completion fluids, with biodegradable formulations representing a growing market segment.

Competitive dynamics feature established oilfield service companies, specialty chemical manufacturers, and regional fluid suppliers competing on technology innovation, service quality, and cost optimization. The market demonstrates consolidation trends as companies seek to expand service capabilities and geographic coverage.

Future outlook remains positive despite commodity price volatility, with technological advancements in completion fluid chemistry, digitalization of fluid management systems, and increasing focus on environmental sustainability driving long-term growth opportunities across the North American energy sector.

Strategic insights reveal several critical factors shaping the North America drilling completion fluids market landscape:

Primary growth catalysts propelling the North America drilling completion fluids market include expanding unconventional resource development, technological innovations in completion techniques, and increasing focus on production optimization. These drivers create sustained demand for advanced fluid solutions across diverse drilling environments.

Unconventional drilling expansion represents the most significant market driver, with horizontal drilling and hydraulic fracturing operations requiring specialized completion fluids. The Permian Basin, Bakken, and Eagle Ford formations continue generating substantial fluid demand as operators pursue enhanced recovery techniques and longer lateral completions.

Technological advancement in completion fluid chemistry enables improved wellbore stability, reduced formation damage, and enhanced production outcomes. Smart fluid systems incorporating nanotechnology, biodegradable additives, and real-time monitoring capabilities address evolving industry requirements for performance and environmental compliance.

Regulatory compliance drives adoption of environmentally sustainable completion fluids, with operators seeking solutions that minimize environmental impact while maintaining operational effectiveness. This trend accelerates development of bio-based additives, closed-loop fluid systems, and advanced recycling technologies.

Economic optimization pressures encourage operators to maximize production efficiency through superior completion fluid selection and application. Cost-effective fluid solutions that reduce completion time, minimize formation damage, and enhance long-term well productivity create competitive advantages in challenging market conditions.

Significant challenges constraining the North America drilling completion fluids market include commodity price volatility, environmental regulations, and technical complexity associated with advanced completion operations. These restraints require strategic adaptation and innovation from market participants.

Commodity price fluctuations directly impact drilling activity levels and completion fluid demand, creating cyclical market conditions that challenge revenue predictability. Oil and gas price volatility influences operator capital allocation decisions, affecting completion fluid procurement and inventory management strategies.

Environmental regulations impose stringent requirements on fluid composition, disposal methods, and operational practices, increasing compliance costs and limiting certain chemical formulations. Regulatory complexity varies across jurisdictions, creating challenges for companies operating in multiple regions.

Technical complexity of modern completion operations requires specialized expertise and advanced fluid formulations, increasing operational risks and costs. Complex wellbore geometries, extreme downhole conditions, and diverse formation characteristics demand customized fluid solutions that may not be readily available.

Supply chain disruptions can impact raw material availability and pricing, affecting completion fluid manufacturing and distribution. Geographic concentration of chemical suppliers and transportation constraints during peak drilling seasons create potential bottlenecks in fluid supply chains.

Competition intensity among service providers pressures profit margins and requires continuous investment in technology development and service enhancement. Price competition, particularly during market downturns, challenges the sustainability of smaller regional suppliers and specialty fluid manufacturers.

Emerging opportunities in the North America drilling completion fluids market encompass technological innovation, environmental sustainability, and geographic expansion potential. These opportunities enable market participants to develop competitive advantages and capture new revenue streams.

Green chemistry development presents substantial opportunities for companies developing environmentally sustainable completion fluids. Bio-based additives, biodegradable formulations, and closed-loop recycling systems address growing environmental concerns while maintaining operational performance standards.

Digital integration opportunities include IoT-enabled fluid monitoring systems, predictive analytics for fluid performance optimization, and automated fluid management solutions. These technologies enhance operational efficiency, reduce costs, and provide valuable data insights for continuous improvement.

Unconventional resource expansion in emerging shale formations and tight oil plays creates demand for specialized completion fluid solutions. New drilling areas require customized fluid formulations adapted to specific geological conditions and operational requirements.

Service diversification opportunities include comprehensive fluid management services, technical consulting, and integrated completion solutions. Companies can differentiate through value-added services that optimize fluid performance and reduce operational complexity for operators.

International expansion potential exists as North American completion fluid technologies and expertise find applications in global unconventional resource development. Export opportunities and technology licensing arrangements can extend market reach beyond regional boundaries.

Complex interactions between supply and demand factors, technological evolution, and regulatory frameworks shape the North America drilling completion fluids market dynamics. Understanding these relationships enables stakeholders to navigate market volatility and capitalize on emerging trends.

Supply-demand balance fluctuates with drilling activity cycles, seasonal variations, and regional development patterns. Peak drilling seasons create temporary supply constraints, while market downturns result in excess capacity and competitive pricing pressures. Capacity utilization rates typically range between 65-85% depending on market conditions.

Technology adoption cycles influence market dynamics as new completion fluid formulations and application techniques gain acceptance. Early adopters benefit from competitive advantages, while widespread adoption eventually commoditizes advanced technologies and shifts competitive focus to cost optimization.

Regulatory evolution continuously reshapes market requirements and opportunities. Environmental regulations drive innovation in sustainable fluid technologies, while safety standards influence operational practices and equipment specifications. Compliance costs and market access requirements vary significantly across jurisdictions.

Economic sensitivity to commodity prices creates cyclical demand patterns that challenge business planning and investment decisions. Companies must balance capacity investments with market volatility while maintaining service quality and technological capabilities during challenging periods.

Comprehensive research approach employed for analyzing the North America drilling completion fluids market combines primary research, secondary data analysis, and industry expert insights to provide accurate market intelligence and strategic recommendations.

Primary research activities include structured interviews with industry executives, technical specialists, and procurement managers across the drilling completion fluids value chain. Survey methodologies capture quantitative data on market trends, technology adoption, and purchasing behaviors from representative industry participants.

Secondary research encompasses analysis of industry publications, regulatory filings, company annual reports, and technical literature to validate primary findings and identify emerging trends. Patent analysis and technology assessments provide insights into innovation trajectories and competitive positioning.

Data validation processes ensure research accuracy through triangulation of multiple information sources, expert review panels, and statistical verification methods. Market sizing methodologies incorporate bottom-up analysis of drilling activity data, completion fluid consumption rates, and regional market dynamics.

Analytical frameworks include Porter’s Five Forces analysis, SWOT assessments, and scenario planning to evaluate market attractiveness and competitive dynamics. Quantitative modeling techniques project market growth trajectories under various economic and technological scenarios.

United States dominance in the North America drilling completion fluids market reflects the country’s extensive unconventional resource development and advanced completion technologies. Major shale formations including the Permian Basin, Bakken, and Marcellus drive substantial completion fluid demand across diverse geological conditions.

Texas leadership stems from Permian Basin activities, which account for approximately 45% of US drilling completions. The region’s favorable geology, established infrastructure, and operator concentration create the largest single market for completion fluids. Eagle Ford and Barnett formations contribute additional demand in the state.

North Dakota significance centers on Bakken formation development, requiring specialized completion fluids for extreme weather conditions and unique geological characteristics. The state’s drilling activities demonstrate seasonal variations with peak operations during favorable weather periods.

Pennsylvania operations in the Marcellus and Utica formations drive completion fluid demand in the Appalachian region. Environmental regulations and population density create unique requirements for environmentally sustainable fluid solutions and careful waste management practices.

Canada contributions include oil sands operations requiring specialized completion fluids for thermal recovery processes and conventional drilling activities in Western Canada. The country’s regulatory environment emphasizes environmental protection and indigenous community engagement in resource development projects.

Mexico opportunities emerge from energy sector reforms enabling increased foreign investment and technology transfer. The country’s offshore and onshore resources require completion fluid solutions adapted to local conditions and regulatory requirements.

Market leadership in the North America drilling completion fluids sector features established oilfield service companies, specialty chemical manufacturers, and regional suppliers competing on technology innovation, service quality, and operational efficiency.

Competitive strategies emphasize technology differentiation, service integration, and geographic expansion to capture market share and enhance profitability. Companies invest in research and development, strategic acquisitions, and partnership arrangements to strengthen competitive positioning.

Market segmentation analysis reveals diverse completion fluid categories serving specific applications and operational requirements across the North America drilling completion fluids market. Understanding segmentation dynamics enables targeted product development and market positioning strategies.

By Fluid Type:

By Application:

By End-User:

Clear brines category represents the largest segment by volume, accounting for approximately 52% of completion fluid usage due to widespread application in conventional and unconventional completions. These cost-effective solutions provide basic wellbore stability and formation protection during completion operations.

Weighted completion fluids serve high-pressure formations and complex completion scenarios requiring precise density control. This segment demonstrates steady growth driven by deepwater drilling activities and high-pressure, high-temperature applications across North American basins.

Synthetic fluids segment exhibits the fastest growth rate due to superior performance characteristics and environmental advantages. These advanced formulations address stringent regulatory requirements while providing enhanced operational benefits including reduced formation damage and improved wellbore stability.

Specialty additives market grows through increasing complexity of completion operations and demand for customized fluid properties. Corrosion inhibitors, biocides, and performance enhancers enable optimization of fluid systems for specific geological conditions and operational requirements.

Horizontal completion applications drive the majority of market growth, reflecting the dominance of unconventional drilling techniques in North American resource development. These operations require specialized fluid formulations capable of maintaining performance across extended lateral sections and multiple fracturing stages.

Independent operator segment demonstrates strong demand for cost-effective completion fluid solutions that balance performance requirements with economic constraints. These companies often prefer standardized fluid systems that provide reliable performance across multiple well completions.

Operators benefit from advanced completion fluid technologies through improved well productivity, reduced completion time, and enhanced operational safety. Superior fluid formulations minimize formation damage, optimize production rates, and extend well life, directly impacting project economics and return on investment.

Service companies gain competitive advantages through comprehensive completion fluid portfolios that address diverse customer requirements. Integrated service offerings including fluid supply, technical support, and waste management create differentiation opportunities and strengthen customer relationships.

Chemical manufacturers capitalize on growing demand for specialized additives and environmentally sustainable formulations. Innovation in completion fluid chemistry creates opportunities for premium pricing and long-term supply agreements with major industry participants.

Equipment suppliers benefit from increasing adoption of automated fluid handling systems and digital monitoring technologies. Integration of completion fluid management with drilling and completion equipment creates synergistic opportunities for comprehensive solution providers.

Environmental stakeholders gain from industry adoption of sustainable completion fluid technologies that reduce environmental impact and improve waste management practices. Green chemistry initiatives and recycling programs address environmental concerns while maintaining operational effectiveness.

Regional communities benefit from responsible completion fluid practices that protect groundwater resources and minimize surface impacts. Industry commitment to environmental stewardship and community engagement creates positive relationships and social license to operate.

Strengths:

Weaknesses:

Opportunities:

Threats:

Environmental sustainability emerges as the dominant trend shaping the North America drilling completion fluids market, with operators increasingly adopting bio-based additives and recyclable fluid systems. This trend responds to regulatory requirements and public concerns about environmental impact of drilling operations.

Digital transformation accelerates through integration of IoT sensors, real-time monitoring systems, and predictive analytics in completion fluid management. These technologies enable optimization of fluid performance, reduction of operational costs, and enhancement of safety protocols across drilling operations.

Customization demand increases as operators seek completion fluid solutions tailored to specific geological conditions and operational requirements. This trend drives development of specialized formulations for unique formation characteristics and completion techniques.

Service consolidation continues as companies seek comprehensive completion fluid solutions including supply, application, monitoring, and waste management services. Integrated service models reduce operational complexity and improve cost efficiency for operators.

Recycling adoption expands through advanced treatment technologies that enable reuse of completion fluids across multiple wells. This trend addresses environmental concerns while reducing fluid costs and waste disposal requirements.

Automation integration grows through deployment of automated fluid handling systems that reduce manual labor requirements and improve operational safety. These systems enhance precision in fluid mixing, pumping, and monitoring operations.

Recent innovations in the North America drilling completion fluids market demonstrate industry commitment to technological advancement and environmental responsibility. MarkWide Research analysis indicates accelerating development of next-generation fluid technologies and service delivery models.

Halliburton’s CleanStream technology represents breakthrough development in environmentally sustainable completion fluids, utilizing bio-based additives that reduce environmental impact while maintaining operational performance. This innovation addresses growing regulatory and public pressure for greener drilling practices.

Schlumberger’s digital fluid management platform integrates IoT sensors, cloud computing, and machine learning algorithms to optimize completion fluid selection and application. The system provides real-time monitoring and predictive analytics capabilities that enhance operational efficiency.

Baker Hughes’ advanced recycling systems enable treatment and reuse of completion fluids across multiple wells, reducing waste generation and operational costs. These systems incorporate membrane filtration, chemical treatment, and quality control technologies.

Strategic partnerships between completion fluid suppliers and technology companies accelerate development of integrated solutions. These collaborations combine chemical expertise with digital technologies to create comprehensive completion fluid management platforms.

Regulatory developments include updated environmental standards and disclosure requirements that influence completion fluid formulations and application practices. Industry adaptation to these requirements drives innovation in sustainable fluid technologies.

Strategic recommendations for North America drilling completion fluids market participants emphasize technology innovation, environmental sustainability, and service differentiation as key success factors in the evolving industry landscape.

Investment priorities should focus on research and development of environmentally sustainable completion fluid formulations that meet regulatory requirements while maintaining operational performance. Companies investing in green chemistry capabilities will capture growing market demand for sustainable solutions.

Digital transformation initiatives require integration of IoT technologies, data analytics, and automation systems to enhance completion fluid management capabilities. These investments improve operational efficiency, reduce costs, and provide competitive differentiation in technology-driven market segments.

Geographic expansion opportunities exist in emerging shale formations and international markets where North American completion fluid expertise can create competitive advantages. Strategic partnerships and joint ventures enable market entry while sharing investment risks and local market knowledge.

Service integration strategies should encompass comprehensive completion fluid solutions including supply chain management, technical services, and waste handling capabilities. Integrated service models create customer value and strengthen competitive positioning through reduced operational complexity.

Workforce development investments in technical training and expertise development address skilled labor shortages while building capabilities for advanced completion fluid technologies. Companies with strong technical capabilities will capture premium market segments and customer relationships.

Long-term prospects for the North America drilling completion fluids market remain positive despite short-term volatility, with technological innovation and environmental sustainability driving market evolution. MWR projections indicate sustained growth supported by unconventional resource development and advancing completion technologies.

Technology advancement will continue reshaping market dynamics through development of smart fluids, nanotechnology applications, and integrated digital management systems. These innovations enhance operational performance while addressing environmental and regulatory requirements that influence market development.

Market consolidation trends are expected to accelerate as companies seek scale advantages and comprehensive service capabilities. Strategic acquisitions and partnerships will create larger, more capable organizations better positioned to serve evolving customer requirements and invest in technology development.

Environmental regulations will increasingly influence completion fluid formulations and application practices, driving continued innovation in sustainable technologies. Companies successfully adapting to environmental requirements will capture growing market segments focused on responsible resource development.

International expansion opportunities will emerge as global unconventional resource development adopts North American completion technologies and expertise. Export potential and technology licensing arrangements can extend market reach beyond regional boundaries while leveraging established capabilities.

Growth projections indicate the market expanding at a 6.8% CAGR over the next five years, driven by increasing horizontal drilling activities, technological innovation, and environmental sustainability initiatives that create new market opportunities and competitive dynamics.

The North America drilling completion fluids market demonstrates resilience and growth potential despite cyclical challenges, supported by technological innovation, environmental sustainability initiatives, and expanding unconventional resource development. Market participants who successfully navigate regulatory requirements, invest in sustainable technologies, and develop comprehensive service capabilities will capture the most significant opportunities in this evolving industry landscape.

Strategic success requires balancing operational performance with environmental responsibility while maintaining cost competitiveness in volatile market conditions. Companies that integrate digital technologies, develop sustainable fluid formulations, and provide comprehensive service solutions will establish competitive advantages and strengthen market positioning.

Future market development will be shaped by continued technological advancement, evolving regulatory frameworks, and changing customer expectations for environmental stewardship. The industry’s ability to adapt to these trends while maintaining operational excellence will determine long-term market growth and profitability across the North American drilling completion fluids sector.

What is Drilling Completion Fluids?

Drilling Completion Fluids are specialized fluids used in the drilling and completion of oil and gas wells. They serve various functions, including maintaining pressure, cooling the drill bit, and transporting cuttings to the surface.

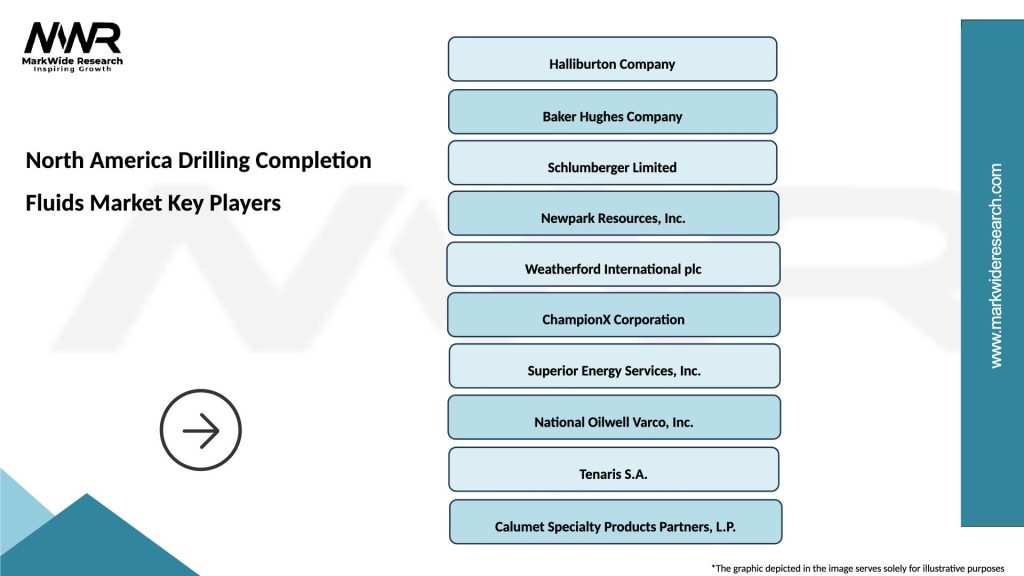

What are the key players in the North America Drilling Completion Fluids Market?

Key players in the North America Drilling Completion Fluids Market include Halliburton, Schlumberger, Baker Hughes, and Newpark Resources, among others. These companies provide a range of products and services tailored to the needs of the oil and gas industry.

What are the growth factors driving the North America Drilling Completion Fluids Market?

The growth of the North America Drilling Completion Fluids Market is driven by increasing oil and gas exploration activities, advancements in drilling technologies, and the rising demand for energy. Additionally, the shift towards unconventional resources is also contributing to market expansion.

What challenges does the North America Drilling Completion Fluids Market face?

The North America Drilling Completion Fluids Market faces challenges such as fluctuating oil prices, environmental regulations, and the need for sustainable practices. These factors can impact investment and operational decisions within the industry.

What opportunities exist in the North America Drilling Completion Fluids Market?

Opportunities in the North America Drilling Completion Fluids Market include the development of eco-friendly fluids, innovations in fluid technology, and the expansion of offshore drilling activities. These trends can enhance operational efficiency and reduce environmental impact.

What trends are shaping the North America Drilling Completion Fluids Market?

Trends shaping the North America Drilling Completion Fluids Market include the increasing use of digital technologies for monitoring and optimization, the rise of automation in drilling processes, and a focus on sustainability. These trends are influencing how companies approach drilling operations.

North America Drilling Completion Fluids Market

| Segmentation Details | Description |

|---|---|

| Product Type | Water-Based Fluids, Oil-Based Fluids, Synthetic Fluids, Foam Fluids |

| Application | Onshore Drilling, Offshore Drilling, Workover Operations, Well Completion |

| End User | Independent Operators, National Oil Companies, Service Companies, Multinational Corporations |

| Technology | Conventional Techniques, Advanced Fluid Systems, Biodegradable Solutions, Smart Fluids |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the North America Drilling Completion Fluids Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at