444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Yaw Drive market is witnessing steady growth, driven by the increasing deployment of wind turbines for renewable energy generation worldwide. Yaw drives play a crucial role in wind turbine systems by enabling the rotation of the nacelle and rotor to align with changing wind directions, maximizing energy capture and operational efficiency. These drives utilize advanced gearing, motor, and control technologies to ensure precise yaw alignment, smooth operation, and reliable performance in diverse wind conditions. With the growing emphasis on clean energy transition and decarbonization efforts, the demand for yaw drives is expected to continue rising, supporting the expansion of wind power capacity and the development of sustainable energy infrastructure globally.

Meaning

Yaw drives are mechanical components installed in wind turbine systems to facilitate the rotation of the nacelle and rotor assembly to align with prevailing wind directions. By adjusting the orientation of the turbine rotor relative to the wind direction, yaw drives optimize energy capture and turbine performance, enhancing overall efficiency and power output. Yaw drives typically consist of gearboxes, yaw motors, bearings, sensors, and control systems that work together to ensure smooth and accurate yawing motion, enabling wind turbines to operate effectively across a range of wind speeds and directions.

Executive Summary

The Yaw Drive market is experiencing steady growth, fueled by the expanding adoption of wind energy as a clean and sustainable power source. This comprehensive report provides insights into the market landscape, key trends, drivers, challenges, and opportunities shaping the industry’s growth trajectory. It offers valuable information for stakeholders, including wind turbine manufacturers, component suppliers, investors, and policymakers, to make informed decisions and capitalize on the evolving market dynamics in the Yaw Drive sector.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Yaw Drive market is characterized by evolving market dynamics, technological innovation, and industry collaboration to address challenges and capitalize on growth opportunities in the wind energy sector. Manufacturers and suppliers of yaw drive components are investing in research and development to improve product performance, reliability, and cost-effectiveness, while wind farm developers and operators are seeking solutions to optimize the operation and maintenance of yaw systems and maximize the return on investment in wind energy projects.

Regional Analysis

The Yaw Drive market exhibits regional variations in demand, influenced by factors such as wind resource potential, energy policies, market maturity, and investment climate. Regions with abundant wind resources, supportive regulatory frameworks, and established wind energy markets, such as Europe, North America, and Asia Pacific, are key markets for yaw drive systems. Emerging economies in Latin America, Africa, and the Middle East are also witnessing increasing investments in wind energy infrastructure, driving demand for yaw drives and related components.

Competitive Landscape

The Yaw Drive market is characterized by a diverse ecosystem of manufacturers, suppliers, and service providers offering a wide range of yaw drive components, systems, and solutions for the wind energy industry. Key players include manufacturers of yaw gearboxes, motors, bearings, sensors, and control systems specializing in wind turbine yaw technology. Competition is intensifying as vendors focus on product differentiation, innovation, and customer service to gain market share and meet the evolving needs of wind turbine OEMs and wind farm developers worldwide.

Segmentation

The Yaw Drive market can be segmented based on component type, technology, application, and end-user industry. By component type, yaw drives comprise gearboxes, motors, bearings, sensors, and control systems that work together to facilitate yaw motion in wind turbine systems. By technology, yaw drive systems utilize various technologies such as planetary gearboxes, direct drive motors, hydraulic systems, and electric actuators to achieve yaw alignment and control. By application, yaw drives are used in onshore and offshore wind farms, wind turbine upgrades, and repowering projects to optimize turbine performance and energy production. By end-user industry, yaw drives are deployed by wind turbine manufacturers, wind farm developers, and wind energy operators responsible for the design, installation, and maintenance of wind turbine yaw systems.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had a mixed impact on the Yaw Drive market, with disruptions to supply chains, project delays, and economic uncertainties affecting wind energy investments and installations globally. While the pandemic has led to short-term challenges such as reduced demand for wind energy projects and delayed deployments of yaw drive systems, it has also underscored the importance of renewable energy and resilience in energy systems. As economies recover and renewable energy investments rebound, the demand for yaw drives is expected to resume, supporting the growth of wind power capacity and the development of sustainable energy infrastructure post-pandemic.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Yaw Drive market is poised for continued growth and innovation in the coming years, driven by the increasing demand for wind energy as a clean and sustainable power source worldwide. As the industry focuses on decarbonization, energy transition, and climate change mitigation, the demand for yaw drives is expected to rise, supporting the expansion of wind power capacity and the development of renewable energy infrastructure globally. By embracing technological innovation, collaboration, and sustainability, stakeholders in the wind energy sector can help accelerate the transition to a cleaner, greener, and more resilient energy future.

Conclusion

In conclusion, the Yaw Drive market presents significant opportunities for stakeholders seeking to advance wind energy technology, enhance operational efficiency, and support the transition to renewable energy sources. By investing in innovation, collaboration, and sustainability, players in the yaw drive sector can address market challenges, capitalize on growth opportunities, and contribute to the development of a cleaner, more sustainable energy ecosystem. As the world strives to combat climate change and achieve energy security, wind energy and yaw drive systems will play a crucial role in powering the transition to a low-carbon future, driving economic growth, and safeguarding the environment for future generations.

What is Yaw Drive?

Yaw Drive refers to a mechanical system used to control the orientation of wind turbines, allowing them to face the wind direction for optimal energy capture. It plays a crucial role in enhancing the efficiency and performance of wind energy systems.

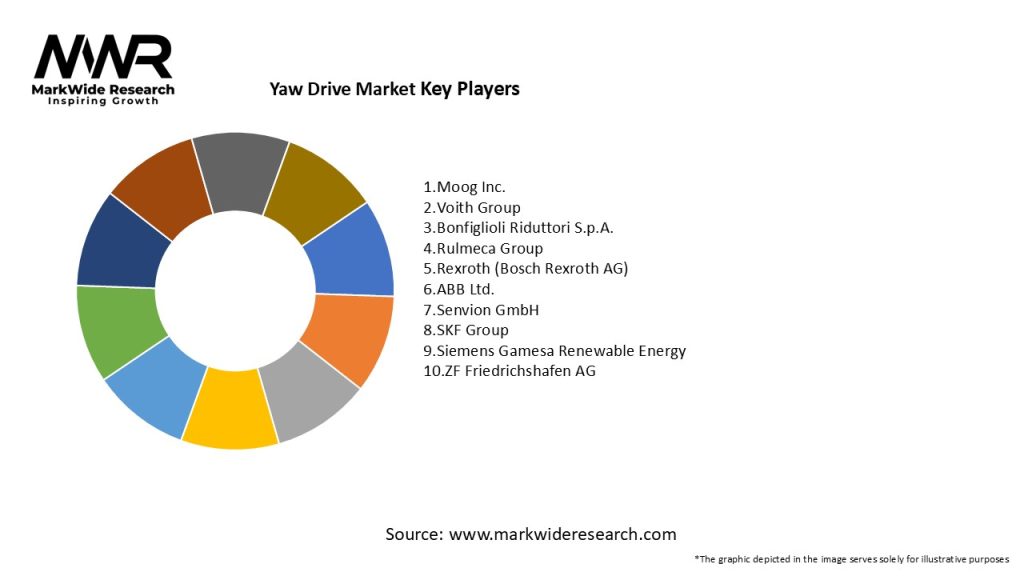

What are the key players in the Yaw Drive Market?

Key players in the Yaw Drive Market include Siemens Gamesa, GE Renewable Energy, and Nordex, which are known for their innovative technologies and solutions in wind turbine manufacturing, among others.

What are the growth factors driving the Yaw Drive Market?

The Yaw Drive Market is driven by the increasing demand for renewable energy sources, advancements in wind turbine technology, and government initiatives promoting sustainable energy solutions. These factors contribute to the expansion of wind energy projects globally.

What challenges does the Yaw Drive Market face?

The Yaw Drive Market faces challenges such as high initial investment costs, maintenance complexities, and the need for skilled labor for installation and repair. These factors can hinder market growth and adoption in certain regions.

What opportunities exist in the Yaw Drive Market?

Opportunities in the Yaw Drive Market include the development of more efficient and cost-effective yaw systems, integration of smart technologies for predictive maintenance, and expansion into emerging markets with growing wind energy potential.

What trends are shaping the Yaw Drive Market?

Trends in the Yaw Drive Market include the increasing use of automation and IoT technologies for enhanced monitoring and control, the shift towards larger and more efficient wind turbines, and a growing focus on sustainability and reducing the carbon footprint of energy production.

Yaw Drive Market

| Segmentation Details | Description |

|---|---|

| Product Type | Electric Yaw Drives, Hydraulic Yaw Drives, Mechanical Yaw Drives, Gearbox Yaw Drives |

| Application | Wind Turbines, Marine Vessels, Industrial Equipment, Aerospace Systems |

| End User | Energy Sector, Maritime Industry, Manufacturing Sector, Aerospace Industry |

| Technology | Direct Drive, Gear Drive, Hydraulic Drive, Electric Drive |

Leading Companies in the Yaw Drive Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at