444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

X-ray inspection systems for food foreign object detection are crucial tools in ensuring food safety and quality. These systems utilize X-ray technology to detect and identify foreign objects such as metal, glass, stone, plastic, and bone contaminants in food products. They are widely used across the food industry, including in processing facilities, packaging lines, and distribution centers, to prevent contamination and ensure compliance with food safety regulations. The market for X-ray inspection systems is driven by stringent food safety standards, increasing consumer awareness, and the rising demand for quality assurance in food production.

Meaning

X-ray inspection systems for food foreign object detection refer to advanced technological solutions used to inspect food products for the presence of contaminants that could pose health risks or compromise product quality. These systems employ X-ray radiation to penetrate food items, producing images that allow operators to detect foreign objects that may be invisible to the naked eye. By identifying contaminants early in the production process, X-ray inspection systems help food manufacturers maintain high standards of safety and quality.

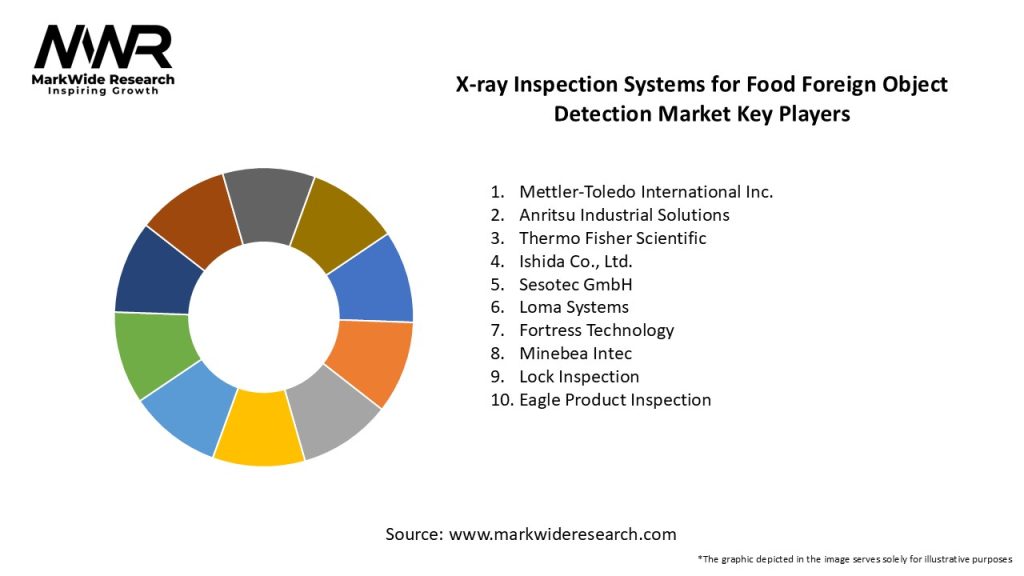

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Executive Summary

The market for X-ray inspection systems for food foreign object detection is experiencing significant growth due to heightened concerns over food safety and quality. Regulatory pressures, increasing global trade, and the need for reliable inspection technologies are driving market expansion. Manufacturers are investing in advanced X-ray systems capable of detecting smaller contaminants and improving inspection accuracy. However, challenges such as high initial costs and the complexity of integrating these systems into existing production lines remain key considerations for industry stakeholders.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The market for X-ray inspection systems for food foreign object detection is dynamic, influenced by regulatory developments, technological advancements, consumer trends, and industry partnerships. Understanding these dynamics is crucial for stakeholders to capitalize on growth opportunities, navigate challenges, and maintain competitiveness.

Regional Analysis

The adoption and growth of X-ray inspection systems vary by region, influenced by factors such as regulatory frameworks, food safety standards, technological infrastructure, and market demand. Regions with stringent food safety regulations and high levels of food production are typically key markets for X-ray inspection systems.

Competitive Landscape

Leading Companies in the X-ray Inspection Systems for Food Foreign Object Detection Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

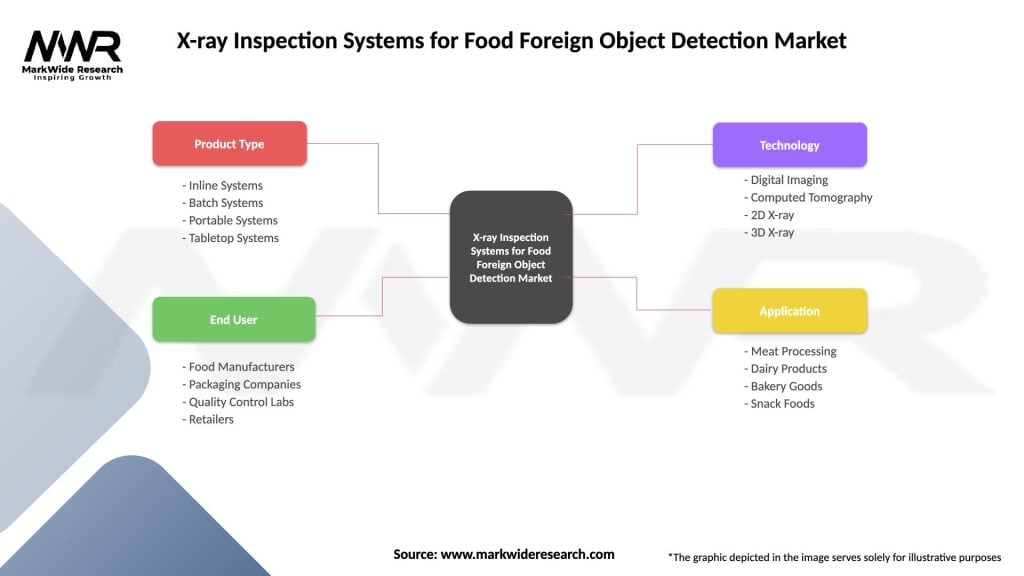

Segmentation

The market for X-ray inspection systems can be segmented based on:

Segmentation allows for a more targeted approach to understanding customer needs, market trends, and growth opportunities within the X-ray inspection systems market.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Understanding these factors through a SWOT analysis helps stakeholders navigate market dynamics, capitalize on opportunities, mitigate threats, and address weaknesses to maintain competitive advantage.

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic underscored the importance of food safety and hygiene, driving increased demand for X-ray inspection systems to maintain product integrity and consumer confidence. The crisis highlighted the resilience of food supply chains and the need for robust inspection technologies to mitigate risks.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the X-ray inspection systems market for food foreign object detection is promising, driven by increasing global food safety regulations, technological advancements, and growing consumer awareness. Key trends such as Industry 4.0 integration, customization of solutions, and sustainability initiatives will shape the market landscape. However, challenges such as high costs, regulatory complexities, and intense competition will require strategic responses from industry players.

Conclusion

X-ray inspection systems play a vital role in ensuring food safety and quality assurance across the food industry. With advancements in technology and increasing regulatory pressures, the demand for reliable and efficient inspection solutions is expected to rise. Stakeholders in the market must focus on innovation, regulatory compliance, and customer-centric solutions to capitalize on growth opportunities and maintain competitiveness. By addressing these factors, the market for X-ray inspection systems for food foreign object detection is poised for continued expansion and evolution in the coming years.

What is X-ray Inspection Systems for Food Foreign Object Detection?

X-ray Inspection Systems for Food Foreign Object Detection are advanced technologies used to identify and eliminate foreign objects in food products. These systems utilize X-ray imaging to detect contaminants such as metal, glass, and plastic, ensuring food safety and quality.

What are the key players in the X-ray Inspection Systems for Food Foreign Object Detection Market?

Key players in the X-ray Inspection Systems for Food Foreign Object Detection Market include Mettler-Toledo International Inc., Anritsu Corporation, and Ishida Co., Ltd., among others. These companies are known for their innovative solutions and contributions to food safety technologies.

What are the growth factors driving the X-ray Inspection Systems for Food Foreign Object Detection Market?

The growth of the X-ray Inspection Systems for Food Foreign Object Detection Market is driven by increasing consumer awareness regarding food safety, stringent regulations on food quality, and the rising demand for processed food products. Additionally, advancements in X-ray technology enhance detection capabilities.

What challenges does the X-ray Inspection Systems for Food Foreign Object Detection Market face?

Challenges in the X-ray Inspection Systems for Food Foreign Object Detection Market include high initial investment costs and the need for regular maintenance of inspection systems. Furthermore, the complexity of certain food products can hinder effective detection.

What opportunities exist in the X-ray Inspection Systems for Food Foreign Object Detection Market?

Opportunities in the X-ray Inspection Systems for Food Foreign Object Detection Market include the development of more sophisticated detection technologies and the expansion of applications in various food sectors, such as meat processing and packaged goods. There is also potential for growth in emerging markets.

What trends are shaping the X-ray Inspection Systems for Food Foreign Object Detection Market?

Trends in the X-ray Inspection Systems for Food Foreign Object Detection Market include the integration of artificial intelligence for improved accuracy and efficiency, as well as the increasing adoption of automation in food processing facilities. These innovations are enhancing the overall effectiveness of foreign object detection.

X-ray Inspection Systems for Food Foreign Object Detection Market

| Segmentation Details | Description |

|---|---|

| Product Type | Inline Systems, Batch Systems, Portable Systems, Tabletop Systems |

| End User | Food Manufacturers, Packaging Companies, Quality Control Labs, Retailers |

| Technology | Digital Imaging, Computed Tomography, 2D X-ray, 3D X-ray |

| Application | Meat Processing, Dairy Products, Bakery Goods, Snack Foods |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the X-ray Inspection Systems for Food Foreign Object Detection Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at