444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The wood boring machines market is a vital segment within the woodworking machinery industry, providing essential equipment for drilling, shaping, and carving wood materials. Wood boring machines encompass a diverse range of equipment, including drill presses, boring machines, mortisers, and CNC routers, catering to various woodworking applications across industries. As the demand for customized and intricate woodwork continues to grow, the wood boring machines market plays a pivotal role in enabling precision and efficiency in woodworking operations.

Meaning

Wood boring machines are specialized tools designed to create holes, slots, and cavities in wooden materials with precision and accuracy. These machines utilize cutting tools, such as drills, boring bits, and router bits, to remove material from wood surfaces and create desired shapes and patterns. Wood boring machines are used in various woodworking applications, including furniture manufacturing, cabinetry, carpentry, and architectural woodworking, to streamline production processes and achieve intricate designs with consistency.

Executive Summary

The wood boring machines market is driven by the increasing demand for customized wood products, advancements in woodworking technologies, and the growing adoption of automated machining solutions. As woodworking industries strive to enhance productivity, reduce production costs, and meet evolving customer demands, the market for wood boring machines continues to expand. Market players are focusing on innovation and product development to introduce advanced machines that offer precision, versatility, and efficiency in wood processing operations.

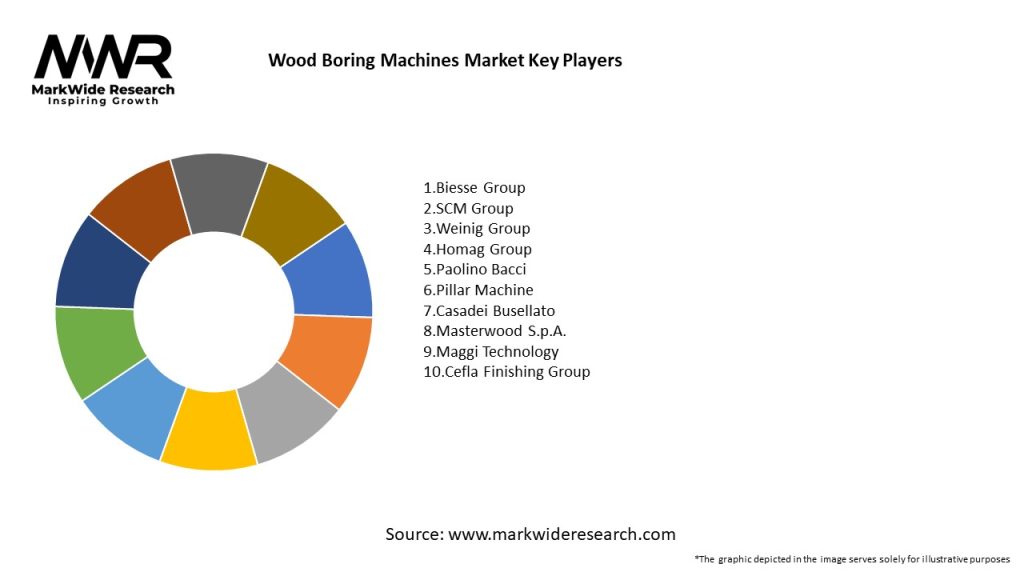

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The wood boring machines market operates in a dynamic environment shaped by technological innovations, market trends, regulatory changes, and competitive dynamics. Understanding these dynamics is essential for market players to identify growth opportunities, address challenges, and formulate effective strategies to stay competitive in the wood processing industry.

Regional Analysis

The wood boring machines market exhibits regional variations in demand, market maturity, and industry dynamics. Regional analysis enables market players to identify growth opportunities, assess competitive landscapes, and tailor their strategies to specific geographic markets and customer preferences.

Competitive Landscape

Leading Companies in the Wood Boring Machines Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The wood boring machines market can be segmented based on various factors, including machine type, end-user industry, geographic region, and application. Segmentation enables market players to target specific customer segments, address unique market needs, and differentiate their offerings in a competitive market landscape.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has impacted the wood boring machines market, influencing market dynamics, customer behavior, and supply chain operations in various ways:

Key Industry Developments

Analyst Suggestions

Future Outlook

The wood boring machines market is poised for growth and innovation, driven by advancements in woodworking technologies, increasing demand for customized wood products, and the adoption of sustainable manufacturing practices. Market players that invest in digital transformation, customer-centric strategies, and sustainability initiatives are well-positioned to capitalize on emerging opportunities and contribute to the advancement of the wood processing industry.

Conclusion

The wood boring machines market plays a critical role in enabling precision, efficiency, and innovation in wood processing operations across industries. As woodworking industries strive to meet customer demands for customized, sustainable, and high-quality wood products, the demand for advanced wood boring machines continues to grow. Market players that embrace digital transformation, sustainability, and customer-centric strategies are poised to succeed in a dynamic and evolving market landscape, driving innovation and growth in the wood processing industry.

What is Wood Boring Machines?

Wood Boring Machines are specialized tools used for creating holes in wood materials. They are commonly utilized in woodworking, construction, and furniture manufacturing to enhance precision and efficiency in drilling operations.

What are the key players in the Wood Boring Machines Market?

Key players in the Wood Boring Machines Market include companies like Bosch, Makita, and DeWalt, which are known for their innovative drilling solutions and high-quality machinery. These companies compete on technology, product range, and customer service, among others.

What are the growth factors driving the Wood Boring Machines Market?

The growth of the Wood Boring Machines Market is driven by increasing demand for precision woodworking, advancements in drilling technology, and the expansion of the construction industry. Additionally, the rise in DIY projects and home renovations contributes to market growth.

What challenges does the Wood Boring Machines Market face?

The Wood Boring Machines Market faces challenges such as the high cost of advanced machinery and competition from alternative drilling methods. Additionally, fluctuations in raw material prices can impact production costs and availability.

What opportunities exist in the Wood Boring Machines Market?

Opportunities in the Wood Boring Machines Market include the development of smart drilling technologies and the growing trend of sustainable woodworking practices. Furthermore, expanding markets in developing regions present potential for increased sales and innovation.

What trends are shaping the Wood Boring Machines Market?

Trends in the Wood Boring Machines Market include the integration of automation and robotics in drilling processes, as well as the increasing focus on energy-efficient machines. Additionally, there is a growing interest in ergonomic designs to enhance user comfort and safety.

Wood Boring Machines Market

| Segmentation Details | Description |

|---|---|

| Product Type | Portable Boring Machines, Stationary Boring Machines, CNC Boring Machines, Multi-Spindle Boring Machines |

| Technology | Electric, Pneumatic, Hydraulic, Manual |

| End User | Furniture Manufacturers, Construction Companies, Woodworking Shops, DIY Enthusiasts |

| Application | Cabinet Making, Flooring Installation, Joinery, Wood Panel Production |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Wood Boring Machines Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at