444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Welding is an essential industrial process used in various sectors, including construction, automotive, aerospace, and manufacturing. However, it also involves inherent risks to workers’ safety due to the intense heat, sparks, and hazardous fumes produced during the welding process. Welding protective clothing plays a crucial role in safeguarding welders from potential workplace hazards and ensuring their well-being. The welding protective clothing market encompasses a wide range of products, including welding jackets, gloves, helmets, aprons, and coveralls, designed to offer optimal protection to workers.

Meaning:

Welding protective clothing refers to specialized garments and equipment designed to safeguard welders from various workplace hazards during welding operations. It includes protective clothing such as flame-resistant jackets, trousers, hoods, gloves, aprons, and face shields, among others. Welding is a high-risk activity that exposes workers to intense heat, sparks, molten metal, and harmful fumes. Therefore, using appropriate protective clothing is essential to minimize the risk of injuries and ensure the safety of welders.

Executive Summary:

The welding protective clothing market has experienced significant growth in recent years due to the increasing emphasis on workplace safety and the rising demand for protective gear in various industrial sectors. This report analyzes the market’s key insights, drivers, restraints, opportunities, and dynamics. It also provides a comprehensive regional analysis, competitive landscape, and segmentation of the market. The impact of the Covid-19 pandemic on the market is examined, along with key industry developments and future outlook. Moreover, the report includes valuable suggestions from analysts for industry participants and stakeholders to make informed decisions.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics:

The welding protective clothing market is influenced by various factors, including safety regulations, industry trends, technological advancements, and the overall economic environment. Changes in any of these aspects can significantly impact the market’s growth trajectory. For instance, the introduction of new safety regulations might lead to a sudden surge in demand for compliant protective clothing. Likewise, technological advancements can result in the development of more efficient and comfortable protective gear, driving customer preferences and overall market growth.

Regional Analysis:

The welding protective clothing market can be analyzed on a regional basis to understand specific trends and opportunities in different geographical areas. Key regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa are considered in this analysis. Each region’s economic conditions, industrial growth, safety regulations, and cultural factors play a vital role in shaping the demand for welding protective clothing.

Competitive Landscape:

Leading Companies in the Welding Protective Clothing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

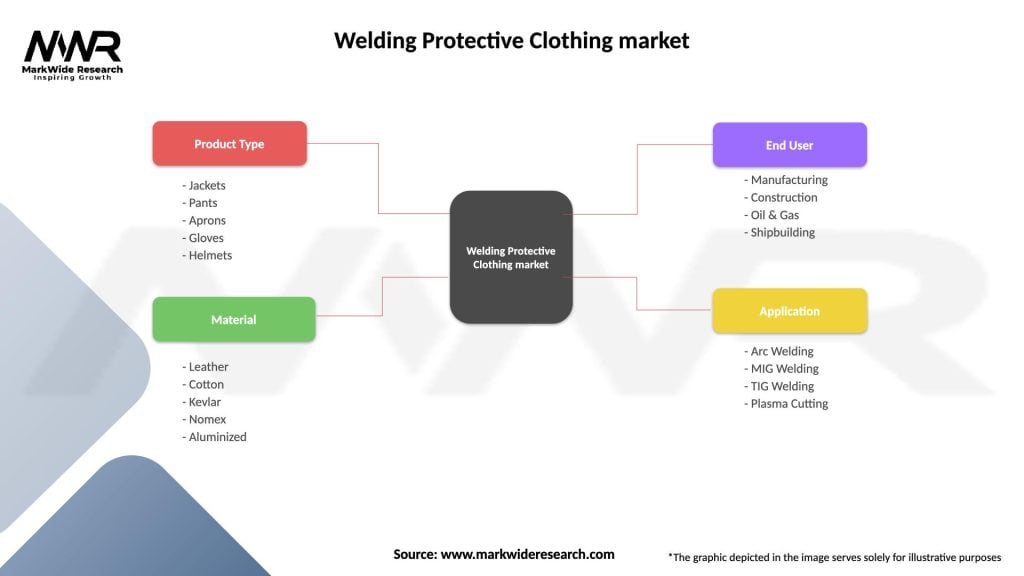

Segmentation:

The welding protective clothing market can be segmented based on various factors, such as product type, material, end-user industry, and distribution channel. This segmentation helps businesses identify specific customer segments and tailor their offerings to meet their unique needs and preferences.

Category-wise Insights:

Different categories of welding protective clothing, such as flame-resistant jackets, gloves, aprons, and face shields, may have distinct market dynamics and growth patterns. Understanding the demand for each category can help manufacturers and suppliers strategize their production and marketing efforts more effectively.

Key Benefits for Industry Participants and Stakeholders:

Industry participants and stakeholders in the welding protective clothing market can benefit in several ways. These include complying with safety regulations, reducing workplace injuries and liabilities, enhancing worker productivity and morale, gaining a competitive advantage, and tapping into emerging market opportunities.

SWOT Analysis:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends:

Identifying key trends in the welding protective clothing market is essential for businesses to stay ahead of the competition and cater to evolving customer preferences. These trends could include the adoption of sustainable materials, advancements in protective clothing technology, or changes in end-user industry requirements.

Covid-19 Impact:

The Covid-19 pandemic had significant repercussions across various industries, including the welding protective clothing market. Analyzing the pandemic’s impact on supply chains, production, demand, and customer behavior provides valuable insights for businesses to adapt their strategies accordingly.

Key Industry Developments:

Understanding recent developments and innovations in the welding protective clothing market helps industry players gauge the level of competition and potential disruption. Tracking key developments enables companies to respond proactively to market changes and maintain their competitive edge.

Analyst Suggestions:

Based on comprehensive research and analysis, industry analysts offer valuable suggestions and recommendations to businesses in the welding protective clothing market. These suggestions may include strategies to address challenges, capitalize on opportunities, improve product offerings, enhance customer engagement, and optimize supply chain management.

Future Outlook:

Analyzing market trends, technological advancements, regulatory changes, and emerging opportunities enables businesses to anticipate the future trajectory of the welding protective clothing market. Understanding the market’s future outlook is essential for developing long-term business strategies and staying competitive in a rapidly evolving industry.

Conclusion:

The welding protective clothing market is witnessing significant growth due to increasing workplace safety awareness and stringent safety regulations. With the rise of industries like construction, manufacturing, and automotive, the demand for welding protective clothing is expected to soar. However, challenges related to cost and skilled labor shortages need to be addressed. By leveraging opportunities like sustainable materials and online retail channels, industry participants can tap into new markets and gain a competitive advantage. As the market continues to evolve, businesses must adapt and innovate to meet the changing demands of customers and emerging trends. With a proactive approach

What is Welding Protective Clothing?

Welding protective clothing refers to specialized garments designed to protect welders from hazards such as heat, sparks, and molten metal. These garments are typically made from flame-resistant materials and include items like jackets, gloves, and helmets.

What are the key players in the Welding Protective Clothing market?

Key players in the Welding Protective Clothing market include companies like Lincoln Electric, Miller Electric, and 3M, which offer a range of protective gear for welders. These companies focus on innovation and quality to meet industry safety standards, among others.

What are the growth factors driving the Welding Protective Clothing market?

The Welding Protective Clothing market is driven by increasing safety regulations in the manufacturing and construction industries, as well as the growing demand for skilled welders. Additionally, advancements in fabric technology are enhancing the protective features of these garments.

What challenges does the Welding Protective Clothing market face?

Challenges in the Welding Protective Clothing market include the high cost of advanced materials and the need for regular maintenance of protective gear. Furthermore, the variability in welding processes can complicate the selection of appropriate protective clothing.

What opportunities exist in the Welding Protective Clothing market?

Opportunities in the Welding Protective Clothing market include the development of smart protective clothing that integrates wearable technology for enhanced safety monitoring. Additionally, expanding into emerging markets presents growth potential for manufacturers.

What trends are shaping the Welding Protective Clothing market?

Trends in the Welding Protective Clothing market include a shift towards lightweight and breathable materials that offer comfort without compromising safety. There is also a growing emphasis on sustainable materials and practices in the production of protective clothing.

Welding Protective Clothing market

| Segmentation Details | Description |

|---|---|

| Product Type | Jackets, Pants, Aprons, Gloves, Helmets |

| Material | Leather, Cotton, Kevlar, Nomex, Aluminized |

| End User | Manufacturing, Construction, Oil & Gas, Shipbuilding |

| Application | Arc Welding, MIG Welding, TIG Welding, Plasma Cutting |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Welding Protective Clothing Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at