444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Warehouse automation systems have revolutionized the logistics and supply chain industry by introducing cutting-edge technologies to streamline operations, enhance efficiency, and optimize inventory management. These systems are designed to automate various tasks traditionally performed by human labor, such as material handling, order picking, packing, and shipping. With the increasing demand for faster order fulfillment and cost-effective warehouse operations, the market for warehouse automation systems has witnessed significant growth over the years.

Meaning

Warehouse automation systems refer to a range of technologies and solutions that automate warehouse processes to improve productivity, accuracy, and speed while reducing operational costs. These systems encompass a wide array of technologies, including robotics, automated guided vehicles (AGVs), conveyor systems, warehouse management software (WMS), and internet of things (IoT) devices. The main objective of implementing warehouse automation systems is to optimize warehouse operations, increase throughput, minimize errors, and create a seamless supply chain.

Executive Summary

The warehouse automation systems market has experienced substantial growth in recent years, driven by the rapid expansion of e-commerce, advancements in robotics and AI technologies, and the need for more efficient inventory management. This report delves into the key market insights, drivers, restraints, opportunities, and market dynamics influencing the growth of the warehouse automation systems market.

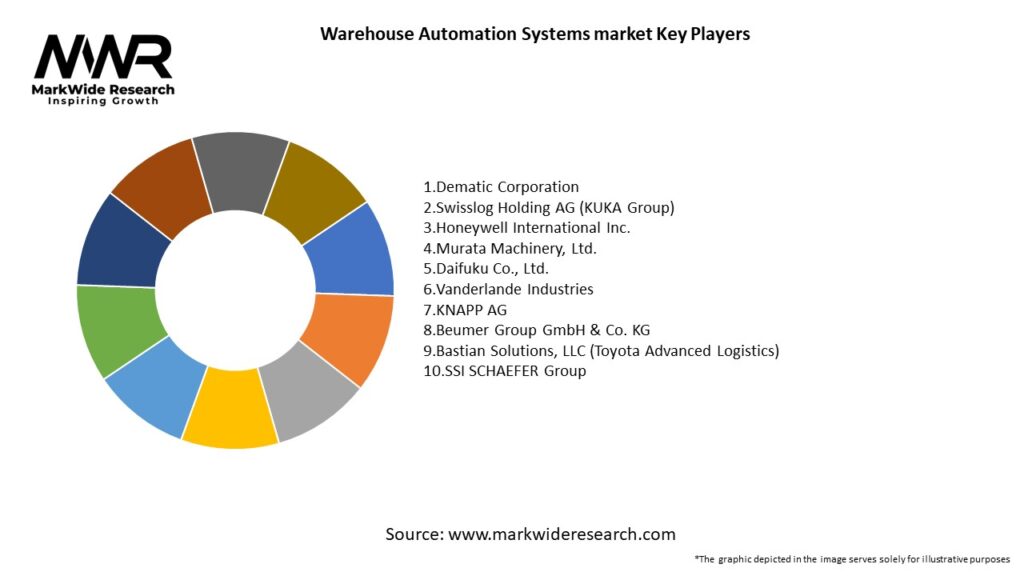

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

The warehouse automation systems market is projected to experience robust growth during the forecast period. Several key factors contribute to this growth, including the increasing demand for faster order fulfillment and delivery, the rise of e-commerce and omnichannel retailing, the need to optimize warehouse space, and the focus on reducing labor costs and human errors.

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The warehouse automation systems market is highly dynamic, driven by technological advancements, changing consumer behavior, and evolving industry trends. The rapid development of robotics, AI, and IoT technologies is reshaping the warehouse automation landscape. Additionally, market players are continuously innovating to offer more cost-effective and efficient solutions to stay competitive.

Regional Analysis

The market for warehouse automation systems is segmented into various regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. North America and Europe are the mature markets, having witnessed significant adoption of automation solutions in the logistics sector. On the other hand, Asia Pacific is the fastest-growing market, fueled by the expansion of e-commerce and the modernization of supply chain infrastructure in countries like China, India, and Japan.

Competitive Landscape

Leading Companies in Warehouse Automation Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

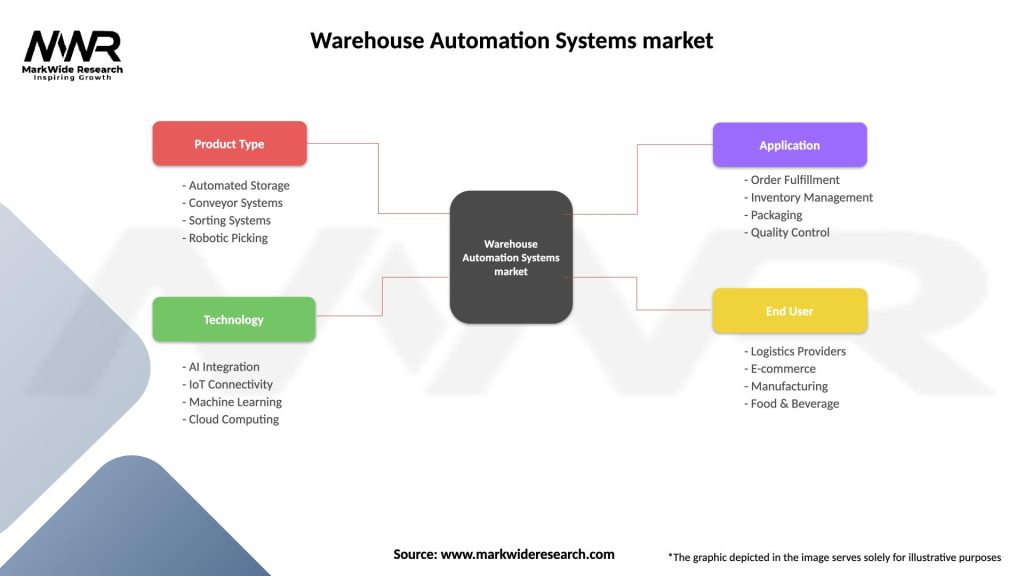

The warehouse automation systems market is segmented based on the following criteria:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has accelerated the adoption of warehouse automation systems. With disruptions in the global supply chain, businesses sought to enhance resilience and agility by investing in automation. The need for contactless operations and reduced dependency on manual labor during the pandemic further fueled the demand for automation solutions.

Key Industry Developments

Analyst Suggestions

Future Outlook

The warehouse automation systems market is expected to witness continued growth in the coming years, driven by technological advancements, increasing demand for faster order fulfillment, and the expansion of the e-commerce industry. Robotics, AI, and IoT will play a pivotal role in shaping the future of warehouse automation, offering more intelligent and adaptable solutions.

Conclusion

The warehouse automation systems market is experiencing robust growth, driven by the need for enhanced efficiency, cost savings, and faster order fulfillment. With advancements in robotics, AI, and IoT technologies, automation solutions are becoming more sophisticated, offering a wide range of benefits to industry participants and stakeholders. As the market continues to evolve, companies must stay attuned to the latest trends and developments to remain competitive in this dynamic landscape. The future of warehouse automation looks promising, with a strong focus on flexibility, scalability, and integrating intelligent technologies to optimize warehouse operations and create a seamless supply chain.

What is Warehouse Automation Systems?

Warehouse Automation Systems refer to the technologies and processes that enhance the efficiency of warehouse operations through automation. This includes the use of robotics, conveyor systems, and software solutions to streamline inventory management, order fulfillment, and shipping processes.

Who are the key players in the Warehouse Automation Systems market?

Key players in the Warehouse Automation Systems market include companies like Dematic, Honeywell Intelligrated, and Swisslog, which provide innovative solutions for warehouse management and automation. These companies focus on enhancing operational efficiency and reducing labor costs, among others.

What are the main drivers of growth in the Warehouse Automation Systems market?

The main drivers of growth in the Warehouse Automation Systems market include the increasing demand for efficient supply chain management, the rise of e-commerce, and the need for improved inventory accuracy. Additionally, advancements in technology, such as AI and IoT, are also contributing to market expansion.

What challenges does the Warehouse Automation Systems market face?

The Warehouse Automation Systems market faces challenges such as high initial investment costs and the complexity of integrating new technologies with existing systems. Additionally, there is a shortage of skilled labor to manage and maintain automated systems, which can hinder adoption.

What opportunities exist in the Warehouse Automation Systems market?

Opportunities in the Warehouse Automation Systems market include the growing trend of smart warehouses and the increasing adoption of automation in various industries such as retail, manufacturing, and logistics. Furthermore, the development of cost-effective automation solutions presents significant growth potential.

What trends are shaping the Warehouse Automation Systems market?

Trends shaping the Warehouse Automation Systems market include the integration of artificial intelligence for predictive analytics, the use of autonomous mobile robots for material handling, and the rise of cloud-based warehouse management systems. These innovations are enhancing operational efficiency and flexibility.

Warehouse Automation Systems market

| Segmentation Details | Description |

|---|---|

| Product Type | Automated Storage, Conveyor Systems, Sorting Systems, Robotic Picking |

| Technology | AI Integration, IoT Connectivity, Machine Learning, Cloud Computing |

| Application | Order Fulfillment, Inventory Management, Packaging, Quality Control |

| End User | Logistics Providers, E-commerce, Manufacturing, Food & Beverage |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in Warehouse Automation Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at