444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview:

The veneer tapes market encompasses a variety of adhesive tapes specifically designed for veneer applications in woodworking and furniture manufacturing. These tapes are used to hold veneer sheets in place during the gluing and pressing process, ensuring precise alignment and minimizing the risk of slippage or misalignment.

Meaning:

Veneer tapes are specialized adhesive tapes utilized in woodworking and furniture manufacturing to secure veneer sheets to substrates such as plywood, MDF (medium-density fiberboard), or particleboard. These tapes provide temporary adhesion, allowing for accurate positioning of veneer sheets before permanent bonding.

Executive Summary:

The veneer tapes market caters to the needs of woodworking professionals, furniture manufacturers, and craftsmen seeking reliable and efficient solutions for veneer application. With a focus on precision, ease of use, and compatibility with various veneer materials, veneer tapes play a crucial role in achieving high-quality veneered surfaces.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics:

The veneer tapes market dynamics are influenced by factors such as technological advancements in adhesive formulations, shifting consumer preferences towards sustainable materials, advancements in woodworking machinery, and evolving industry regulations.

Regional Analysis:

The demand for veneer tapes varies by region, influenced by factors such as the concentration of woodworking industries, furniture manufacturing hubs, availability of raw materials, and economic conditions affecting construction and renovation activities.

Competitive Landscape:

Leading Companies in the Veneer Tapes Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

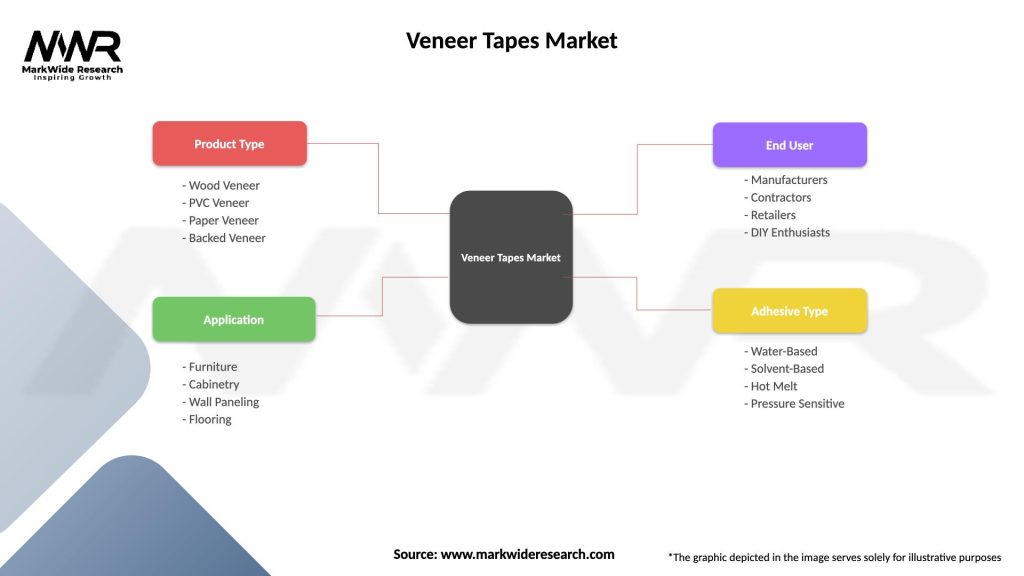

Segmentation:

The veneer tapes market can be segmented based on factors such as adhesive type (pressure-sensitive adhesive, hot melt adhesive), backing material (paper, film), width, length, color, and end-use application (cabinet making, furniture production, architectural woodworking).

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Strengths

• The veneer tapes market benefits from the growing demand for high-quality finishing materials in the furniture and cabinetry industries, enhancing product appeal.

• Advanced manufacturing techniques have improved the durability and adhesive properties of veneer tapes, increasing their application versatility.

• A strong emphasis on aesthetics in interior design is driving the adoption of veneer tapes for decorative purposes, supporting market growth.

• Established distribution networks and partnerships with manufacturers ensure consistent supply and accessibility of veneer tapes to end-users.

Weaknesses

• The reliance on raw materials, such as wood and adhesives, makes the veneer tapes market vulnerable to fluctuations in supply chain costs and availability.

• Limited awareness among small-scale manufacturers about the benefits of veneer tapes may hinder broader market penetration and growth.

• The production process for veneer tapes can be resource-intensive, potentially leading to higher operational costs that may affect pricing strategies.

• Environmental concerns regarding deforestation and sustainability practices may limit the market’s appeal among eco-conscious consumers.

Opportunities

• Increasing consumer interest in sustainable and eco-friendly products presents an opportunity for the development of biodegradable veneer tapes.

• The rise of e-commerce platforms offers new channels for distribution, allowing manufacturers to reach a wider audience and enhance sales.

• Expanding applications in sectors like automotive and construction could drive innovation and diversification within the veneer tapes market.

• Collaborations with interior designers and architects can create new market segments and enhance product visibility in high-end applications.

Threats

• Intense competition from alternative surface finishing products, such as laminates and paints, poses a significant challenge to the veneer tapes market.

• Regulatory changes concerning the use of certain adhesives and materials in veneer tapes may impose additional compliance costs on manufacturers.

• Economic downturns can lead to reduced consumer spending on non-essential goods, negatively impacting demand for veneer tapes.

• The potential for trade tariffs and import restrictions can disrupt supply chains and increase costs, affecting market stability.

Market Key Trends:

Covid-19 Impact:

The Covid-19 pandemic has underscored the importance of efficient and hygienic manufacturing processes in woodworking and furniture production, leading to increased interest in adhesive tape solutions such as veneer tapes as alternatives to traditional clamping methods.

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The future outlook for the veneer tapes market remains positive, driven by factors such as urbanization, renovation activities, growing demand for customized furniture solutions, and advancements in adhesive technology. Manufacturers that innovate, differentiate, and align with industry trends are poised for sustained growth and success in the evolving woodworking and furniture manufacturing landscape.

Conclusion:

In conclusion, veneer tapes play a vital role in the woodworking and furniture manufacturing industries, offering efficient, reliable, and cost-effective solutions for veneer application projects. With their ability to enhance precision, streamline production processes, and achieve professional finishes, veneer tapes are essential components in the pursuit of high-quality, aesthetically pleasing wood surfaces. As the demand for customized furniture solutions and sustainable manufacturing practices continues to rise, veneer tapes are expected to remain indispensable tools for woodworking professionals and furniture manufacturers worldwide.

What is Veneer Tapes?

Veneer tapes are thin strips of wood or synthetic materials used to cover the edges of furniture, cabinetry, and other wood products. They provide a finished look and protect the underlying material from damage and moisture.

What are the key players in the Veneer Tapes Market?

Key players in the Veneer Tapes Market include companies like Scapa Group, 3M, and Tesa SE, which are known for their innovative adhesive solutions and high-quality veneer products. These companies compete on product quality, application versatility, and customer service, among others.

What are the growth factors driving the Veneer Tapes Market?

The growth of the Veneer Tapes Market is driven by the increasing demand for furniture and interior design solutions, as well as the rise in DIY home improvement projects. Additionally, advancements in adhesive technology are enhancing the performance and application of veneer tapes.

What challenges does the Veneer Tapes Market face?

The Veneer Tapes Market faces challenges such as fluctuating raw material prices and competition from alternative edge banding solutions. Additionally, environmental regulations regarding the use of certain adhesives can impact production processes.

What opportunities exist in the Veneer Tapes Market?

Opportunities in the Veneer Tapes Market include the growing trend of sustainable and eco-friendly products, as well as the expansion of the construction and furniture industries in emerging markets. Innovations in product design and functionality also present new avenues for growth.

What trends are shaping the Veneer Tapes Market?

Current trends in the Veneer Tapes Market include the increasing use of digital printing on veneer tapes for customization and aesthetic appeal. There is also a shift towards using biodegradable materials in production to meet consumer demand for sustainable options.

Veneer Tapes Market

| Segmentation Details | Description |

|---|---|

| Product Type | Wood Veneer, PVC Veneer, Paper Veneer, Backed Veneer |

| Application | Furniture, Cabinetry, Wall Paneling, Flooring |

| End User | Manufacturers, Contractors, Retailers, DIY Enthusiasts |

| Adhesive Type | Water-Based, Solvent-Based, Hot Melt, Pressure Sensitive |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Veneer Tapes Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at