444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

In the realm of packaging solutions, VCI stands as a beacon of innovation, championing the preservation of metals and other materials susceptible to corrosion. Vapor Corrosion Inhibitors work by releasing molecules that form a protective layer on the surface of metals, preventing moisture and corrosive elements from making direct contact. This method has gained widespread adoption across various industries, including automotive, aerospace, electronics, and military, as it ensures that products remain in impeccable condition throughout their journey from production to end-use.

Meaning

VCI packaging, short for Vapor Corrosion Inhibitor packaging, is a revolutionary concept that addresses the age-old problem of corrosion in a novel and effective way. It involves the integration of specialized materials, often in the form of films, papers, or devices, into the packaging structure. These materials release volatile corrosion inhibitors into the surrounding environment, forming an invisible shield on the surface of susceptible materials. The inhibitors hinder the electrochemical reactions that cause corrosion, thereby extending the shelf life and usability of various products.

Executive Summary

The VCI packaging market is currently undergoing a phase of exponential growth, driven by the escalating demand for efficient corrosion protection solutions. This report provides an in-depth analysis of the key factors influencing the market, including drivers, restraints, and opportunities. Moreover, it examines the market dynamics, regional variations, competitive landscape, industry segmentation, emerging trends, and the lasting impact of the COVID-19 pandemic. By presenting a holistic view of the VCI packaging market, stakeholders and industry participants can make informed decisions to enhance their market presence and capitalize on upcoming opportunities.

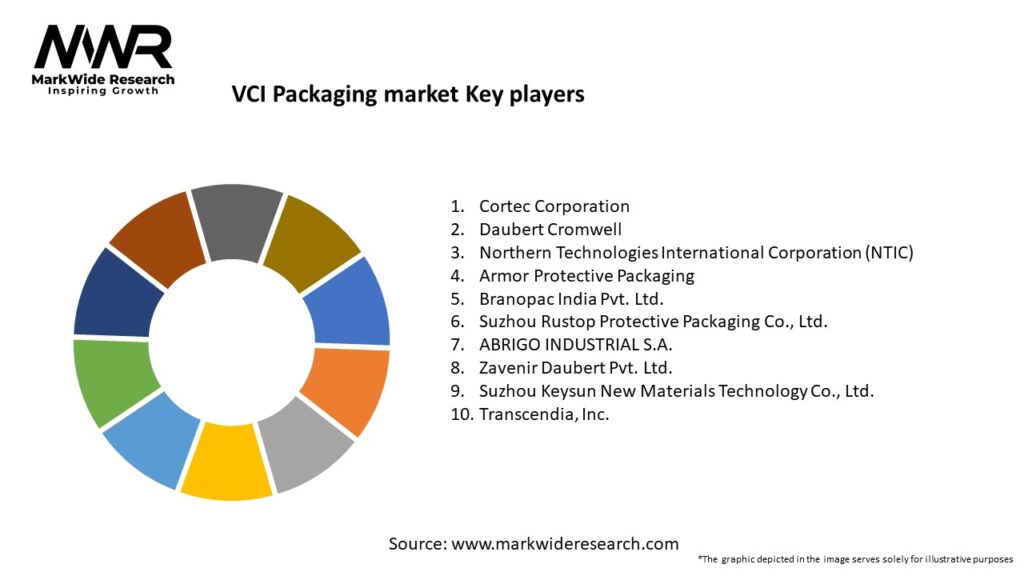

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The VCI packaging market is propelled by several key drivers that underscore its significance and potential impact on various industries.

Market Restraints

While the VCI packaging market holds immense promise, it is not without its challenges. Several factors temper the growth of this market.

Market Opportunities

Amidst the challenges, numerous opportunities abound for the VCI packaging market to flourish.

Market Dynamics

The VCI packaging market is characterized by dynamic factors that shape its trajectory and impact its growth.

Regional Analysis

The adoption of VCI packaging varies across regions due to differences in industrial activities, awareness levels, and economic conditions.

Competitive Landscape

Leading Companies in the VCI Packaging Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The VCI packaging market can be segmented based on various criteria to understand its diverse applications and offerings.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

COVID-19 Impact

The COVID-19 pandemic brought about significant disruptions across industries, and the VCI packaging market was no exception.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the VCI packaging market appears promising, with several trends and developments shaping its trajectory.

Conclusion

The VCI packaging market stands at the forefront of corrosion protection innovation, revolutionizing the way industries safeguard their products. By forming a protective shield against the destructive forces of corrosion, VCI packaging preserves the value, quality, and safety of goods during storage and transportation. As global industries continue to recognize the significance of corrosion prevention, the VCI packaging market is poised for remarkable growth. By staying attuned to market trends, technological advancements, and consumer preferences, stakeholders and industry participants can capitalize on the opportunities presented by this dynamic market, ensuring their products reach customers in impeccable condition while contributing to a more sustainable future.

What is VCI Packaging?

VCI Packaging refers to Vapor Corrosion Inhibitor Packaging, which is designed to protect metal products from corrosion during storage and transportation. This type of packaging releases vapor that forms a protective layer on the metal surface, preventing rust and degradation.

What are the key companies in the VCI Packaging market?

Key companies in the VCI Packaging market include Cortec Corporation, Daubert Cromwell, and Aicello Corporation, among others. These companies specialize in developing innovative VCI solutions for various industries, including automotive, electronics, and manufacturing.

What are the growth factors driving the VCI Packaging market?

The growth of the VCI Packaging market is driven by increasing demand for corrosion protection in industries such as automotive and aerospace. Additionally, the rise in international trade and the need for effective packaging solutions to prevent damage during transit are significant factors.

What challenges does the VCI Packaging market face?

The VCI Packaging market faces challenges such as the availability of alternative corrosion protection methods and the environmental concerns associated with certain packaging materials. Additionally, regulatory compliance regarding packaging materials can pose challenges for manufacturers.

What opportunities exist in the VCI Packaging market?

Opportunities in the VCI Packaging market include the development of eco-friendly packaging solutions and the expansion into emerging markets. As industries seek sustainable options, there is potential for growth in biodegradable VCI materials.

What trends are shaping the VCI Packaging market?

Trends in the VCI Packaging market include the increasing adoption of smart packaging technologies and the integration of advanced materials that enhance corrosion protection. Additionally, there is a growing focus on sustainability and reducing the environmental impact of packaging solutions.

VCI Packaging market

| Segmentation Details | Description |

|---|---|

| Product Type | Films, Papers, Bags, Foils |

| Material | Polyethylene, Polypropylene, Aluminum, Wax |

| Application | Electronics, Machinery, Automotive Parts, Aerospace |

| End User | Manufacturers, Distributors, OEMs, Aftermarket Providers |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the VCI Packaging Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at