444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The vacuum insulated panel (VIP) for construction market serves as a key solution within the construction industry, offering advanced thermal insulation for buildings and structures. Vacuum insulated panels are innovative building materials designed to minimize heat transfer, enhance energy efficiency, and improve indoor comfort in residential, commercial, and industrial construction projects. This market segment encompasses a range of VIP products tailored to various applications, architectural designs, and sustainability goals, providing architects, builders, and developers with versatile solutions for achieving high-performance building envelopes.

Meaning

Vacuum insulated panels (VIPs) for construction refer to high-performance thermal insulation materials composed of a rigid core, typically encapsulated within a gas-tight envelope under vacuum conditions. These panels achieve exceptional thermal resistance by minimizing conductive heat transfer through the elimination of air molecules within the panel core. VIPs offer superior insulation properties compared to traditional insulation materials, such as foam boards or fiberglass batts, enabling architects and builders to achieve higher levels of energy efficiency and thermal comfort in buildings.

Executive Summary

The vacuum insulated panel (VIP) for construction market is poised for significant growth as building owners, developers, and policymakers increasingly prioritize energy efficiency, sustainability, and occupant comfort in building design and construction. VIPs offer a compelling solution for achieving stringent energy performance targets, reducing heating and cooling loads, and optimizing building envelope design. With advancements in VIP technology, manufacturing processes, and market awareness, the adoption of vacuum insulated panels is expected to accelerate across residential, commercial, and institutional construction sectors.

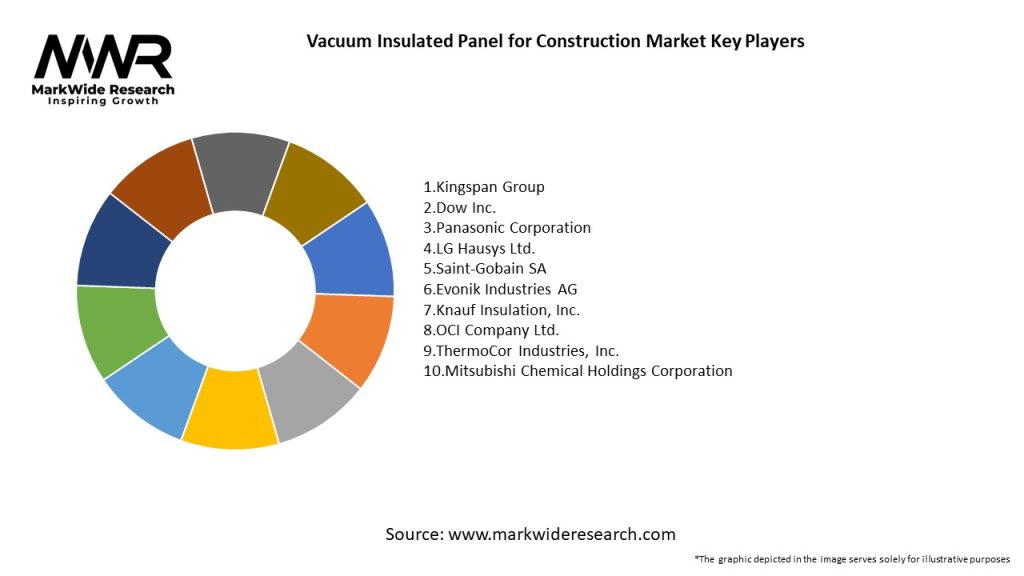

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The vacuum insulated panel for construction market operates within a dynamic landscape shaped by technological innovation, regulatory evolution, market demand, and competitive forces. Understanding market dynamics, industry trends, and customer needs is essential for manufacturers, distributors, and stakeholders to capitalize on opportunities, address challenges, and navigate the evolving landscape of energy-efficient building solutions.

Regional Analysis

Regional variations in climate, building codes, energy policies, and construction practices influence the adoption and demand for vacuum insulated panels in different geographic markets. Market analysis and segmentation by region provide insights into regional trends, regulatory frameworks, and market dynamics, guiding strategic decisions and market entry strategies for companies operating in the global VIP for construction market.

Competitive Landscape

Leading Companies in the Vacuum Insulated Panel for Construction Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

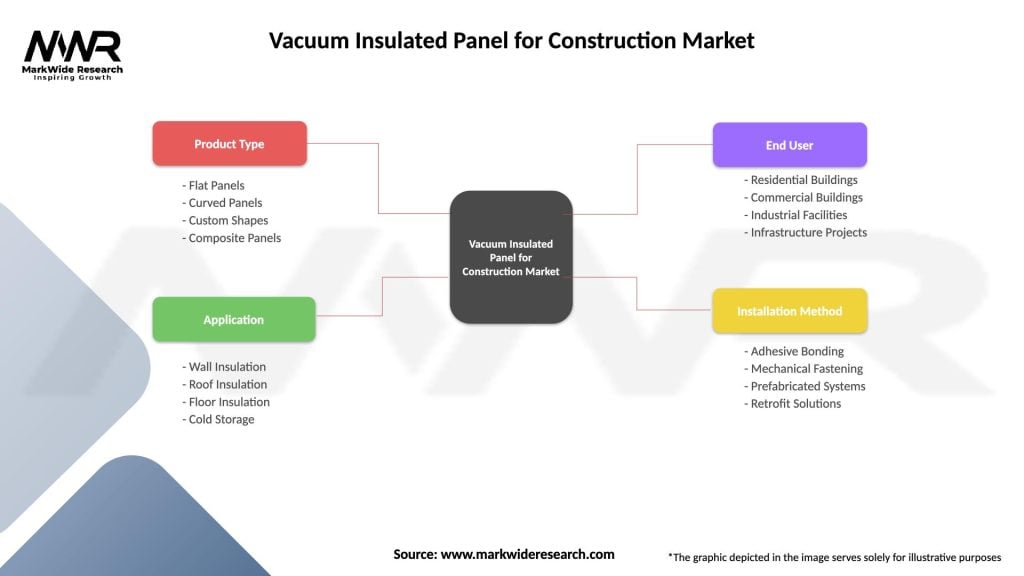

Segmentation

Market segmentation based on VIP core materials, panel dimensions, application types, and end-use sectors provides insights into customer preferences, market trends, and competitive dynamics in the vacuum insulated panel for construction market. Segmentation enables suppliers to target specific market segments, tailor product offerings, and develop targeted marketing strategies to meet the diverse needs and requirements of architects, engineers, contractors, and building owners.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths

• Vacuum insulated panels (VIPs) offer superior thermal performance compared to traditional insulation materials, significantly enhancing energy efficiency in construction projects.

• The lightweight nature of VIPs facilitates easier handling and installation, reducing labor costs and time on construction sites.

• Increasing awareness of sustainability and energy conservation drives demand for high-performance insulation solutions, positioning VIPs favorably in the market.

• Technological advancements in VIP manufacturing processes have improved durability and cost-effectiveness, making them more accessible for widespread use in construction.

Weaknesses

• The high initial cost of vacuum insulated panels can deter builders and contractors from adopting this advanced insulation technology, impacting market penetration.

• VIPs are sensitive to punctures and damage, which can compromise their insulation properties, necessitating careful handling during installation and transport.

• Limited awareness and understanding of VIPs among some construction professionals may hinder their adoption despite the benefits they offer.

• The market for VIPs is relatively niche, which may limit economies of scale and result in higher prices compared to conventional insulation options.

Opportunities

• Growing government regulations and incentives focused on energy efficiency in construction present a favorable environment for the adoption of vacuum insulated panels.

• The rising trend of green building certifications and sustainable construction practices enhances the market potential for VIPs as eco-friendly insulation solutions.

• Expanding applications of VIPs beyond traditional construction, such as in refrigeration and packaging, could open new revenue streams for manufacturers.

• Increased investment in research and development can lead to innovations in VIP technology, improving performance and reducing costs, thereby attracting more users.

Threats

• Intense competition from established insulation materials and emerging technologies could limit the market share and growth potential of vacuum insulated panels.

• Economic fluctuations and uncertainties in the construction industry may impact investment in high-performance insulation solutions like VIPs.

• Regulatory changes related to building codes and insulation standards could impose additional challenges for VIP manufacturers and users.

Market Key Trends

Key trends such as energy efficiency regulations, sustainability mandates, digitalization, and smart building technologies influence the vacuum insulated panel for construction market, driving innovation, market adoption, and industry transformation.

Covid-19 Impact

The COVID-19 pandemic has impacted the vacuum insulated panel for construction market, influencing construction activity, supply chain disruptions, project timelines, and market dynamics, while also highlighting the importance of resilient, healthy, and energy-efficient buildings in the post-pandemic recovery and future-proofing strategies.

Key Industry Developments

Industry developments such as product innovations, technology advancements, market expansions, and strategic collaborations shape the evolution of the vacuum insulated panel for construction market, fostering growth, differentiation, and competitiveness among market players.

Analyst Suggestions

Recommendations for industry stakeholders include embracing technological advancements, addressing installation challenges, promoting market education and awareness, and leveraging sustainability initiatives to capitalize on growth opportunities and mitigate market risks in the vacuum insulated panel for construction market.

Future Outlook

The future outlook for the vacuum insulated panel for construction market is optimistic, with continued growth expected driven by increasing demand for energy-efficient buildings, green construction practices, and sustainable development initiatives worldwide. However, challenges such as cost competitiveness, installation complexity, and market fragmentation require strategic collaboration, innovation, and market differentiation to unlock the full potential of vacuum insulated panels in shaping the future of high-performance building envelopes.

Conclusion

In conclusion, the vacuum insulated panel for construction market represents a dynamic and evolving segment within the building materials industry, offering innovative solutions for achieving energy-efficient, sustainable, and resilient building envelopes. With increasing focus on energy conservation, environmental sustainability, and occupant comfort, vacuum insulated panels are poised to play a pivotal role in shaping the future of building design, construction, and operation, contributing to a more sustainable, resilient, and equitable built environment for generations to come.

What is Vacuum Insulated Panel for Construction?

Vacuum Insulated Panels (VIPs) for construction are advanced insulation materials that provide superior thermal performance by creating a vacuum between two layers of material. They are commonly used in building applications to enhance energy efficiency and reduce heat loss.

What are the key players in the Vacuum Insulated Panel for Construction Market?

Key players in the Vacuum Insulated Panel for Construction Market include companies like Kingspan Group, Panasonic Corporation, and Dow Inc., which are known for their innovative insulation solutions and commitment to sustainability, among others.

What are the growth factors driving the Vacuum Insulated Panel for Construction Market?

The growth of the Vacuum Insulated Panel for Construction Market is driven by increasing energy efficiency regulations, rising demand for sustainable building materials, and the need for space-saving insulation solutions in modern architecture.

What challenges does the Vacuum Insulated Panel for Construction Market face?

Challenges in the Vacuum Insulated Panel for Construction Market include high manufacturing costs, limited awareness among builders and contractors, and potential issues with panel durability and installation techniques.

What future opportunities exist in the Vacuum Insulated Panel for Construction Market?

Future opportunities in the Vacuum Insulated Panel for Construction Market include advancements in material technology, increasing adoption in retrofitting projects, and growing interest in energy-efficient building designs that prioritize thermal performance.

What trends are shaping the Vacuum Insulated Panel for Construction Market?

Trends shaping the Vacuum Insulated Panel for Construction Market include the integration of smart building technologies, a shift towards eco-friendly materials, and the development of customized insulation solutions tailored to specific construction needs.

Vacuum Insulated Panel for Construction Market

| Segmentation Details | Description |

|---|---|

| Product Type | Flat Panels, Curved Panels, Custom Shapes, Composite Panels |

| Application | Wall Insulation, Roof Insulation, Floor Insulation, Cold Storage |

| End User | Residential Buildings, Commercial Buildings, Industrial Facilities, Infrastructure Projects |

| Installation Method | Adhesive Bonding, Mechanical Fastening, Prefabricated Systems, Retrofit Solutions |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Vacuum Insulated Panel for Construction Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at