The US welding consumables market is a thriving sector within the larger welding industry. Welding consumables refer to the materials and equipment used in welding processes, including electrodes, wires, fluxes, gases, and protective gear. These consumables play a crucial role in ensuring the quality and efficiency of welding operations across various industries.

Welding consumables are essential components in the welding process that facilitate the joining of metals by creating a strong bond between them. They act as a filler material or flux and provide necessary protection to prevent oxidation, contamination, and other defects during welding. The selection of appropriate welding consumables depends on factors such as the type of metal being welded, the welding technique employed, and the desired strength and durability of the joint.

Executive Summary

The US welding consumables market has witnessed significant growth in recent years, driven by the expansion of the manufacturing and construction sectors. The increasing demand for high-quality welding consumables, coupled with technological advancements in welding processes, has further boosted market growth. However, the market also faces challenges such as the rising cost of raw materials and environmental concerns related to certain welding consumables.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

- Growing Demand for Welding Consumables: The US market for welding consumables is experiencing steady growth due to the increasing need for welding operations across various industries such as automotive, construction, oil and gas, and power generation.

- Technological Advancements: The adoption of advanced welding technologies, such as laser welding and robotic welding, has led to the development of innovative welding consumables with enhanced performance and efficiency.

- Environmental Concerns: Environmental regulations and sustainability initiatives are pushing manufacturers to develop eco-friendly welding consumables that minimize harmful emissions and waste generation.

- Shift towards Automation: The rising labor costs and the need for improved productivity have resulted in a growing trend towards automated welding systems, which require specialized welding consumables.

- Focus on Quality and Durability: End-users are increasingly demanding welding consumables that offer superior strength, durability, and resistance to corrosion, thereby driving market growth.

Market Drivers

- Growing Industrialization: The rapid industrialization in the US has led to increased demand for welding consumables across industries such as automotive, aerospace, shipbuilding, and infrastructure development.

- Infrastructure Development: Large-scale infrastructure projects, including the construction of bridges, highways, and commercial buildings, require extensive welding operations, thus driving the demand for welding consumables.

- Expansion of Oil and Gas Sector: The exploration and production activities in the US oil and gas sector have created a significant demand for welding consumables, particularly in pipeline construction and maintenance.

- Automotive Industry Growth: The automotive industry’s continuous expansion, driven by factors such as rising disposable incomes and technological advancements, is fueling the demand for welding consumables in the manufacturing of vehicles.

- Repair and Maintenance Activities: The need for repair and maintenance of aging infrastructure, industrial machinery, and equipment drives the demand for welding consumables.

Market Restraints

- Rising Raw Material Costs: Fluctuations in the prices of raw materials used in welding consumables, such as steel, aluminum, and copper, pose a challenge to market growth.

- Health and Safety Concerns: Welding operations involve risks such as exposure to harmful fumes, ultraviolet radiation, and noise, leading to concerns regarding the health and safety of workers. This factor can limit the market growth to some extent.

- Availability of Substitutes: In certain applications, alternative joining technologies such as adhesive bonding and fastening systems can replace welding, which may affect the demand for welding consumables.

- Environmental Impact: Some welding consumables release harmful emissions and generate waste, contributing to environmental pollution. Regulatory measures aimed at reducing environmental impact pose challenges to the market.

- Skilled Labor Shortage: The shortage of skilled welders in the US poses a challenge to the adoption of welding technologies and the demand for welding consumables.

Market Opportunities

- Growing Demand for Lightweight Materials: The increasing focus on fuel efficiency and emission reduction in industries such as automotive and aerospace presents opportunities for the development of welding consumables suitable for lightweight materials like aluminum and composites.

- Renewable Energy Sector: The expansion of the renewable energy sector, including wind and solar power, requires welding consumables for the fabrication and installation of components, creating a potential market opportunity.

- Technological Advancements: Continuous advancements in welding technologies, such as friction stir welding and hybrid welding, create opportunities for the development of specialized welding consumables tailored to these processes.

- Emerging Applications: The adoption of welding in emerging applications such as 3D printing, additive manufacturing, and the construction of advanced materials presents opportunities for welding consumables manufacturers to cater to these evolving needs.

- Infrastructure Modernization: The need for infrastructure modernization and upgradation offers opportunities for welding consumables, particularly in sectors such as transportation, energy, and utilities.

Market Dynamics

The US welding consumables market is driven by a combination of factors, including industrial growth, technological advancements, and regulatory requirements. The market is characterized by intense competition among key players, who focus on product innovation, strategic partnerships, and expanding their distribution networks to gain a competitive edge. Additionally, market participants strive to address environmental concerns and meet customer demands for high-quality, durable, and cost-effective welding consumables.

Regional Analysis

The US welding consumables market exhibits regional variations in terms of demand and growth opportunities. Key regions driving market growth include:

- Western Region: The Western region, encompassing states such as California and Washington, benefits from strong industrial and manufacturing sectors, including aerospace, automotive, and technology, leading to increased demand for welding consumables.

- Southern Region: The Southern region, comprising states like Texas and Florida, experiences growth due to the presence of major industries such as oil and gas, construction, and transportation, which require welding consumables for their operations.

- Midwestern Region: The Midwestern region, with states like Ohio and Michigan, is known for its manufacturing and automotive industries, contributing to the demand for welding consumables in the region.

- Northeastern Region: The Northeastern region, including states like New York and Pennsylvania, has a diverse industrial base, including sectors like construction, energy, and infrastructure, which drive the demand for welding consumables.

Competitive Landscape

Leading companies in the US Welding Consumables Market:

- Lincoln Electric Holdings, Inc.

- ESAB (Colfax Corporation)

- ITW Welding

- voestalpine Böhler Welding GmbH

- Hobart Brothers Company

- Harris Products Group (Lincoln Electric Holdings, Inc.)

- Airgas, Inc. (Air Liquide S.A.)

- Welding Alloys Group

- The Harris Products Group, a Lincoln Electric Company

- Kobe Steel Ltd.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

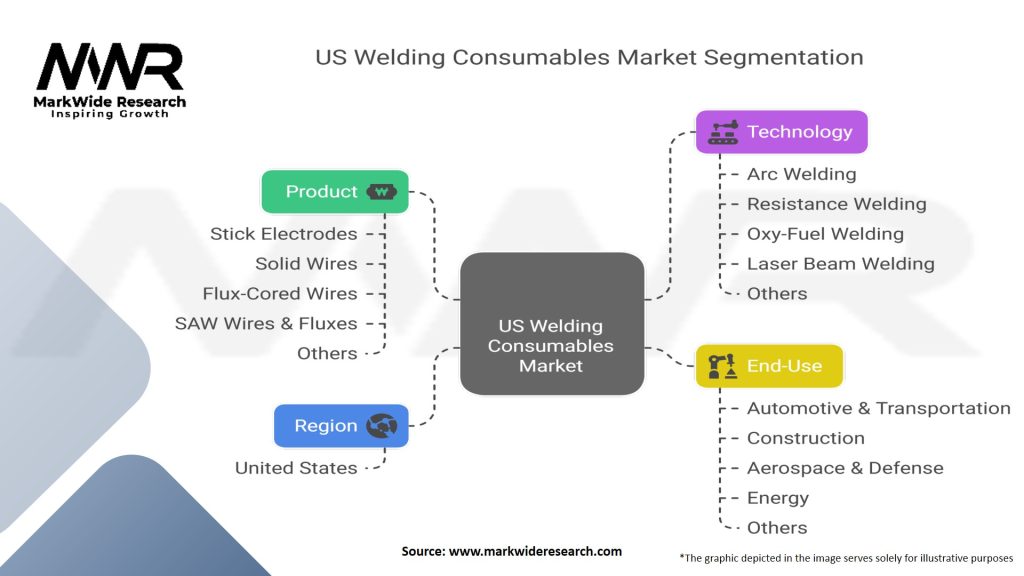

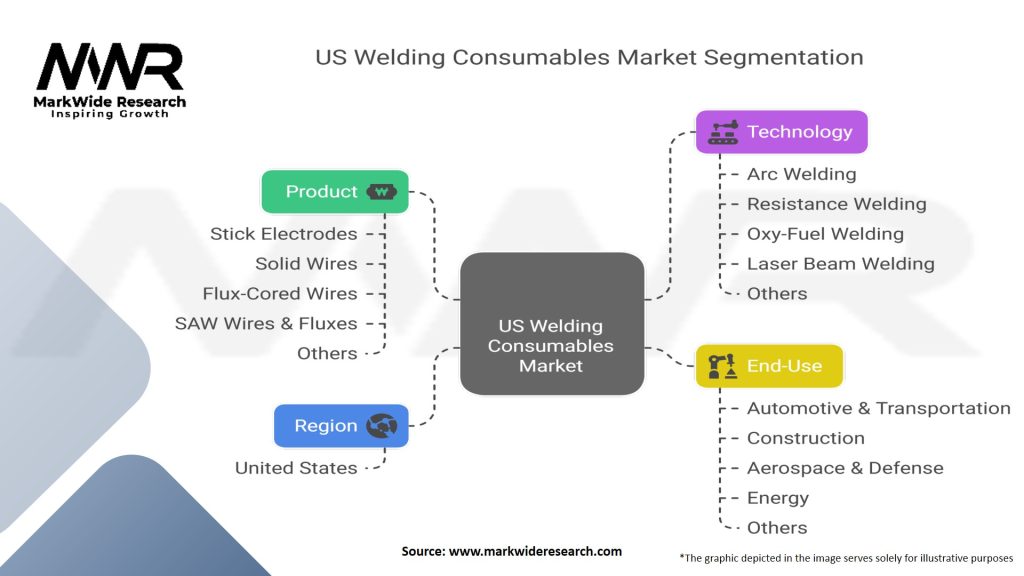

Segmentation

The US welding consumables market can be segmented based on various criteria, including:

- Type of Consumables: a. Electrodes b. Fluxes and Wires c. Gases d. Others (including protective gear, welding rods, etc.)

- Welding Technique: a. Arc Welding b. Resistance Welding c. Oxy-fuel Welding d. Others (including Laser Welding, Ultrasonic Welding, etc.)

- End-use Industry: a. Automotive b. Construction c. Oil and Gas d. Power Generation e. Aerospace and Defense f. Others (including Shipbuilding, Electronics, etc.)

- Distribution Channel: a. Direct Sales b. Distributors and Wholesalers c. Online Retailers d. Others (including OEMs, Dealers, etc.)

Segmentation allows market players to identify specific customer segments, understand their unique requirements, and develop targeted marketing and sales strategies.

Category-wise Insights

- Electrodes: Electrodes are a widely used category of welding consumables, providing a stable arc, filler metal, and flux for welding operations. They are available in various types, such as stick electrodes, solid wires, and cored wires, each suitable for specific applications.

- Fluxes and Wires: Fluxes and wires are used in welding processes such as gas metal arc welding (GMAW) and submerged arc welding (SAW). They provide shielding gas, filler metal, and flux to protect the weld pool and ensure a sound joint.

- Gases: Gases such as argon, helium, and carbon dioxide are essential for shielding the weld pool from atmospheric contamination and maintaining the stability of the arc during welding.

- Others: This category includes additional welding consumables such as protective gear (helmets, gloves, etc.), welding rods, and specialty materials used in specific welding applications.

Each category of welding consumables serves a distinct purpose and caters to specific welding techniques and industry requirements.

Key Benefits for Industry Participants and Stakeholders

The US welding consumables market offers several benefits for industry participants and stakeholders:

- Revenue Generation: The growing demand for welding consumables presents revenue opportunities for manufacturers, distributors, and retailers operating in the market.

- Technological Advancements: Participants in the market can leverage technological advancements in welding processes and consumables to develop innovative products that meet customer demands for improved quality, efficiency, and performance.

- Diversification: The market allows industry participants to diversify their product portfolios by offering a wide range of welding consumables tailored to different applications and industry verticals.

- Collaborative Partnerships: Strategic collaborations and partnerships between welding consumables manufacturers, distributors, and end-users can lead to mutual benefits such as knowledge sharing, market expansion, and cost optimization.

- Industry Growth: The overall growth of the welding consumables market contributes to the growth and development of associated industries, including manufacturing, construction, and infrastructure.

SWOT Analysis

- Strengths:

- Strong demand from various industries, including automotive, construction, and oil and gas.

- Technological advancements in welding processes and consumables.

- Established distribution networks and supply chains.

- Weaknesses:

- Fluctuating raw material prices, affecting profit margins.

- Environmental concerns associated with certain welding consumables.

- Shortage of skilled welders, leading to labor constraints.

- Opportunities:

- Growing demand for lightweight materials and renewable energy.

- Advancements in welding technologies and emerging applications.

- Infrastructure modernization and upgradation projects.

- Threats:

- Availability of substitutes for welding, such as adhesive bonding and fastening systems.

- Stringent environmental regulations impacting the market.

- Intense competition among key players.

Market Key Trends

- Rising Demand for High-performance Welding Consumables: The market is witnessing a shift towards high-performance welding consumables that offer improved weld quality, higher productivity, and enhanced durability.

- Adoption of Automation and Robotics: The integration of automation and robotics in welding processes is driving the demand for specialized welding consumables compatible with these advanced systems.

- Sustainable and Eco-friendly Solutions: There is an increasing focus on developing eco-friendly welding consumables that reduce emissions, waste generation, and environmental impact.

- Industry 4.0 and Digitalization: The implementation of Industry 4.0 technologies, such as Internet of Things (IoT) and data analytics, is enabling remote monitoring and optimization of welding processes, influencing the demand for smart welding consumables.

- Customization and Tailored Solutions: Manufacturers are offering customized welding consumables to meet specific customer requirements, providing enhanced product performance and cost-effectiveness.

Covid-19 Impact

The COVID-19 pandemic had a significant impact on the US welding consumables market. The temporary shutdown of manufacturing facilities, construction projects, and automotive production disrupted the demand for welding consumables. However, with the gradual resumption of economic activities, the market is recovering, driven by pent-up demand, infrastructure investments, and the resumption of manufacturing operations.

The pandemic also highlighted the need for robust and resilient supply chains to ensure the availability of welding consumables. Manufacturers implemented safety protocols, remote work arrangements, and digitization to mitigate the impact of the pandemic and ensure business continuity.

Key Industry Developments

- Product Innovations: Manufacturers are focusing on developing advanced welding consumables with improved performance, ease of use, and reduced environmental impact.

- Strategic Partnerships and Collaborations: Market players are forming strategic partnerships to combine their expertise and resources, expand their market presence, and develop innovative solutions.

- Acquisitions and Mergers: Companies are engaging in mergers and acquisitions to strengthen their product portfolios, enhance their technological capabilities, and gain a competitive advantage in the market.

- Investments in R&D: Market participants are investing in research and development activities to introduce new products and technologies that address evolving industry requirements and offer competitive advantages.

- Expansion into Emerging Markets: Leading players are expanding their operations into emerging markets to tap into the growing demand for welding consumables in these regions.

Analyst Suggestions

- Focus on Technological Advancements: Companies should invest in research and development to stay at the forefront of technological advancements in welding processes and consumables. This includes exploring automation, robotics, and digitalization opportunities.

- Sustainability and Environmental Responsibility: Manufacturers should prioritize the development of eco-friendly welding consumables that comply with environmental regulations and meet customer demands for sustainable solutions.

- Strategic Partnerships and Collaborations: Collaboration with key stakeholders, such as end-users, distributors, and technology providers, can help companies expand their market reach, access new customers, and enhance product offerings.

- Skill Development and Training: Addressing the shortage of skilled welders by investing in training programs, certifications, and apprenticeships will ensure a skilled workforce to support the market’s growth.

- Market Diversification: Companies should consider diversifying their product portfolios and expanding into emerging industries and regions to capitalize on untapped market opportunities.

Future Outlook

The US welding consumables market is poised for steady growth in the coming years. Factors such as industrial expansion, infrastructure development, technological advancements, and sustainability initiatives will drive market growth. The market is expected to witness increased demand for high-performance welding consumables, lightweight materials, and eco-friendly solutions.

With the rise of automation, robotics, and digitalization, the market will experience a shift towards smart welding consumables and data-driven optimization of welding processes. Manufacturers will focus on product innovation, strategic partnerships, and market diversification to gain a competitive edge.

Conclusion

The US welding consumables market is a dynamic and evolving sector, driven by the growing demand for welding operations across industries. The market offers opportunities for manufacturers, distributors, and retailers to cater to diverse customer needs and leverage technological advancements in welding processes and consumables.

While facing challenges such as raw material price fluctuations, environmental concerns, and labor shortages, the market continues to grow due to industrial expansion, infrastructure development, and the adoption of advanced welding technologies. The future outlook is positive, with a focus on sustainability, customization, and digitalization shaping the market’s trajectory.

Industry participants and stakeholders must stay proactive in adapting to market trends, investing in R&D, forming strategic partnerships, and addressing skill development to capitalize on the opportunities presented by the US welding consumables market.

Leading companies in the US Welding Consumables Market:

- Lincoln Electric Holdings, Inc.

- ESAB (Colfax Corporation)

- ITW Welding

- voestalpine Böhler Welding GmbH

- Hobart Brothers Company

- Harris Products Group (Lincoln Electric Holdings, Inc.)

- Airgas, Inc. (Air Liquide S.A.)

- Welding Alloys Group

- The Harris Products Group, a Lincoln Electric Company

- Kobe Steel Ltd.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.