444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The US Solar Ingot Wafer Market is a crucial segment of the solar energy industry, providing the foundation for photovoltaic (PV) cell production. Solar ingots and wafers serve as the building blocks for solar cells, which convert sunlight into electricity. The market’s growth is driven by increasing demand for renewable energy sources, government incentives for solar adoption, and technological advancements in solar cell manufacturing.

Meaning

The US Solar Ingot Wafer Market involves the production and supply of silicon ingots and wafers used in the manufacturing of solar cells. Silicon ingots are cylindrical blocks of high-purity silicon, produced through a process called crystal pulling. These ingots are sliced into thin wafers, which undergo further processing to create solar cells. Solar ingots and wafers are essential components of solar photovoltaic modules, contributing to the growth of the solar energy sector.

Executive Summary

The US Solar Ingot Wafer Market is experiencing steady growth, driven by factors such as declining solar module costs, increasing efficiency of solar cells, and government initiatives promoting renewable energy adoption. The market presents opportunities for industry players to innovate in manufacturing processes, improve material efficiency, and expand production capacity to meet growing demand for solar energy solutions.

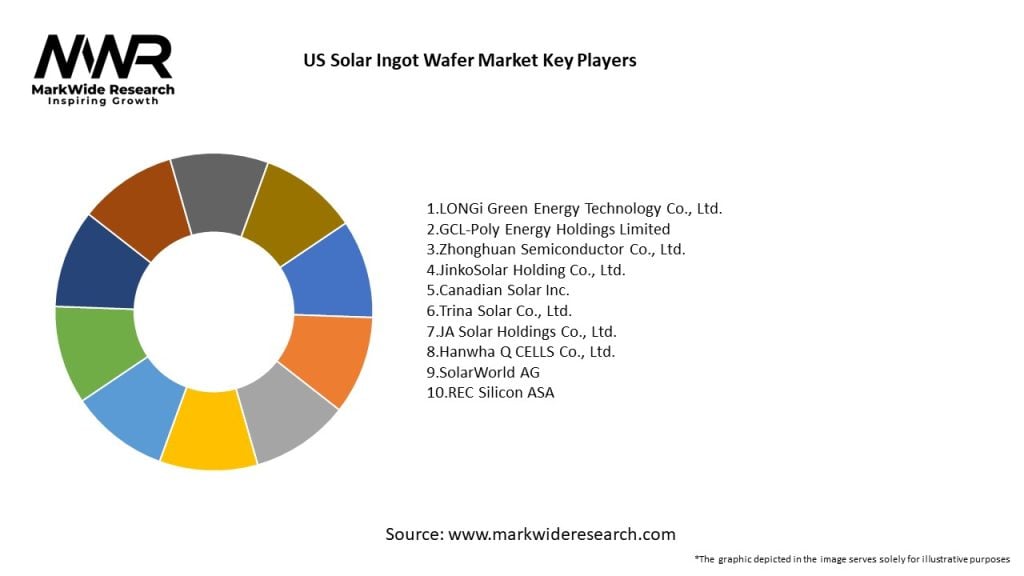

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The US Solar Ingot Wafer Market operates within a dynamic ecosystem shaped by technological innovation, market forces, policy developments, and consumer preferences. Understanding and navigating these dynamics is essential for industry participants to capitalize on opportunities, mitigate risks, and sustain growth in the evolving solar energy landscape.

Regional Analysis

The US Solar Ingot Wafer Market exhibits regional variations in demand, manufacturing capacity, and market dynamics. Key regions, such as California, Texas, Arizona, and Florida, have favorable solar energy policies, high solar irradiance levels, and robust market demand, driving the growth of the solar ingot wafer market.

Competitive Landscape

Leading Companies in the US Solar Ingot Wafer Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The US Solar Ingot Wafer Market can be segmented based on various factors, including:

Segmentation enables market players to target specific customer segments, optimize product offerings, and address unique market requirements.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The US Solar Ingot Wafer Market offers several benefits for industry participants and stakeholders:

SWOT Analysis

A SWOT analysis of the US Solar Ingot Wafer Market provides insights into its strengths, weaknesses, opportunities, and threats:

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has affected the US Solar Ingot Wafer Market in several ways:

Key Industry Developments

Analyst Suggestions

Future Outlook

The US Solar Ingot Wafer Market is poised for continued growth and innovation, driven by the transition towards a low-carbon economy, increasing energy demand, and technological advancements in solar energy conversion. Despite challenges posed by market uncertainties, policy shifts, and global disruptions, the long-term outlook for the solar industry remains positive, with solar energy expected to play a significant role in meeting future energy needs and addressing climate change.

Conclusion

The US Solar Ingot Wafer Market represents a vital segment of the renewable energy sector, contributing to the widespread adoption of solar power and the transition towards a sustainable energy future. With ongoing advancements in technology, policy support, and market dynamics, the solar ingot wafer market presents opportunities for innovation, growth, and collaboration across the solar value chain. By leveraging these opportunities, addressing challenges, and embracing a vision of clean, affordable, and reliable solar energy, stakeholders can drive positive change and accelerate the transition towards a greener, more resilient energy system.

What is Solar Ingot Wafer?

Solar ingot wafers are thin slices of crystalline silicon used in the production of solar cells. They serve as the foundational material for converting sunlight into electricity in photovoltaic systems.

What are the key players in the US Solar Ingot Wafer Market?

Key players in the US Solar Ingot Wafer Market include companies like First Solar, SunPower, and REC Group, which are known for their advancements in solar technology and manufacturing processes, among others.

What are the growth factors driving the US Solar Ingot Wafer Market?

The US Solar Ingot Wafer Market is driven by increasing demand for renewable energy, government incentives for solar installations, and advancements in solar technology that enhance efficiency and reduce costs.

What challenges does the US Solar Ingot Wafer Market face?

Challenges in the US Solar Ingot Wafer Market include fluctuating raw material prices, competition from alternative energy sources, and regulatory hurdles that can impact production and installation.

What opportunities exist in the US Solar Ingot Wafer Market?

Opportunities in the US Solar Ingot Wafer Market include the growing trend towards energy independence, innovations in solar technology, and increasing investments in sustainable energy solutions.

What trends are shaping the US Solar Ingot Wafer Market?

Trends in the US Solar Ingot Wafer Market include the shift towards higher efficiency solar cells, the integration of smart technology in solar systems, and a focus on sustainability and eco-friendly manufacturing practices.

US Solar Ingot Wafer Market

| Segmentation Details | Description |

|---|---|

| Product Type | Monocrystalline, Polycrystalline, Bifacial, Thin-Film |

| Technology | Photovoltaic, Concentrated Solar Power, Hybrid Systems, Organic Photovoltaics |

| End User | Residential, Commercial, Industrial, Utility |

| Application | Power Generation, Off-Grid Systems, Building-Integrated Photovoltaics, Solar Farms |

Leading Companies in the US Solar Ingot Wafer Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at