444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The US Lubricant Contaminated HDPE Container Waste market refers to the industry involved in the management, disposal, and recycling of high-density polyethylene (HDPE) containers contaminated with lubricant substances. These containers are widely used in various industries for storing and transporting lubricants such as engine oil, hydraulic oil, and industrial lubricants.

Meaning

Lubricant-contaminated HDPE container waste refers to the discarded HDPE containers that have come into contact with lubricants during their use. These containers cannot be reused for their original purpose due to the risk of contamination. Proper management of this waste is crucial to prevent environmental pollution and ensure the responsible disposal or recycling of these containers.

Executive Summary

The US Lubricant Contaminated HDPE Container Waste market is experiencing steady growth due to the increasing awareness of environmental concerns and the need for sustainable waste management practices. The market players are focusing on developing innovative technologies for the efficient treatment and recycling of lubricant-contaminated HDPE containers. This report provides valuable insights into the market dynamics, drivers, restraints, opportunities, and key trends shaping the industry.

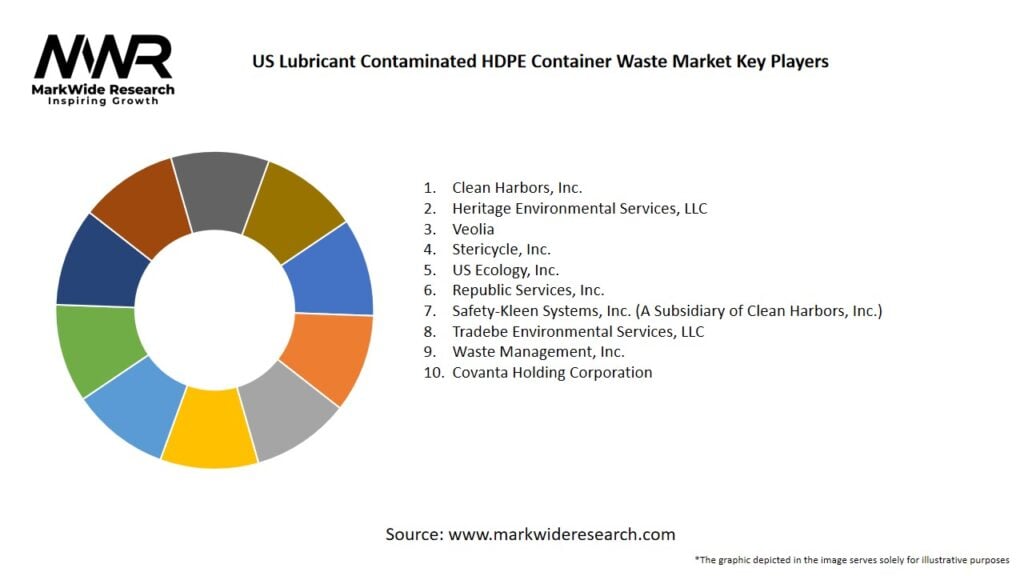

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The US Lubricant Contaminated HDPE Container Waste market is dynamic and influenced by various factors. The increasing focus on environmental sustainability, stringent regulations, technological advancements, and industry collaborations play significant roles in shaping the market landscape. Industry players need to stay updated with these dynamics to capitalize on the emerging opportunities and address the challenges effectively.

Regional Analysis

The US Lubricant Contaminated HDPE Container Waste market exhibits regional variations influenced by factors such as industrial activities, population density, waste management infrastructure, and regulatory frameworks. Different regions may have varying levels of awareness and adoption of recycling practices. The market analysis should consider these regional nuances to develop targeted strategies for each area.

Competitive Landscape

Leading Companies in the US Lubricant Contaminated HDPE Container Waste Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

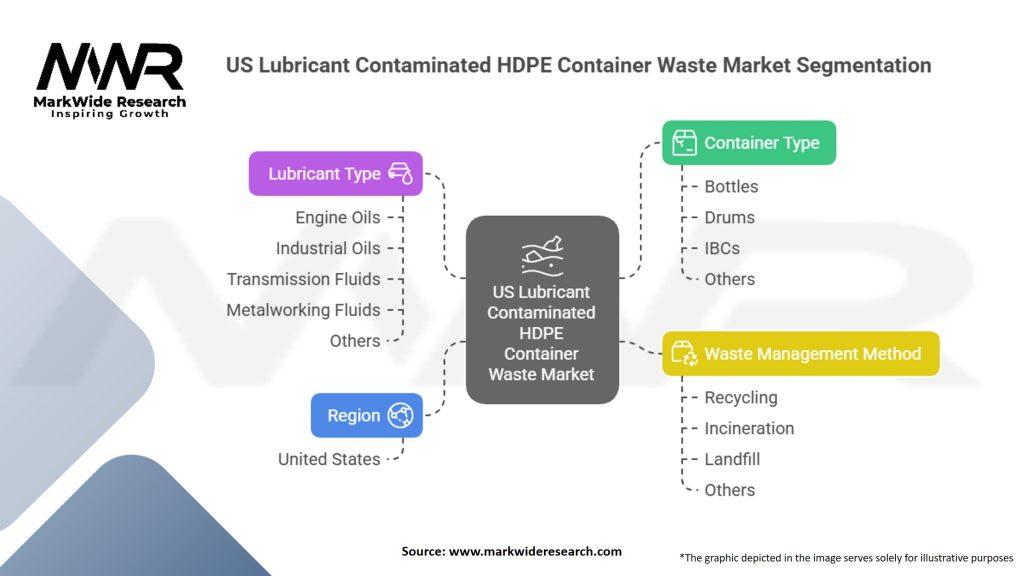

Segmentation

The US Lubricant Contaminated HDPE Container Waste market can be segmented based on various factors such as waste management methods, recycling technologies, end-use industries, and geographical regions. By understanding these segments, market participants can tailor their strategies to cater to specific customer needs and maximize their market share.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has had a mixed impact on the US Lubricant Contaminated HDPE Container Waste market. While the initial lockdowns and disruptions in industrial activities led to a temporary decline in waste generation, the subsequent recovery and increased focus on hygiene and cleanliness have boosted the demand for lubricants and, consequently, the generation of lubricant-contaminated HDPE container waste. The pandemic has also highlighted the importance of sustainable waste management practices and accelerated the adoption of recycling technologies.

Key Industry Developments

Analyst Suggestions

Future Outlook

The US Lubricant Contaminated HDPE Container Waste market is expected to grow steadily in the coming years. Factors such as increasing environmental awareness, stringent regulations, and the adoption of sustainable practices will drive market growth. Technological advancements, collaborative initiatives, and a focus on circular economy principles will shape the industry’s future. The market participants who embrace innovation, invest in research and development, and prioritize environmental sustainability will have a competitive advantage.

Conclusion

The US Lubricant Contaminated HDPE Container Waste market is witnessing growth driven by environmental concerns, regulations, and the adoption of sustainable waste management practices. Recycling technologies, collaboration between industry stakeholders, and digital solutions are playing significant roles in shaping the market. Despite challenges such as limited awareness and complex recycling processes, the market offers opportunities for cost savings, resource conservation, and environmental sustainability. With continued investments in research and development and a focus on compliance and collaboration, the industry can achieve long-term success in managing and recycling lubricant-contaminated HDPE containers.

What is the US Lubricant Contaminated HDPE Container Waste Market?

The US Lubricant Contaminated HDPE Container Waste Market refers to the sector dealing with the disposal, recycling, and management of high-density polyethylene containers that have been contaminated with lubricants. This market encompasses various processes aimed at minimizing environmental impact and promoting sustainable waste management practices.

Who are the key players in the US Lubricant Contaminated HDPE Container Waste Market?

Key players in the US Lubricant Contaminated HDPE Container Waste Market include companies like Clean Harbors, Veolia, and Waste Management, among others. These companies specialize in waste management and recycling services tailored to contaminated materials.

What are the main drivers of the US Lubricant Contaminated HDPE Container Waste Market?

The main drivers of the US Lubricant Contaminated HDPE Container Waste Market include increasing environmental regulations, the growing emphasis on recycling and sustainability, and the rising awareness of the hazards associated with improper disposal of contaminated containers.

What challenges does the US Lubricant Contaminated HDPE Container Waste Market face?

Challenges in the US Lubricant Contaminated HDPE Container Waste Market include the high costs associated with proper disposal and recycling processes, regulatory compliance complexities, and the need for advanced technologies to effectively treat contaminated materials.

What opportunities exist in the US Lubricant Contaminated HDPE Container Waste Market?

Opportunities in the US Lubricant Contaminated HDPE Container Waste Market include the development of innovative recycling technologies, partnerships between waste management companies and lubricant manufacturers, and the potential for increased consumer demand for sustainable products and practices.

What trends are shaping the US Lubricant Contaminated HDPE Container Waste Market?

Trends shaping the US Lubricant Contaminated HDPE Container Waste Market include the rise of circular economy initiatives, advancements in waste processing technologies, and a growing focus on corporate sustainability commitments among manufacturers and consumers.

US Lubricant Contaminated HDPE Container Waste Market

| Segmentation | Details |

|---|---|

| Container Type | Bottles, Drums, IBCs (Intermediate Bulk Containers), Others |

| Lubricant Type | Engine Oils, Industrial Oils, Transmission Fluids, Metalworking Fluids, Others |

| Waste Management Method | Recycling, Incineration, Landfill, Others |

| Region | United States |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the US Lubricant Contaminated HDPE Container Waste Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at