444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The US Industrial Lubricants Market is a critical segment of the country’s industrial sector, providing essential lubrication solutions to various industries such as manufacturing, automotive, aerospace, energy, and construction. Industrial lubricants play a vital role in reducing friction, wear, and heat generation in machinery and equipment, thereby enhancing operational efficiency, prolonging equipment lifespan, and minimizing maintenance costs. With the US economy’s diverse industrial landscape and technological advancements driving innovation in lubricant formulations, the market for industrial lubricants in the US continues to evolve and expand.

Meaning

Industrial lubricants refer to specialized fluids or greases used to reduce friction and wear between moving parts in industrial machinery and equipment. These lubricants come in various forms, including oils, greases, fluids, and pastes, and are formulated to withstand extreme temperatures, pressures, and operating conditions encountered in industrial applications. Industrial lubricants are essential for maintaining equipment performance, preventing premature failure, and ensuring smooth and efficient operation across a wide range of industrial sectors in the US.

Executive Summary

The US Industrial Lubricants Market is witnessing steady growth driven by the increasing demand for high-performance lubrication solutions in industrial operations. Key factors contributing to market expansion include the growing emphasis on equipment reliability and efficiency, stringent regulatory requirements, and technological advancements in lubricant formulations. Market players are focused on product innovation, strategic partnerships, and sustainability initiatives to capitalize on emerging market trends and maintain a competitive edge in the US industrial lubricants market.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The US Industrial Lubricants Market operates in a dynamic environment influenced by factors such as technological advancements, regulatory changes, economic conditions, and competitive dynamics. These dynamics shape market trends, consumer preferences, and industry strategies, requiring stakeholders to adapt and innovate to stay competitive and capitalize on emerging opportunities.

Regional Analysis

The US Industrial Lubricants Market encompasses diverse geographic regions with unique industrial landscapes, regulatory frameworks, and market dynamics. While industrial hubs such as the Midwest, Gulf Coast, and Northeast represent significant market opportunities due to their concentration of manufacturing and energy industries, emerging regions like the Southeast and Southwest offer growth potential driven by infrastructure development and industrial diversification initiatives.

Competitive Landscape

Leading Companies in US Industrial Lubricants Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

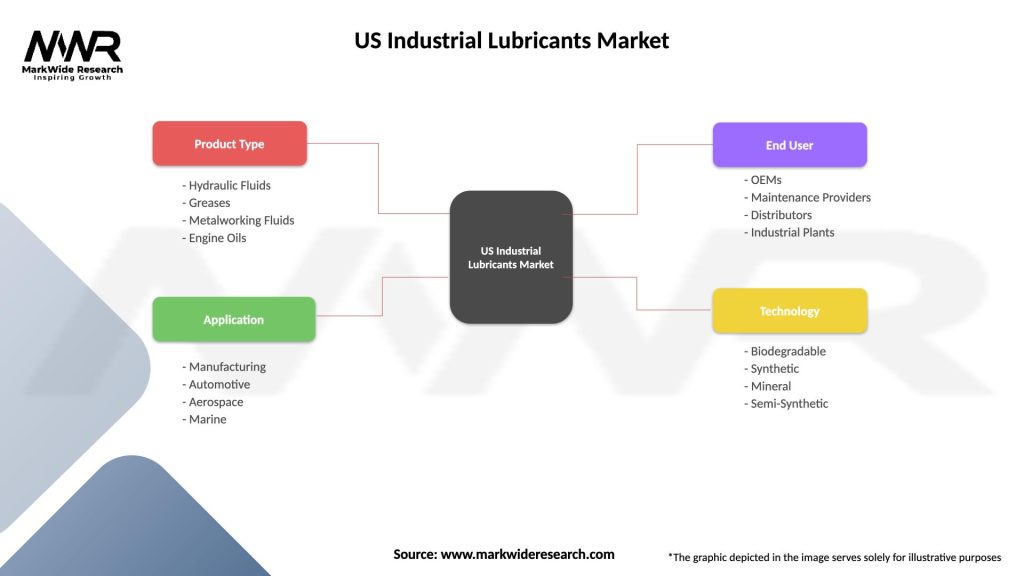

Segmentation

The US Industrial Lubricants Market can be segmented based on various factors, including:

Segmentation enables lubricant manufacturers to target specific customer segments, tailor their product offerings, and optimize their marketing and distribution strategies to maximize market penetration and profitability.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

A SWOT analysis of the US Industrial Lubricants Market reveals the following insights:

Understanding these factors helps industry stakeholders identify market opportunities, address challenges, and develop strategic initiatives to enhance their competitive position and market performance in the US Industrial Lubricants Market.

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had mixed effects on the US Industrial Lubricants Market. While the initial disruptions in supply chains, manufacturing operations, and demand for industrial products impacted lubricant sales and distribution, the subsequent recovery and rebound in industrial activity, infrastructure spending, and economic stimulus measures supported market growth and revitalization.

Key Industry Developments

Analyst Suggestions

Future Outlook

The US Industrial Lubricants Market is poised for continued growth and innovation driven by factors such as technological advancements, sustainability imperatives, and infrastructure investments. Manufacturers that prioritize product innovation, customer-centricity, and sustainability will be well-positioned to capitalize on emerging market opportunities and sustain long-term growth and competitiveness in the dynamic US industrial lubricants market landscape.

Conclusion

The US Industrial Lubricants Market plays a vital role in supporting the country’s diverse industrial sectors by providing essential lubrication solutions that enhance equipment performance, reliability, and sustainability. Despite challenges such as price volatility, environmental concerns, and competitive pressures, the market offers significant opportunities for innovation, growth, and differentiation through technological advancements, sustainability initiatives, and customer engagement strategies. By embracing innovation, sustainability, and resilience, lubricant manufacturers can navigate market dynamics, meet customer needs, and drive value creation in the dynamic and competitive US Industrial Lubricants Market.

What is Industrial Lubricants?

Industrial lubricants are substances used to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. They are essential in various applications, including machinery, automotive, and manufacturing processes.

What are the key players in the US Industrial Lubricants Market?

Key players in the US Industrial Lubricants Market include ExxonMobil, Chevron, and Shell, which are known for their extensive product lines and innovations in lubricant technology. Other notable companies include Total and Fuchs, among others.

What are the main drivers of the US Industrial Lubricants Market?

The main drivers of the US Industrial Lubricants Market include the increasing demand for high-performance lubricants in manufacturing and automotive sectors, as well as the growing focus on energy efficiency and equipment longevity. Additionally, advancements in lubricant formulations are contributing to market growth.

What challenges does the US Industrial Lubricants Market face?

The US Industrial Lubricants Market faces challenges such as stringent environmental regulations and the need for sustainable products. Additionally, fluctuating raw material prices can impact production costs and pricing strategies.

What opportunities exist in the US Industrial Lubricants Market?

Opportunities in the US Industrial Lubricants Market include the development of bio-based lubricants and the increasing adoption of smart lubrication technologies. The rise of electric vehicles also presents new avenues for lubricant innovation.

What trends are shaping the US Industrial Lubricants Market?

Trends shaping the US Industrial Lubricants Market include the shift towards synthetic lubricants, which offer better performance and longer life, and the growing emphasis on sustainability and eco-friendly products. Additionally, digitalization in maintenance practices is influencing lubricant usage patterns.

US Industrial Lubricants Market

| Segmentation Details | Description |

|---|---|

| Product Type | Hydraulic Fluids, Greases, Metalworking Fluids, Engine Oils |

| Application | Manufacturing, Automotive, Aerospace, Marine |

| End User | OEMs, Maintenance Providers, Distributors, Industrial Plants |

| Technology | Biodegradable, Synthetic, Mineral, Semi-Synthetic |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in US Industrial Lubricants Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at