444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The US industrial coatings market is a thriving sector within the country’s manufacturing industry. Industrial coatings refer to specialized paints and coatings used to protect and enhance the surfaces of various industrial products and equipment. These coatings are designed to provide corrosion resistance, chemical resistance, UV protection, and improved aesthetics, among other benefits. The market for industrial coatings in the US is driven by the strong demand from industries such as automotive, aerospace, construction, oil and gas, and marine, among others.

Meaning

Industrial coatings are applied to surfaces to provide protection against corrosion, wear and tear, and other forms of damage. These coatings are typically used in industries where products and equipment are subjected to harsh environments, such as extreme temperatures, chemicals, moisture, and abrasion. By applying industrial coatings, manufacturers can extend the lifespan of their products and enhance their performance, thereby reducing maintenance costs and improving overall efficiency.

Executive Summary

The US industrial coatings market is witnessing steady growth due to several factors such as increased industrialization, infrastructure development, and technological advancements. The market is highly competitive, with both domestic and international players vying for market share. The demand for industrial coatings is driven by the need for durable and long-lasting protection for industrial equipment and products. With a wide range of applications across various industries, the industrial coatings market in the US is poised for further growth in the coming years.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

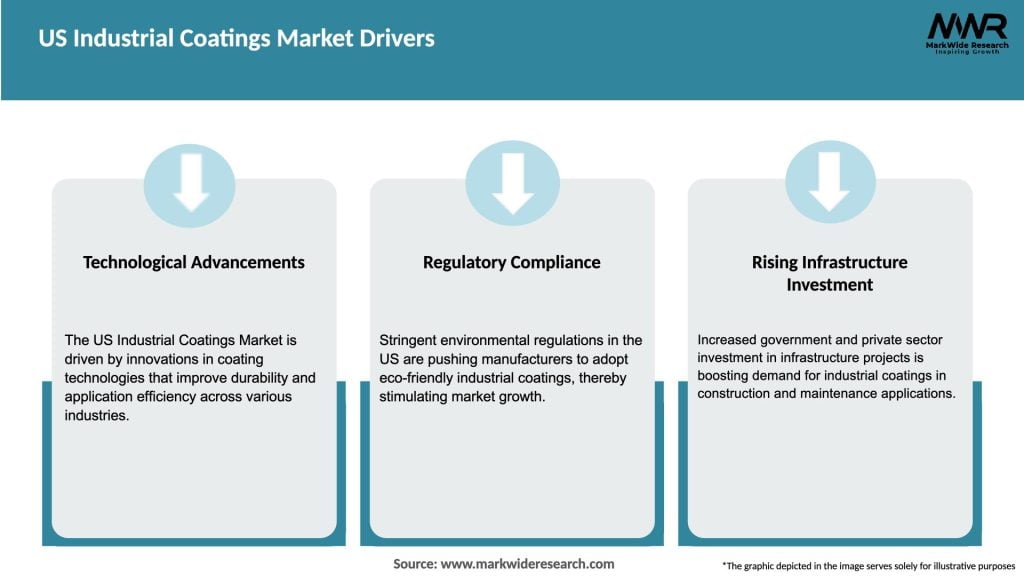

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The US industrial coatings market is influenced by several dynamic factors that shape its growth and trajectory. These dynamics include technological advancements, regulatory landscape, market competition, customer preferences, and economic conditions.

Technological advancements in coating materials, application techniques, and curing processes drive innovation in the market. Manufacturers are constantly exploring new formulations and solutions to meet evolving industry requirements. The development of environmentally friendly coatings and the integration of advanced functionalities, such as antimicrobial properties and self-healing capabilities, contribute to market growth.

The regulatory landscape plays a significant role in shaping the industrial coatings market. Stringent environmental regulations, workplace safety standards, and quality certifications require manufacturers to develop compliant coatings. Compliance with these regulations is crucial for market participants to gain a competitive edge and establish trust among customers.

Competition within the industrial coatings market is intense. Manufacturers compete based on factors such as product performance, quality, price, distribution network, and customer service. The presence of numerous players, both domestic and international, fosters innovation and drives market growth through healthy competition.

Customer preferences and market trends play a vital role in shaping the demand for industrial coatings. Industries such as automotive, aerospace, and construction have specific requirements for coatings in terms of performance, aesthetics, and sustainability. Manufacturers need to stay abreast of changing customer preferences and adapt their offerings accordingly to maintain a competitive edge.

Economic conditions, such as GDP growth, industrial output, and investments in infrastructure development, significantly impact the industrial coatings market. Economic downturns can lead to reduced industrial activities and capital expenditure, affecting the demand for coatings. Conversely, periods of economic growth and increased investments create opportunities for market expansion.

Regional Analysis

The US industrial coatings market exhibits regional variations in terms of demand, end-use industries, and market dynamics. The market can be segmented into various regions, including but not limited to:

The regional analysis helps manufacturers and stakeholders understand the demand patterns and industry dynamics in specific areas, enabling them to tailor their strategies and offerings accordingly.

Competitive Landscape

Leading Companies in the US Industrial Coatings Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

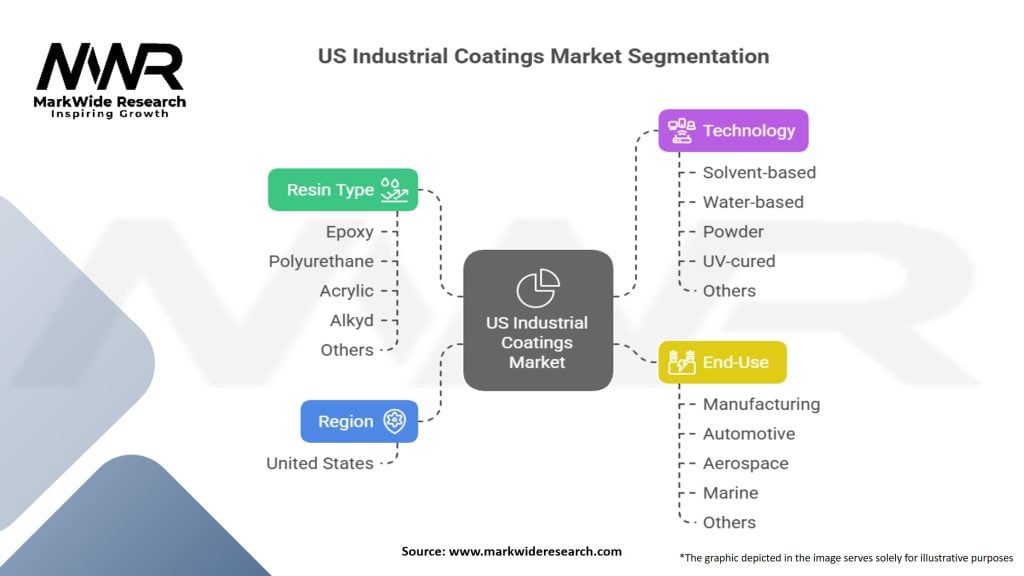

Segmentation

The US industrial coatings market can be segmented based on various factors, including coating type, end-use industry, and application method. Each segmentation provides insights into the specific market dynamics and demands within those segments.

Segmentation allows manufacturers and stakeholders to identify specific market opportunities, target their offerings, and align their strategies with the unique requirements of each segment.

Category-wise Insights

Understanding the characteristics and applications of different coating categories helps manufacturers and customers make informed decisions and select the most suitable coatings for their specific requirements.

Key Benefits for Industry Participants and Stakeholders

Understanding the key benefits of industrial coatings helps industry participants and stakeholders appreciate the value proposition and make informed decisions regarding their adoption and usage.

SWOT Analysis

A SWOT analysis provides an overview of the strengths, weaknesses, opportunities, and threats in the US industrial coatings market:

Strengths:

Weaknesses:

Opportunities:

Threats:

A comprehensive SWOT analysis helps industry participants identify their strengths and weaknesses, capitalize on opportunities, and mitigate threats for sustained growth and success in the market.

Market Key Trends

Understanding key market trends enables manufacturers and stakeholders to align their strategies, investments, and product development efforts with the evolving industry landscape.

Covid-19 Impact

The COVID-19 pandemic has significantly impacted the US industrial coatings market. The measures implemented to control the spread of the virus, such as lockdowns, travel restrictions, and social distancing, disrupted industrial activities, supply chains, and customer demand.

The pandemic led to a temporary halt or slowdown in manufacturing operations, affecting the demand for industrial coatings. Industries such as automotive, aerospace, and construction witnessed reduced production and project delays, leading to lower coating requirements.

Moreover, the uncertainty and economic challenges caused by the pandemic resulted in cautious spending by consumers and businesses. This, in turn, affected the demand for industrial coatings in various end-use industries.

However, as the economy recovers and industrial activities resume, the market is expected to regain momentum. The focus on infrastructure development, increased investments in renewable energy, and the need for maintenance and repair activities provide opportunities for market recovery and growth.

Manufacturers and industry participants are adapting to the new normal by implementing safety protocols, digital solutions, and flexible production processes to mitigate the impact of future disruptions and ensure business continuity.

Key Industry Developments

These industry developments reflect the continuous efforts by market participants to stay ahead in a dynamic and competitive market landscape.

Analyst Suggestions

By following these suggestions, manufacturers can enhance their market competitiveness, adapt to changing industry dynamics, and position themselves as leaders in the US industrial coatings market.

Future Outlook

The future outlook for the US industrial coatings market is optimistic, driven by factors such as infrastructure development, technological advancements, and sustainability requirements. The market is expected to witness steady growth as industries continue to invest in protective coatings for their products and equipment.

Infrastructure development projects, including transportation, renewable energy, and public infrastructure, will drive the demand for industrial coatings. The emphasis on sustainability and environmental regulations will promote the adoption of eco-friendly coatings with low VOC content and reduced environmental impact.

Technological advancements will continue to play a crucial role in shaping the market, with developments in nanocoatings, digitalization, and automation driving innovation. Specialty coatings tailored to specific industry requirements will gain prominence, offering enhanced functionalities and performance.

While challenges such as volatile raw material prices, environmental concerns, and intense competition persist, industry participants can overcome them through strategic collaborations, continuous innovation, and a customer-centric approach.

Overall, the US industrial coatings market is poised for growth, with opportunities arising from emerging industries, increasing maintenance and repair activities, and the focus on sustainable solutions. By aligning their strategies with market trends and customer needs, manufacturers can capitalize on these opportunities and achieve long-term success.

Conclusion

The US industrial coatings market is a thriving sector driven by the demand for protective coatings in various industries. Industrial coatings provide crucial benefits such as corrosion resistance, durability, and enhanced aesthetics, ensuring the longevity and performance of products and equipment.

The market is influenced by factors such as industrialization, technological advancements, regulatory compliance, and customer preferences. While the market offers significant opportunities, it also faces challenges such as volatile raw material prices and intense competition. To succeed in this market, manufacturers should focus on innovation, sustainability, and customer satisfaction. Expanding product portfolios, embracing digitalization, and forming strategic partnerships can help manufacturers stay competitive in the rapidly evolving market landscape.

What are US Industrial Coatings?

US Industrial Coatings refer to protective and decorative coatings applied to various substrates in industrial applications, including metals, plastics, and wood. They are designed to enhance durability, corrosion resistance, and aesthetic appeal in sectors such as manufacturing, automotive, and construction.

Who are the key players in the US Industrial Coatings Market?

Key players in the US Industrial Coatings Market include PPG Industries, Sherwin-Williams, AkzoNobel, and BASF, among others. These companies are known for their innovative products and extensive distribution networks.

What are the main drivers of growth in the US Industrial Coatings Market?

The main drivers of growth in the US Industrial Coatings Market include the increasing demand for protective coatings in the automotive and construction industries, advancements in coating technologies, and a growing focus on sustainability and eco-friendly products.

What challenges does the US Industrial Coatings Market face?

The US Industrial Coatings Market faces challenges such as stringent environmental regulations, fluctuating raw material prices, and competition from alternative coating solutions. These factors can impact production costs and market dynamics.

What opportunities exist in the US Industrial Coatings Market?

Opportunities in the US Industrial Coatings Market include the development of advanced coatings with enhanced performance characteristics, the expansion of applications in emerging industries, and the increasing adoption of smart coatings that offer additional functionalities.

What trends are shaping the US Industrial Coatings Market?

Trends shaping the US Industrial Coatings Market include the rise of environmentally friendly coatings, the integration of nanotechnology for improved performance, and the growing demand for customized solutions tailored to specific industrial needs.

US Industrial Coatings Market

| Segmentation | Details |

|---|---|

| Resin Type | Epoxy, Polyurethane, Acrylic, Alkyd, Others |

| Technology | Solvent-based, Water-based, Powder, UV-cured, Others |

| End-Use | Manufacturing, Automotive, Aerospace, Marine, Others |

| Region | United States |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the US Industrial Coatings Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at