444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview:

The US Industrial Barrier Systems market is a critical component of the nation’s industrial safety infrastructure, providing solutions to enhance workplace safety, protect assets, and mitigate potential hazards. Industrial barrier systems encompass a range of physical barriers, guardrails, bollards, and safety fencing designed to create safe zones within industrial facilities, warehouses, and manufacturing plants. The market’s growth is driven by a heightened focus on workplace safety, compliance with regulations, and the need to safeguard personnel and equipment.

Meaning:

Industrial barrier systems refer to physical structures strategically placed in industrial settings to control and mitigate risks. These systems act as protective barriers, preventing unauthorized access, controlling the flow of traffic, and safeguarding against accidents. Industrial barrier systems play a crucial role in creating safe work environments and reducing the potential for workplace injuries.

Executive Summary:

The US Industrial Barrier Systems market has witnessed steady growth in recent years, driven by increased awareness of occupational safety, stringent regulatory requirements, and the growing emphasis on accident prevention. The market offers a diverse range of barrier solutions, including guardrails, safety barriers, and impact-resistant barriers, catering to the unique safety needs of various industries. As industrial facilities prioritize employee safety and asset protection, the demand for effective barrier systems continues to rise.

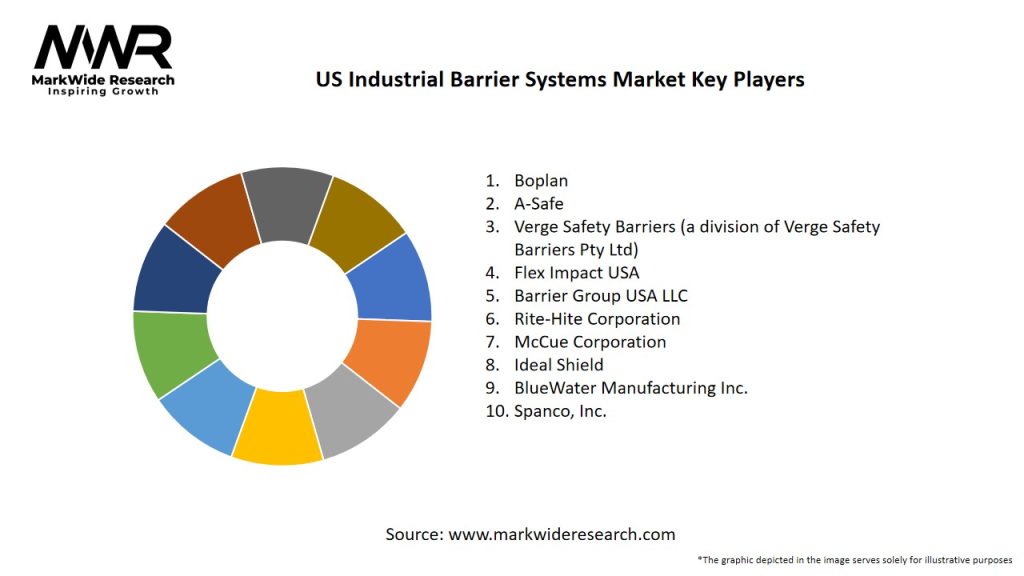

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics:

The US Industrial Barrier Systems market operates in a dynamic environment shaped by factors such as technological advancements, regulatory changes, and industry trends. Understanding these dynamics is crucial for businesses to adapt to market shifts and capitalize on emerging opportunities.

Regional Analysis:

The demand for industrial barrier systems varies across regions in the US due to differences in industrial activity, regulatory environments, and the prevalence of specific industries. A comprehensive regional analysis helps identify localized needs and tailor solutions to specific market demands.

Competitive Landscape:

Leading Companies in US Industrial Barrier Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation:

The US Industrial Barrier Systems market can be segmented based on various factors:

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

A SWOT analysis provides an overview of the US Industrial Barrier Systems market’s strengths, weaknesses, opportunities, and threats:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends:

Covid-19 Impact:

The Covid-19 pandemic has influenced the US Industrial Barrier Systems market in several ways:

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The future outlook for the US Industrial Barrier Systems market is positive, with sustained growth expected. The market will be shaped by advancements in materials and technology, increased awareness of safety measures, and collaborations to establish industry standards. As businesses prioritize employee safety and regulatory compliance, the demand for effective industrial barrier solutions will continue to rise.

Conclusion:

The US Industrial Barrier Systems market plays a pivotal role in fostering workplace safety, protecting assets, and mitigating potential hazards in industrial settings. The market’s growth is fueled by a commitment to compliance with safety regulations, the adoption of innovative materials and technologies, and the increasing emphasis on accident prevention. As the industrial landscape evolves, businesses that invest in advanced and customized barrier solutions will contribute to creating safer and more secure working environments. By staying attuned to market trends, embracing innovation, and addressing the unique safety challenges of various industries, industrial barrier system providers can navigate the dynamic landscape and support the overall well-being of the workforce and industrial assets.

What is Industrial Barrier Systems?

Industrial Barrier Systems are safety solutions designed to protect personnel and equipment in various industrial environments. They are used to delineate areas, prevent unauthorized access, and enhance safety in manufacturing, warehousing, and construction sites.

What are the key players in the US Industrial Barrier Systems Market?

Key players in the US Industrial Barrier Systems Market include companies like A-Safe, Barrier Systems, and Tuffcoat, which specialize in manufacturing safety barriers and related products for industrial applications, among others.

What are the growth factors driving the US Industrial Barrier Systems Market?

The growth of the US Industrial Barrier Systems Market is driven by increasing safety regulations, the rise in industrial automation, and the growing need for workplace safety solutions across various sectors such as manufacturing and logistics.

What challenges does the US Industrial Barrier Systems Market face?

Challenges in the US Industrial Barrier Systems Market include the high initial costs of installation, the need for regular maintenance, and the potential for technological obsolescence as new safety solutions emerge.

What opportunities exist in the US Industrial Barrier Systems Market?

Opportunities in the US Industrial Barrier Systems Market include the development of smart barrier systems integrated with IoT technology, increasing demand for customized solutions, and expansion into emerging industries such as renewable energy and e-commerce.

What trends are shaping the US Industrial Barrier Systems Market?

Trends in the US Industrial Barrier Systems Market include the adoption of modular barrier systems for flexibility, the use of sustainable materials in manufacturing, and the integration of advanced safety features such as sensors and alarms.

US Industrial Barrier Systems Market

| Segmentation Details | Description |

|---|---|

| Product Type | Temporary Barriers, Permanent Barriers, Crash Barriers, Safety Barriers |

| Application | Construction Sites, Road Safety, Industrial Facilities, Event Management |

| Material | Steel, Concrete, Plastic, Composite |

| End User | Manufacturing, Transportation, Events, Public Safety |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in US Industrial Barrier Systems Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at