444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The US automotive parts magnesium die casting market is a dynamic sector that plays a pivotal role in the automotive manufacturing landscape. Magnesium die casting involves the precise and efficient shaping of automotive parts using magnesium alloys, known for their lightweight yet durable properties. This market segment contributes significantly to the production of vehicles that are fuel-efficient, environmentally friendly, and technologically advanced.

Meaning

The US automotive parts magnesium die casting market refers to the industry dedicated to the manufacturing of automotive components through the process of die casting using magnesium alloys. This process involves injecting molten magnesium into a mold to create intricate and precisely shaped automotive parts, contributing to the overall performance and aesthetics of vehicles.

Executive Summary

The US automotive parts magnesium die casting market is experiencing substantial growth due to its role in shaping the modern automotive industry. As automotive manufacturers strive to meet stringent fuel efficiency standards and consumer demands for innovative vehicle designs, magnesium die casting emerges as a key solution. This market segment enhances vehicle performance while reducing weight, contributing to improved fuel economy and reduced emissions.

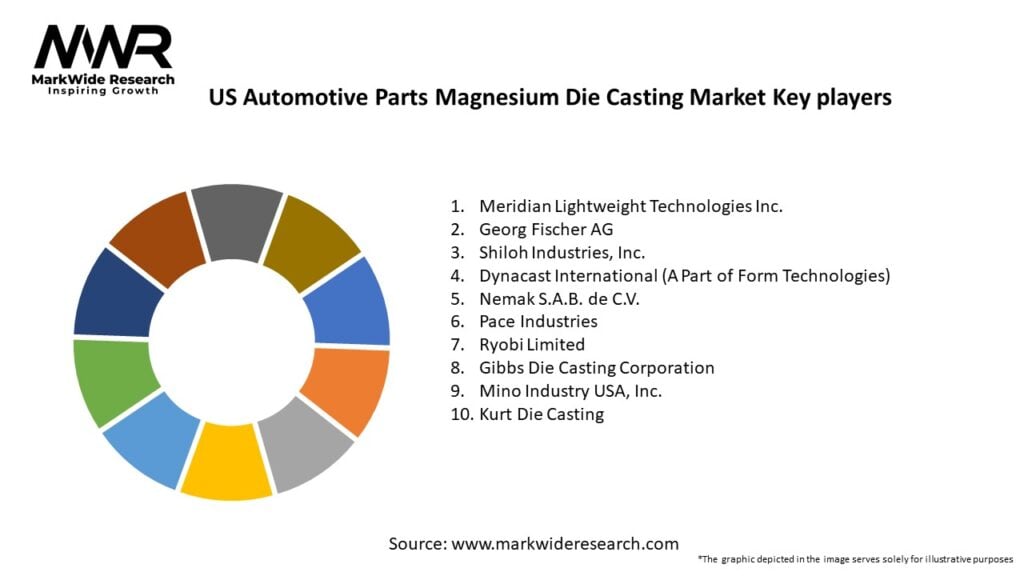

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

The market for US automotive parts magnesium die casting is driven by the need for lightweight materials in vehicle manufacturing. Magnesium alloys offer a unique combination of low weight and high strength, making them suitable for various automotive applications. This market is witnessing an increased focus on research and development to expand the range of components that can be produced through magnesium die casting.

Market Drivers

Several drivers propel the growth of the US automotive parts magnesium die casting market. The automotive industry’s shift towards electric and hybrid vehicles demands lightweight components to maximize energy efficiency. Magnesium die casting meets this demand while maintaining structural integrity. Additionally, the market benefits from advancements in casting technologies that enable the production of complex and intricate parts.

Market Restraints

Despite its advantages, the US automotive parts magnesium die casting market faces challenges. The cost of magnesium alloys and the die casting process itself can be higher compared to other materials and manufacturing methods. Moreover, magnesium’s susceptibility to corrosion necessitates additional protective measures, which can add to production costs.

Market Opportunities

Opportunities in the market lie in the ongoing research and development efforts to enhance magnesium alloys’ properties and reduce production costs. As sustainability becomes a focal point, magnesium’s recyclability and its potential for reduced vehicle weight contribute to the overall eco-friendliness of automobiles. Collaborations between material scientists and automotive manufacturers can drive innovation in this market.

Market Dynamics

The dynamics of the US automotive parts magnesium die casting market are influenced by evolving automotive design trends, regulatory standards, and advancements in material science. The market is witnessing a shift towards hybrid designs that combine traditional materials with magnesium die-cast components, optimizing both performance and sustainability.

Regional Analysis

The US automotive parts magnesium die casting market displays variations based on geographic regions. Manufacturing hubs, automotive clusters, and research centers across the country drive market growth. Regions with a strong automotive presence, such as the Midwest and Southern states, are key contributors to the demand for magnesium die-cast components.

Competitive Landscape

Leading Companies in US Automotive Parts Magnesium Die Casting Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The US automotive parts magnesium die casting market can be segmented based on component type, application, and vehicle type. Component types range from engine parts and transmission components to interior and exterior elements. Applications span across powertrain, chassis, body structure, and more. Vehicle types include passenger cars, commercial vehicles, and electric vehicles.

Category-wise Insights

Different categories of automotive components benefit from magnesium die casting. Engine parts, such as cylinder heads and engine blocks, benefit from magnesium’s lightweight and heat dissipation properties. Structural components contribute to overall vehicle safety while maintaining weight efficiency. Interior components also find applications in magnesium die casting due to their precision and aesthetic appeal.

Key Benefits for Industry Participants and Stakeholders

The US automotive parts magnesium die casting market offers multiple advantages to industry participants and stakeholders. Automakers can enhance fuel efficiency and overall vehicle performance while meeting regulatory standards. Suppliers of magnesium alloys and die casting technologies find a growing market for their products. Consumers benefit from improved vehicle dynamics and reduced emissions.

SWOT Analysis

Strengths: The market’s strengths lie in the lightweight and high-strength properties of magnesium alloys, contributing to advanced vehicle designs.

Weaknesses: Challenges include the higher cost of magnesium alloys, susceptibility to corrosion, and complexities in the die casting process.

Opportunities: Opportunities arise from ongoing R&D efforts to enhance magnesium’s properties, its recyclability, and its potential in sustainable vehicle design.

Threats: Rapid changes in automotive design trends and the availability of alternative lightweight materials pose threats to the market’s growth.

Market Key Trends

Key trends in the US automotive parts magnesium die casting market include the integration of magnesium components in electric vehicles to optimize battery efficiency. Additionally, the adoption of innovative casting technologies, such as vacuum die casting, is becoming prominent. The market is also witnessing a trend towards collaboration between material scientists and automotive engineers.

Covid-19 Impact

The COVID-19 pandemic had implications for the US automotive parts magnesium die casting market. Supply chain disruptions, temporary shutdowns, and shifts in consumer demand impacted the automotive sector as a whole. However, the push for sustainability and lightweight design remains unchanged, creating a continued demand for magnesium die-cast components in the long term.

Key Industry Developments

Recent developments in the market include the introduction of advanced casting techniques that enhance the quality of magnesium die-cast parts. Additionally, research efforts are focused on creating magnesium alloys with improved corrosion resistance. The market is witnessing collaborations between academia, research institutions, and industry players to drive innovation.

Analyst Suggestions

Industry analysts suggest a dual focus on innovation and cost-effectiveness. Continued investment in R&D can lead to the development of new magnesium alloys with enhanced properties. Furthermore, exploring methods to streamline the die casting process and reduce production costs will contribute to broader market adoption.

Future Outlook

The future of the US automotive parts magnesium die casting market is promising. As the automotive industry continues to evolve, the demand for lightweight and sustainable materials will persist. The market is likely to witness advancements in casting technologies, improved magnesium alloys, and expanded applications in various vehicle components.

Conclusion

In conclusion, the US automotive parts magnesium die casting market occupies a pivotal position in shaping the automotive landscape. With a focus on lightweight design, sustainability, and innovation, this market segment contributes to the production of vehicles that are efficient, safe, and technologically advanced. As the automotive industry embraces new trends, the role of magnesium die casting will continue to be integral to its evolution.

The US automotive parts magnesium die casting market plays a pivotal role in shaping the automotive industry’s landscape by providing lightweight, durable, and efficient components. The steady growth of this market is driven by the automotive sector’s increasing demand for high-performance materials that enhance fuel efficiency and contribute to sustainability goals.

What is Automotive Parts Magnesium Die Casting?

Automotive Parts Magnesium Die Casting refers to the process of creating components for vehicles using magnesium alloys through die casting techniques. This method is favored for its ability to produce lightweight, durable parts that enhance fuel efficiency and performance in automotive applications.

What are the key players in the US Automotive Parts Magnesium Die Casting Market?

Key players in the US Automotive Parts Magnesium Die Casting Market include companies like Dynacast, Meridian Lightweight Technologies, and Nemak, which specialize in manufacturing magnesium die-cast components for various automotive applications, among others.

What are the growth factors driving the US Automotive Parts Magnesium Die Casting Market?

The US Automotive Parts Magnesium Die Casting Market is driven by the increasing demand for lightweight materials to improve fuel efficiency and reduce emissions. Additionally, advancements in die casting technology and the growing trend of electric vehicles are contributing to market growth.

What challenges does the US Automotive Parts Magnesium Die Casting Market face?

Challenges in the US Automotive Parts Magnesium Die Casting Market include the high cost of magnesium materials and the technical difficulties associated with casting complex geometries. Furthermore, competition from alternative materials like aluminum can hinder market expansion.

What opportunities exist in the US Automotive Parts Magnesium Die Casting Market?

Opportunities in the US Automotive Parts Magnesium Die Casting Market include the rising adoption of electric vehicles, which require lightweight components for better performance. Additionally, innovations in recycling processes for magnesium can enhance sustainability and reduce costs.

What trends are shaping the US Automotive Parts Magnesium Die Casting Market?

Trends in the US Automotive Parts Magnesium Die Casting Market include the increasing use of advanced manufacturing techniques such as 3D printing and automation. There is also a growing focus on sustainability, with manufacturers exploring eco-friendly practices in the production of magnesium components.

US Automotive Parts Magnesium Die Casting Market

| Segmentation Details | Description |

|---|---|

| Product Type | Engine Components, Transmission Housings, Chassis Parts, Structural Components |

| End User | OEMs, Aftermarket Providers, Tier-1 Suppliers, Vehicle Assemblers |

| Manufacturing Stage | Die Casting, Machining, Finishing, Assembly |

| Material | Magnesium Alloys, Aluminum Alloys, Zinc Alloys, Others |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in US Automotive Parts Magnesium Die Casting Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at