Key Market Insights

-

Carbon fiber composites constitute over 60% of the unmanned composites market value, driven by the need for maximum strength-to-weight ratio in UAV airframes and rotor blades.

-

Thermoplastic composites are gaining traction for rapid prototyping and damage tolerance in UGV body panels and landing gear components.

-

Hybrid material systems—combining CFRP with foam cores or honeycomb structures—address buoyancy and stiffness requirements in unmanned surface and underwater vessels.

-

Automated fiber placement (AFP) and automated tape laying (ATL) technologies reduce labor costs and improve part repeatability, crucial for high-volume UAV production.

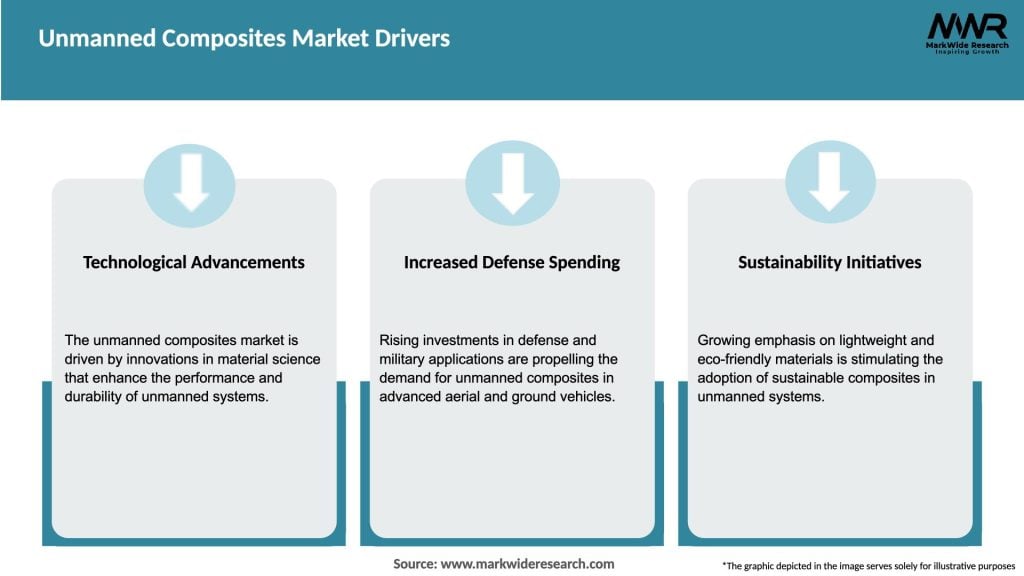

Market Drivers

-

Defense Modernization: Governments are investing in next-generation unmanned platforms for ISR (intelligence, surveillance, reconnaissance) and combat roles, demanding composite structures that enhance range and payload carriage.

-

Commercial Drone Adoption: Growth in industries such as e-commerce delivery, precision agriculture, and infrastructure inspection is driving large-scale production of lightweight, reliable UAVs.

-

Autonomous Marine Systems: Offshore energy, environmental monitoring, and maritime security operations increasingly rely on USVs and UUVs, requiring composites that resist corrosion and pressure at depth.

-

Performance Optimization: Composite materials enable aerodynamic shaping, vibration damping, and stealth features, improving mission endurance and reducing radar cross-section.

-

Regulatory Support: Easing of airspace regulations for drones and incentives for renewable energy inspections using unmanned systems stimulate demand for composite-based platforms.

Market Restraints

-

High Material Costs: Premium fibers (e.g., aerospace-grade carbon) and specialty resins elevate raw-material expenses, impacting overall system affordability.

-

Complex Manufacturing: Achieving tight tolerances and defect-free laminates requires skilled labor and rigorous quality control, limiting production scalability in some regions.

-

Recycling Challenges: Thermoset composites are difficult to recycle, raising end-of-life disposal concerns and potential environmental liabilities.

-

Certification Hurdles: Lack of standardized industry certification processes for unmanned composite airframes can delay fielding and increase development costs.

-

Supply Chain Constraints: Concentration of high-performance fiber production in a few geographies exposes manufacturers to geopolitical and logistics risks.

Market Opportunities

-

Bio-Based and Recyclable Composites: Development of natural-fiber-reinforced and depolymerizable resin systems addresses sustainability goals and circular-economy mandates.

-

Embedded Multifunctionality: Integrating sensors, antennas, and de-icing elements within composite lay-ups reduces assembly complexity and enhances system reliability.

-

Low-Cost Unmanned Platforms: Adoption of lower-grade carbon and glass fiber composites in entry-level commercial drones and UGVs can expand market reach among SMEs.

-

Localized Manufacturing Hubs: Establishing composite fabrication centers close to major unmanned system OEMs in Asia Pacific and Eastern Europe reduces lead times and logistics costs.

-

Advanced Repair Technologies: Innovations in field-repairable resins and heat-recovery stitching techniques prolong service life and lower maintenance overhead.

Market Dynamics

-

Vertical Integration: Unmanned system integrators are acquiring or partnering with composite producers to secure dedicated material supply and co-develop tailor-made solutions.

-

Process Automation: Investments in AFP, ATL, and robotic trimming accelerate cycle times and enhance part consistency in high-volume UAV production.

-

Design for Manufacturability: Early collaboration between design engineers and composite specialists ensures optimal fiber orientation, minimal scrap, and efficient assembly.

-

Regional Ecosystems: National “drone corridors” and test-bed zones foster local supply chains for composites and unmanned platforms.

-

Digital Twin & Simulation: Advanced modeling of composite lay-ups and structural behavior under dynamic loads streamlines certification and reduces prototyping iterations.

Regional Analysis

-

North America: Leading market share driven by defense spending on UAV swarms, significant R&D in advanced composites, and a mature aerospace industry ecosystem.

-

Europe: Growth fueled by commercial drone adoption in logistics, strong regulatory frameworks, and the maritime sector’s use of USVs for offshore wind farm inspection.

-

Asia Pacific: Fastest-growing region powered by large-scale manufacturing of consumer and enterprise drones, rising government focus on border surveillance, and expanding UUV applications in aquaculture.

-

Latin America: Emerging demand for low-cost agricultural drones and river-patrolling USVs; local composite capacity is nascent but expanding.

-

Middle East & Africa: Strategic investments in border security UAVs and offshore oil-field monitoring USVs drive composite demand, although local manufacturing remains limited.

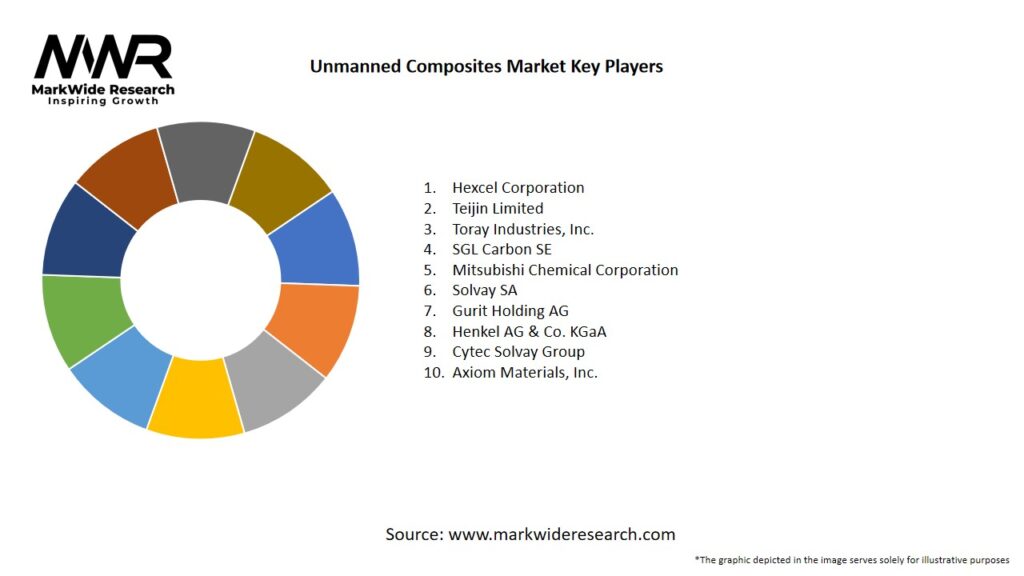

Competitive Landscape

Leading companies in the Unmanned Composites Market:

- Hexcel Corporation

- Teijin Limited

- Toray Industries, Inc.

- SGL Carbon SE

- Mitsubishi Chemical Corporation

- Solvay SA

- Gurit Holding AG

- Henkel AG & Co. KGaA

- Cytec Solvay Group

- Axiom Materials, Inc.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

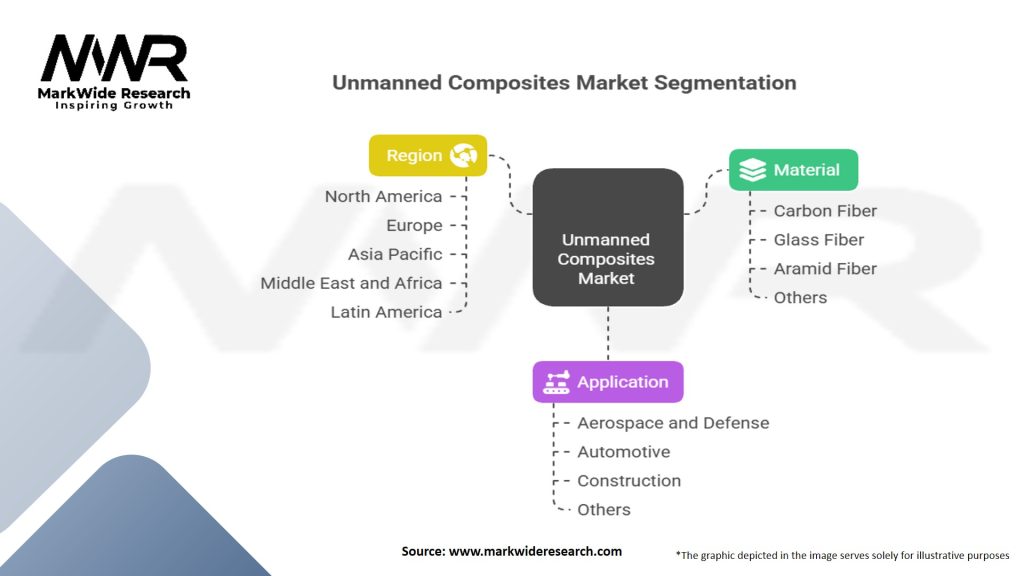

Segmentation

-

By Fiber Type: Carbon Fiber, Glass Fiber, Aramid Fiber, Hybrid Composites

-

By Matrix: Thermoset Resins (Epoxy, Polyester, Vinyl Ester), Thermoplastics (PEEK, PPS)

-

By Vehicle Class: UAVs, UGVs, USVs, UUVs

-

By Application: Airframes & Rotor Blades, Hull & Pressure Vessels, Structural Frames, Payload Mounts & Sensor Housings

Category-wise Insights

-

Carbon Fiber Composites: Dominant in high-end UAVs and UUV pressure vessels for unmatched stiffness and low weight.

-

Glass Fiber Composites: Preferred in commercial drones and ground-vehicle body panels for cost-effectiveness and corrosion resistance.

-

Aramid Fiber Composites: Utilized in ballistic-grade panels and high-impact UGV armor systems due to excellent energy absorption.

-

Thermoplastic Composites: Gaining ground for rapid reworkability and damage tolerance in field-serviceable unmanned platforms.

Key Benefits for Industry Participants and Stakeholders

-

Enhanced Endurance: Weight reduction from composites extends flight times and patrol ranges of unmanned platforms.

-

Payload Flexibility: High strength-to-weight ratios allow integration of heavier sensors and communication equipment without compromising performance.

-

Corrosion & Fatigue Resistance: Composite hulls and structural parts outperform metals in maritime and high-dynamic environments, reducing maintenance intervals.

-

Stealth & EMI Shielding: Formulations with tailored fiber orientations and conductive coatings enable low radar cross-sections and EMI control.

-

Design Freedom: Complex geometries, integrated stiffening features, and curved shapes are more easily realized with composite molds and AFP processes.

SWOT Analysis

Strengths:

-

Unmatched strength-to-weight and corrosion resistance.

-

Broad spectrum of formulations for varied environmental and structural requirements.

Weaknesses:

-

High upfront material and processing costs.

-

Challenges in large-scale recycling and end-of-life disposal.

Opportunities:

-

Bio-resin and recyclable composite development to meet sustainability mandates.

-

Embedded multifunctional composites combining structure with sensing or energy storage.

Threats:

-

Supply chain disruptions for high-performance fiber feedstocks.

-

Competition from emerging metal-matrix and ceramic-matrix composite technologies.

Market Key Trends

-

Multifunctional Composites: Embedding optical fibers, strain gauges, and antennas within the laminate for integrated health monitoring and communication.

-

Rapid Cure Systems: Development of fast-curing prepregs and in situ polymerizable resins to shorten production cycles for commercial drones.

-

Digital Manufacturing: Use of machine-learning algorithms to optimize fiber placement paths and reduce defects in complex geometries.

-

Circular Economy Initiatives: Research into thermoplastic composite recycling and chemical depolymerization of thermosets for resource recovery.

-

Customized Material Kits: Supplier-provided “tailored kits” with pre-validated fiber, resin, and process parameters for specific unmanned applications.

Covid-19 Impact

The pandemic initially disrupted supply chains for fibers and resins, delaying unmanned system deliveries. However, renewed emphasis on autonomous inspection (e.g., infrastructure, healthcare facility monitoring) and contactless delivery drones spurred composite demand in late 2020 and beyond. Suppliers accelerated digital collaboration tools and remote certification processes to maintain project timelines.

Key Industry Developments

-

Strategic Alliances: Partnerships between fiber producers and UAV OEMs to co-develop lightweight wing and fuselage structures.

-

Facility Investments: Expansion of AFP and ATL lines in Asia Pacific and North America to serve growing unmanned applications.

-

Product Launches: Introduction of high-toughness, low-void-content prepregs formulated specifically for unmanned marine vehicles.

-

Regulatory Milestones: Establishment of unmanned composite part certification guidelines by aviation and maritime authorities streamlining market entry.

Analyst Suggestions

-

Diversify Fiber Sources: Secure alternative carbon and glass fiber supplies to minimize geopolitical and logistical risks.

-

Invest in Recycling R&D: Prioritize development of thermoplastic and recyclable resin systems to address sustainability mandates and reduce life-cycle costs.

-

Enhance Embedded Functionality: Collaborate with sensor and electronics manufacturers to integrate health-monitoring capabilities directly into composite structures.

-

Expand Technical Services: Provide design-for-manufacture consulting, simulation validation, and on-site process support to accelerate customer adoption and reduce development cycles.

Future Outlook

The Unmanned Composites market is set to sustain double-digit growth as unmanned platforms proliferate across defense, commercial, and industrial sectors. Advances in material science—particularly in multifunctional, sustainable, and rapid-process composites—will unlock new performance thresholds. Coupled with Industry 4.0 manufacturing and digital-twin validation, composites will remain pivotal to next-generation unmanned system evolution, driving longer missions, higher payloads, and greater reliability in diverse operating environments.

Conclusion

Composites have become the cornerstone of unmanned system design, enabling ultra-light, high-strength, and multifunctional structures that meet the exacting demands of modern missions. As the market scales—from tactical military drones to civilian delivery fleets and autonomous maritime platforms—continued innovation in materials, processes, and sustainability will define competitive advantage. Stakeholders who leverage integrated design, manufacturing automation, and circular-economy practices will lead the charge in shaping the future of the Unmanned Composites market.