444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The United States data center cooling market represents a critical infrastructure segment experiencing unprecedented growth driven by the exponential expansion of digital services, cloud computing, and artificial intelligence applications. Data center cooling systems have become essential components for maintaining optimal operating temperatures and ensuring reliable performance of high-density computing equipment across enterprise facilities, hyperscale data centers, and edge computing locations.

Market dynamics indicate robust expansion with the sector growing at a compound annual growth rate (CAGR) of 8.2% through the forecast period. The increasing deployment of high-performance computing systems, graphics processing units for AI workloads, and cryptocurrency mining operations has intensified cooling requirements, driving demand for advanced thermal management solutions. Energy efficiency considerations have become paramount as data centers account for approximately 2% of total U.S. electricity consumption.

Technology evolution in cooling systems encompasses traditional air-based cooling, liquid cooling solutions, immersion cooling technologies, and hybrid approaches designed to optimize thermal management while minimizing energy consumption. The market encompasses various cooling methodologies including computer room air conditioning (CRAC), computer room air handling (CRAH), chilled water systems, direct expansion cooling, and emerging technologies like two-phase immersion cooling.

Regional distribution shows concentrated activity in major metropolitan areas including Northern Virginia, Silicon Valley, Dallas-Fort Worth, Chicago, and Atlanta, where hyperscale cloud providers and enterprise data centers maintain significant infrastructure investments. The market benefits from supportive regulatory frameworks promoting energy efficiency standards and sustainability initiatives across federal and state jurisdictions.

The United States data center cooling market refers to the comprehensive ecosystem of thermal management technologies, systems, and services designed to maintain optimal operating temperatures within data center facilities across the United States. This market encompasses cooling equipment, installation services, maintenance solutions, and energy management systems that ensure reliable operation of computing infrastructure while optimizing power consumption and operational efficiency.

Data center cooling involves the systematic removal of heat generated by servers, storage systems, networking equipment, and power infrastructure through various methodologies including air-based cooling, liquid cooling, and advanced thermal management technologies. The market includes both traditional cooling approaches such as raised floor air distribution and modern solutions like direct-to-chip liquid cooling and immersion cooling systems.

Market participants include cooling equipment manufacturers, system integrators, maintenance service providers, and technology consultants who collectively deliver comprehensive thermal management solutions. The ecosystem supports various facility types from small enterprise data centers to massive hyperscale facilities operated by cloud service providers, telecommunications companies, and colocation providers.

Strategic market analysis reveals the United States data center cooling market experiencing transformational growth driven by accelerating digitalization, cloud adoption, and emerging technologies requiring advanced thermal management capabilities. The sector demonstrates strong fundamentals with increasing demand for energy-efficient cooling solutions that can handle higher heat densities while reducing operational expenses and environmental impact.

Technology trends indicate a significant shift toward liquid cooling adoption, with market penetration increasing by 35% annually as organizations deploy high-performance computing systems and AI accelerators generating substantial thermal loads. Traditional air cooling maintains dominance in existing facilities, while new deployments increasingly incorporate hybrid cooling architectures combining multiple thermal management approaches.

Market segmentation shows diversified demand across enterprise data centers, hyperscale cloud facilities, colocation providers, and edge computing deployments. Hyperscale operators represent the largest demand segment, accounting for approximately 45% of cooling system deployments due to massive infrastructure investments and stringent efficiency requirements.

Competitive dynamics feature established cooling equipment manufacturers, innovative technology startups, and integrated solution providers competing on efficiency metrics, total cost of ownership, and sustainability credentials. The market benefits from continuous innovation in cooling technologies, smart monitoring systems, and predictive maintenance capabilities that enhance operational reliability and reduce energy consumption.

Primary market drivers encompass the fundamental transformation of computing infrastructure toward higher density deployments, artificial intelligence workloads, and edge computing applications requiring sophisticated thermal management solutions. The following insights characterize current market dynamics:

Digital transformation acceleration serves as the primary catalyst driving unprecedented demand for data center cooling solutions across the United States. The exponential growth of cloud computing services, streaming platforms, social media applications, and e-commerce platforms requires massive computing infrastructure generating substantial thermal loads that necessitate sophisticated cooling technologies.

Artificial intelligence adoption represents a transformational driver as organizations deploy GPU-accelerated computing systems for machine learning, deep learning, and AI inference applications. These high-performance computing workloads generate thermal densities significantly exceeding traditional server deployments, requiring advanced liquid cooling solutions and specialized thermal management approaches to maintain optimal operating conditions.

Edge computing proliferation creates new cooling requirements as computing resources move closer to end users through distributed infrastructure deployments. Edge data centers require compact, efficient cooling solutions suitable for diverse environments including retail locations, manufacturing facilities, and telecommunications sites where traditional cooling approaches may not be feasible.

Hyperscale infrastructure expansion by major cloud service providers drives substantial cooling system deployments as these operators construct massive data center facilities to support global digital services. Hyperscale operators demand highly efficient, scalable cooling solutions that can accommodate rapid capacity expansion while maintaining stringent efficiency and reliability requirements.

Energy cost optimization motivates data center operators to invest in advanced cooling technologies that reduce operational expenses through improved efficiency and reduced power consumption. Cooling system efficiency directly impacts total cost of ownership, making energy-efficient solutions increasingly attractive for cost-conscious operators seeking to optimize long-term operational economics.

High capital investment requirements represent a significant barrier for organizations considering advanced cooling technology deployments, particularly for liquid cooling systems and immersion cooling solutions that require substantial upfront investments in specialized equipment, installation, and infrastructure modifications. Many organizations struggle to justify the initial costs despite long-term operational benefits.

Technical complexity concerns limit adoption of advanced cooling technologies as organizations worry about operational challenges, maintenance requirements, and potential reliability issues associated with sophisticated thermal management systems. Liquid cooling implementations require specialized expertise and maintenance protocols that may exceed internal capabilities of smaller data center operators.

Infrastructure compatibility challenges constrain cooling system upgrades in existing facilities where legacy infrastructure may not accommodate modern cooling technologies without extensive modifications. Retrofitting existing data centers with advanced cooling systems often requires significant structural changes, power upgrades, and operational disruptions that deter implementation.

Skills shortage in specialized cooling system design, installation, and maintenance creates implementation barriers as organizations struggle to find qualified technicians and engineers with expertise in advanced thermal management technologies. The technical skills gap particularly affects liquid cooling and immersion cooling deployments requiring specialized knowledge and experience.

Regulatory uncertainty regarding environmental standards, refrigerant regulations, and energy efficiency requirements creates planning challenges for cooling system investments. Organizations hesitate to commit to specific technologies when regulatory frameworks continue evolving, potentially affecting long-term viability and compliance requirements for cooling infrastructure investments.

Liquid cooling market expansion presents substantial opportunities as organizations increasingly recognize the efficiency advantages and necessity of liquid cooling for high-density computing applications. The growing deployment of AI accelerators, high-performance computing systems, and cryptocurrency mining operations creates expanding demand for direct liquid cooling solutions that can handle extreme thermal loads efficiently.

Edge computing cooling solutions offer significant growth potential as distributed computing infrastructure requires specialized thermal management approaches suitable for diverse deployment environments. Micro data centers and edge computing facilities need compact, efficient cooling systems that can operate reliably in challenging conditions while maintaining energy efficiency and minimal maintenance requirements.

Sustainability-focused innovations create opportunities for cooling technology providers developing environmentally responsible solutions that reduce water consumption, eliminate harmful refrigerants, and improve overall energy efficiency. Green cooling technologies align with corporate sustainability commitments and regulatory trends favoring environmentally conscious infrastructure investments.

Smart cooling systems integration represents a growing opportunity as data center operators seek intelligent thermal management solutions incorporating IoT sensors, machine learning algorithms, and predictive analytics capabilities. AI-powered cooling optimization can significantly improve efficiency while reducing operational costs through automated system adjustments and predictive maintenance scheduling.

Service-based business models offer opportunities for cooling solution providers to develop recurring revenue streams through cooling-as-a-service offerings, comprehensive maintenance contracts, and performance-based agreements. These models reduce customer capital investment requirements while providing predictable revenue streams for cooling technology vendors and service providers.

Supply chain evolution within the United States data center cooling market reflects increasing sophistication as manufacturers develop specialized components for high-density cooling applications while service providers expand capabilities to support complex thermal management deployments. The ecosystem demonstrates growing maturity with established relationships between cooling equipment manufacturers, system integrators, and end-user organizations.

Technology convergence drives market dynamics as cooling solutions increasingly integrate with broader data center infrastructure management systems, incorporating smart sensors, automated controls, and predictive analytics capabilities. This convergence enables holistic facility optimization where cooling systems operate in coordination with power management, space utilization, and workload scheduling systems.

Competitive intensity continues escalating as established cooling equipment manufacturers face competition from innovative startups developing disruptive technologies like immersion cooling and advanced liquid cooling solutions. Market participants compete on efficiency metrics, total cost of ownership, reliability, and sustainability credentials while investing heavily in research and development activities.

Customer requirements evolution reflects increasing sophistication as data center operators develop detailed specifications for cooling performance, energy efficiency, maintenance requirements, and environmental impact. Procurement processes now emphasize lifecycle cost analysis, sustainability metrics, and integration capabilities rather than focusing solely on initial equipment costs.

Regulatory influence shapes market dynamics through evolving energy efficiency standards, environmental regulations, and sustainability requirements that affect cooling system selection criteria. Policy developments at federal and state levels increasingly favor energy-efficient technologies and environmentally responsible cooling solutions, influencing market demand patterns and technology adoption trends.

Comprehensive market analysis employs multiple research methodologies to ensure accurate assessment of the United States data center cooling market, incorporating both quantitative and qualitative research approaches. The methodology encompasses primary research activities including industry expert interviews, customer surveys, and vendor consultations to gather firsthand insights into market trends, technology developments, and competitive dynamics.

Secondary research components involve extensive analysis of industry publications, technical specifications, regulatory documents, and corporate financial reports to understand market structure, technology trends, and competitive positioning. Data validation processes ensure accuracy through cross-referencing multiple sources and conducting follow-up interviews with industry participants to verify key findings and market assessments.

Market sizing methodology utilizes bottom-up analysis examining individual market segments, technology categories, and regional variations to develop comprehensive market assessments. The approach incorporates installation data, capacity deployments, and technology adoption rates to create detailed market models reflecting current conditions and future growth projections.

Competitive analysis framework evaluates market participants across multiple dimensions including technology capabilities, market presence, customer relationships, and strategic positioning. Vendor assessment criteria encompass product portfolios, innovation capabilities, service offerings, and market share analysis to provide comprehensive competitive landscape insights.

Trend analysis methodology incorporates technology roadmap assessments, regulatory impact analysis, and customer requirement evolution to identify emerging opportunities and potential market disruptions. The approach considers macro-economic factors, industry developments, and technological innovations that may influence future market dynamics and growth patterns.

Northern Virginia region maintains market leadership as the largest data center hub in the United States, accounting for approximately 25% of national cooling system deployments. The region benefits from proximity to federal government agencies, major internet exchanges, and favorable regulatory environment supporting data center development. Hyperscale operators including major cloud service providers maintain substantial infrastructure investments requiring advanced cooling solutions.

Silicon Valley and broader California market represents a significant segment driven by technology company headquarters, research facilities, and innovation centers requiring sophisticated computing infrastructure. The region demonstrates strong adoption of advanced cooling technologies including liquid cooling and immersion cooling solutions, supported by environmental regulations favoring energy-efficient systems and sustainability initiatives.

Texas market concentration in Dallas-Fort Worth and Austin areas reflects growing data center activity supported by favorable business climate, abundant power availability, and strategic geographic positioning. The region shows increasing deployment of hyperscale facilities and edge computing infrastructure requiring diverse cooling solutions adapted to local climate conditions and operational requirements.

Chicago and Midwest region benefits from central geographic location, robust telecommunications infrastructure, and competitive power costs attracting data center investments. The market demonstrates balanced demand across enterprise data centers, colocation facilities, and cloud infrastructure requiring various cooling approaches suited to different facility types and operational models.

Southeast regional markets including Atlanta, Charlotte, and Miami show accelerating growth driven by expanding digital economy, favorable business conditions, and strategic connectivity to Latin American markets. The region requires climate-adapted cooling solutions capable of handling high ambient temperatures and humidity conditions while maintaining energy efficiency standards.

Market leadership encompasses established cooling equipment manufacturers, innovative technology companies, and comprehensive solution providers competing across different technology segments and customer categories. The competitive environment demonstrates increasing sophistication as participants develop specialized offerings for specific applications and market segments.

Competitive strategies focus on technology innovation, energy efficiency improvements, comprehensive service offerings, and strategic partnerships with data center operators, system integrators, and technology vendors. Market participants invest heavily in research and development activities to develop next-generation cooling technologies addressing evolving customer requirements and emerging applications.

Technology-based segmentation reflects diverse cooling approaches serving different applications and operational requirements across the United States data center market. Each technology category addresses specific thermal management challenges while offering distinct advantages in efficiency, cost, and implementation complexity.

By Cooling Technology:

By Facility Type:

By Component Category:

Air-based cooling systems continue dominating the market due to established infrastructure, proven reliability, and lower initial investment requirements. However, efficiency limitations become apparent in high-density deployments where traditional air cooling struggles to handle thermal loads exceeding 15-20kW per rack. Modern air cooling systems incorporate intelligent controls, variable speed fans, and optimized airflow management to improve efficiency.

Liquid cooling adoption accelerates rapidly with market penetration growing at 40% annually as organizations deploy high-performance computing systems, AI accelerators, and cryptocurrency mining equipment generating extreme thermal loads. Direct-to-chip cooling solutions demonstrate superior efficiency for high-density applications while rear-door heat exchangers provide retrofit options for existing facilities.

Immersion cooling technology represents the frontier of thermal management innovation, offering exceptional efficiency for ultra-high-density applications while reducing space requirements and eliminating traditional cooling infrastructure. Two-phase immersion cooling systems demonstrate particular promise for AI and high-performance computing workloads requiring maximum thermal management efficiency.

Hybrid cooling architectures gain popularity as organizations seek to optimize thermal management across diverse workload types within single facilities. These systems combine air cooling for standard applications with liquid cooling for high-density zones, providing flexibility and efficiency optimization across different computing requirements.

Smart cooling systems incorporating IoT sensors, machine learning algorithms, and predictive analytics represent the evolution toward intelligent thermal management. These systems provide real-time optimization capabilities, predictive maintenance scheduling, and automated efficiency improvements that reduce operational costs while enhancing reliability.

Data center operators benefit from advanced cooling technologies through reduced operational costs, improved energy efficiency, and enhanced infrastructure reliability. Modern cooling systems enable higher computing densities while maintaining optimal operating conditions, allowing operators to maximize facility utilization and revenue generation potential.

Technology vendors gain competitive advantages through partnerships with cooling solution providers, enabling integrated offerings that address customer requirements for comprehensive infrastructure solutions. Cooling system integration enhances overall system performance while providing differentiation opportunities in competitive technology markets.

Cloud service providers achieve operational excellence through advanced cooling technologies that reduce power consumption, improve system reliability, and enable rapid capacity scaling. Efficient cooling systems directly impact profitability by reducing operational expenses while supporting service level agreement commitments to customers.

Enterprise organizations benefit from reliable, efficient cooling solutions that ensure business continuity while reducing total cost of ownership for internal IT infrastructure. Advanced cooling technologies enable organizations to deploy modern computing systems supporting digital transformation initiatives without compromising operational reliability.

Environmental stakeholders benefit from energy-efficient cooling technologies that reduce overall environmental impact of data center operations. Sustainable cooling solutions contribute to corporate sustainability goals while supporting broader environmental objectives through reduced energy consumption and improved resource utilization.

Strengths:

Weaknesses:

Opportunities:

Threats:

Liquid cooling mainstream adoption represents the most significant trend transforming the data center cooling landscape as organizations increasingly recognize the necessity of liquid cooling for modern high-density computing applications. Direct liquid cooling solutions demonstrate superior efficiency compared to traditional air cooling while enabling higher rack densities and improved space utilization.

AI-driven cooling optimization emerges as a transformative trend incorporating machine learning algorithms, predictive analytics, and automated control systems to optimize cooling performance dynamically. Intelligent cooling systems can reduce energy consumption by 15-25% while improving reliability through predictive maintenance and automated fault detection capabilities.

Sustainability integration becomes increasingly important as data center operators prioritize environmental responsibility through energy-efficient cooling technologies, reduced water consumption, and elimination of harmful refrigerants. Green cooling initiatives align with corporate sustainability commitments while potentially reducing operational costs through improved efficiency.

Modular cooling solutions gain popularity as organizations seek flexible, scalable thermal management approaches that can adapt to changing requirements and rapid capacity expansion needs. Prefabricated cooling systems offer reduced deployment timeframes and improved quality control while providing flexibility for future modifications and upgrades.

Edge computing cooling specialization develops as distributed computing infrastructure requires unique thermal management approaches suitable for diverse deployment environments. Compact cooling solutions designed for edge applications must operate reliably in challenging conditions while maintaining energy efficiency and minimal maintenance requirements.

Technology breakthrough announcements continue shaping the cooling market landscape as manufacturers introduce innovative solutions addressing evolving customer requirements. Recent developments include next-generation immersion cooling systems offering improved efficiency and simplified deployment processes for high-density computing applications.

Strategic partnership formations between cooling technology providers and major data center operators create opportunities for customized solution development and large-scale deployments. These collaborations often result in innovative cooling approaches specifically designed for unique operational requirements and performance objectives.

Regulatory developments at federal and state levels increasingly emphasize energy efficiency standards and environmental requirements affecting cooling system selection criteria. Policy initiatives promoting sustainable data center operations create market opportunities for energy-efficient cooling technologies while potentially constraining traditional approaches.

Investment activities in cooling technology startups and established manufacturers demonstrate strong investor confidence in market growth potential and technology innovation opportunities. Venture capital funding supports development of disruptive cooling technologies including advanced liquid cooling and immersion cooling solutions.

Industry consolidation trends reflect market maturation as larger companies acquire specialized cooling technology providers to expand product portfolios and market reach. These strategic acquisitions often combine complementary technologies and capabilities to create comprehensive thermal management solutions.

MarkWide Research analysis indicates organizations should prioritize comprehensive cooling strategy development that considers current requirements, future growth plans, and emerging technology trends. The approach should evaluate total cost of ownership across different cooling technologies while considering operational complexity, maintenance requirements, and energy efficiency implications.

Technology evaluation frameworks should incorporate efficiency metrics, scalability considerations, and integration capabilities when assessing cooling solutions for specific applications. Organizations benefit from pilot program implementations that allow hands-on evaluation of advanced cooling technologies before committing to large-scale deployments.

Vendor selection criteria should emphasize proven experience, comprehensive service capabilities, and long-term technology roadmaps rather than focusing solely on initial equipment costs. Strategic partnerships with cooling solution providers can provide access to latest innovations while ensuring ongoing support and optimization services.

Skills development investments become critical as organizations deploy advanced cooling technologies requiring specialized expertise for optimal operation and maintenance. Training programs and certification initiatives help build internal capabilities while reducing dependence on external service providers for routine operations.

Sustainability planning should integrate cooling system selection with broader environmental objectives, considering energy efficiency, water consumption, and refrigerant impact. Green cooling initiatives can provide competitive advantages while supporting corporate sustainability commitments and regulatory compliance requirements.

Market trajectory analysis indicates continued robust growth for the United States data center cooling market driven by accelerating digital transformation, artificial intelligence adoption, and edge computing expansion. MWR projections suggest the market will maintain strong momentum with cooling technology evolution supporting increasingly demanding thermal management requirements.

Technology evolution will likely favor liquid cooling and immersion cooling solutions as computing densities continue increasing beyond the capabilities of traditional air cooling systems. Innovation cycles are expected to accelerate with cooling technology providers investing heavily in research and development to address emerging applications and efficiency requirements.

Market consolidation may continue as larger companies acquire specialized cooling technology providers to expand capabilities and market reach. This consolidation could result in comprehensive solution offerings that integrate cooling systems with broader data center infrastructure management platforms and services.

Regulatory influence will likely increase as environmental concerns and energy efficiency requirements drive policy developments affecting cooling system selection and operation. Compliance requirements may favor advanced cooling technologies that demonstrate superior environmental performance and energy efficiency metrics.

Geographic expansion opportunities may emerge as data center development spreads to secondary markets and edge computing requirements create distributed cooling demands. Regional market development could benefit cooling solution providers with flexible, scalable offerings suitable for diverse deployment scenarios and operational requirements.

The United States data center cooling market stands at a transformational inflection point driven by evolving computing requirements, sustainability imperatives, and technological innovation. The sector demonstrates strong fundamentals with sustained demand growth, continuous technology advancement, and increasing recognition of cooling system importance for data center operational excellence.

Market dynamics favor advanced cooling technologies including liquid cooling and immersion cooling solutions that can address the thermal management challenges of modern high-density computing applications. Organizations increasingly recognize that cooling system selection directly impacts operational efficiency, energy costs, and infrastructure reliability, driving demand for sophisticated thermal management solutions.

Competitive landscape evolution reflects increasing sophistication as market participants develop specialized offerings for specific applications while investing in comprehensive service capabilities and strategic partnerships. The market benefits from continuous innovation cycles that deliver improved efficiency, reliability, and sustainability performance across different cooling technology categories.

Future market development will likely be characterized by accelerating adoption of advanced cooling technologies, increasing integration with intelligent infrastructure management systems, and growing emphasis on sustainability and environmental responsibility. Organizations that proactively evaluate and implement appropriate cooling strategies will be well-positioned to capitalize on digital transformation opportunities while optimizing operational performance and cost efficiency in the evolving data center landscape.

What is Data Center Cooling?

Data Center Cooling refers to the methods and technologies used to maintain optimal temperature and humidity levels in data centers, ensuring the efficient operation of servers and IT equipment. Effective cooling is crucial for preventing overheating and ensuring reliability in data processing environments.

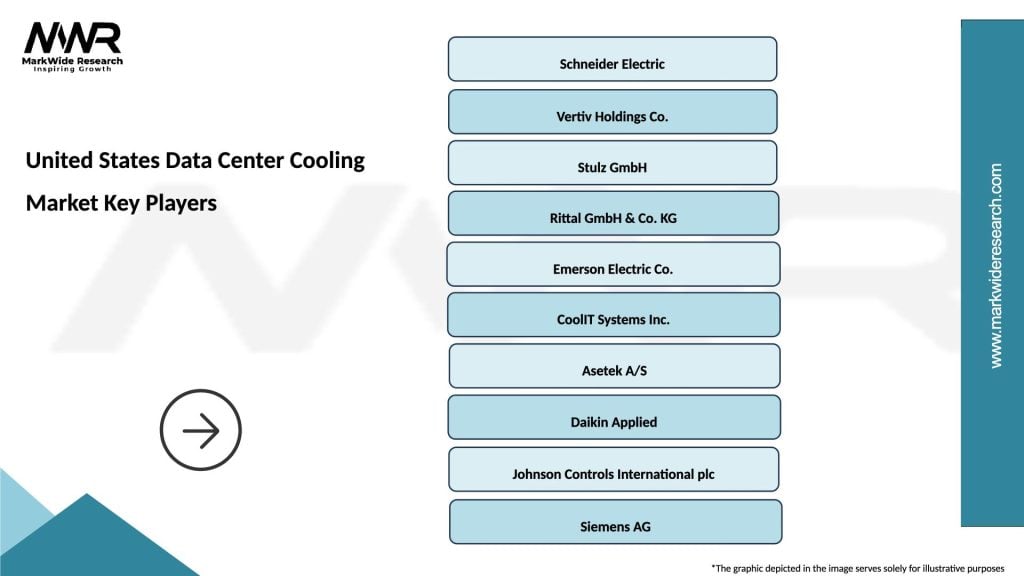

What are the key players in the United States Data Center Cooling Market?

Key players in the United States Data Center Cooling Market include companies like Schneider Electric, Vertiv, and Rittal, which provide innovative cooling solutions and technologies. These companies focus on energy efficiency and advanced cooling systems to meet the growing demands of data centers, among others.

What are the main drivers of the United States Data Center Cooling Market?

The main drivers of the United States Data Center Cooling Market include the increasing demand for data storage and processing, the rise of cloud computing, and the need for energy-efficient cooling solutions. Additionally, the growth of big data analytics and IoT applications further fuels the market’s expansion.

What challenges does the United States Data Center Cooling Market face?

The United States Data Center Cooling Market faces challenges such as high operational costs, the complexity of integrating new cooling technologies, and the need for compliance with environmental regulations. Additionally, the rapid pace of technological advancements can make it difficult for companies to keep up.

What opportunities exist in the United States Data Center Cooling Market?

Opportunities in the United States Data Center Cooling Market include the development of sustainable cooling technologies and the increasing adoption of AI and machine learning for optimizing cooling efficiency. Furthermore, the expansion of edge computing presents new avenues for innovative cooling solutions.

What trends are shaping the United States Data Center Cooling Market?

Trends shaping the United States Data Center Cooling Market include the shift towards liquid cooling solutions, the integration of renewable energy sources, and the focus on modular data center designs. These trends reflect the industry’s commitment to sustainability and efficiency in cooling operations.

United States Data Center Cooling Market

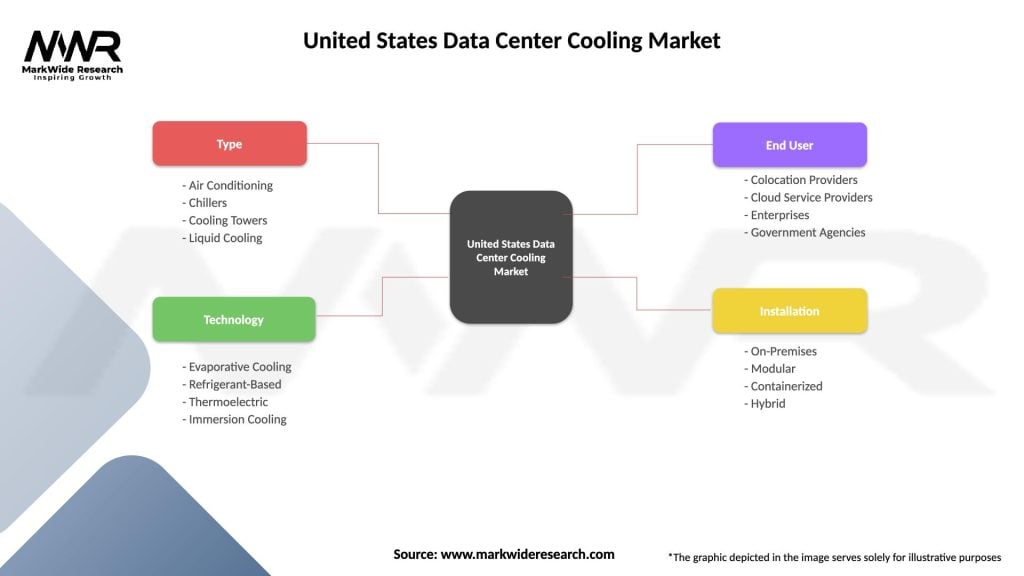

| Segmentation Details | Description |

|---|---|

| Type | Air Conditioning, Chillers, Cooling Towers, Liquid Cooling |

| Technology | Evaporative Cooling, Refrigerant-Based, Thermoelectric, Immersion Cooling |

| End User | Colocation Providers, Cloud Service Providers, Enterprises, Government Agencies |

| Installation | On-Premises, Modular, Containerized, Hybrid |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the United States Data Center Cooling Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at