444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The United States beverage contract bottling and filling market is a rapidly growing sector within the beverage industry. It involves the outsourcing of bottling and filling operations by beverage companies to specialized contract manufacturers. These contract manufacturers provide the necessary infrastructure, equipment, and expertise to efficiently package and distribute various types of beverages.

Meaning

Beverage contract bottling and filling refer to the process of outsourcing the packaging and distribution of beverages to third-party companies. These companies have the necessary facilities, equipment, and expertise to handle the bottling and filling operations for a wide range of beverages, including carbonated drinks, juices, energy drinks, bottled water, and alcoholic beverages.

Executive Summary

The United States beverage contract bottling and filling market has witnessed significant growth in recent years. The demand for outsourcing these operations has increased due to several factors, such as cost-effectiveness, operational efficiency, and flexibility. Beverage companies are increasingly relying on contract manufacturers to handle their packaging and distribution needs, allowing them to focus on their core competencies.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The United States beverage contract bottling and filling market is driven by the increasing demand for cost-effective and efficient packaging solutions, the need for product innovation, and the growing focus on sustainability. The market dynamics are influenced by factors such as changing consumer preferences, evolving regulations, and advancements in technology.

Regional Analysis

The United States beverage contract bottling and filling market is geographically diverse, with several key regions contributing to its growth. Major market players are concentrated in regions such as California, Texas, Florida, and New York, which have a high concentration of beverage companies and established infrastructure to support contract bottling and filling operations.

Competitive Landscape

Leading Companies in the United States Beverage Contract Bottling and Filling Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

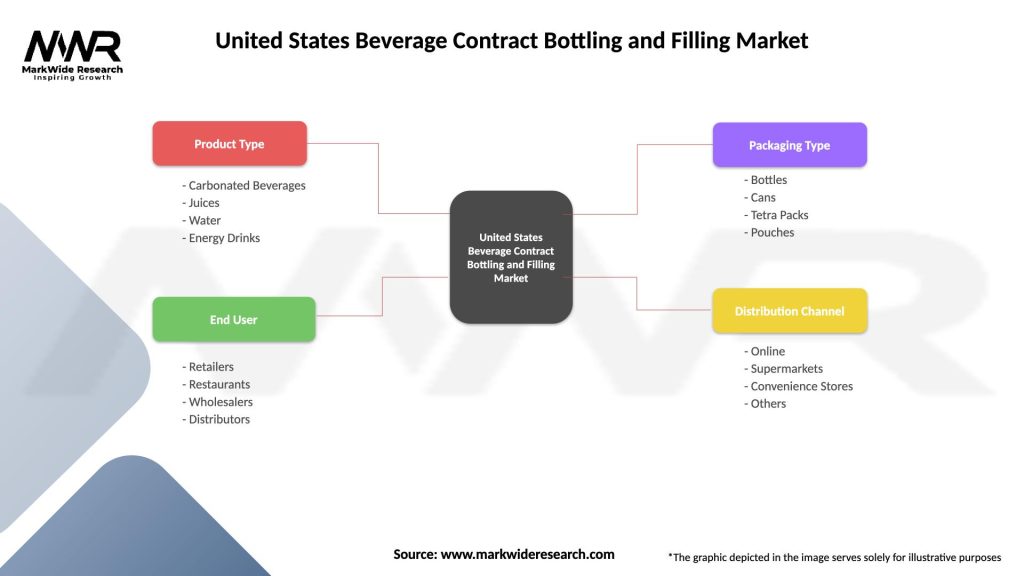

Segmentation

The United States beverage contract bottling and filling market can be segmented based on the type of beverage, packaging format, and end-user. The beverage types include carbonated drinks, juices, energy drinks, bottled water, alcoholic beverages, and others. Packaging formats may include bottles, cans, tetra packs, pouches, and more. End-users can range from large multinational beverage companies to small and medium-sized enterprises (SMEs) and private label brands.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had a mixed impact on the United States beverage contract bottling and filling market. While there was an initial disruption in the supply chain due to lockdown measures and restrictions, the market quickly rebounded as beverage companies sought efficient packaging solutions to meet the increased demand for packaged beverages through online channels and home deliveries. Contract bottlers and fillers implemented stringent safety measures to ensure uninterrupted operations and maintain product quality during the pandemic.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future of the United States beverage contract bottling and filling market looks promising. The market is expected to witness steady growth, driven by factors such as increasing outsourcing trends, advancements in technology, growing demand for sustainable packaging, and the expansion of the beverage industry. Contract bottlers and fillers that can effectively adapt to changing market dynamics and offer innovative solutions will be well-positioned to thrive in the coming years.

Conclusion

The United States beverage contract bottling and filling market offers significant opportunities for beverage companies to outsource their packaging and distribution operations. The market is driven by cost efficiency, operational flexibility, and the expertise provided by contract manufacturers. Despite challenges related to quality control and intellectual property, the market continues to grow due to increasing demand for sustainable packaging, product innovation, and the expanding beverage industry. By embracing technological advancements, focusing on quality control, and adopting a customer-centric approach, contract bottlers and fillers can capitalize on the market’s potential and shape the future of the industry.

What is Beverage Contract Bottling and Filling?

Beverage Contract Bottling and Filling refers to the outsourcing of bottling and filling processes for beverages to specialized companies. This includes various segments such as soft drinks, juices, and alcoholic beverages, allowing brands to focus on marketing and distribution.

What are the key players in the United States Beverage Contract Bottling and Filling Market?

Key players in the United States Beverage Contract Bottling and Filling Market include Coca-Cola, PepsiCo, and Keurig Dr Pepper, among others. These companies dominate the market through extensive distribution networks and diverse product offerings.

What are the growth factors driving the United States Beverage Contract Bottling and Filling Market?

The growth of the United States Beverage Contract Bottling and Filling Market is driven by increasing consumer demand for ready-to-drink beverages, the rise of health-conscious products, and the expansion of e-commerce channels. Additionally, innovations in packaging technology are enhancing product appeal.

What challenges does the United States Beverage Contract Bottling and Filling Market face?

Challenges in the United States Beverage Contract Bottling and Filling Market include fluctuating raw material costs, regulatory compliance issues, and competition from private label brands. These factors can impact profit margins and operational efficiency.

What opportunities exist in the United States Beverage Contract Bottling and Filling Market?

Opportunities in the United States Beverage Contract Bottling and Filling Market include the growing trend of sustainable packaging solutions and the increasing popularity of craft beverages. Companies can leverage these trends to attract environmentally conscious consumers.

What trends are shaping the United States Beverage Contract Bottling and Filling Market?

Trends shaping the United States Beverage Contract Bottling and Filling Market include the rise of functional beverages, such as those with added vitamins and minerals, and the shift towards personalized nutrition. Additionally, advancements in automation and digitalization are transforming production processes.

United States Beverage Contract Bottling and Filling Market

| Segmentation Details | Description |

|---|---|

| Product Type | Carbonated Beverages, Juices, Water, Energy Drinks |

| End User | Retailers, Restaurants, Wholesalers, Distributors |

| Packaging Type | Bottles, Cans, Tetra Packs, Pouches |

| Distribution Channel | Online, Supermarkets, Convenience Stores, Others |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the United States Beverage Contract Bottling and Filling Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at