444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The United States Automotive Heat Exchanger Market refers to the industry within the United States that is responsible for the production, distribution, and sale of automotive heat exchangers. Heat exchangers play a crucial role in vehicles, as they help regulate the temperature of various components, such as engines, transmissions, and HVAC systems. These devices transfer thermal energy between two or more fluids to maintain optimum operating temperatures. The market for automotive heat exchangers in the United States is influenced by various factors, including technological advancements, regulatory requirements, consumer preferences, and the overall performance of the automotive industry.

Meaning

Automotive heat exchangers are mechanical devices designed to transfer heat efficiently between two or more fluids. In the context of vehicles, heat exchangers help manage the temperature of critical components, ensuring optimal performance and longevity. The heat exchanger’s design and functionality vary based on its application within the vehicle, such as cooling the engine, condensing refrigerant in the air conditioning system, or regulating transmission fluid temperatures. These devices typically consist of metal or aluminum fins and tubes that enhance heat transfer by maximizing the surface area exposed to the passing fluids. The United States Automotive Heat Exchanger Market focuses on the manufacturing, distribution, and supply of such devices to the automotive industry within the country.

Executive Summary

The United States Automotive Heat Exchanger Market has experienced steady growth in recent years due to the increasing demand for vehicles, technological advancements in heat exchanger designs, and a focus on improving fuel efficiency and reducing emissions. The market is highly competitive, with several key players operating within the country. Automotive manufacturers and suppliers continually strive to develop innovative heat exchanger solutions to meet evolving industry requirements.

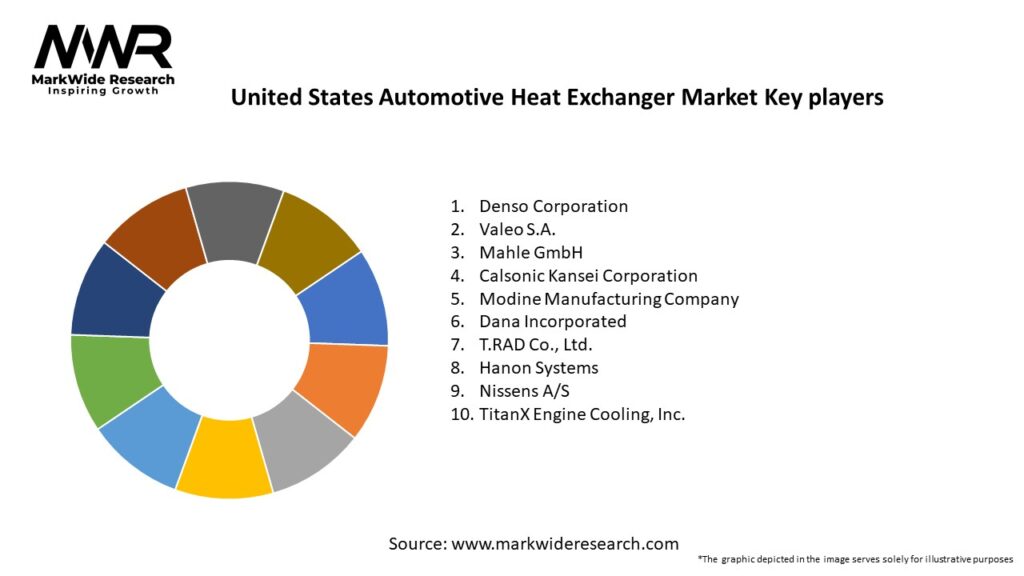

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The United States Automotive Heat Exchanger Market is influenced by several dynamics, including technological advancements, regulatory policies, market competition, and consumer preferences. These dynamics shape the demand, supply, and innovation within the market, driving manufacturers and suppliers to adapt and evolve their offerings.

Technological advancements play a vital role in the automotive heat exchanger market. Continuous research and development efforts aim to improve heat exchanger efficiency, reduce weight and size, and enhance durability. The integration of advanced materials, such as aluminum alloys and composite materials, enables manufacturers to develop heat exchangers with higher thermal conductivity and corrosion resistance.

Regulatory policies significantly impact the market dynamics. Emission regulations drive the adoption of advanced heat exchanger systems, as they play a critical role in controlling engine temperatures and reducing pollutant emissions. Additionally, government initiatives to promote electric vehicles and improve fuel efficiency provide opportunities for heat exchanger manufacturers to develop specialized solutions for these vehicles.

The market is highly competitive, with numerous players vying for market share. To maintain a competitive edge, manufacturers focus on product differentiation, cost optimization, and technological advancements. Collaborations and partnerships with automotive manufacturers also play a crucial role in securing contracts and gaining a competitive advantage.

Consumer preferences and market trends influence the demand for specific types of heat exchangers. Factors such as vehicle type, fuel efficiency, and environmental consciousness drive the market towards more compact, lightweight, and efficient heat exchanger designs. As consumers increasingly prioritize sustainability and energy efficiency, heat exchangers that contribute to these goals gain popularity.

Regional Analysis

The United States Automotive Heat Exchanger Market exhibits regional variations in terms of production, demand, and consumer preferences. The major regions for heat exchanger manufacturing and consumption include the Midwest, Northeast, South, and West Coast.

The Midwest region, known as the “Detroit of the United States,” is a significant hub for automotive manufacturing. It houses several automobile manufacturers, assembly plants, and component suppliers. The region’s strong automotive industry drives the demand for heat exchangers, both for original equipment manufacturers (OEMs) and the aftermarket.

The Northeast region, particularly states like Michigan and Ohio, also hosts a substantial automotive industry presence. Heat exchanger manufacturers in this region cater to the needs of local OEMs and supply components to other regions within the United States.

The South region, including states such as Texas, Alabama, and Tennessee, is another important area for automotive manufacturing. The presence of assembly plants and automotive suppliers in this region drives the demand for heat exchangers. The South’s warm climate also highlights the importance of efficient cooling systems in vehicles, further boosting the heat exchanger market.

The West Coast, encompassing states like California, hosts a significant market for electric vehicles. As the adoption of EVs increases in the United States, the demand for heat exchangers tailored for electric vehicles is expected to grow in this region. Additionally, the West Coast’s emphasis on environmental sustainability and stringent emission standards fosters the demand for advanced heat exchanger systems.

Competitive Landscape

Leading Companies in the United States Automotive Heat Exchanger Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

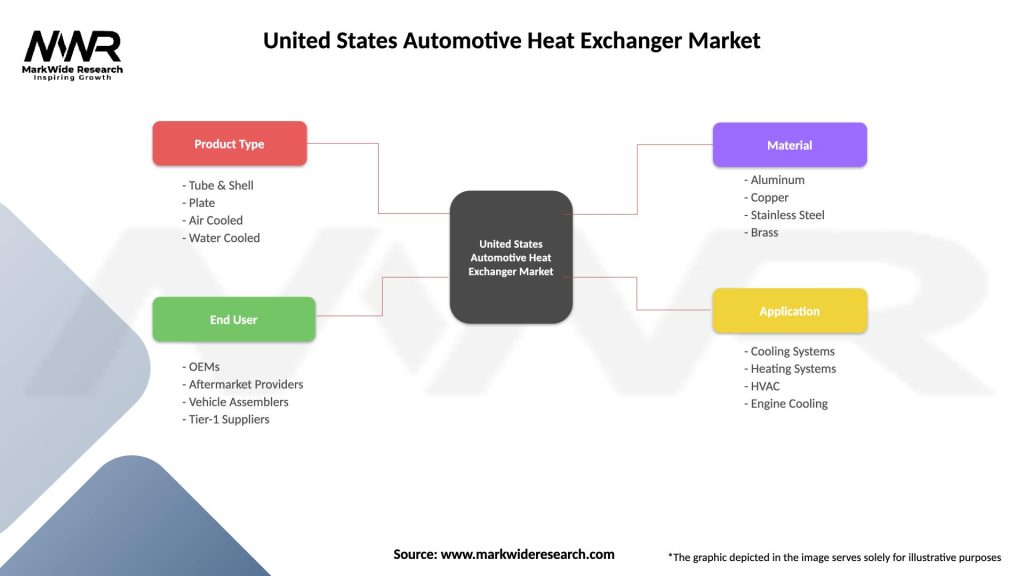

The United States Automotive Heat Exchanger Market can be segmented based on product type, vehicle type, and end-use industry.

By Product Type:

By Vehicle Type:

By End-Use Industry:

Segmentation allows market players to target specific customer segments and tailor their products accordingly. It helps identify the demand patterns for different heat exchanger types based on the vehicle type and end-use industry.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The United States Automotive Heat Exchanger Market offers several benefits for industry participants and stakeholders, including:

SWOT Analysis

A SWOT (Strengths, Weaknesses, Opportunities, and Threats) analysis provides an overview of the United States Automotive Heat Exchanger Market’s internal and external factors influencing its current and future performance.

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the United States Automotive Heat Exchanger Market. The automotive industry experienced a decline in sales and production due to temporary closures, supply chain disruptions, and reduced consumer spending. As a result, the demand for automotive heat exchangers also decreased during the pandemic.

However, the market exhibited resilience and began to recover as economic activities resumed and automotive production resumed. The industry’s focus on electric vehicles and the increasing demand for sustainable solutions provided some opportunities for heat exchanger manufacturers. The need for efficient battery cooling systems in electric vehicles and the emphasis on reducing emissions remained key factors driving the market.

The pandemic also highlighted the importance of thermal management systems in vehicles, as maintaining a clean and controlled cabin environment became a priority. Heat exchangers used in HVAC systems played a crucial role in ensuring passenger comfort and safety by efficiently managing air temperature and quality.

Overall, while the pandemic posed challenges to the United States Automotive Heat Exchanger Market, the industry demonstrated resilience and adaptability in response to changing market dynamics.

Key Industry Developments

Analyst Suggestions

Future Outlook

The United States Automotive Heat Exchanger Market is expected to witness steady growth in the coming years. The market’s growth will be driven by factors such as the increasing demand for vehicles, the shift towards electric and hybrid vehicles, and the ongoing focus on fuel efficiency and emission reduction. Technological advancements in heat exchanger designs, materials, and manufacturing processes will further enhance the market’s potential. The integration of advanced materials and lightweight designs will continue to be a key trend, driven by the need to improve vehicle efficiency and reduce emissions. The electrification of vehicles will create new opportunities for heat exchanger manufacturers, as electric vehicles require efficient thermal management systems to maintain battery performance.

Sustainability will remain a critical factor, with market players emphasizing eco-friendly solutions and materials. Additive manufacturing and nanofluid technologies are expected to gain further prominence, enabling customized designs and improved heat transfer capabilities. To capitalize on the market’s growth potential, industry participants should focus on technological advancements, collaboration with automotive manufacturers, sustainability, and aftermarket support. By staying at the forefront of innovation and meeting evolving industry requirements, heat exchanger manufacturers can position themselves for success in the United States Automotive Heat Exchanger Market.

Conclusion

The United States Automotive Heat Exchanger Market is a dynamic and competitive industry driven by factors such as technological advancements, regulatory requirements, and consumer preferences. Heat exchangers play a vital role in managing temperature in vehicles, optimizing performance, and ensuring durability. The market offers opportunities for revenue generation, technological advancements, collaborations, and sustainability initiatives. Segmentation allows manufacturers to target specific customer segments, and category-wise insights highlight the importance of different heat exchanger types. The market’s regional analysis demonstrates variations in demand and production across different regions within the United States. While the market faces challenges such as intense competition and raw material price fluctuations, it also presents opportunities such as electrification, advanced materials, and aftermarket demand. By embracing technological advancements, collaborating with automotive manufacturers, prioritizing sustainability, and enhancing aftermarket support, industry participants can thrive in the evolving United States Automotive Heat Exchanger Market.

What is Automotive Heat Exchanger?

Automotive heat exchangers are devices used in vehicles to transfer heat between two or more fluids. They play a crucial role in maintaining optimal engine temperatures and improving overall vehicle efficiency.

What are the key players in the United States Automotive Heat Exchanger Market?

Key players in the United States Automotive Heat Exchanger Market include companies like Valeo, Mahle, and Denso, which are known for their innovative heat exchanger solutions and extensive product offerings in the automotive sector, among others.

What are the main drivers of the United States Automotive Heat Exchanger Market?

The main drivers of the United States Automotive Heat Exchanger Market include the increasing demand for fuel-efficient vehicles, advancements in automotive technology, and the growing focus on reducing emissions in the automotive industry.

What challenges does the United States Automotive Heat Exchanger Market face?

Challenges in the United States Automotive Heat Exchanger Market include the high cost of raw materials, stringent regulatory requirements, and the need for continuous innovation to meet evolving consumer demands.

What opportunities exist in the United States Automotive Heat Exchanger Market?

Opportunities in the United States Automotive Heat Exchanger Market include the rising trend of electric vehicles, which require efficient thermal management systems, and the potential for growth in aftermarket services and replacements.

What trends are shaping the United States Automotive Heat Exchanger Market?

Trends shaping the United States Automotive Heat Exchanger Market include the integration of lightweight materials to enhance fuel efficiency, the development of compact designs for better space utilization, and the increasing use of advanced manufacturing techniques.

United States Automotive Heat Exchanger Market

| Segmentation Details | Description |

|---|---|

| Product Type | Tube & Shell, Plate, Air Cooled, Water Cooled |

| End User | OEMs, Aftermarket Providers, Vehicle Assemblers, Tier-1 Suppliers |

| Material | Aluminum, Copper, Stainless Steel, Brass |

| Application | Cooling Systems, Heating Systems, HVAC, Engine Cooling |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the United States Automotive Heat Exchanger Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at