444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview

The United States articulated robot market is witnessing significant growth due to advancements in automation technologies across various industries. Articulated robots, also known as multi-axis robots, are widely used for complex tasks that require precise movement and flexibility. These robots consist of multiple interconnected joints, allowing them to mimic human arm movements with a high degree of accuracy. They are extensively used in industries such as automotive, electronics, food and beverage, pharmaceuticals, and aerospace.

Meaning

Articulated robots are highly versatile machines designed to perform various tasks in an automated manner. These robots consist of several joints, which enable them to move in multiple directions and carry out intricate operations. They are equipped with advanced sensors and programming capabilities that allow them to adapt to different environments and perform precise tasks with speed and accuracy.

Executive Summary

The United States articulated robot market is experiencing steady growth, driven by the increasing demand for automation across industries. These robots offer numerous benefits, such as improved productivity, enhanced product quality, reduced labor costs, and increased workplace safety. With advancements in artificial intelligence and machine learning, articulated robots are becoming smarter and more efficient, enabling businesses to streamline their operations and gain a competitive edge.

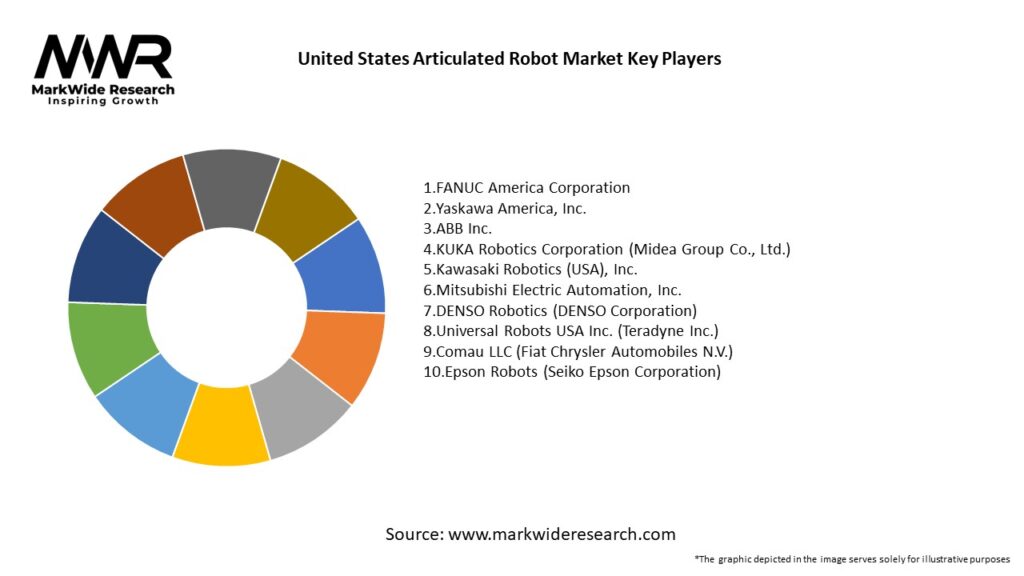

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The United States articulated robot market is characterized by intense competition among key players. Manufacturers are focusing on developing robots with improved precision, speed, and versatility to cater to the evolving needs of industries. Collaborative robots, in particular, are gaining traction, as they facilitate human-robot interaction in shared workspaces. The market is also witnessing strategic partnerships and acquisitions aimed at expanding product portfolios and geographical reach.

Regional Analysis

The United States articulated robot market is segmented into various regions, including the West Coast, East Coast, Midwest, and South. The West Coast, comprising states such as California and Washington, holds a significant share due to the presence of major automotive and technology companies. The East Coast, with states like New York and Massachusetts, is a hub for pharmaceutical and healthcare industries. The Midwest, known for its manufacturing sector, also contributes to the market growth. The South is witnessing a rising adoption of articulated robots in industries such as food processing and logistics.

Competitive Landscape

Leading companies in the United States Articulated Robot Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

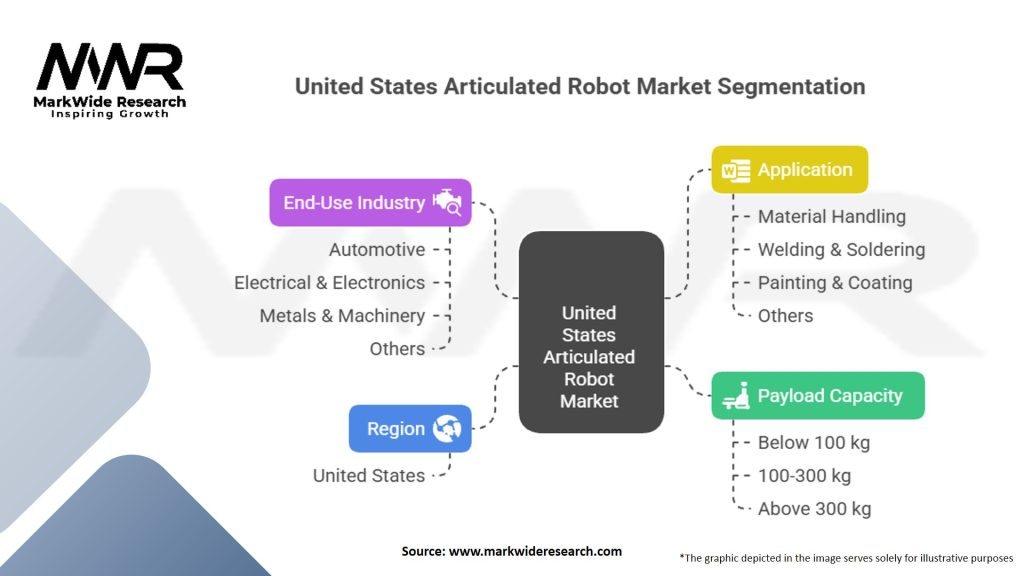

Segmentation

The United States articulated robot market can be segmented based on industry verticals, robot type, payload capacity, and end-user applications. By industry verticals, the market can be categorized into automotive, electronics, food and beverage, pharmaceuticals, aerospace, and others. Based on robot type, the market can be classified into SCARA, delta, Cartesian, and articulated robots. Payload capacity segments include low, medium, and high payload robots. The end-user applications segment comprises assembly, welding and soldering, material handling, packaging, painting and dispensing, and inspection and testing.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a mixed impact on the United States articulated robot market. While some industries, such as automotive and aerospace, experienced a slowdown in production, others, like pharmaceuticals and food processing, witnessed increased demand. The pandemic highlighted the need for automation to ensure business continuity and reduce reliance on human labor. This led to an accelerated adoption of articulated robots in various sectors, particularly in tasks that require social distancing and reduced human contact.

Key Industry Developments

Analyst Suggestions

Future Outlook

The United States articulated robot market is expected to witness steady growth in the coming years. The increasing focus on automation, the rise of collaborative robots, and advancements in robotic technologies will drive market expansion. The demand for articulated robots is anticipated to grow across industries such as automotive, electronics, food and beverage, pharmaceuticals, and aerospace. Continued investment in research and development, as well as strategic partnerships, will play a crucial role in shaping the future of the market.

Conclusion

The United States articulated robot market is experiencing significant growth, driven by the increasing demand for automation across industries. These robots offer precise movement, flexibility, and enhanced productivity, making them valuable assets for various applications. While initial costs and skilled workforce availability pose challenges, the market presents numerous opportunities, including the emergence of collaborative robots and the integration of Industry 4.0 technologies. With continuous advancements in robotic technologies and strategic industry collaborations, the future of the United States articulated robot market looks promising.

What is the United States articulated robot?

The United States articulated robot refers to a type of robotic arm that is designed with multiple joints, allowing for a wide range of motion and flexibility. These robots are commonly used in manufacturing, assembly, and automation processes due to their precision and adaptability.

Who are the key players in the United States articulated robot market?

Key players in the United States articulated robot market include companies such as Fanuc, ABB, KUKA, and Yaskawa, which are known for their advanced robotic solutions and innovations in automation technology, among others.

What are the main drivers of growth in the United States articulated robot market?

The main drivers of growth in the United States articulated robot market include the increasing demand for automation in manufacturing, the need for precision in production processes, and advancements in robotics technology that enhance operational efficiency.

What challenges does the United States articulated robot market face?

Challenges in the United States articulated robot market include high initial investment costs, the complexity of integration into existing systems, and the need for skilled labor to operate and maintain these advanced robotic systems.

What opportunities exist in the United States articulated robot market?

Opportunities in the United States articulated robot market include the expansion of robotics in sectors such as healthcare, logistics, and agriculture, as well as the potential for collaborative robots that work alongside humans to enhance productivity.

What trends are shaping the United States articulated robot market?

Trends shaping the United States articulated robot market include the rise of artificial intelligence integration, the development of more compact and versatile robotic systems, and the increasing focus on sustainability and energy efficiency in robotic applications.

United States Articulated Robot Market

| Segmentation | Details |

|---|---|

| Payload Capacity | Below 100 kg, 100-300 kg, Above 300 kg |

| End-Use Industry | Automotive, Electrical & Electronics, Metals & Machinery, Others |

| Application | Material Handling, Welding & Soldering, Painting & Coating, Others |

| Region | United States |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the United States Articulated Robot Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at