444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview:

In the expansive landscape of adhesive solutions, hot-melt adhesives have emerged as a powerful force, and the United Kingdom stands witness to a dynamic market growth in this realm. Hot-melt adhesives, also known as hot glue, are thermoplastic adhesives that melt and form a bond upon cooling. This versatile bonding method finds application across various industries due to its quick setting time, strong adhesion, and minimal environmental impact. The United Kingdom, a hub of industrial innovation, has seen a significant surge in the demand for hot-melt adhesives owing to their diverse applications and reliability.

Meaning:

Hot-melt adhesives, as the name suggests, are adhesives that are thermally melted to create a bonding effect. Comprising polymers, stabilizers, and other additives, these adhesives are heated to a molten state and then applied to the bonding surfaces. Upon cooling, they solidify and establish a strong bond. This efficient bonding method eliminates the need for solvents or water, reducing the risk of environmental pollution. The UK market has embraced hot-melt adhesives across sectors like packaging, automotive, textiles, electronics, and more.

Executive Summary:

The United Kingdom’s hot-melt adhesives market is witnessing a remarkable growth trajectory. Fueled by their versatility and eco-friendly nature, hot-melt adhesives have become a preferred choice for industries seeking efficient bonding solutions. This executive summary encapsulates the crucial insights into market trends, growth drivers, opportunities, and challenges that shape the landscape of hot-melt adhesives in the UK.

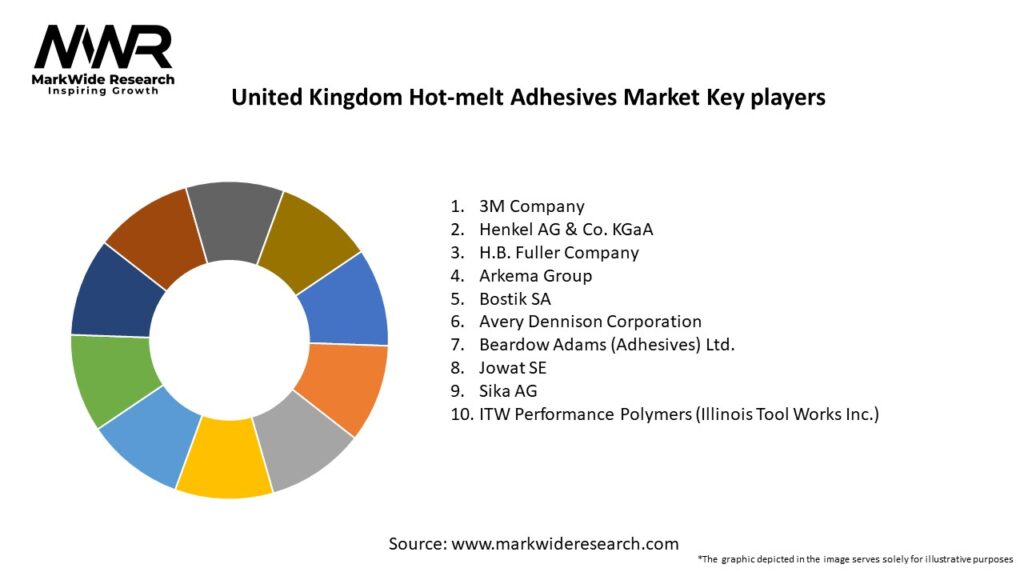

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

Regional Analysis

The United Kingdom is one of the leading markets for hot-melt adhesives in Europe, with high demand coming from industries such as packaging, automotive, and electronics. The packaging industry, driven by the e-commerce boom, is a key contributor to market growth. Additionally, the automotive industry’s focus on lightweight materials and efficient manufacturing processes is expected to further increase the demand for hot-melt adhesives.

The market in the UK is also driven by the adoption of eco-friendly and bio-based adhesives as industries strive to meet sustainability goals and comply with stringent environmental regulations. As a result, there is a significant focus on the development of more sustainable hot-melt adhesives that cater to the increasing demand for green products.

Competitive Landscape

Leading Companies in the United Kingdom Hot-melt Adhesives Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

By Type

By Application

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact:

The Covid-19 pandemic posed unprecedented challenges to industries worldwide, including the hot-melt adhesives sector in the UK. Supply chain disruptions and reduced manufacturing activities initially impacted the market. However, the adhesive industry showcased resilience by adapting to new norms, such as remote collaboration and digital transformation. As industries recover, hot-melt adhesives play a pivotal role in expediting production ramp-up.

Key Industry Developments:

The UK hot-melt adhesives market continually evolves through key industry developments. Technological advancements have led to improved adhesive formulations, enhancing their performance across diverse applications. Collaborations between adhesive manufacturers and end-users have resulted in tailor-made solutions that address specific challenges. Regulatory changes promoting eco-friendly practices further shape the industry landscape.

Analyst Suggestions:

Industry analysts suggest proactive measures to harness the full potential of the UK hot-melt adhesives market. Stakeholders should invest in research and development to innovate new adhesive formulations that cater to evolving industry demands. Exploring untapped applications, such as medical devices and renewable energy, can also lead to market expansion. Furthermore, fostering partnerships with sustainability-focused organizations enhances the industry’s environmental footprint.

Future Outlook:

The future of the UK hot-melt adhesives market shines bright with opportunities. As technology continues to evolve, adhesive manufacturers are expected to develop products with enhanced performance, durability, and adaptability. The growth of industries like renewable energy and medical devices will open new avenues for hot-melt adhesive applications. Collaborative efforts toward sustainability will position the UK as a hotspot for eco-conscious adhesive solutions.

Conclusion:

The United Kingdom’s hot-melt adhesives market is a dynamic realm where innovation meets efficiency. The market’s remarkable growth is fueled by diverse applications across industries and a growing preference for sustainable solutions. As hot-melt adhesives cement their position as a go-to bonding method, the future promises exciting developments and collaborations that will reshape industries and create stronger bonds for generations to come.

What is Hot-melt Adhesives?

Hot-melt adhesives are thermoplastic materials that are applied in a molten state and solidify upon cooling. They are widely used in various applications such as packaging, woodworking, and automotive assembly due to their strong bonding properties and quick setting times.

What are the key players in the United Kingdom Hot-melt Adhesives Market?

Key players in the United Kingdom Hot-melt adhesives market include Henkel AG, 3M Company, Bostik, and Sika AG, among others. These companies are known for their innovative adhesive solutions and extensive product portfolios.

What are the growth factors driving the United Kingdom Hot-melt Adhesives Market?

The growth of the United Kingdom hot-melt adhesives market is driven by increasing demand from the packaging industry, advancements in adhesive technologies, and the rising trend of automation in manufacturing processes.

What challenges does the United Kingdom Hot-melt Adhesives Market face?

Challenges in the United Kingdom hot-melt adhesives market include fluctuating raw material prices, environmental regulations regarding VOC emissions, and competition from alternative adhesive technologies.

What opportunities exist in the United Kingdom Hot-melt Adhesives Market?

Opportunities in the United Kingdom hot-melt adhesives market include the growing demand for eco-friendly adhesives, expansion in the automotive and construction sectors, and the potential for product innovation in specialty adhesives.

What trends are shaping the United Kingdom Hot-melt Adhesives Market?

Trends in the United Kingdom hot-melt adhesives market include the increasing use of bio-based adhesives, advancements in application techniques, and a focus on sustainability and recyclability in adhesive formulations.

United Kingdom Hot-melt Adhesives Market

| Segmentation Details | Description |

|---|---|

| Product Type | Polyamide, Ethylene Vinyl Acetate, Styrenic Block Copolymers, Polyurethane |

| End Use Industry | Packaging, Automotive, Construction, Electronics |

| Application | Labeling, Assembly, Bonding, Coating |

| Form | Granules, Films, Liquids, Sticks |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the United Kingdom Hot-melt Adhesives Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at