444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The United Kingdom electric vehicle battery electrolyte market represents a critical component of the nation’s rapidly expanding electric mobility ecosystem. As the UK accelerates its transition toward carbon neutrality by 2050, the demand for advanced battery technologies has reached unprecedented levels. Battery electrolytes serve as the essential medium that enables ion transport between electrodes in electric vehicle batteries, directly impacting performance, safety, and longevity of energy storage systems.

Market dynamics indicate robust growth driven by government initiatives, automotive industry transformation, and technological advancements in electrolyte formulations. The UK’s commitment to phasing out internal combustion engine vehicles by 2030 has created substantial opportunities for electrolyte manufacturers and suppliers. Growth projections suggest the market is expanding at a compound annual growth rate of 12.8%, reflecting the increasing adoption of electric vehicles across commercial and passenger segments.

Key market participants include both established chemical manufacturers and innovative startups developing next-generation electrolyte solutions. The competitive landscape encompasses liquid electrolytes, solid-state electrolytes, and hybrid formulations designed to meet diverse performance requirements. Regional concentration shows significant activity in England’s automotive corridors, with approximately 68% of market activity concentrated in the Midlands and Southeast regions where major automotive manufacturers maintain operations.

The United Kingdom electric vehicle battery electrolyte market refers to the comprehensive ecosystem of companies, technologies, and supply chains involved in the production, distribution, and application of electrolyte solutions specifically designed for electric vehicle battery systems within the UK territory. Battery electrolytes are chemical substances that facilitate the movement of ions between the positive and negative electrodes in rechargeable battery cells, enabling the storage and release of electrical energy essential for electric vehicle operation.

Market scope encompasses various electrolyte types including liquid organic electrolytes, aqueous electrolytes, ionic liquid electrolytes, and emerging solid-state electrolyte technologies. These solutions must meet stringent automotive standards for safety, performance, and environmental compliance while supporting the UK’s broader objectives for sustainable transportation and reduced carbon emissions.

Strategic positioning of the UK electric vehicle battery electrolyte market reflects the nation’s ambitious climate goals and supportive policy framework for electric mobility adoption. The market benefits from substantial government investments in battery technology research, manufacturing capabilities, and charging infrastructure development. Industry transformation is accelerating as traditional automotive manufacturers pivot toward electric vehicle production while new market entrants introduce innovative battery technologies.

Technology evolution focuses on improving energy density, charging speeds, thermal stability, and safety characteristics of electrolyte formulations. Advanced electrolyte solutions incorporating additives and novel chemical compositions are addressing key challenges such as battery degradation, temperature sensitivity, and fire safety concerns. Market penetration rates show that lithium-ion battery electrolytes account for approximately 85% of current market applications, with emerging technologies gaining traction.

Supply chain dynamics reveal increasing localization efforts as manufacturers seek to reduce dependence on international suppliers and enhance supply security. The UK’s strategic focus on building domestic battery manufacturing capabilities is driving investments in electrolyte production facilities and research partnerships between academic institutions and industry players.

Market intelligence reveals several critical insights shaping the UK electric vehicle battery electrolyte landscape:

Primary growth drivers propelling the UK electric vehicle battery electrolyte market stem from multiple interconnected factors creating a favorable environment for sustained expansion. Government initiatives represent the most significant catalyst, with comprehensive policy frameworks supporting electric vehicle adoption through financial incentives, regulatory mandates, and infrastructure investments.

Environmental consciousness among consumers and businesses is driving unprecedented demand for sustainable transportation solutions. The UK’s commitment to achieving net-zero carbon emissions by 2050 has created urgency around electric vehicle deployment, directly benefiting electrolyte suppliers and manufacturers. Corporate sustainability mandates are compelling fleet operators and logistics companies to transition toward electric vehicles, expanding the addressable market for battery components.

Technological advancements in battery chemistry and electrolyte formulations are enabling improved performance characteristics that address traditional electric vehicle limitations. Enhanced energy density, faster charging capabilities, and extended battery life are making electric vehicles more attractive to consumers, thereby increasing demand for advanced electrolyte solutions. Cost reduction trends in battery manufacturing are making electric vehicles more price-competitive with conventional vehicles, accelerating market adoption.

Infrastructure development including rapid expansion of charging networks is reducing range anxiety and supporting broader electric vehicle acceptance. The UK’s substantial investments in charging infrastructure create confidence among consumers and businesses considering electric vehicle adoption, indirectly driving demand for battery components including electrolytes.

Market constraints affecting the UK electric vehicle battery electrolyte sector include several technical, economic, and regulatory challenges that may impact growth trajectories. Supply chain vulnerabilities represent a significant concern, particularly regarding critical raw materials sourced from geographically concentrated regions. Dependencies on lithium, cobalt, and other essential materials create potential disruptions that could affect electrolyte production and pricing.

Technical limitations of current electrolyte technologies continue to pose challenges for widespread electric vehicle adoption. Issues such as temperature sensitivity, degradation over charge cycles, and safety concerns related to flammability require ongoing research and development investments. Performance trade-offs between energy density, safety, and cost effectiveness create complex optimization challenges for manufacturers.

Regulatory complexity surrounding battery safety standards, environmental compliance, and transportation regulations can create barriers for new market entrants and increase compliance costs for existing players. Certification processes for automotive applications are lengthy and expensive, potentially delaying product introductions and limiting innovation speed.

Economic factors including inflation, energy costs, and currency fluctuations can impact manufacturing costs and profitability for electrolyte producers. Capital intensity required for establishing manufacturing facilities and research capabilities may limit market participation to well-funded organizations, potentially constraining competition and innovation.

Emerging opportunities within the UK electric vehicle battery electrolyte market present substantial potential for growth and innovation across multiple dimensions. Next-generation technologies including solid-state electrolytes offer transformative possibilities for battery performance, safety, and manufacturing efficiency. Companies developing breakthrough electrolyte formulations have opportunities to capture significant market share as the industry evolves toward advanced battery architectures.

Circular economy initiatives create opportunities for electrolyte recycling and recovery technologies, addressing both environmental concerns and resource scarcity issues. Sustainable manufacturing approaches incorporating renewable energy sources and environmentally friendly production processes can provide competitive advantages as sustainability becomes increasingly important to customers and regulators.

Market expansion beyond traditional automotive applications presents opportunities in energy storage systems, marine applications, and aerospace sectors. Grid-scale energy storage projects supporting renewable energy integration require large quantities of battery systems, creating additional demand for electrolyte solutions. Commercial vehicle electrification including buses, delivery vehicles, and heavy-duty trucks represents a rapidly growing market segment with specific performance requirements.

International expansion opportunities exist as UK-based companies leverage domestic expertise to serve global markets. Export potential for advanced electrolyte technologies developed in the UK could generate additional revenue streams while supporting the nation’s trade objectives. Strategic partnerships with international automotive manufacturers and battery producers can facilitate market access and technology transfer opportunities.

Market dynamics within the UK electric vehicle battery electrolyte sector reflect complex interactions between technological innovation, regulatory frameworks, competitive pressures, and consumer adoption patterns. Technology convergence is creating new possibilities as advances in materials science, chemistry, and manufacturing processes enable improved electrolyte performance characteristics.

Competitive intensity is increasing as established chemical manufacturers compete with specialized battery technology companies and emerging startups. Innovation cycles are accelerating as companies invest heavily in research and development to differentiate their products and capture market share. Patent landscapes are becoming increasingly important as intellectual property protection becomes critical for maintaining competitive advantages.

Customer requirements are evolving rapidly as automotive manufacturers seek electrolyte solutions that support faster charging, longer range, improved safety, and reduced costs. Performance benchmarks are continuously rising as electric vehicle adoption expands and consumer expectations increase. Customization demands are growing as different vehicle applications require tailored electrolyte formulations optimized for specific use cases.

Regulatory evolution continues to shape market dynamics as safety standards, environmental regulations, and performance requirements become more stringent. MarkWide Research analysis indicates that regulatory compliance costs are increasing but also driving innovation toward safer and more environmentally friendly electrolyte solutions.

Comprehensive research methodology employed for analyzing the UK electric vehicle battery electrolyte market incorporates multiple data collection and analysis techniques to ensure accuracy and reliability of insights. Primary research includes structured interviews with industry executives, technical experts, regulatory officials, and key stakeholders across the electric vehicle and battery supply chain ecosystem.

Secondary research encompasses analysis of government publications, industry reports, academic studies, patent databases, and financial disclosures from publicly traded companies. Market data validation involves cross-referencing information from multiple sources to ensure consistency and accuracy of findings. Quantitative analysis incorporates statistical modeling techniques to project market trends and growth trajectories.

Industry expert consultations provide qualitative insights into market dynamics, technological developments, and competitive landscapes. Regulatory analysis examines current and proposed legislation affecting the electric vehicle and battery industries. Technology assessment evaluates emerging electrolyte technologies and their potential market impact through expert interviews and technical literature review.

Data triangulation methods ensure research findings are supported by multiple independent sources and analytical approaches. Continuous monitoring of market developments enables real-time updates to research findings as new information becomes available.

Regional distribution of the UK electric vehicle battery electrolyte market reveals significant geographical concentration aligned with automotive manufacturing clusters and research institutions. England dominates market activity with approximately 78% of total market presence, driven by major automotive manufacturing facilities in the Midlands and Southeast regions.

The Midlands region serves as a critical hub for automotive manufacturing and battery technology development, hosting major vehicle production facilities and supplier networks. West Midlands particularly benefits from the presence of established automotive manufacturers and emerging electric vehicle production lines. East Midlands contributes significantly through logistics and distribution networks supporting the broader automotive supply chain.

Southeast England represents another key regional market driven by proximity to research institutions, technology companies, and transportation networks. London and surrounding areas contribute through corporate headquarters, research facilities, and early adoption of electric vehicle technologies in commercial and public transportation sectors.

Northern England shows growing importance as manufacturing capabilities expand and government initiatives support regional economic development. Scotland contributes approximately 12% of market activity through renewable energy integration projects and specialized manufacturing capabilities. Wales accounts for roughly 8% of market presence with focus on sustainable manufacturing and automotive component production.

Regional specialization is emerging as different areas develop expertise in specific aspects of the electrolyte supply chain, from raw material processing to advanced formulation development and manufacturing.

Competitive dynamics within the UK electric vehicle battery electrolyte market feature a diverse mix of international chemical companies, specialized battery technology firms, and emerging innovative startups. Market leadership is distributed among several key players, each bringing distinct capabilities and strategic advantages to the marketplace.

Strategic positioning varies among competitors, with some focusing on high-volume commodity electrolytes while others specialize in advanced formulations for premium applications. Innovation strategies emphasize safety improvements, performance enhancements, and cost optimization to meet evolving customer requirements.

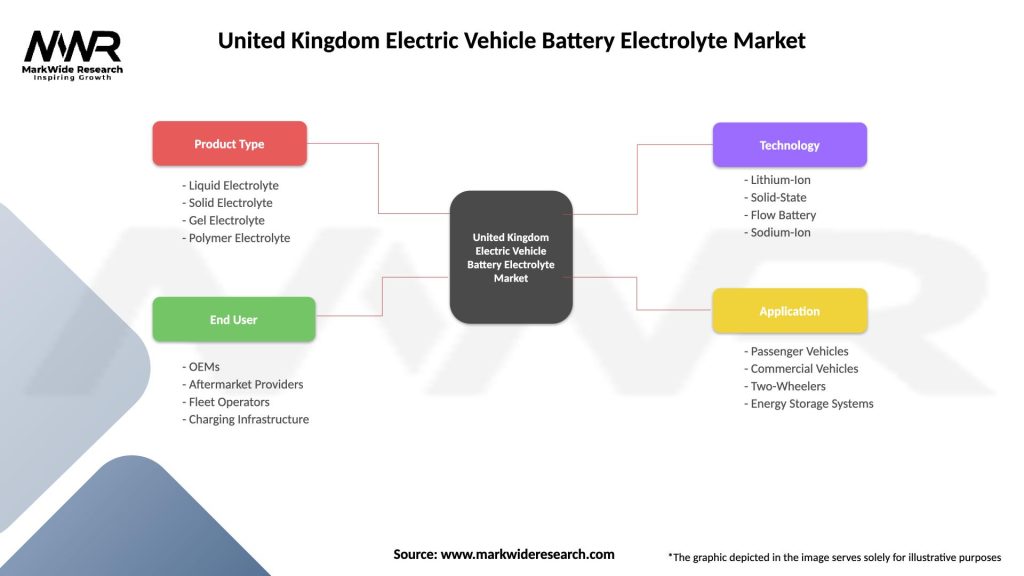

Market segmentation of the UK electric vehicle battery electrolyte market reveals distinct categories based on technology type, application, and end-user requirements. Technology-based segmentation represents the primary classification method, reflecting fundamental differences in electrolyte chemistry and performance characteristics.

By Technology:

By Application:

By End-User:

Liquid electrolyte category maintains market dominance due to mature technology, established supply chains, and proven performance in automotive applications. Lithium hexafluorophosphate remains the preferred salt for most applications, offering optimal balance of conductivity, stability, and safety characteristics. Organic carbonate solvents including ethylene carbonate and dimethyl carbonate provide the foundation for most commercial formulations.

Solid-state electrolyte category represents the most promising growth opportunity, with potential to revolutionize battery performance and safety. Ceramic electrolytes offer superior thermal stability and safety characteristics but face challenges related to manufacturing costs and interface compatibility. Polymer electrolytes provide easier processing and flexibility but typically exhibit lower ionic conductivity than liquid alternatives.

Additive technologies play increasingly important roles in optimizing electrolyte performance across all categories. Flame retardant additives enhance safety characteristics while solid electrolyte interface forming additives improve battery cycle life and performance stability. Conductive salts and stabilizing agents enable customization of electrolyte properties for specific applications.

Performance optimization focuses on balancing multiple requirements including ionic conductivity, electrochemical stability, thermal stability, and safety characteristics. MWR analysis indicates that next-generation electrolyte formulations are achieving performance improvements of 25-30% across key metrics compared to conventional solutions.

Industry participants in the UK electric vehicle battery electrolyte market enjoy multiple strategic advantages and benefits from the rapidly expanding market opportunity. Automotive manufacturers benefit from access to advanced electrolyte technologies that enable improved vehicle performance, safety, and cost competitiveness in the growing electric vehicle market.

Chemical companies and electrolyte manufacturers gain opportunities to leverage existing capabilities while developing new revenue streams in a high-growth market segment. Technology transfer from traditional chemical applications to battery electrolytes allows companies to utilize existing expertise while accessing new market opportunities. Research and development investments in electrolyte technologies can generate intellectual property assets with significant commercial value.

Government stakeholders benefit from economic development opportunities, job creation, and progress toward environmental objectives through support of the electric vehicle ecosystem. Tax revenue generation from expanding manufacturing activities and export opportunities contribute to broader economic benefits. Environmental improvements from reduced transportation emissions support climate change mitigation goals.

Consumers ultimately benefit from improved electric vehicle performance, safety, and affordability enabled by advanced electrolyte technologies. Enhanced charging speeds, extended driving range, and improved safety characteristics make electric vehicles more attractive and practical for everyday use. Cost reductions in battery systems translate to more affordable electric vehicles and lower total ownership costs.

Research institutions gain access to industry funding, collaborative opportunities, and real-world applications for fundamental research in electrochemistry and materials science. Academic-industry partnerships accelerate technology development while providing educational opportunities for students and researchers.

Strengths:

Weaknesses:

Opportunities:

Threats:

Technological convergence represents a dominant trend as electrolyte development increasingly integrates with broader battery system optimization. Artificial intelligence and machine learning applications are accelerating electrolyte formulation development by enabling rapid screening of chemical compositions and performance prediction. Digital twin technologies allow virtual testing and optimization of electrolyte performance under various operating conditions.

Sustainability focus is driving development of environmentally friendly electrolyte formulations with reduced environmental impact throughout the lifecycle. Bio-based electrolytes derived from renewable sources are gaining attention as alternatives to petroleum-based formulations. Recycling technologies for electrolyte recovery and reuse are becoming increasingly important as circular economy principles gain prominence.

Safety enhancement continues as a critical trend with development of flame-retardant and non-flammable electrolyte formulations. Thermal runaway prevention technologies are being integrated into electrolyte designs to improve battery safety characteristics. Smart electrolytes with self-healing properties and built-in safety mechanisms represent emerging innovations.

Performance optimization trends focus on achieving higher energy density, faster charging capabilities, and extended battery life through advanced electrolyte chemistry. Fast-charging electrolytes capable of supporting ultra-rapid charging rates above 350kW are becoming commercially viable. Wide temperature range electrolytes enable electric vehicle operation in extreme climatic conditions.

Manufacturing innovation includes development of continuous production processes, automated quality control systems, and modular manufacturing approaches that enable flexible production scaling. Industry 4.0 technologies are being implemented to optimize manufacturing efficiency and quality consistency.

Recent industry developments highlight the dynamic nature of the UK electric vehicle battery electrolyte market with significant investments, partnerships, and technological breakthroughs shaping the competitive landscape. Manufacturing capacity expansion represents a major trend as companies establish or expand UK production facilities to serve growing domestic and European demand.

Strategic partnerships between automotive manufacturers and electrolyte suppliers are becoming more common as companies seek to secure supply chains and accelerate technology development. Joint ventures combining automotive expertise with chemical manufacturing capabilities are creating new market dynamics and competitive advantages.

Government initiatives including the Automotive Transformation Fund and Faraday Battery Challenge are providing substantial funding for battery technology development and manufacturing capability building. Research grants supporting university-industry collaborations are accelerating innovation in electrolyte technologies.

Regulatory developments including updated safety standards and environmental regulations are influencing product development priorities and market requirements. Certification processes for automotive applications are becoming more standardized, facilitating market entry for new technologies.

International expansion by UK-based companies is increasing as domestic expertise gains recognition in global markets. Export agreements and technology licensing deals are generating additional revenue streams while supporting the UK’s trade objectives in advanced manufacturing sectors.

Strategic recommendations for market participants emphasize the importance of balancing short-term market opportunities with long-term technology development investments. Portfolio diversification across different electrolyte technologies and applications can help companies manage risks while capturing growth opportunities across multiple market segments.

Investment priorities should focus on solid-state electrolyte research and development as this technology represents the most significant long-term opportunity for performance improvements and market differentiation. Manufacturing capability building through domestic production facilities can provide supply chain security and cost advantages while supporting UK economic development objectives.

Partnership strategies with automotive manufacturers, research institutions, and international technology companies can accelerate innovation and market access while sharing development costs and risks. Collaborative research programs can leverage complementary expertise and resources to address complex technical challenges.

Market positioning should emphasize unique value propositions such as safety improvements, performance enhancements, or sustainability benefits rather than competing solely on cost. Differentiation strategies based on technical expertise and innovation can command premium pricing and build sustainable competitive advantages.

Regulatory compliance should be viewed as an opportunity to demonstrate leadership in safety and environmental responsibility rather than merely a cost burden. Proactive engagement with regulatory development processes can help shape standards in favorable directions while building credibility with customers and stakeholders.

Long-term prospects for the UK electric vehicle battery electrolyte market remain highly positive, driven by sustained government support, technological advancement, and growing consumer acceptance of electric vehicles. Market expansion is expected to continue at robust rates as electric vehicle adoption accelerates and new applications emerge in energy storage and industrial sectors.

Technology evolution will likely center on solid-state electrolyte commercialization, with MarkWide Research projecting that solid-state technologies could capture approximately 35% market share by 2030 as manufacturing costs decline and performance advantages become more pronounced. Next-generation formulations incorporating advanced additives and novel chemical compositions will enable continued performance improvements.

Manufacturing landscape transformation is anticipated as companies establish larger-scale production facilities and implement advanced manufacturing technologies. Automation and digitalization will improve production efficiency and quality consistency while reducing manufacturing costs. Supply chain localization efforts will continue as companies seek to reduce dependence on international suppliers.

Market consolidation may occur as smaller players are acquired by larger companies seeking to expand capabilities or market access. Strategic alliances and joint ventures will likely increase as companies combine resources to address complex technical challenges and market requirements.

Global competitiveness of UK companies is expected to strengthen as domestic expertise and manufacturing capabilities mature. Export opportunities will expand as international markets recognize the quality and innovation of UK electrolyte technologies. Economic impact from the growing industry will contribute significantly to UK manufacturing sector growth and employment creation.

The United Kingdom electric vehicle battery electrolyte market represents a dynamic and rapidly evolving sector with substantial growth potential driven by government policy support, technological innovation, and increasing electric vehicle adoption. Market fundamentals remain strong with robust demand projections, expanding manufacturing capabilities, and continuous technology advancement creating favorable conditions for sustained growth.

Strategic positioning of the UK market benefits from established automotive industry expertise, world-class research institutions, and supportive government policies that collectively create a competitive advantage in the global electrolyte market. Technology leadership in emerging areas such as solid-state electrolytes and sustainable formulations positions UK companies for long-term success in evolving market conditions.

Investment opportunities across the value chain from research and development through manufacturing and distribution offer attractive prospects for companies seeking exposure to the growing electric vehicle ecosystem. Collaborative approaches combining industry expertise with academic research capabilities will likely drive the most significant innovations and market breakthroughs.

Future success in the UK electric vehicle battery electrolyte market will depend on companies’ ability to balance immediate market opportunities with long-term technology development investments while building sustainable competitive advantages through innovation, partnerships, and operational excellence. The market’s trajectory toward continued expansion and technological sophistication creates compelling opportunities for well-positioned participants across the industry ecosystem.

What is Electric Vehicle Battery Electrolyte?

Electric Vehicle Battery Electrolyte refers to the medium that allows the flow of ions between the anode and cathode in a battery, crucial for energy storage and transfer in electric vehicles. It plays a significant role in determining the battery’s performance, safety, and longevity.

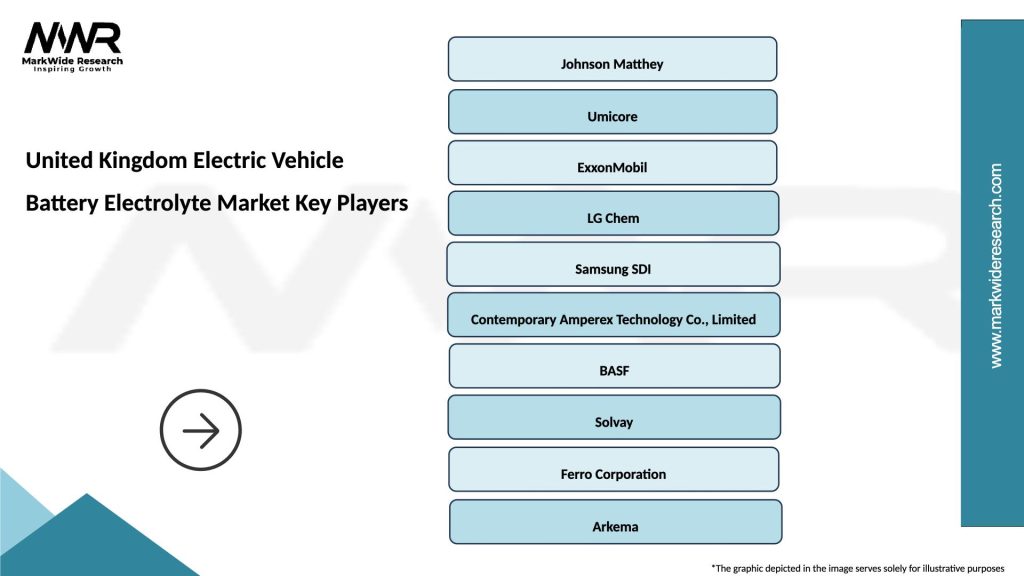

What are the key players in the United Kingdom Electric Vehicle Battery Electrolyte Market?

Key players in the United Kingdom Electric Vehicle Battery Electrolyte Market include companies like Johnson Matthey, BASF, and Umicore, which are involved in the development and supply of advanced electrolyte solutions for electric vehicle batteries, among others.

What are the growth factors driving the United Kingdom Electric Vehicle Battery Electrolyte Market?

The growth of the United Kingdom Electric Vehicle Battery Electrolyte Market is driven by the increasing demand for electric vehicles, advancements in battery technology, and government initiatives promoting sustainable transportation solutions.

What challenges does the United Kingdom Electric Vehicle Battery Electrolyte Market face?

Challenges in the United Kingdom Electric Vehicle Battery Electrolyte Market include the high cost of advanced materials, safety concerns related to electrolyte stability, and the need for improved recycling processes for used batteries.

What opportunities exist in the United Kingdom Electric Vehicle Battery Electrolyte Market?

Opportunities in the United Kingdom Electric Vehicle Battery Electrolyte Market include the development of solid-state electrolytes, which promise enhanced safety and performance, and the growing trend towards electric vehicle adoption in various sectors, including public transport and logistics.

What trends are shaping the United Kingdom Electric Vehicle Battery Electrolyte Market?

Trends in the United Kingdom Electric Vehicle Battery Electrolyte Market include the shift towards sustainable and eco-friendly materials, innovations in electrolyte formulations to improve battery efficiency, and increased collaboration between automotive manufacturers and electrolyte suppliers.

United Kingdom Electric Vehicle Battery Electrolyte Market

| Segmentation Details | Description |

|---|---|

| Product Type | Liquid Electrolyte, Solid Electrolyte, Gel Electrolyte, Polymer Electrolyte |

| End User | OEMs, Aftermarket Providers, Fleet Operators, Charging Infrastructure |

| Technology | Lithium-Ion, Solid-State, Flow Battery, Sodium-Ion |

| Application | Passenger Vehicles, Commercial Vehicles, Two-Wheelers, Energy Storage Systems |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the United Kingdom Electric Vehicle Battery Electrolyte Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at