444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The United Arab Emirates flexible plastic packaging market represents a dynamic and rapidly evolving sector within the broader packaging industry. This market encompasses a wide range of applications including food and beverage packaging, pharmaceutical packaging, personal care products, and industrial applications. The UAE’s strategic position as a regional hub for trade and commerce has significantly contributed to the growth of flexible plastic packaging solutions across various industries.

Market dynamics in the UAE are driven by several key factors including urbanization, changing consumer preferences, and the country’s vision to become a leading logistics and manufacturing hub in the Middle East. The flexible plastic packaging sector has experienced substantial growth with adoption rates increasing by approximately 12% annually across different application segments. This growth trajectory reflects the increasing demand for convenient, lightweight, and cost-effective packaging solutions that meet modern consumer expectations.

Regional positioning plays a crucial role in market development, with the UAE serving as a gateway for flexible packaging solutions throughout the Gulf Cooperation Council (GCC) region. The country’s advanced infrastructure, strategic location, and business-friendly policies have attracted numerous international packaging manufacturers and suppliers, creating a competitive and innovative market environment.

The United Arab Emirates flexible plastic packaging market refers to the comprehensive ecosystem of flexible packaging solutions manufactured, distributed, and consumed within the UAE territory. This market encompasses various types of flexible packaging materials including polyethylene films, polypropylene films, polyester films, and multi-layer barrier films designed for diverse applications across multiple industries.

Flexible plastic packaging is characterized by its ability to conform to the shape of the product it contains, offering superior protection, extended shelf life, and enhanced convenience compared to rigid packaging alternatives. These packaging solutions are typically manufactured using advanced extrusion, lamination, and printing technologies that enable customization for specific product requirements and branding needs.

Market scope includes both domestic production facilities and imported packaging solutions, serving local manufacturers, retailers, and end consumers. The market encompasses various packaging formats such as pouches, bags, wraps, films, and specialized barrier packaging designed to meet specific industry requirements including food safety standards, pharmaceutical regulations, and industrial specifications.

Strategic market analysis reveals that the UAE flexible plastic packaging market has emerged as a critical component of the country’s manufacturing and retail sectors. The market demonstrates robust growth potential driven by increasing consumer demand for convenient packaging solutions, expanding retail infrastructure, and growing emphasis on product safety and quality preservation.

Key market segments include food and beverage packaging, which accounts for approximately 45% of market demand, followed by pharmaceutical and healthcare packaging, personal care products, and industrial applications. The food packaging segment particularly benefits from the UAE’s growing food processing industry and increasing consumer preference for packaged and convenience foods.

Technological advancement represents a significant market driver, with manufacturers increasingly adopting advanced barrier technologies, sustainable materials, and smart packaging solutions. The integration of digital printing capabilities and customization options has enhanced the market’s ability to serve diverse customer requirements while maintaining cost-effectiveness and operational efficiency.

Market outlook remains positive with projected growth rates of 8-10% annually over the next five years, supported by continued economic diversification, population growth, and increasing consumer spending on packaged goods. The market is expected to benefit from ongoing infrastructure development and the UAE’s strategic initiatives to enhance its position as a regional manufacturing and logistics hub.

Market intelligence indicates several critical insights that shape the UAE flexible plastic packaging landscape:

Economic diversification initiatives undertaken by the UAE government have created a favorable environment for flexible plastic packaging market growth. The country’s focus on developing manufacturing capabilities and reducing dependence on oil revenues has led to increased investment in packaging infrastructure and technology advancement.

Population growth and urbanization represent fundamental market drivers, with the UAE’s population continuing to expand and urban centers experiencing rapid development. This demographic shift has resulted in increased demand for packaged goods, convenience foods, and consumer products that rely heavily on flexible plastic packaging solutions.

Retail sector expansion has significantly contributed to market growth, with the proliferation of modern retail formats including hypermarkets, supermarkets, and convenience stores. These retail channels require sophisticated packaging solutions that ensure product quality, extend shelf life, and provide attractive presentation to consumers.

Food processing industry development has emerged as a critical driver, with numerous international and domestic food manufacturers establishing operations in the UAE. This industrial growth has created substantial demand for specialized flexible packaging solutions that meet food safety standards and regulatory requirements while maintaining cost-effectiveness.

E-commerce growth has introduced new packaging requirements, with online retailers demanding flexible packaging solutions that provide product protection during shipping while minimizing packaging waste and transportation costs. This trend has accelerated the adoption of innovative flexible packaging formats designed specifically for e-commerce applications.

Environmental concerns regarding plastic waste and sustainability have emerged as significant market restraints. Increasing awareness about environmental impact has led to regulatory pressures and consumer demands for more sustainable packaging alternatives, challenging traditional flexible plastic packaging approaches.

Raw material price volatility represents a persistent challenge for market participants, with fluctuating petroleum prices directly impacting the cost of plastic resins and other packaging materials. This volatility affects profit margins and pricing strategies across the supply chain.

Regulatory compliance requirements have become increasingly stringent, particularly in food contact applications and pharmaceutical packaging. Meeting these regulatory standards requires significant investment in quality control systems, testing procedures, and certification processes that can increase operational costs.

Competition from alternative packaging materials including paper-based solutions, biodegradable materials, and rigid packaging formats presents ongoing challenges. These alternatives often appeal to environmentally conscious consumers and businesses seeking to reduce their environmental footprint.

Skilled workforce shortage in specialized packaging technologies and quality control processes has constrained market growth in certain segments. The need for technical expertise in advanced packaging technologies requires ongoing investment in training and development programs.

Sustainable packaging innovation presents significant opportunities for market expansion, with growing demand for recyclable, biodegradable, and compostable flexible packaging solutions. Companies investing in sustainable technologies and materials are positioned to capture increasing market share as environmental consciousness continues to grow.

Smart packaging technologies offer substantial growth potential, including the integration of sensors, QR codes, and other digital technologies that enhance product traceability, safety monitoring, and consumer engagement. These advanced packaging solutions command premium pricing and create competitive advantages.

Pharmaceutical sector expansion represents a high-value opportunity, with the UAE’s growing healthcare industry requiring specialized flexible packaging solutions for medications, medical devices, and healthcare products. This segment typically offers higher margins and long-term customer relationships.

Export market development leveraging the UAE’s strategic location and logistics infrastructure provides opportunities to serve broader regional markets. The country’s position as a regional hub enables packaging manufacturers to efficiently serve customers across the Middle East and Africa.

Customization and personalization trends create opportunities for specialized packaging solutions that meet specific customer requirements. Digital printing technologies and flexible manufacturing processes enable cost-effective customization that appeals to brand owners seeking differentiation.

Supply chain integration has become increasingly important in the UAE flexible plastic packaging market, with manufacturers seeking to optimize operations through vertical integration and strategic partnerships. This integration enables better cost control, quality assurance, and customer service delivery.

Technology adoption continues to reshape market dynamics, with automation, digital printing, and advanced materials processing technologies improving efficiency and product quality. Companies investing in modern equipment and processes gain competitive advantages through reduced costs and enhanced capabilities.

Customer relationship management has evolved to focus on long-term partnerships rather than transactional relationships. Packaging suppliers are increasingly providing value-added services including design consultation, technical support, and supply chain optimization to strengthen customer loyalty.

Market consolidation trends are evident as larger companies acquire smaller players to expand capabilities, geographic reach, and customer bases. This consolidation creates opportunities for improved efficiency and market coverage while potentially reducing competition in certain segments.

Innovation cycles are accelerating as companies respond to changing customer needs and regulatory requirements. The pace of new product development and technology implementation has increased significantly, requiring continuous investment in research and development capabilities.

Comprehensive market analysis was conducted using a multi-faceted research approach combining primary and secondary research methodologies. The research framework incorporated quantitative data analysis, qualitative insights from industry experts, and detailed examination of market trends and competitive dynamics.

Primary research activities included structured interviews with key industry stakeholders including packaging manufacturers, raw material suppliers, end-user companies, and regulatory authorities. These interviews provided valuable insights into market challenges, opportunities, and future trends that shape the flexible plastic packaging landscape in the UAE.

Secondary research encompassed analysis of industry reports, government publications, trade association data, and company financial statements. This research provided quantitative market data, historical trends, and comparative analysis across different market segments and geographic regions.

Data validation processes ensured accuracy and reliability of research findings through cross-referencing multiple sources, expert review, and statistical analysis. The research methodology incorporated quality control measures to maintain high standards of data integrity and analytical rigor.

Market modeling techniques were employed to project future market trends and growth scenarios based on historical data, current market conditions, and identified growth drivers. These models provide framework for understanding potential market developments and strategic planning considerations.

Dubai emirate represents the largest market segment within the UAE, accounting for approximately 40% of total market demand. The emirate’s position as a commercial and logistics hub, combined with its large population and extensive retail infrastructure, drives substantial demand for flexible plastic packaging across all application segments.

Abu Dhabi emirate constitutes approximately 35% of market share, supported by significant industrial development, government sector demand, and growing retail presence. The emirate’s focus on economic diversification and manufacturing development has created substantial opportunities for packaging suppliers.

Sharjah emirate accounts for roughly 15% of market demand, with strong industrial base and manufacturing activities driving packaging requirements. The emirate’s strategic location and industrial infrastructure make it an important market for flexible packaging applications in manufacturing and logistics sectors.

Northern emirates including Ajman, Ras Al Khaimah, Fujairah, and Umm Al Quwain collectively represent approximately 10% of market share. These emirates are experiencing growing demand driven by population growth, retail development, and increasing industrial activities.

Regional distribution networks have evolved to efficiently serve customers across all emirates, with major suppliers establishing distribution centers and service facilities in key locations. This geographic coverage ensures reliable supply chain performance and customer support throughout the UAE market.

Market leadership is distributed among several key players who have established strong positions through strategic investments, technological capabilities, and customer relationships. The competitive environment is characterized by both international companies and regional players competing across different market segments.

Competitive strategies focus on differentiation through technology advancement, customer service excellence, and specialized application expertise. Companies are investing in modern equipment, quality systems, and technical capabilities to maintain competitive advantages in their target market segments.

By Material Type:

By Application:

By End-User:

Food packaging applications demonstrate the strongest growth dynamics, driven by expanding food processing industry and changing consumer preferences toward packaged and convenience foods. This category benefits from increasing demand for extended shelf life, portion control, and attractive product presentation that flexible packaging provides effectively.

Pharmaceutical packaging represents the highest value segment with stringent quality requirements and regulatory compliance needs. This category requires specialized materials, clean room manufacturing environments, and comprehensive documentation systems that create barriers to entry but offer attractive profit margins for qualified suppliers.

Personal care packaging shows consistent growth driven by increasing consumer spending on cosmetics, toiletries, and health products. This category emphasizes aesthetic appeal, brand differentiation, and convenience features that showcase the versatility of flexible packaging solutions.

Industrial packaging applications provide stable demand from manufacturing and agricultural sectors requiring durable, cost-effective packaging solutions. This category focuses on functional performance, chemical compatibility, and supply chain efficiency rather than aesthetic considerations.

Sustainable packaging solutions are emerging as a distinct category across all applications, with customers increasingly demanding environmentally friendly alternatives. This category represents significant growth potential as regulatory requirements and consumer preferences continue to favor sustainable packaging options.

Manufacturers benefit from flexible plastic packaging through reduced material costs, improved production efficiency, and enhanced product protection. The lightweight nature of flexible packaging reduces transportation costs while providing excellent barrier properties that extend product shelf life and reduce waste throughout the supply chain.

Retailers gain advantages through improved inventory management, reduced storage space requirements, and enhanced product presentation capabilities. Flexible packaging enables efficient space utilization in retail environments while providing attractive branding opportunities that support sales and customer engagement.

Consumers experience benefits including product freshness, convenience features, and portion control options that enhance their purchasing and consumption experience. Flexible packaging often provides resealable features, easy opening mechanisms, and transparent windows that improve usability and product visibility.

Environmental stakeholders benefit from reduced material usage, lower transportation emissions, and increasing availability of recyclable and biodegradable flexible packaging options. The lightweight nature of flexible packaging contributes to reduced carbon footprint throughout the product lifecycle.

Supply chain participants realize advantages through improved logistics efficiency, reduced handling costs, and enhanced product protection during transportation and storage. Flexible packaging’s durability and space efficiency optimize supply chain operations while minimizing product damage and loss.

Strengths:

Weaknesses:

Opportunities:

Threats:

Sustainability transformation represents the most significant trend reshaping the UAE flexible plastic packaging market. Companies are increasingly investing in recyclable materials, biodegradable alternatives, and circular economy approaches that address environmental concerns while maintaining packaging performance and cost-effectiveness.

Digital integration is revolutionizing packaging applications through smart labels, QR codes, and IoT-enabled packaging solutions that enhance product traceability, consumer engagement, and supply chain visibility. These technologies create new value propositions and differentiation opportunities for packaging suppliers.

Customization and personalization trends are driving demand for flexible manufacturing processes that enable small-batch production, variable data printing, and specialized packaging formats. Digital printing technologies and flexible production systems support these customization requirements cost-effectively.

E-commerce optimization has emerged as a critical trend with packaging solutions specifically designed for online retail applications. These solutions prioritize product protection during shipping, space efficiency, and consumer unboxing experience while minimizing packaging waste.

Health and safety focus has intensified following global health concerns, with increased demand for antimicrobial packaging, tamper-evident features, and enhanced barrier properties that ensure product safety and consumer confidence.

Manufacturing capacity expansion has been a prominent development with several companies investing in new production facilities and equipment upgrades to meet growing market demand. These investments focus on advanced technologies that improve efficiency, quality, and environmental performance.

Strategic partnerships between packaging manufacturers and end-user companies have increased, creating collaborative relationships that drive innovation and ensure supply chain security. These partnerships often involve joint development of specialized packaging solutions and long-term supply agreements.

Technology acquisitions and licensing agreements have enabled UAE companies to access advanced packaging technologies and manufacturing processes. These developments enhance competitive capabilities and enable entry into higher-value market segments.

Regulatory compliance initiatives have driven industry-wide improvements in quality systems, environmental management, and product safety standards. Companies are investing in certifications and compliance systems that meet international requirements and customer expectations.

Sustainability programs have been launched by major industry players, including recycling initiatives, sustainable material development, and waste reduction programs. These developments demonstrate industry commitment to environmental responsibility and regulatory compliance.

MarkWide Research analysis indicates that companies should prioritize investment in sustainable packaging technologies and materials to address growing environmental concerns and regulatory requirements. This strategic focus will position companies favorably as market preferences continue to shift toward environmentally responsible packaging solutions.

Technology integration should be a key strategic priority, with companies investing in digital printing capabilities, automation systems, and smart packaging technologies that enhance operational efficiency and create new value propositions for customers. These investments will support long-term competitive advantages and market differentiation.

Market diversification strategies should focus on expanding into high-value segments such as pharmaceutical packaging, specialty food applications, and export markets. This diversification reduces dependence on traditional market segments while accessing higher-margin opportunities.

Partnership development with key customers, suppliers, and technology providers should be prioritized to create collaborative relationships that drive innovation and ensure market access. These partnerships can provide competitive advantages through shared resources and expertise.

Workforce development programs should be implemented to address skilled labor shortages and build technical capabilities required for advanced packaging technologies. Investment in training and development will support operational excellence and innovation capabilities.

Market growth prospects remain positive with projected expansion driven by continued economic development, population growth, and increasing consumer demand for packaged goods. The market is expected to benefit from ongoing infrastructure development and the UAE’s strategic initiatives to enhance its position as a regional manufacturing hub.

Technological advancement will continue to reshape the market landscape with increasing adoption of sustainable materials, smart packaging solutions, and automated manufacturing processes. Companies investing in these technologies will gain competitive advantages and access to premium market segments.

Regulatory evolution is expected to drive further emphasis on environmental sustainability, product safety, and quality standards. Companies that proactively address these regulatory trends will be better positioned for long-term success and market leadership.

Regional integration opportunities will expand as the UAE leverages its strategic location and logistics infrastructure to serve broader Middle East and African markets. This regional expansion will provide growth opportunities and scale economies for UAE-based packaging companies.

Innovation acceleration will continue as companies respond to changing customer needs and competitive pressures. The pace of new product development and technology implementation is expected to increase, requiring continuous investment in research and development capabilities to maintain market competitiveness.

The United Arab Emirates flexible plastic packaging market represents a dynamic and evolving sector with substantial growth potential driven by economic diversification, population expansion, and changing consumer preferences. The market demonstrates resilience and adaptability in responding to challenges while capitalizing on emerging opportunities in sustainability, technology integration, and regional expansion.

Strategic positioning of the UAE as a regional trade and logistics hub provides significant advantages for flexible packaging companies seeking to serve broader Middle East and African markets. The country’s advanced infrastructure, business-friendly environment, and strategic location create favorable conditions for market development and expansion.

Future success in this market will depend on companies’ ability to adapt to changing regulatory requirements, embrace sustainable packaging solutions, and invest in advanced technologies that meet evolving customer needs. The integration of digital technologies, sustainable materials, and innovative packaging formats will be critical for maintaining competitive advantages and accessing premium market segments.

Market outlook remains optimistic with continued growth expected across all major application segments, supported by ongoing economic development and increasing consumer demand for high-quality packaging solutions. Companies that strategically position themselves to address sustainability concerns, leverage technological advancement, and build strong customer relationships will be well-positioned to capitalize on the significant opportunities available in the UAE flexible plastic packaging market.

What is Flexible Plastic Packaging?

Flexible Plastic Packaging refers to packaging made from flexible materials that can be easily shaped and molded. It is widely used in various applications such as food packaging, consumer goods, and medical supplies due to its lightweight and versatile nature.

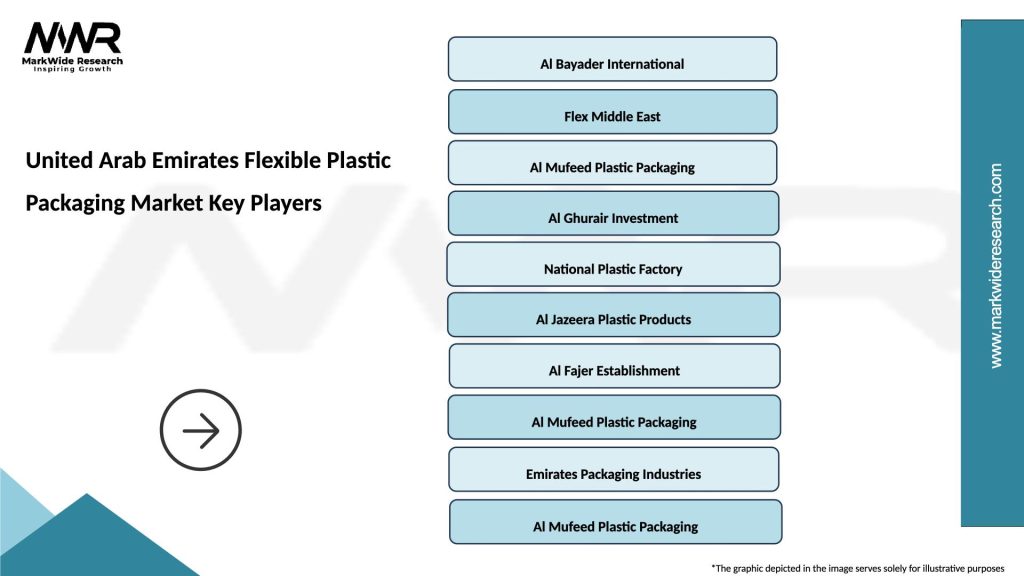

What are the key players in the United Arab Emirates Flexible Plastic Packaging Market?

Key players in the United Arab Emirates Flexible Plastic Packaging Market include Al Bayader International, Gulf Plastic Industries, and National Plastic Factory, among others.

What are the growth factors driving the United Arab Emirates Flexible Plastic Packaging Market?

The growth of the United Arab Emirates Flexible Plastic Packaging Market is driven by increasing demand for convenient packaging solutions, the rise of e-commerce, and a growing focus on sustainable packaging options.

What challenges does the United Arab Emirates Flexible Plastic Packaging Market face?

Challenges in the United Arab Emirates Flexible Plastic Packaging Market include regulatory pressures regarding plastic waste, competition from alternative packaging materials, and fluctuating raw material prices.

What opportunities exist in the United Arab Emirates Flexible Plastic Packaging Market?

Opportunities in the United Arab Emirates Flexible Plastic Packaging Market include the development of biodegradable packaging solutions, innovations in packaging technology, and expanding applications in the food and beverage sector.

What trends are shaping the United Arab Emirates Flexible Plastic Packaging Market?

Trends in the United Arab Emirates Flexible Plastic Packaging Market include a shift towards eco-friendly materials, increased automation in packaging processes, and the growing popularity of resealable and multi-use packaging designs.

United Arab Emirates Flexible Plastic Packaging Market

| Segmentation Details | Description |

|---|---|

| Product Type | Stand-Up Pouches, Shrink Films, Rigid Containers, Flexible Bags |

| Material | Polyethylene, Polypropylene, Polyvinyl Chloride, Bioplastics |

| End User | Food & Beverage, Personal Care, Pharmaceuticals, Household Products |

| Packaging Type | Retail Packaging, Bulk Packaging, Industrial Packaging, Others |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the United Arab Emirates Flexible Plastic Packaging Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at