444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The United Arab Emirates data center cooling market represents a rapidly expanding segment within the region’s digital infrastructure ecosystem. As the UAE continues its transformation into a global technology hub, the demand for efficient and reliable data center cooling solutions has reached unprecedented levels. The market is experiencing robust growth, driven by the exponential increase in data generation, cloud computing adoption, and the government’s ambitious digitalization initiatives.

Market dynamics indicate that the UAE’s strategic position as a regional data hub has attracted significant investments from global technology giants and local enterprises alike. The harsh desert climate, with temperatures often exceeding 45°C during summer months, presents unique challenges that require sophisticated cooling technologies. This environmental factor has created a specialized market segment focused on energy-efficient and climate-adapted cooling solutions.

Growth projections suggest the market is expanding at a compound annual growth rate (CAGR) of 12.8%, reflecting the increasing digitalization across various sectors including banking, telecommunications, government services, and e-commerce. The UAE’s position as a regional financial center and its growing status as a technology innovation hub continue to drive demand for advanced data center infrastructure, with cooling systems representing a critical component of operational efficiency.

Regional leadership in smart city initiatives, particularly in Dubai and Abu Dhabi, has further accelerated the adoption of cutting-edge data center technologies. The market encompasses various cooling methodologies, from traditional air-based systems to innovative liquid cooling solutions and hybrid approaches designed to optimize energy consumption while maintaining optimal operating temperatures.

The United Arab Emirates data center cooling market refers to the comprehensive ecosystem of technologies, systems, and services designed to maintain optimal operating temperatures within data center facilities across the UAE. This market encompasses all thermal management solutions required to ensure reliable operation of IT equipment, servers, storage systems, and networking infrastructure in the region’s challenging climatic conditions.

Core components of this market include precision air conditioning systems, liquid cooling solutions, free cooling technologies, containment systems, and advanced monitoring and control mechanisms. The market also encompasses related services such as installation, maintenance, energy optimization, and system upgrades that ensure continuous and efficient cooling operations.

Technological scope extends from traditional computer room air conditioning (CRAC) units to sophisticated immersion cooling systems, reflecting the diverse needs of different data center configurations. The market addresses cooling requirements for various facility types, including enterprise data centers, colocation facilities, edge computing sites, and hyperscale installations that serve the UAE’s growing digital economy.

Strategic positioning of the UAE as a regional technology and business hub has created substantial opportunities within the data center cooling market. The convergence of government digitalization initiatives, private sector digital transformation, and the region’s role as a connectivity bridge between Asia, Europe, and Africa has established a robust foundation for market growth.

Market segmentation reveals diverse cooling approaches, with air-based cooling systems currently maintaining the largest market share at approximately 68% of total installations. However, liquid cooling solutions are gaining significant traction, particularly in high-density computing environments and AI-focused data centers, representing the fastest-growing segment with adoption rates increasing by 35% annually.

Investment patterns indicate strong capital allocation toward energy-efficient cooling technologies, driven by both environmental considerations and operational cost optimization. The UAE’s commitment to achieving net-zero emissions by 2050 has accelerated the adoption of sustainable cooling solutions, with free cooling and hybrid systems experiencing increased deployment across new data center projects.

Competitive landscape features a mix of international technology leaders and regional specialists, creating a dynamic market environment that fosters innovation and competitive pricing. The market benefits from the UAE’s business-friendly environment, strategic location, and robust infrastructure development programs that support continued expansion of data center operations.

Primary market drivers encompass several interconnected factors that collectively fuel demand for advanced cooling solutions:

Technology evolution within the market reflects the ongoing shift toward more sophisticated and efficient cooling methodologies. Traditional approaches are being supplemented and, in some cases, replaced by innovative solutions that address both performance requirements and sustainability objectives.

Government digitalization initiatives serve as the primary catalyst for data center cooling market expansion in the UAE. The UAE Government Strategy 2071 and various smart city programs have created substantial demand for digital infrastructure, directly translating into increased requirements for reliable cooling solutions. These initiatives have established the foundation for sustained market growth across multiple sectors.

Climate challenges unique to the UAE region have created specialized market opportunities for cooling technology providers. The extreme heat conditions, with ambient temperatures regularly exceeding international data center design standards, require innovative approaches to thermal management. This environmental factor has driven the development of region-specific cooling solutions that optimize performance under challenging conditions.

Energy efficiency mandates implemented by local authorities have accelerated the adoption of advanced cooling technologies. The UAE’s commitment to sustainable development and carbon neutrality has created regulatory frameworks that favor energy-efficient cooling solutions, driving market demand for technologies that reduce power consumption while maintaining optimal performance levels.

Digital economy growth across various sectors including fintech, e-commerce, logistics, and telecommunications has created diverse cooling requirements. Each sector presents unique operational patterns and performance requirements, driving demand for customized cooling solutions that address specific application needs while maintaining cost-effectiveness and reliability.

Foreign investment attraction policies have encouraged international technology companies to establish regional operations in the UAE, creating substantial demand for world-class data center infrastructure. These investments require cooling solutions that meet international standards while adapting to local environmental conditions, creating opportunities for both global and regional cooling technology providers.

High initial capital requirements represent a significant barrier to market entry and expansion, particularly for advanced cooling technologies such as liquid cooling systems and sophisticated containment solutions. The substantial upfront investment required for cutting-edge cooling infrastructure can limit adoption among smaller enterprises and startups, potentially slowing overall market growth in certain segments.

Technical complexity associated with implementing and maintaining advanced cooling systems creates challenges for organizations lacking specialized expertise. The integration of sophisticated cooling technologies with existing infrastructure requires skilled personnel and comprehensive training programs, which may not be readily available in all market segments or geographic locations within the UAE.

Water scarcity concerns in the UAE region limit the deployment of certain cooling technologies that rely heavily on water consumption. Traditional evaporative cooling systems and some liquid cooling approaches face restrictions due to the region’s water conservation priorities, requiring alternative solutions that may be more expensive or less efficient in certain applications.

Regulatory compliance complexity can create implementation delays and additional costs for cooling system deployments. Navigating various environmental, safety, and building code requirements across different emirates and free zones requires specialized knowledge and may extend project timelines, potentially impacting market growth rates.

Supply chain dependencies on international manufacturers for specialized cooling components can create vulnerabilities in project delivery and maintenance operations. Global supply chain disruptions, trade restrictions, or currency fluctuations can impact the availability and cost of critical cooling system components, affecting market stability and growth predictability.

Sustainability-focused innovations present substantial opportunities for cooling technology providers who can develop solutions that align with the UAE’s environmental objectives. The growing emphasis on green data centers and carbon-neutral operations creates demand for cooling systems that minimize environmental impact while maintaining optimal performance levels.

Edge computing expansion across the UAE creates opportunities for modular and distributed cooling solutions. As computing resources move closer to end-users through edge deployments, there is increasing demand for compact, efficient cooling systems that can operate reliably in diverse environments, from urban centers to remote locations.

Artificial intelligence integration in cooling system management offers opportunities for providers who can develop intelligent solutions that optimize performance automatically. AI-powered cooling systems that adapt to changing conditions, predict maintenance requirements, and optimize energy consumption represent a growing market segment with significant potential.

Retrofit and modernization projects in existing data centers create opportunities for cooling system upgrades and replacements. As older facilities seek to improve efficiency and reduce operating costs, there is substantial demand for modern cooling solutions that can integrate with legacy infrastructure while delivering improved performance.

Public-private partnerships in smart city and digital infrastructure projects offer opportunities for cooling technology providers to participate in large-scale deployments. These collaborations can provide access to substantial projects while contributing to the UAE’s broader digitalization objectives, creating win-win scenarios for all stakeholders.

Competitive intensity within the UAE data center cooling market continues to increase as both international and regional players vie for market share. This competition has driven innovation, improved service quality, and more competitive pricing structures, ultimately benefiting end-users through enhanced value propositions and technological advancement.

Technology convergence is reshaping market dynamics as cooling solutions increasingly integrate with broader data center management systems. The convergence of cooling, power management, and monitoring technologies creates opportunities for comprehensive solutions while challenging traditional market boundaries and vendor relationships.

Customer sophistication has evolved significantly, with data center operators becoming more knowledgeable about cooling technologies and their impact on total cost of ownership. This trend has shifted market dynamics toward value-based selling, where providers must demonstrate clear ROI and performance benefits rather than competing solely on initial purchase price.

Regulatory evolution continues to influence market dynamics as environmental standards become more stringent and energy efficiency requirements increase. According to MarkWide Research analysis, regulatory changes are driving efficiency improvements of up to 30% in new cooling system deployments, reshaping competitive positioning and technology selection criteria.

Partnership ecosystems are becoming increasingly important as cooling technology providers collaborate with data center developers, system integrators, and service providers to deliver comprehensive solutions. These partnerships enable more effective market penetration while providing customers with integrated solutions that address multiple infrastructure requirements simultaneously.

Primary research methodology employed comprehensive data collection through structured interviews with key stakeholders across the UAE data center cooling ecosystem. This approach included discussions with data center operators, cooling technology vendors, system integrators, and regulatory officials to gather firsthand insights into market trends, challenges, and opportunities.

Secondary research analysis incorporated extensive review of industry publications, government reports, company financial statements, and technical documentation to validate primary findings and identify broader market patterns. This research phase ensured comprehensive coverage of market dynamics and provided historical context for current trends and future projections.

Market segmentation analysis utilized multiple classification frameworks to understand market structure and competitive positioning. Segmentation approaches included technology type, application sector, facility size, and geographic distribution within the UAE, providing detailed insights into market composition and growth patterns across different segments.

Competitive landscape mapping involved detailed analysis of major market participants, their product portfolios, market positioning, and strategic initiatives. This analysis included assessment of both direct competitors and adjacent technology providers who might enter the market, providing comprehensive understanding of competitive dynamics.

Trend analysis and forecasting incorporated quantitative modeling techniques combined with expert judgment to develop market projections and identify emerging trends. This methodology considered various scenarios and external factors that could influence market development, ensuring robust and realistic market outlook assessments.

Dubai emirate maintains the largest share of the UAE data center cooling market, accounting for approximately 45% of total installations. The emirate’s position as a regional business hub, combined with its advanced telecommunications infrastructure and strategic location, has attracted numerous data center investments that require sophisticated cooling solutions. Dubai’s free zones and business-friendly policies continue to drive demand for world-class cooling technologies.

Abu Dhabi region represents the second-largest market segment, with approximately 35% market share, driven by government digitalization initiatives and the presence of major financial institutions. The capital’s focus on sustainable development has created particular demand for energy-efficient cooling solutions that align with environmental objectives while supporting the emirate’s growing digital economy.

Northern Emirates including Sharjah, Ajman, Ras Al Khaimah, Fujairah, and Umm Al Quwain collectively account for the remaining 20% of market activity. These regions are experiencing growing demand for edge computing solutions and smaller-scale data center deployments that require modular and cost-effective cooling approaches tailored to local requirements and constraints.

Free zone concentrations across various emirates have created specialized market segments with unique cooling requirements. Dubai Internet City, Abu Dhabi Global Financial Centre, and other technology-focused free zones have established themselves as major consumers of advanced cooling technologies, driving innovation and competitive dynamics within the market.

Geographic distribution patterns reflect the UAE’s urban development and economic activity concentration. Coastal locations benefit from potential free cooling opportunities during cooler months, while inland facilities require more robust cooling solutions to address extreme temperature conditions throughout the year.

Market leadership is distributed among several key players who have established strong positions through different strategic approaches:

Regional players have also established significant market presence by focusing on local market knowledge, rapid service response, and cost-competitive solutions. These companies often partner with international technology providers to deliver comprehensive solutions that combine global innovation with regional expertise and support capabilities.

Competitive differentiation occurs across multiple dimensions including technology innovation, energy efficiency, service quality, local presence, and total cost of ownership. Market leaders are increasingly focusing on integrated solutions that combine cooling hardware with intelligent management software and comprehensive service offerings.

By Technology Type:

By Application Sector:

By Facility Size:

Precision Air Conditioning remains the dominant cooling category, representing the foundation of most data center thermal management strategies. These systems offer proven reliability, established maintenance procedures, and compatibility with existing infrastructure, making them the preferred choice for many enterprise deployments. Recent innovations in this category focus on improved efficiency and intelligent controls.

Liquid Cooling Solutions represent the fastest-growing category, driven by increasing server densities and specialized applications such as artificial intelligence and high-performance computing. MWR data indicates that liquid cooling adoption rates are increasing by 42% annually in high-density deployments, reflecting the technology’s superior thermal management capabilities for demanding applications.

Containment Systems have evolved from optional accessories to essential components of modern data center cooling strategies. Hot aisle and cold aisle containment solutions improve cooling efficiency by 25-35% while reducing energy consumption, making them increasingly popular across all facility types and sizes.

Free Cooling Technologies offer significant opportunities in the UAE market, particularly during cooler months when ambient conditions allow for reduced mechanical cooling requirements. These systems can achieve energy savings of 20-40% during favorable weather conditions, making them attractive for cost-conscious operators.

Monitoring and Control Systems have become increasingly sophisticated, incorporating artificial intelligence and machine learning capabilities to optimize cooling performance automatically. These systems enable efficiency improvements of 15-25% through predictive maintenance and dynamic optimization of cooling parameters.

Data Center Operators benefit from advanced cooling solutions through reduced operational costs, improved reliability, and enhanced sustainability credentials. Modern cooling systems can reduce energy consumption by 30-40% compared to legacy installations while providing better temperature control and system monitoring capabilities that minimize downtime risks.

Technology Vendors gain access to a growing market with diverse requirements that reward innovation and specialization. The UAE’s position as a regional hub creates opportunities for vendors to establish local presence and serve broader Middle East markets, while the demanding climate conditions drive premium pricing for high-performance solutions.

System Integrators benefit from the complexity of modern cooling deployments, which require specialized expertise in design, installation, and commissioning. The integration of cooling systems with broader data center infrastructure creates opportunities for comprehensive service offerings and long-term customer relationships.

End-User Organizations achieve improved IT performance, reduced operational risks, and better cost predictability through modern cooling solutions. Advanced systems provide better temperature control, reduced maintenance requirements, and improved energy efficiency that directly impacts total cost of ownership.

Government Entities advance their digitalization objectives while achieving sustainability goals through the deployment of efficient cooling technologies. Modern systems support the UAE’s smart city initiatives and carbon neutrality commitments while enabling the digital infrastructure required for economic diversification.

Strengths:

Weaknesses:

Opportunities:

Threats:

Artificial Intelligence Integration is transforming cooling system management through predictive analytics, automated optimization, and intelligent maintenance scheduling. AI-powered cooling systems can reduce energy consumption by 20-30% while improving reliability through predictive failure detection and proactive maintenance interventions.

Sustainability Prioritization has become a dominant trend as organizations seek to reduce their environmental impact and align with the UAE’s carbon neutrality objectives. This trend is driving adoption of energy-efficient cooling technologies, renewable energy integration, and circular economy principles in cooling system design and operation.

Edge Computing Proliferation is creating demand for distributed cooling solutions that can operate autonomously in diverse environments. Edge deployments require cooling systems that are compact, reliable, and capable of remote monitoring and management, driving innovation in modular cooling technologies.

Liquid Cooling Adoption is accelerating as server densities increase and specialized applications such as AI and cryptocurrency mining require superior thermal management. Direct-to-chip and immersion cooling solutions are becoming mainstream for high-performance computing applications that cannot be adequately cooled by traditional air-based systems.

Service-Oriented Models are gaining popularity as organizations seek to reduce capital expenditure and transfer operational risks to specialized providers. Cooling-as-a-Service models enable organizations to access advanced cooling technologies while benefiting from expert management and guaranteed performance levels.

Major Infrastructure Investments by global cloud providers have established the UAE as a regional data center hub, creating substantial demand for advanced cooling solutions. These investments have attracted supporting ecosystem development and established the foundation for continued market growth across multiple technology segments.

Government Digital Initiatives including smart city projects and digital government services have created substantial demand for data center infrastructure and associated cooling systems. These initiatives have established long-term growth drivers while demonstrating the government’s commitment to digital transformation and technology adoption.

Technology Partnerships between international cooling technology providers and local system integrators have enhanced market capabilities and service quality. These partnerships combine global innovation with local market knowledge and support capabilities, creating more effective solutions for UAE market requirements.

Sustainability Certifications and green building standards have become increasingly important in data center development, driving adoption of energy-efficient cooling technologies. LEED certification requirements and similar standards are influencing cooling system selection and design approaches across new data center projects.

Research and Development Investments in climate-adapted cooling technologies have produced solutions specifically designed for Middle East operating conditions. These innovations address the unique challenges of extreme heat and water scarcity while maintaining international performance and reliability standards.

Technology Diversification represents a critical strategy for cooling solution providers seeking to capture market opportunities across different segments. MarkWide Research analysis suggests that vendors offering comprehensive portfolios spanning air-based, liquid, and hybrid cooling solutions are better positioned to serve diverse customer requirements and market segments.

Local Partnership Development should be prioritized by international vendors seeking to establish sustainable market presence in the UAE. Partnerships with local system integrators, service providers, and distributors enable more effective market penetration while providing the local support capabilities that customers increasingly demand.

Sustainability Integration must become a core component of product development and market positioning strategies. Organizations that can demonstrate clear environmental benefits and alignment with the UAE’s sustainability objectives will be better positioned to win major projects and establish long-term customer relationships.

Service Capability Enhancement should focus on developing comprehensive support offerings that extend beyond equipment supply to include design, installation, commissioning, maintenance, and optimization services. Customers increasingly value integrated solutions that provide single-point accountability and guaranteed performance outcomes.

Innovation Investment in emerging technologies such as AI-powered optimization, advanced materials, and novel cooling approaches will be essential for maintaining competitive advantage. The rapid pace of technology evolution requires continuous innovation investment to avoid obsolescence and capture emerging market opportunities.

Market expansion is expected to continue at a robust pace, driven by ongoing digitalization initiatives, increasing data generation, and the UAE’s growing role as a regional technology hub. The market is projected to maintain strong growth momentum with a CAGR of 12.8% over the next five years, reflecting sustained demand across multiple application segments.

Technology evolution will continue toward more efficient and intelligent cooling solutions that can adapt automatically to changing conditions and requirements. Artificial intelligence integration, advanced materials, and novel cooling approaches will reshape the competitive landscape while providing customers with superior performance and operational benefits.

Sustainability focus will intensify as environmental regulations become more stringent and organizations seek to achieve carbon neutrality objectives. This trend will drive continued adoption of energy-efficient cooling technologies and renewable energy integration, creating opportunities for providers who can deliver environmentally responsible solutions.

Edge computing growth will create new market segments requiring specialized cooling solutions that can operate reliably in distributed environments. The proliferation of IoT devices, autonomous vehicles, and real-time applications will drive demand for edge data centers and associated cooling infrastructure across urban and remote locations.

Regional integration opportunities will emerge as the UAE serves as a gateway to broader Middle East and African markets. Organizations that establish strong positions in the UAE market will be well-positioned to expand into adjacent markets and serve regional customers from their UAE base operations.

The United Arab Emirates data center cooling market represents a dynamic and rapidly expanding sector that reflects the country’s transformation into a global technology hub. The convergence of government digitalization initiatives, private sector digital transformation, extreme climate conditions, and strategic geographic positioning has created a unique market environment with substantial growth opportunities and specialized requirements.

Market fundamentals remain strong, supported by continued investment in digital infrastructure, growing data generation, and the UAE’s role as a regional connectivity hub. The challenging climate conditions that initially appeared as market constraints have evolved into competitive advantages for providers who can deliver superior performance under extreme operating conditions.

Technology innovation continues to drive market evolution, with artificial intelligence, liquid cooling, and sustainability-focused solutions representing key growth areas. The increasing sophistication of cooling technologies, combined with growing customer awareness of total cost of ownership considerations, is creating opportunities for providers who can demonstrate clear value propositions and performance benefits.

Future success in the UAE data center cooling market will require a combination of technological excellence, local market knowledge, comprehensive service capabilities, and strong sustainability credentials. Organizations that can integrate these elements while adapting to the unique requirements of the UAE market will be well-positioned to capture the substantial opportunities that lie ahead in this dynamic and growing sector.

What is Data Center Cooling?

Data Center Cooling refers to the methods and technologies used to maintain optimal temperature and humidity levels in data centers, ensuring the efficient operation of servers and IT equipment. Effective cooling is crucial for preventing overheating and ensuring reliability in data center operations.

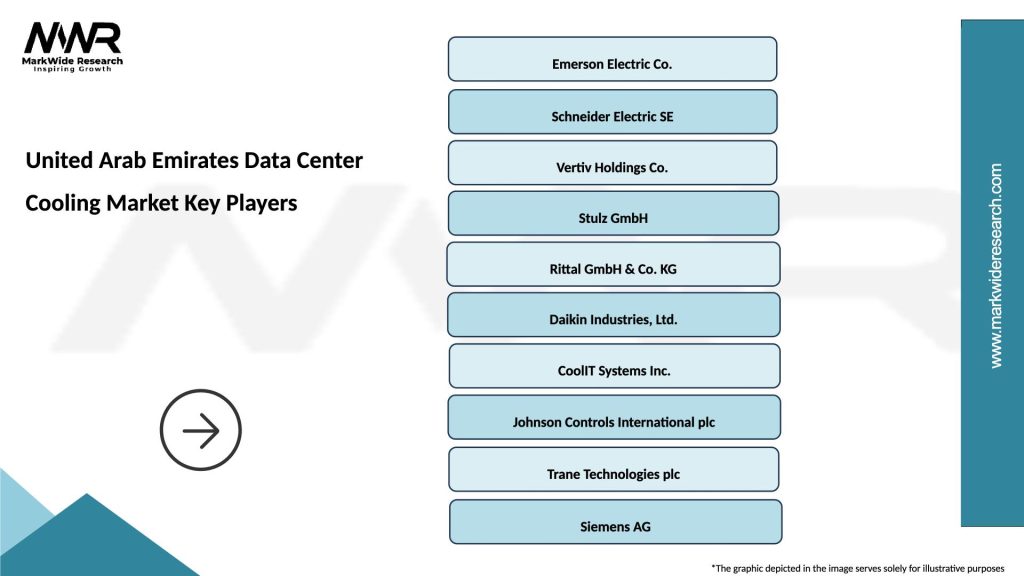

What are the key players in the United Arab Emirates Data Center Cooling Market?

Key players in the United Arab Emirates Data Center Cooling Market include companies like Schneider Electric, Vertiv, and STULZ, which provide innovative cooling solutions and technologies for data centers, among others.

What are the main drivers of the United Arab Emirates Data Center Cooling Market?

The main drivers of the United Arab Emirates Data Center Cooling Market include the rapid growth of data centers due to increased digitalization, the rising demand for energy-efficient cooling solutions, and the need for reliable IT infrastructure to support cloud computing and big data applications.

What challenges does the United Arab Emirates Data Center Cooling Market face?

Challenges in the United Arab Emirates Data Center Cooling Market include high energy consumption associated with cooling systems, the need for skilled personnel to manage advanced cooling technologies, and the increasing costs of maintaining and upgrading cooling infrastructure.

What opportunities exist in the United Arab Emirates Data Center Cooling Market?

Opportunities in the United Arab Emirates Data Center Cooling Market include the adoption of innovative cooling technologies such as liquid cooling and free cooling, as well as the potential for growth in green data centers that prioritize sustainability and energy efficiency.

What trends are shaping the United Arab Emirates Data Center Cooling Market?

Trends shaping the United Arab Emirates Data Center Cooling Market include the increasing use of artificial intelligence for optimizing cooling operations, the shift towards modular data center designs, and the growing emphasis on sustainability and reducing carbon footprints in cooling solutions.

United Arab Emirates Data Center Cooling Market

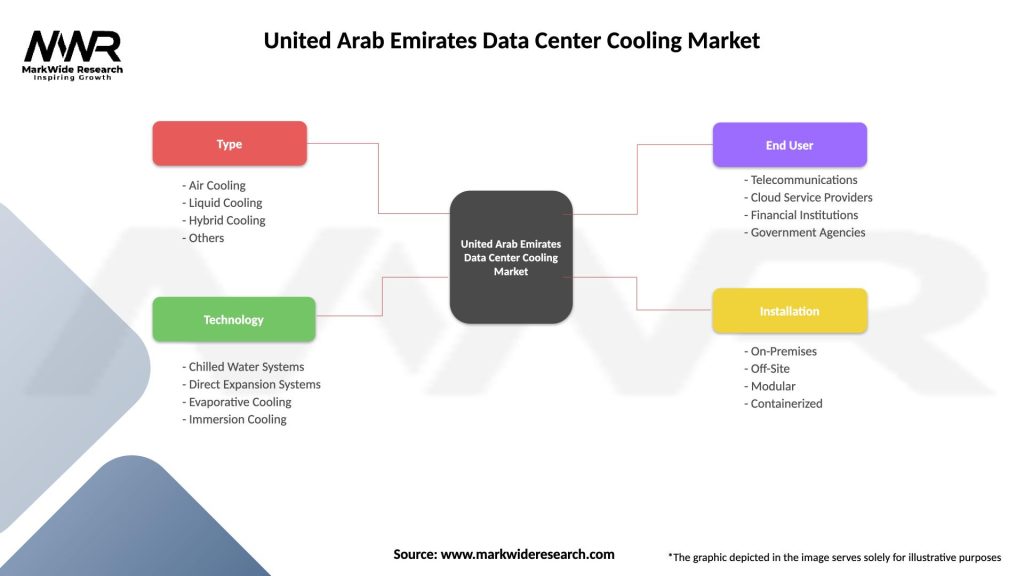

| Segmentation Details | Description |

|---|---|

| Type | Air Cooling, Liquid Cooling, Hybrid Cooling, Others |

| Technology | Chilled Water Systems, Direct Expansion Systems, Evaporative Cooling, Immersion Cooling |

| End User | Telecommunications, Cloud Service Providers, Financial Institutions, Government Agencies |

| Installation | On-Premises, Off-Site, Modular, Containerized |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the United Arab Emirates Data Center Cooling Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at