444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The Ukraine prefabricated buildings market represents a rapidly evolving construction sector that has gained significant momentum due to reconstruction efforts, urbanization trends, and the growing demand for cost-effective building solutions. Prefabricated construction in Ukraine encompasses modular homes, commercial structures, industrial facilities, and temporary housing solutions that are manufactured off-site and assembled at the final location. The market has experienced substantial growth driven by the need for quick deployment of buildings, reduced construction timelines, and improved quality control measures.

Market dynamics indicate that Ukraine’s prefabricated buildings sector is experiencing a transformation period, with growth rates reaching approximately 12.5% annually in recent years. The construction industry’s shift toward sustainable and efficient building methods has positioned prefabricated solutions as a preferred choice for various applications. Reconstruction initiatives following recent challenges have particularly accelerated demand for rapid deployment building solutions, creating new opportunities for market participants.

Regional distribution shows that approximately 35% of prefabricated building demand originates from urban centers, while rural and semi-urban areas account for the remaining market share. The technology adoption rate has increased significantly, with modern prefabricated systems gaining 68% acceptance among construction professionals and developers across Ukraine.

The Ukraine prefabricated buildings market refers to the comprehensive ecosystem of manufacturing, distribution, and installation of building components and complete structures that are produced in controlled factory environments and subsequently assembled at construction sites. This market encompasses various building types including residential homes, commercial complexes, industrial facilities, educational institutions, and emergency housing solutions.

Prefabricated construction involves the off-site manufacturing of building elements using standardized processes, advanced materials, and quality control systems. These components are then transported to the construction site for rapid assembly, significantly reducing construction time, labor costs, and material waste. The approach enables consistent quality, improved safety standards, and enhanced energy efficiency compared to traditional construction methods.

Market participants include manufacturers of prefabricated components, system integrators, construction companies, architects, engineers, and end-users ranging from individual homeowners to large-scale developers. The ecosystem also encompasses suppliers of raw materials, transportation services, and specialized installation teams that ensure proper assembly and integration of prefabricated elements.

Ukraine’s prefabricated buildings market stands at a pivotal juncture, characterized by robust growth potential and increasing adoption across multiple construction segments. The market has demonstrated resilience and adaptability, with prefabricated solutions emerging as a critical component of the country’s construction and reconstruction efforts. Technology advancement and improved manufacturing capabilities have enhanced the quality and versatility of prefabricated building systems.

Key market drivers include the urgent need for rapid construction solutions, cost optimization requirements, and growing environmental consciousness among stakeholders. The market benefits from approximately 45% faster construction timelines compared to traditional building methods, making prefabricated solutions particularly attractive for time-sensitive projects. Quality improvements in manufacturing processes have resulted in buildings that meet or exceed conventional construction standards.

Competitive landscape features both domestic and international players, with local manufacturers gaining market share through customized solutions and competitive pricing. The market structure supports innovation and technological advancement, with companies investing in modern manufacturing equipment and sustainable building materials. Market penetration continues to expand across residential, commercial, and industrial segments, indicating broad-based acceptance of prefabricated construction methods.

Strategic analysis reveals several critical insights that define the Ukraine prefabricated buildings market landscape:

Market maturity indicators suggest that Ukraine’s prefabricated buildings sector is transitioning from an emerging market to a more established industry segment. Adoption rates continue to increase as awareness grows regarding the benefits and capabilities of modern prefabricated construction systems.

Reconstruction demand serves as the primary catalyst driving Ukraine’s prefabricated buildings market growth. The urgent need for rapid deployment of housing, commercial, and infrastructure facilities has created unprecedented demand for construction solutions that can be implemented quickly and efficiently. Prefabricated systems address this need by offering significantly reduced construction timelines while maintaining quality standards.

Cost optimization pressures across the construction industry have made prefabricated solutions increasingly attractive to developers and end-users. The ability to achieve 20-30% cost savings through efficient manufacturing processes, reduced labor requirements, and minimized material waste has positioned prefabricated buildings as economically viable alternatives to traditional construction methods.

Labor shortage challenges in the construction sector have accelerated adoption of prefabricated solutions that require fewer on-site workers and specialized skills. The controlled factory environment enables more efficient use of skilled labor while reducing dependency on local construction workforce availability. Quality control advantages inherent in factory production have also contributed to growing market acceptance.

Environmental consciousness among stakeholders has driven demand for sustainable construction methods. Prefabricated buildings typically generate less waste, consume fewer resources, and offer improved energy efficiency compared to conventional construction. Sustainability initiatives by government and private sector organizations have further supported market growth through incentives and preferential policies.

Initial investment requirements for prefabricated building systems can be substantial, particularly for smaller developers and individual consumers. The upfront costs associated with design, manufacturing, and transportation may exceed traditional construction budgets, creating barriers to market entry for price-sensitive segments. Financing challenges can limit accessibility for certain market participants.

Transportation limitations present logistical challenges for prefabricated building components, especially for large or complex structures. Infrastructure constraints, including road conditions and bridge weight limits, can restrict the size and configuration of prefabricated elements. Delivery costs may become prohibitive for remote locations or projects requiring specialized transportation equipment.

Regulatory complexities surrounding building codes, permits, and approval processes can create delays and additional costs for prefabricated construction projects. Inconsistent standards across different regions and municipalities may complicate project planning and execution. Compliance requirements often necessitate additional documentation and certification processes.

Market perception challenges persist among some stakeholders who associate prefabricated buildings with lower quality or limited design options. Educational initiatives are required to demonstrate the capabilities and benefits of modern prefabricated systems. Traditional construction industry resistance to change can slow adoption rates in certain market segments.

Reconstruction programs present substantial opportunities for prefabricated building manufacturers and suppliers. Large-scale infrastructure and housing reconstruction initiatives require rapid deployment capabilities that align perfectly with prefabricated construction advantages. Government partnerships and public-private collaborations can provide stable demand and revenue streams for market participants.

Export potential to neighboring countries and international markets offers significant growth opportunities for Ukrainian prefabricated building manufacturers. The competitive cost structure and improving quality standards position Ukrainian companies favorably in regional markets. International expansion can provide diversification benefits and access to larger market opportunities.

Technology advancement opportunities include integration of smart building systems, renewable energy solutions, and advanced materials into prefabricated structures. Innovation initiatives can differentiate products and create premium market segments with higher profit margins. Digital manufacturing technologies and automation can further improve efficiency and quality.

Sustainable construction trends create opportunities for environmentally focused prefabricated building solutions. Green building certifications, energy-efficient designs, and sustainable materials can command premium pricing and access specialized market segments. Environmental regulations may favor prefabricated construction methods over traditional alternatives.

Supply chain evolution within Ukraine’s prefabricated buildings market reflects broader industry transformation trends. Manufacturers are developing more sophisticated production capabilities while suppliers adapt to changing material requirements and quality standards. Vertical integration strategies enable companies to control more aspects of the production and delivery process, improving efficiency and quality control.

Demand patterns show increasing sophistication among end-users who seek customized solutions that meet specific functional and aesthetic requirements. The market has evolved from basic modular structures to complex architectural designs that rival traditional construction quality. Customer expectations continue to rise regarding design flexibility, energy efficiency, and integration capabilities.

Competitive dynamics feature both collaboration and competition among market participants. Strategic partnerships between manufacturers, suppliers, and construction companies create integrated value chains that benefit end-users. Market consolidation trends may emerge as successful companies acquire smaller players to expand capabilities and market reach.

Technology adoption rates indicate that approximately 75% of manufacturers have invested in modern production equipment and digital design tools. Innovation cycles are accelerating as companies seek competitive advantages through improved products and services. Research and development investments focus on materials science, manufacturing processes, and system integration capabilities.

Comprehensive market analysis for Ukraine’s prefabricated buildings sector employs multiple research methodologies to ensure accuracy and reliability of findings. Primary research includes extensive interviews with industry executives, manufacturers, suppliers, construction companies, and end-users to gather firsthand insights into market conditions, trends, and challenges.

Secondary research encompasses analysis of industry reports, government statistics, trade publications, and academic studies related to prefabricated construction and the broader building industry. Data triangulation methods validate findings across multiple sources to ensure consistency and reliability of market intelligence.

Quantitative analysis utilizes statistical modeling and forecasting techniques to project market trends and growth patterns. Qualitative assessment provides context and interpretation for numerical data, helping to explain underlying market dynamics and causal relationships. Survey methodologies capture stakeholder opinions and preferences across different market segments.

Market validation processes include expert reviews, industry feedback sessions, and cross-referencing with established market benchmarks. Continuous monitoring ensures that research findings remain current and relevant as market conditions evolve. Data quality assurance protocols maintain high standards for accuracy and completeness throughout the research process.

Western Ukraine represents the largest regional market for prefabricated buildings, accounting for approximately 40% of total demand. This region benefits from proximity to European markets, established manufacturing infrastructure, and strong reconstruction activity. Industrial development and commercial construction projects drive significant demand for prefabricated solutions in major cities and industrial zones.

Central Ukraine including the capital region demonstrates strong growth potential with approximately 30% market share. Urban development projects, government facilities, and residential construction create diverse demand for prefabricated building systems. Transportation advantages and access to skilled labor support manufacturing and assembly operations in this region.

Eastern regions present both challenges and opportunities, with reconstruction needs creating substantial demand for rapid deployment building solutions. Despite infrastructure challenges, the region accounts for approximately 20% of market activity. Industrial reconstruction and housing rehabilitation projects drive prefabricated building demand in this area.

Southern Ukraine shows emerging market potential with growing acceptance of prefabricated construction methods. Agricultural and port-related industrial facilities create specialized demand for prefabricated structures. Regional development initiatives and infrastructure improvements support market expansion in coastal and agricultural areas.

Market leadership in Ukraine’s prefabricated buildings sector features a mix of domestic manufacturers and international companies with local operations. The competitive environment encourages innovation and quality improvements while maintaining cost competitiveness.

Competitive strategies focus on product differentiation, cost optimization, and service quality improvements. Companies invest in modern manufacturing equipment, skilled workforce development, and customer relationship management. Market positioning varies from low-cost providers to premium solution specialists, creating opportunities across different market segments.

Strategic partnerships between manufacturers, suppliers, and construction companies create integrated value propositions for end-users. Technology licensing agreements with international companies enable access to advanced manufacturing techniques and product designs.

By Building Type:

By Construction Material:

By End User:

Residential Prefabricated Buildings dominate the market with strong demand for single-family homes and multi-family housing solutions. Affordability factors and rapid construction capabilities make prefabricated residential buildings attractive to both developers and individual homeowners. Energy efficiency improvements and modern design options have enhanced market acceptance in this category.

Commercial Prefabricated Buildings show robust growth driven by business expansion needs and reconstruction requirements. Flexibility advantages allow for rapid deployment of office spaces, retail facilities, and service buildings. The ability to relocate or expand prefabricated commercial structures provides additional value for growing businesses.

Industrial Prefabricated Buildings serve specialized requirements for manufacturing, storage, and logistics facilities. Large-span capabilities and heavy-duty construction standards make prefabricated systems suitable for industrial applications. Cost savings and construction speed advantages are particularly important for industrial users with time-sensitive project requirements.

Institutional Prefabricated Buildings address specific needs for educational, healthcare, and government facilities. Compliance requirements and specialized functional needs create unique challenges and opportunities in this segment. Quality standards and long-term durability considerations are critical factors for institutional buyers.

Manufacturers benefit from predictable production schedules, improved quality control, and economies of scale that reduce per-unit costs. Factory-based production enables year-round manufacturing regardless of weather conditions, improving capacity utilization and revenue stability. Advanced manufacturing techniques and automation opportunities provide competitive advantages.

Construction Companies gain access to faster project completion times, reduced labor requirements, and improved project predictability. Risk mitigation through controlled manufacturing processes and standardized components reduces construction delays and cost overruns. Prefabricated systems enable companies to take on more projects with existing resources.

Developers achieve faster time-to-market, reduced construction costs, and improved return on investment through prefabricated building solutions. Market differentiation opportunities arise from offering innovative and sustainable building options to end-users. Reduced construction timelines enable faster revenue generation and improved cash flow management.

End Users benefit from cost savings, faster occupancy, and consistent quality standards in prefabricated buildings. Energy efficiency improvements and modern design options provide long-term value and reduced operating costs. Customization capabilities ensure that prefabricated buildings meet specific functional and aesthetic requirements.

Strengths:

Weaknesses:

Opportunities:

Threats:

Sustainable Construction trends are driving increased adoption of environmentally friendly prefabricated building systems. Green building certifications and energy efficiency requirements are becoming standard expectations rather than premium features. Manufacturers are investing in sustainable materials and production processes to meet growing environmental consciousness among stakeholders.

Technology Integration represents a major trend with smart building systems, IoT connectivity, and automated controls becoming standard features in prefabricated buildings. Digital design tools and virtual reality capabilities enable better customer visualization and customization options. Advanced manufacturing technologies improve precision and enable more complex architectural designs.

Modular Expansion capabilities are increasingly important as end-users seek buildings that can grow and adapt to changing needs. Flexible design systems allow for future additions and modifications without major structural changes. This trend particularly appeals to growing businesses and evolving residential needs.

Quality Enhancement continues as manufacturers invest in better materials, improved manufacturing processes, and enhanced quality control systems. Performance standards for prefabricated buildings now match or exceed traditional construction quality in many applications. Customer expectations for durability and longevity drive continuous improvement initiatives.

Manufacturing Capacity Expansion by leading companies demonstrates confidence in market growth potential. Several major manufacturers have announced investments in new production facilities and equipment upgrades to meet increasing demand. Technology modernization initiatives focus on automation and digital manufacturing capabilities.

Strategic Partnerships between manufacturers, suppliers, and construction companies are creating integrated value chains that benefit end-users. Collaboration agreements with international technology providers enable access to advanced manufacturing techniques and product innovations. Joint ventures facilitate market expansion and capability development.

Product Innovation initiatives focus on developing specialized solutions for specific market segments and applications. Research and development investments target improved materials, enhanced energy efficiency, and integrated building systems. New product launches demonstrate industry commitment to meeting evolving customer needs.

Market Expansion activities include geographic expansion within Ukraine and exploration of export opportunities. Distribution network development improves market coverage and customer service capabilities. International market entry strategies position Ukrainian companies for global growth opportunities.

MarkWide Research analysis suggests that companies should focus on technology advancement and quality improvement initiatives to maintain competitive advantages in the evolving market. Investment priorities should include modern manufacturing equipment, skilled workforce development, and customer service enhancement programs.

Market positioning strategies should emphasize the unique value propositions of prefabricated buildings, including speed, quality, and cost advantages. Educational initiatives can help overcome market perception challenges and demonstrate the capabilities of modern prefabricated systems. Customer testimonials and case studies provide powerful marketing tools.

Partnership development with suppliers, construction companies, and technology providers can create competitive advantages and improve market access. Vertical integration opportunities should be evaluated to control more aspects of the value chain and improve margins. Strategic alliances can provide access to new markets and capabilities.

Sustainability initiatives should be prioritized as environmental consciousness continues to grow among stakeholders. Green building features and sustainable manufacturing processes can differentiate products and access premium market segments. Certification programs and environmental compliance demonstrate commitment to sustainability goals.

Market growth projections indicate continued expansion of Ukraine’s prefabricated buildings sector, with growth rates expected to maintain momentum at approximately 10-15% annually over the next five years. Reconstruction activities and urbanization trends will continue to drive demand for rapid deployment building solutions across multiple market segments.

Technology advancement will play a crucial role in market evolution, with digital manufacturing, smart building systems, and sustainable materials becoming standard features. MWR projections suggest that technology adoption rates will reach 85% of manufacturers within the next three years, driving quality improvements and cost optimization.

Market maturation will bring increased competition and consolidation as successful companies expand their capabilities and market reach. International expansion opportunities will become increasingly important for growth and diversification. Export potential to regional markets offers significant revenue opportunities for Ukrainian manufacturers.

Regulatory evolution is expected to favor prefabricated construction methods through streamlined approval processes and supportive policies. Quality standards will continue to improve as the industry matures and customer expectations rise. Environmental regulations may provide additional advantages for sustainable prefabricated building systems.

Ukraine’s prefabricated buildings market represents a dynamic and rapidly evolving sector with substantial growth potential driven by reconstruction needs, cost optimization requirements, and technological advancement. The market has demonstrated resilience and adaptability while positioning itself as a critical component of the country’s construction industry transformation.

Key success factors include quality improvement, technology adoption, and customer education initiatives that demonstrate the capabilities and benefits of modern prefabricated building systems. Companies that invest in manufacturing capabilities, workforce development, and customer relationships are best positioned to capitalize on market opportunities and achieve sustainable growth.

Future prospects remain positive as market fundamentals support continued expansion across residential, commercial, and industrial segments. The combination of urgent reconstruction needs, cost pressures, and environmental consciousness creates a favorable environment for prefabricated building solutions. Strategic positioning and continuous innovation will determine long-term success in this competitive and evolving market landscape.

What is Prefabricated Buildings?

Prefabricated buildings are structures that are manufactured off-site in advance, typically in standard sections that can be easily transported and assembled. They are commonly used in residential, commercial, and industrial applications due to their efficiency and cost-effectiveness.

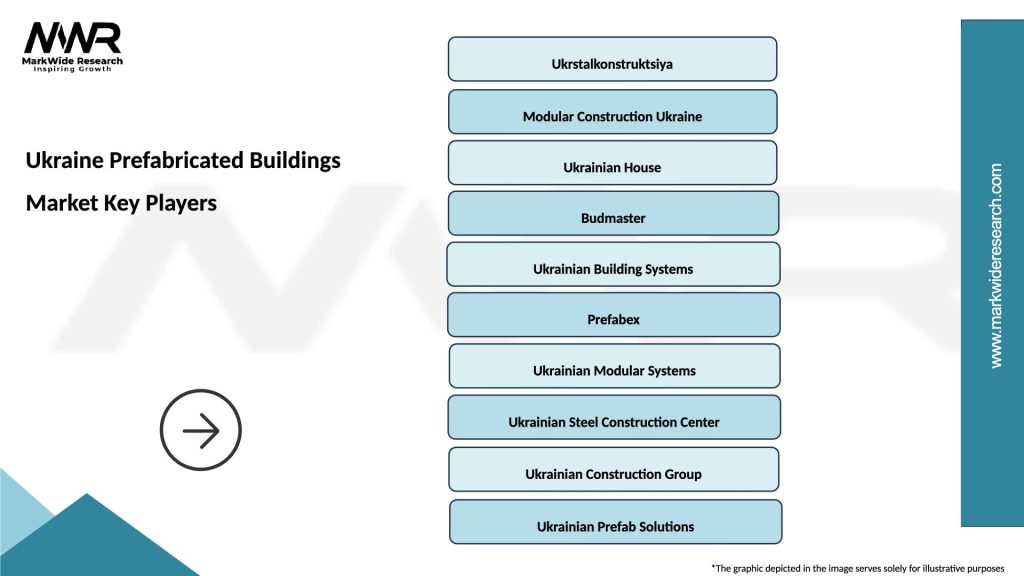

What are the key players in the Ukraine Prefabricated Buildings Market?

Key players in the Ukraine Prefabricated Buildings Market include companies like KNAUF, KBE, and KAMAZ, which specialize in various prefabricated construction solutions. These companies are known for their innovative designs and sustainable building practices, among others.

What are the growth factors driving the Ukraine Prefabricated Buildings Market?

The growth of the Ukraine Prefabricated Buildings Market is driven by factors such as the increasing demand for affordable housing, the need for rapid construction solutions, and the rising focus on sustainable building practices. Additionally, government initiatives to promote modern construction techniques contribute to market expansion.

What challenges does the Ukraine Prefabricated Buildings Market face?

The Ukraine Prefabricated Buildings Market faces challenges such as regulatory hurdles, limited consumer awareness, and competition from traditional construction methods. These factors can hinder the adoption of prefabricated solutions in certain regions.

What opportunities exist in the Ukraine Prefabricated Buildings Market?

Opportunities in the Ukraine Prefabricated Buildings Market include the potential for innovation in design and materials, the expansion of modular construction techniques, and the increasing interest in eco-friendly building solutions. These trends can lead to new market entrants and collaborations.

What trends are shaping the Ukraine Prefabricated Buildings Market?

Trends shaping the Ukraine Prefabricated Buildings Market include the integration of smart technologies in prefabricated designs, a shift towards sustainable materials, and the growing popularity of modular construction. These trends reflect a broader movement towards efficiency and environmental responsibility in the construction industry.

Ukraine Prefabricated Buildings Market

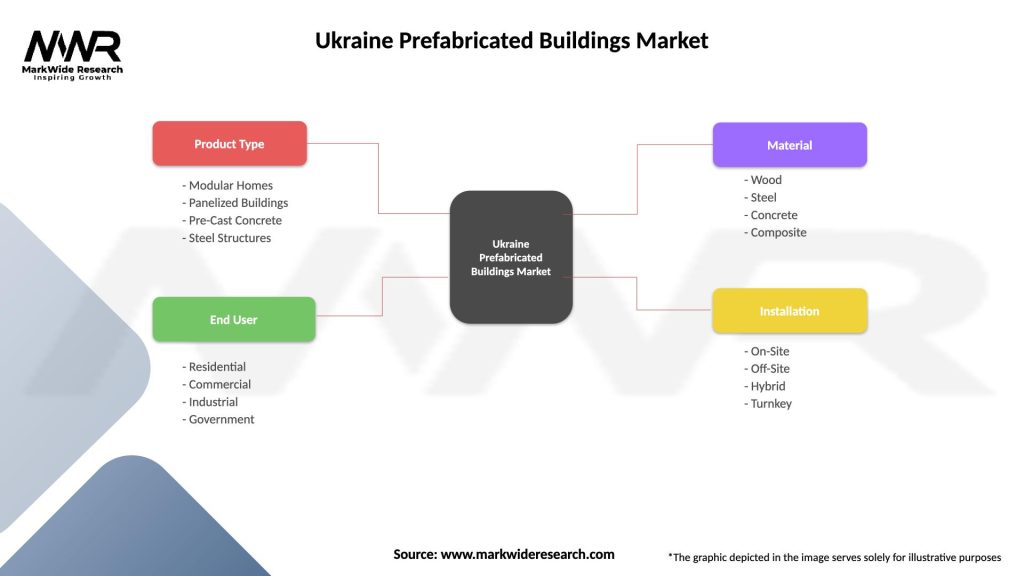

| Segmentation Details | Description |

|---|---|

| Product Type | Modular Homes, Panelized Buildings, Pre-Cast Concrete, Steel Structures |

| End User | Residential, Commercial, Industrial, Government |

| Material | Wood, Steel, Concrete, Composite |

| Installation | On-Site, Off-Site, Hybrid, Turnkey |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Ukraine Prefabricated Buildings Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at