444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview:

The Turntable Stretch Wrapper Market stands as a beacon of efficiency in the realm of packaging solutions. Turntable stretch wrappers are ingenious devices that automate and optimize the process of securing loads with stretch film. By harnessing rotational motion and advanced technology, these wrappers ensure that goods are packaged securely, ready for transport, and protected from damage.

From its foundational meaning to the intricate market dynamics, this journey delves into the heart of the market, capturing insights, trends, challenges, and opportunities that shape its present and future.

Meaning:

The Turntable Stretch Wrapper Market revolves around turntable-based machines designed to streamline and enhance the pallet wrapping process. These machines automate the task of applying stretch film around goods placed on a rotating turntable. The core meaning lies in their ability to ensure consistent and uniform wrapping, minimizing the risk of load shifting, while maximizing the use of stretch film.

Executive Summary:

The Turntable Stretch Wrapper Market navigates the intersection of technology and packaging precision. In industries where logistics and supply chain efficiency are paramount, turntable stretch wrappers provide a strategic advantage. The market’s essence lies in its ability to transform pallet packaging, enhancing stability, minimizing material waste, and ultimately contributing to cost savings.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

The growth of the Turntable Stretch Wrapper Market is primarily driven by the following factors:

Market Restraints

While the Turntable Stretch Wrapper Market is growing, several factors may restrain its expansion:

Market Opportunities

The Turntable Stretch Wrapper Market offers several growth opportunities:

Market Dynamics

The dynamics of the Turntable Stretch Wrapper Market are shaped by several key factors:

Regional Analysis

The Global Turntable Stretch Wrapper Market varies by region, with certain areas experiencing higher demand due to manufacturing, logistics, and e-commerce growth:

Competitive Landscape

Leading Companies in the Turntable Stretch Wrapper Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

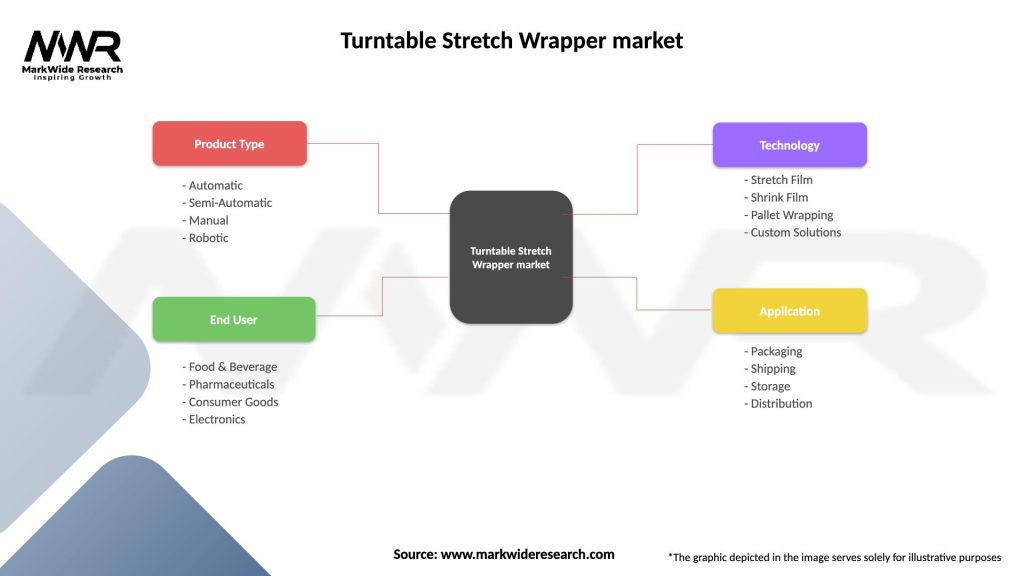

The Turntable Stretch Wrapper Market can be segmented based on the following factors:

Product Type

End-Use Industry

Geography

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact:

The Covid-19 pandemic reverberated across industries, including the Turntable Stretch Wrapper Market. Temporary supply chain disruptions impacted equipment availability. However, the pandemic underscored the essential role of efficient packaging in ensuring goods’ safe transit and delivery. The market’s ability to adapt to fluctuating demands and maintain operational continuity reflects its resilience.

Key Industry Developments:

The Turntable Stretch Wrapper Market has witnessed significant industry developments. Collaborative efforts between turntable stretch wrapper manufacturers and robotics companies led to hybrid solutions that merge automation with manual intervention. Technological advancements, such as intuitive touchscreens and remote monitoring capabilities, enhance user experience and operational convenience.

Analyst Suggestions:

Industry analysts provide insightful suggestions for navigating the Turntable Stretch Wrapper Market. Emphasizing user-friendly interfaces and training programs facilitates quick equipment adoption. Collaborations with packaging material suppliers optimize the compatibility between turntable stretch wrappers and film materials. Moreover, proactive maintenance and rapid customer support enhance equipment uptime and customer satisfaction.

Future Outlook:

The future of the Turntable Stretch Wrapper Market is characterized by pioneering packaging efficiency and innovation. As industries adopt smart manufacturing practices, turntable stretch wrappers will integrate seamlessly into automated packaging lines. Sustainability will remain a focal point, influencing material choices and equipment design. The market’s agility in adapting to emerging packaging trends will solidify its role in enhancing supply chain efficiency.

Conclusion:

In conclusion, the Turntable Stretch Wrapper Market stands as a testament to the fusion of engineering excellence and packaging precision. From warehouses to distribution centers, turntable stretch wrappers uphold the integrity of products during transit. As industries prioritize efficiency and sustainability, these machines will continue to play a pivotal role in safeguarding goods, optimizing logistics, and propelling packaging progress into the future.

What is Turntable Stretch Wrapper?

A Turntable Stretch Wrapper is a packaging machine that uses a rotating turntable to wrap products with stretch film. This equipment is commonly used in warehouses and distribution centers to secure palletized goods for storage and transportation.

What are the key companies in the Turntable Stretch Wrapper market?

Key companies in the Turntable Stretch Wrapper market include Signode Industrial Group, Aetna Group, and Lantech, among others.

What are the growth factors driving the Turntable Stretch Wrapper market?

The growth of the Turntable Stretch Wrapper market is driven by the increasing demand for efficient packaging solutions in industries such as food and beverage, pharmaceuticals, and consumer goods. Additionally, the rise in e-commerce has led to a greater need for secure packaging methods.

What challenges does the Turntable Stretch Wrapper market face?

The Turntable Stretch Wrapper market faces challenges such as the high initial investment costs and the need for regular maintenance. Additionally, competition from alternative packaging solutions can hinder market growth.

What opportunities exist in the Turntable Stretch Wrapper market?

Opportunities in the Turntable Stretch Wrapper market include advancements in automation and technology, which can enhance efficiency and reduce labor costs. Furthermore, the growing emphasis on sustainable packaging solutions presents new avenues for innovation.

What trends are shaping the Turntable Stretch Wrapper market?

Trends in the Turntable Stretch Wrapper market include the integration of smart technology for monitoring and control, as well as the increasing use of biodegradable stretch films. These trends reflect a shift towards more efficient and environmentally friendly packaging solutions.

Turntable Stretch Wrapper market

| Segmentation Details | Description |

|---|---|

| Product Type | Automatic, Semi-Automatic, Manual, Robotic |

| End User | Food & Beverage, Pharmaceuticals, Consumer Goods, Electronics |

| Technology | Stretch Film, Shrink Film, Pallet Wrapping, Custom Solutions |

| Application | Packaging, Shipping, Storage, Distribution |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Turntable Stretch Wrapper Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at