444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The Turkey cold storage market represents a rapidly expanding sector within the country’s logistics and food preservation infrastructure. This market encompasses refrigerated warehousing facilities, temperature-controlled distribution centers, and specialized cold chain solutions that serve various industries including food and beverage, pharmaceuticals, and agricultural products. Turkey’s strategic location between Europe and Asia positions it as a crucial hub for international cold storage operations, driving significant investment in modern refrigeration technologies and automated storage systems.

Market dynamics indicate robust growth driven by increasing demand for frozen and chilled products, expanding retail chains, and growing export activities. The sector is experiencing transformation through technological advancement, with facilities adopting IoT-enabled monitoring systems, energy-efficient refrigeration technologies, and automated inventory management solutions. Growth projections suggest the market will expand at a compound annual growth rate of 8.2% over the forecast period, reflecting strong fundamentals and increasing investment in cold chain infrastructure.

Regional distribution shows concentration in major metropolitan areas including Istanbul, Ankara, and Izmir, with emerging facilities in agricultural regions to support farm-to-market logistics. The market serves diverse end-users from large-scale food processors to pharmaceutical companies requiring specialized temperature-controlled storage solutions. Investment trends indicate growing interest from international operators seeking to establish regional distribution hubs in Turkey’s expanding cold storage landscape.

The Turkey cold storage market refers to the comprehensive ecosystem of temperature-controlled warehousing and distribution facilities operating within Turkey’s borders, designed to preserve perishable goods at specific temperature ranges throughout the supply chain. This market encompasses various facility types including blast freezers, chilled storage warehouses, multi-temperature distribution centers, and specialized pharmaceutical cold storage units that maintain precise environmental conditions for sensitive products.

Cold storage facilities in Turkey serve multiple functions beyond simple refrigeration, incorporating advanced inventory management systems, automated retrieval technologies, and integrated logistics solutions. These facilities support the preservation of food quality, extend product shelf life, and enable efficient distribution of temperature-sensitive goods across domestic and international markets. Market participants include facility operators, logistics service providers, technology suppliers, and end-user industries requiring reliable cold chain solutions.

Operational scope extends from small-scale regional facilities serving local markets to large-scale distribution centers supporting national and international supply chains. The market integrates various temperature zones, from deep-freeze storage at -25°C to controlled ambient conditions, accommodating diverse product requirements across multiple industry sectors.

Turkey’s cold storage market demonstrates exceptional growth potential driven by expanding food retail sectors, increasing consumer demand for frozen products, and growing pharmaceutical distribution requirements. The market benefits from Turkey’s strategic geographic position, serving as a bridge between European and Asian markets while supporting robust domestic consumption patterns. Infrastructure development initiatives and government support for logistics modernization create favorable conditions for market expansion.

Key market drivers include urbanization trends increasing demand for processed foods, expanding e-commerce grocery delivery services, and growing pharmaceutical exports requiring specialized temperature-controlled storage. The sector attracts significant investment from both domestic and international operators seeking to capitalize on Turkey’s growing economy and strategic location advantages. Technology adoption rates show 65% of facilities implementing advanced monitoring systems and automated inventory management solutions.

Competitive landscape features a mix of established local operators and international logistics companies establishing regional operations. Market consolidation trends indicate growing partnerships between facility operators and technology providers to enhance operational efficiency and service capabilities. Future prospects remain positive with continued investment in infrastructure development and technological advancement supporting long-term market growth.

Strategic insights reveal several critical factors shaping Turkey’s cold storage market development and competitive dynamics:

Primary growth drivers propelling Turkey’s cold storage market expansion reflect both domestic consumption trends and international trade opportunities. The increasing urbanization rate, currently at 76% of the population, drives demand for processed and frozen food products requiring reliable cold chain infrastructure. Consumer lifestyle changes toward convenience foods and ready-to-eat meals create sustained demand for temperature-controlled storage and distribution services.

Export growth initiatives significantly impact market development as Turkey positions itself as a major agricultural exporter to European and Middle Eastern markets. The country’s diverse agricultural production, including fruits, vegetables, and processed foods, requires extensive cold storage capacity to maintain product quality during transportation and storage. Government support for export promotion includes infrastructure investment incentives and logistics zone development programs.

Pharmaceutical sector expansion creates specialized demand for temperature-controlled storage facilities meeting stringent regulatory requirements. Turkey’s growing pharmaceutical manufacturing and distribution activities require dedicated cold storage solutions maintaining precise temperature ranges and comprehensive monitoring systems. E-commerce growth in grocery delivery services drives investment in urban cold storage facilities supporting last-mile distribution networks.

Food safety regulations and quality standards implementation encourage investment in modern cold storage facilities equipped with advanced monitoring and traceability systems. Retail chain expansion across Turkey creates demand for regional distribution centers with integrated cold storage capabilities supporting efficient supply chain operations.

Operational challenges facing Turkey’s cold storage market include high energy costs associated with refrigeration systems, representing approximately 40% of total operational expenses for typical facilities. Energy price volatility creates uncertainty in operational planning and profitability projections, particularly for energy-intensive deep-freeze storage operations. Infrastructure limitations in certain regions restrict market expansion opportunities and increase logistics costs for rural agricultural areas.

Skilled workforce shortage presents ongoing challenges as cold storage operations require specialized technical knowledge for refrigeration systems, automated equipment, and temperature monitoring technologies. Training requirements and certification processes increase operational costs and limit rapid facility expansion in emerging markets. Regulatory compliance complexity, particularly for pharmaceutical and export-oriented facilities, requires significant investment in quality management systems and documentation processes.

Initial capital requirements for establishing modern cold storage facilities remain substantial, including refrigeration equipment, building infrastructure, and technology systems. Financing challenges for smaller operators limit market participation and consolidation opportunities. Competition from established logistics providers with existing cold storage capabilities creates barriers for new market entrants seeking to establish independent operations.

Seasonal demand fluctuations in agricultural regions create capacity utilization challenges, requiring flexible operational strategies and diversified customer bases to maintain consistent revenue streams throughout the year.

Emerging opportunities in Turkey’s cold storage market reflect evolving consumer preferences, technological advancement, and expanding international trade relationships. The growing organic food market creates demand for specialized storage solutions maintaining product integrity and certification requirements. Premium food segments including artisanal and specialty products require dedicated cold storage facilities with enhanced quality control capabilities.

Technology integration opportunities include implementing artificial intelligence for predictive maintenance, blockchain for supply chain traceability, and advanced analytics for inventory optimization. Automation potential in warehouse operations offers significant efficiency improvements and cost reduction opportunities for forward-thinking operators. Sustainability initiatives create opportunities for implementing renewable energy systems and eco-friendly refrigeration technologies.

Regional expansion into underserved markets presents growth opportunities, particularly in agricultural regions requiring improved cold chain infrastructure. Partnership opportunities with international logistics companies seeking regional distribution hubs offer potential for joint ventures and strategic alliances. The growing pharmaceutical export market creates demand for specialized cold storage facilities meeting international regulatory standards.

Value-added services including packaging, labeling, and quality testing create additional revenue streams and competitive differentiation opportunities. Cross-docking capabilities and multi-temperature storage solutions enable facilities to serve diverse customer requirements and optimize capacity utilization across different product categories.

Market dynamics in Turkey’s cold storage sector reflect the interplay between supply chain modernization, consumer behavior changes, and technological advancement. Demand patterns show increasing preference for frozen and chilled products, with frozen food consumption growing at 12% annually across urban markets. This trend drives investment in expanded cold storage capacity and improved distribution networks supporting retail and food service sectors.

Supply chain integration trends indicate growing collaboration between cold storage operators, transportation providers, and technology companies to create comprehensive logistics solutions. Vertical integration strategies enable some operators to control multiple supply chain stages, from storage through final delivery, improving service quality and cost efficiency. Horizontal expansion through strategic acquisitions and partnerships allows operators to achieve geographic coverage and operational scale.

Competitive dynamics feature increasing differentiation through service quality, technology capabilities, and specialized expertise in particular industry sectors. Price competition remains significant in commodity storage segments, while specialized services command premium pricing through value-added capabilities. Customer relationship management becomes increasingly important as clients seek long-term partnerships rather than transactional storage arrangements.

Regulatory environment continues evolving with enhanced food safety requirements and environmental standards influencing facility design and operational procedures. MarkWide Research analysis indicates that regulatory compliance costs represent approximately 15% of operational budgets for facilities serving pharmaceutical and export markets.

Research approach for analyzing Turkey’s cold storage market employs comprehensive primary and secondary research methodologies to ensure accurate market assessment and reliable forecasting. Primary research includes structured interviews with facility operators, logistics service providers, technology suppliers, and end-user companies across various industry sectors. Survey methodologies capture quantitative data on capacity utilization, investment plans, and operational challenges facing market participants.

Secondary research incorporates analysis of government statistics, industry association reports, trade publications, and regulatory documentation to establish market context and historical trends. Data triangulation methods validate findings across multiple sources to ensure accuracy and reliability of market insights. Financial analysis of publicly traded companies provides insights into profitability trends and investment patterns within the sector.

Market sizing methodology utilizes bottom-up analysis based on facility capacity data, utilization rates, and pricing information collected through primary research activities. Forecasting models incorporate economic indicators, demographic trends, and industry-specific drivers to project future market development. Regional analysis methodology examines local market conditions, competitive dynamics, and growth opportunities across different geographic areas.

Quality assurance procedures include expert review panels, data validation protocols, and cross-reference verification to maintain research standards and analytical rigor throughout the study process.

Regional distribution of Turkey’s cold storage market shows significant concentration in major metropolitan areas and strategic logistics hubs. Istanbul region commands approximately 35% market share due to its position as the country’s commercial center and major port facilities supporting international trade. The region benefits from extensive transportation infrastructure, large consumer markets, and proximity to European export destinations.

Ankara and Central Anatolia represent emerging markets with growing cold storage capacity supporting agricultural processing and distribution activities. This region shows strong growth potential driven by government initiatives promoting inland logistics hubs and agricultural value-added processing. Izmir and Aegean region focus on agricultural exports, particularly fruits and vegetables, requiring specialized cold storage facilities with rapid cooling capabilities and export documentation services.

Mediterranean region development centers on citrus and fresh produce exports, with facilities designed for seasonal capacity fluctuations and specialized handling requirements. Black Sea region shows increasing investment in cold storage infrastructure supporting hazelnut processing and seafood distribution. Eastern regions present development opportunities for agricultural cold storage, though infrastructure limitations currently restrict large-scale facility development.

Urban markets including Bursa, Adana, and Gaziantep demonstrate growing demand for cold storage facilities serving regional retail chains and food processing industries. Border regions with Georgia, Syria, and Iraq present opportunities for transit cold storage facilities supporting cross-border trade activities.

Competitive structure in Turkey’s cold storage market features a diverse mix of domestic operators, international logistics companies, and specialized cold chain service providers. Market leadership positions are held by companies combining operational scale, geographic coverage, and technological capabilities to serve diverse customer requirements across multiple industry sectors.

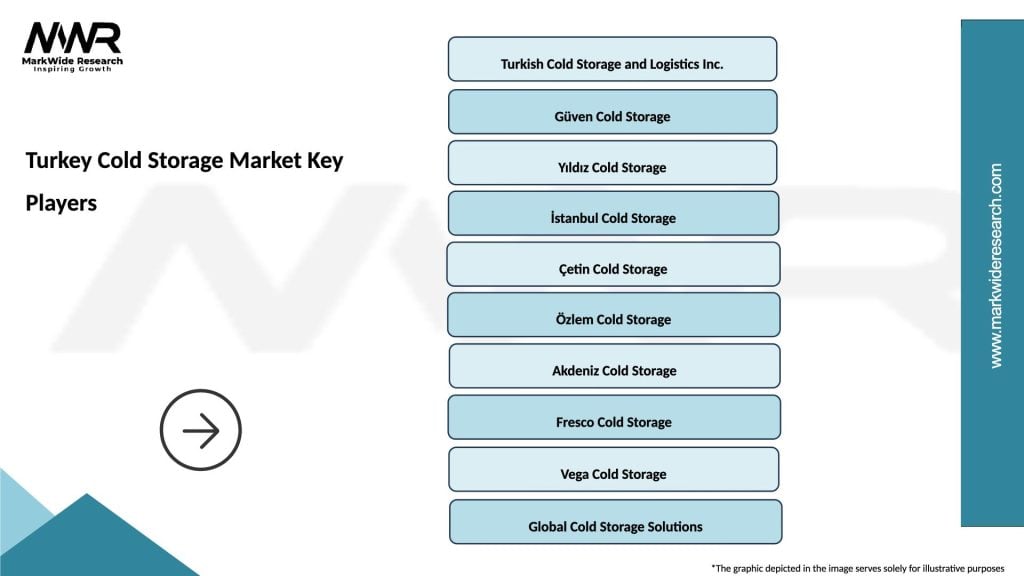

Key market participants include:

Competitive strategies emphasize technology differentiation, service quality enhancement, and geographic expansion to capture market share. Strategic partnerships between operators and technology providers create competitive advantages through advanced monitoring systems and automated operations. Consolidation trends indicate increasing merger and acquisition activity as companies seek operational scale and market coverage expansion.

Market segmentation analysis reveals diverse applications and temperature requirements across Turkey’s cold storage market. By temperature range, the market divides into chilled storage (0°C to 8°C), frozen storage (-18°C to -25°C), and deep-freeze storage (below -25°C), each serving specific product categories and industry requirements.

By application sector:

By facility type:

By ownership model:

Food and beverage segment dominates Turkey’s cold storage market, representing approximately 70% of total capacity utilization. This category encompasses diverse subcategories including dairy products requiring precise temperature control, meat and poultry processing facilities with specialized handling requirements, and frozen food distribution supporting retail and food service sectors. Growth drivers include expanding retail chains, increasing consumer preference for convenience foods, and growing export activities in processed food products.

Pharmaceutical cold storage represents the fastest-growing segment with annual growth rates exceeding 15% driven by expanding domestic pharmaceutical manufacturing and increasing vaccine distribution requirements. This specialized category requires stringent temperature monitoring, backup power systems, and comprehensive documentation for regulatory compliance. Investment priorities focus on automated monitoring systems, redundant refrigeration equipment, and qualified personnel training.

Agricultural storage shows seasonal demand patterns with peak utilization during harvest periods and lower capacity requirements during off-seasons. This category requires flexible operational strategies and diversified customer bases to maintain profitability throughout the year. Technology adoption includes controlled atmosphere storage for extended preservation and automated inventory management for efficient handling of diverse product types.

Chemical storage represents a specialized niche requiring expertise in hazardous material handling and environmental compliance. This category commands premium pricing due to specialized infrastructure requirements and regulatory complexity.

Facility operators benefit from Turkey’s growing cold storage market through multiple revenue streams and operational advantages. Geographic positioning enables operators to serve both domestic markets and international transit requirements, optimizing capacity utilization and revenue generation. Technology integration opportunities allow operators to differentiate services, improve operational efficiency, and command premium pricing for value-added capabilities.

End-user companies gain access to professional cold storage services without significant capital investment in facility infrastructure. Scalability benefits enable companies to adjust storage capacity based on seasonal requirements and business growth without long-term facility commitments. Risk mitigation through professional storage services reduces product loss, maintains quality standards, and ensures regulatory compliance.

Technology providers benefit from growing demand for advanced monitoring systems, automation equipment, and energy-efficient refrigeration technologies. Service opportunities include maintenance contracts, system upgrades, and consulting services supporting facility optimization and operational improvement initiatives.

Logistics service providers can integrate cold storage capabilities with transportation and distribution services, creating comprehensive supply chain solutions for temperature-sensitive products. Value creation opportunities include cross-docking services, inventory management, and specialized handling capabilities for diverse product categories.

Government stakeholders benefit from improved food safety standards, enhanced export capabilities, and economic development through logistics sector investment and employment creation.

Strengths:

Weaknesses:

Opportunities:

Threats:

Automation integration represents a dominant trend transforming Turkey’s cold storage operations through implementation of robotic systems, automated inventory management, and intelligent monitoring technologies. Facility operators increasingly adopt automated storage and retrieval systems to improve operational efficiency, reduce labor costs, and enhance inventory accuracy. Technology advancement includes AI-powered predictive maintenance systems and machine learning algorithms optimizing energy consumption and operational performance.

Sustainability initiatives gain prominence as operators implement energy-efficient refrigeration systems, renewable energy integration, and environmentally friendly refrigerants. Green building standards influence facility design and construction, with operators seeking LEED certification and other sustainability credentials. Carbon footprint reduction becomes a competitive differentiator as customers prioritize environmentally responsible supply chain partners.

Multi-temperature facilities emerge as preferred solutions enabling operators to serve diverse customer requirements within single locations. Flexible design concepts allow facilities to adjust temperature zones based on seasonal demand patterns and customer needs. Consolidation services enable smaller customers to access professional cold storage without minimum volume commitments.

Digital transformation accelerates through implementation of cloud-based management systems, mobile applications for inventory tracking, and blockchain technology for supply chain transparency. MWR analysis indicates that 85% of new facilities incorporate digital management systems from initial operations.

Recent developments in Turkey’s cold storage market reflect increasing investment, technological advancement, and strategic partnerships shaping industry evolution. Major facility expansions include new distribution centers in strategic locations supporting both domestic distribution and international trade activities. Technology partnerships between operators and solution providers create advanced monitoring and automation capabilities improving operational efficiency and service quality.

International investment continues growing as global logistics companies establish regional operations in Turkey to serve European, Asian, and Middle Eastern markets. Strategic acquisitions enable market consolidation and geographic expansion for established operators seeking scale advantages and market coverage enhancement. Government initiatives supporting logistics infrastructure development create favorable conditions for continued market expansion.

Regulatory developments include enhanced food safety standards and environmental compliance requirements influencing facility design and operational procedures. Industry certification programs promote quality standards and professional development within the cold storage sector. Research and development activities focus on energy-efficient technologies and sustainable operational practices.

Partnership agreements between cold storage operators and e-commerce companies support growing online grocery delivery services requiring specialized urban fulfillment capabilities. Cross-border collaboration initiatives facilitate international trade through improved cold chain connectivity and documentation processes.

Strategic recommendations for Turkey’s cold storage market participants emphasize technology adoption, operational efficiency, and market positioning strategies. Facility operators should prioritize investment in automated systems and energy-efficient technologies to improve competitiveness and operational sustainability. Geographic diversification strategies can reduce market concentration risks and capture emerging opportunities in underserved regions.

Technology integration recommendations include implementing comprehensive monitoring systems, predictive maintenance capabilities, and customer portal solutions enhancing service quality and operational transparency. Partnership strategies with transportation providers, technology companies, and end-user industries can create competitive advantages and revenue diversification opportunities.

Market entry strategies for new participants should focus on specialized niches, regional markets, or value-added services differentiating from established competitors. Investment priorities should emphasize flexible facility designs accommodating diverse temperature requirements and seasonal demand variations. Sustainability initiatives including renewable energy adoption and environmental certification can create competitive differentiation and cost reduction opportunities.

Risk management strategies should address energy cost volatility, regulatory compliance requirements, and competitive pressures through diversified customer bases and operational flexibility. MarkWide Research recommends that operators maintain minimum 18-month cash reserves to manage seasonal fluctuations and unexpected market changes.

Future prospects for Turkey’s cold storage market remain highly positive with continued growth expected across all major segments and geographic regions. Market expansion will be driven by increasing domestic consumption, growing export activities, and expanding pharmaceutical distribution requirements. Technology advancement will continue transforming operations through automation, artificial intelligence, and sustainable refrigeration systems.

Investment trends indicate sustained capital deployment in facility expansion, technology upgrades, and geographic diversification initiatives. International operators are expected to increase market participation through direct investment, partnerships, and strategic acquisitions. Government support for logistics infrastructure development will create favorable conditions for continued market growth and modernization.

Emerging opportunities include specialized storage for biotechnology products, organic food certification services, and integrated e-commerce fulfillment solutions. Regional development initiatives will create new market opportunities in currently underserved areas, particularly agricultural regions requiring improved cold chain infrastructure.

Long-term projections suggest the market will achieve sustained growth rates exceeding 8% annually through the forecast period, supported by economic development, population growth, and evolving consumer preferences. Consolidation trends will continue as operators seek scale advantages and operational efficiency improvements through strategic combinations and partnerships.

Turkey’s cold storage market presents exceptional growth opportunities driven by strategic geographic positioning, expanding domestic demand, and increasing international trade activities. The market benefits from strong fundamentals including diverse agricultural production, growing pharmaceutical sector, and government support for logistics infrastructure development. Technology adoption and operational modernization continue transforming the sector, creating competitive advantages for forward-thinking operators.

Market dynamics favor continued expansion with multiple growth drivers including urbanization, e-commerce development, and export promotion initiatives. Investment opportunities exist across various segments from traditional food storage to specialized pharmaceutical facilities requiring advanced monitoring and compliance capabilities. Competitive landscape evolution through consolidation and strategic partnerships will create stronger market participants with enhanced service capabilities.

Future success in Turkey’s cold storage market will depend on technology integration, operational efficiency, and strategic positioning to serve evolving customer requirements. Sustainability initiatives and environmental compliance will become increasingly important competitive factors as customers prioritize responsible supply chain partners. The market’s long-term outlook remains highly favorable with sustained growth expected across all major segments and geographic regions.

What is Cold Storage?

Cold storage refers to the process of storing perishable goods at low temperatures to extend their shelf life. This is crucial for industries such as food and pharmaceuticals, where maintaining product integrity is essential.

What are the key players in the Turkey Cold Storage Market?

Key players in the Turkey Cold Storage Market include companies like Aygun Cold Storage, Kargil, and Aegean Cold Storage, which provide various cold storage solutions for food and pharmaceutical products, among others.

What are the main drivers of the Turkey Cold Storage Market?

The main drivers of the Turkey Cold Storage Market include the increasing demand for fresh produce, the growth of the e-commerce food sector, and the rising need for efficient supply chain management in the food industry.

What challenges does the Turkey Cold Storage Market face?

Challenges in the Turkey Cold Storage Market include high operational costs, the need for advanced technology to maintain temperature control, and regulatory compliance related to food safety standards.

What opportunities exist in the Turkey Cold Storage Market?

Opportunities in the Turkey Cold Storage Market include the expansion of logistics networks, the adoption of automation technologies, and the growing trend of online grocery shopping, which requires efficient cold storage solutions.

What trends are shaping the Turkey Cold Storage Market?

Trends shaping the Turkey Cold Storage Market include the integration of IoT for real-time monitoring, the use of energy-efficient refrigeration systems, and the increasing focus on sustainable practices in cold storage operations.

Turkey Cold Storage Market

| Segmentation Details | Description |

|---|---|

| Product Type | Refrigerated Warehouses, Blast Freezers, Cold Storage Containers, Cold Rooms |

| End User | Food & Beverage, Pharmaceuticals, Logistics Providers, Retail Chains |

| Technology | Refrigeration Systems, Insulation Materials, Monitoring Solutions, Energy Management |

| Application | Meat Storage, Dairy Preservation, Seafood Handling, Frozen Vegetables |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Turkey Cold Storage Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at