Turbomolecular pumps play a crucial role in various industries, particularly in high-vacuum applications. These pumps are known for their ability to provide high pumping speeds, low ultimate pressures, and clean operation, making them indispensable in sectors such as semiconductor manufacturing, analytical instrumentation, and research laboratories. This market analysis will delve into the meaning of turbomolecular pumps, provide an executive summary of the market, discuss key market insights, drivers, restraints, and opportunities, examine the market dynamics, conduct a regional analysis, explore the competitive landscape, present segmentation and category-wise insights, highlight the key benefits for industry participants and stakeholders, perform a SWOT analysis, evaluate the market’s key trends and the impact of Covid-19, analyze key industry developments, provide analyst suggestions, offer a future outlook, and conclude the analysis.

Turbomolecular pumps are high-speed rotational devices designed to create a vacuum by continuously transferring gas molecules from the inlet to the outlet of the pump. They operate based on the principle of momentum transfer, using a series of rotating blades to accelerate gas molecules, creating a pressure differential and pumping action. These pumps are capable of achieving ultra-high vacuum levels, making them essential in applications that require the removal of gases and particles to ensure precise and contamination-free processes.

Executive Summary

The turbomolecular pumps market has experienced significant growth in recent years, driven by the expanding semiconductor industry, rising demand for analytical instrumentation, and increasing investments in research and development activities. The market is characterized by technological advancements, product innovation, and strategic collaborations. However, certain challenges, such as high initial costs and the need for skilled technicians for maintenance, have restrained market growth to some extent. Nevertheless, emerging opportunities in emerging economies, advancements in pump technology, and the adoption of turbomolecular pumps in new applications are expected to fuel market growth in the coming years.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

- Growing demand for turbomolecular pumps in the semiconductor industry due to their ability to provide clean and efficient vacuum solutions.

- Increasing adoption of analytical instrumentation for research and quality control purposes, driving the demand for turbomolecular pumps.

- Technological advancements, such as the development of magnetically levitated turbomolecular pumps, offering improved performance and reliability.

- Rising investments in research and development activities, particularly in emerging economies, creating opportunities for turbomolecular pump manufacturers.

- Stringent regulations regarding the emission of volatile organic compounds (VOCs) in various industries, necessitating the use of high-quality vacuum pumps like turbomolecular pumps.

Market Drivers

- Growing demand for semiconductors and electronic devices, driving the need for high-precision manufacturing processes and vacuum solutions.

- Expansion of the analytical instrumentation industry, particularly in pharmaceuticals, biotechnology, and environmental monitoring sectors, boosting the demand for turbomolecular pumps.

- Increasing investments in research and development activities, both in academia and industrial sectors, creating a need for reliable vacuum systems.

- Advancements in turbomolecular pump technology, such as the integration of intelligent control systems and the development of oil-free pumps, improving their performance and efficiency.

- Rising concerns regarding environmental pollution and the need for sustainable manufacturing processes, driving the adoption of turbomolecular pumps that offer clean and energy-efficient vacuum solutions.

Market Restraints

- High initial costs associated with turbomolecular pumps, limiting their adoption, particularly among small and medium-sized enterprises.

- The requirement for skilled technicians for installation, operation, and maintenance of turbomolecular pumps, adding to the overall cost and complexity.

- Limitations in pumping certain gases and particulate matter, necessitating the use of complementary pumping technologies in specific applications.

- Occasional risks of pump contamination due to backstreaming, requiring additional precautions and maintenance efforts.

- Volatility in raw material prices, particularly for critical components of turbomolecular pumps, impacting the overall cost and profitability for manufacturers.

Market Opportunities

- Rapid industrialization and the growth of key end-use industries in emerging economies present significant opportunities for turbomolecular pump manufacturers.

- Increasing demand for turbomolecular pumps in the aerospace industry for applications such as space simulation, satellite testing, and vacuum chambers.

- Adoption of turbomolecular pumps in emerging applications, including additive manufacturing, thin film deposition, and materials research.

- Integration of advanced control systems and automation in turbomolecular pumps, enabling remote monitoring, predictive maintenance, and enhanced performance.

- Collaborations and partnerships between pump manufacturers and research institutions to develop next-generation turbomolecular pumps with higher efficiency and reliability.

Market Dynamics

The turbomolecular pumps market is influenced by several dynamic factors, including technological advancements, market trends, regulatory landscape, and competitive dynamics. Technological developments, such as the introduction of magnetically levitated turbomolecular pumps and the integration of intelligent control systems, have significantly improved the performance and reliability of these pumps. Market trends, such as the increasing adoption of oil-free turbomolecular pumps and the focus on sustainability, have shaped the demand for specific pump types. Furthermore, stringent regulations related to emissions and workplace safety have driven the need for high-quality vacuum solutions, including turbomolecular pumps. The market is highly competitive, with several prominent players competing based on product quality, performance, and after-sales services.

- Supply Side Factors:

- Manufacturing Innovations: Advances in manufacturing technologies are enabling the production of more efficient and durable turbomolecular pumps.

- Strategic Partnerships: Collaborations between manufacturers and research institutions can foster innovation and enhance product offerings.

- Demand Side Factors:

- Industry Growth: The expansion of key industries, such as electronics and pharmaceuticals, is increasing the demand for high-performance vacuum solutions.

- Consumer Preferences: Growing consumer preferences for reliable and efficient vacuum systems are influencing purchasing decisions.

- Economic Factors:

- Investment in Infrastructure: Increased investments in industrial infrastructure support the demand for turbomolecular pumps.

- Global Economic Trends: Economic fluctuations can impact the spending capacity of industries relying on vacuum technologies.

Regional Analysis

- North America:

- Market Leader: North America holds a significant share of the turbomolecular pumps market, driven by the presence of key players and advanced industrial sectors.

- Innovation Hub: The region is known for its research activities and technological advancements in vacuum technology.

- Europe:

- Growing Demand: Europe is witnessing steady growth due to stringent regulations in industries like pharmaceuticals and aerospace that require high-quality vacuum solutions.

- Sustainability Focus: The emphasis on environmentally friendly technologies is fostering the development of energy-efficient pumps.

- Asia-Pacific:

- Rapid Growth: The Asia-Pacific region is experiencing significant growth due to the booming semiconductor and electronics industries, particularly in countries like China, Japan, and South Korea.

- Investment in R&D: Increased investments in research and development are driving the demand for advanced turbomolecular pumps.

- Latin America:

- Emerging Market Potential: The region presents opportunities for growth as industrialization increases and demand for high-quality vacuum solutions rises.

- Government Initiatives: Supportive government policies aimed at enhancing industrial capabilities are fostering market expansion.

- Middle East and Africa:

- Untapped Opportunities: The Middle East and Africa have significant untapped potential for turbomolecular pump manufacturers as industries develop.

- Focus on Infrastructure Development: Investments in infrastructure are driving the demand for reliable vacuum systems.

Competitive Landscape

Leading Companies in the Turbomolecular Pumps Market:

- Edwards Vacuum LLC

- Pfeiffer Vacuum GmbH

- Shimadzu Corporation

- Osaka Vacuum Ltd.

- ULVAC Technologies, Inc.

- Agilent Technologies, Inc.

- Atlas Copco AB

- KYKY Technology Development Ltd.

- Osaka Vacuum, Ltd.

- Leybold GmbH

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

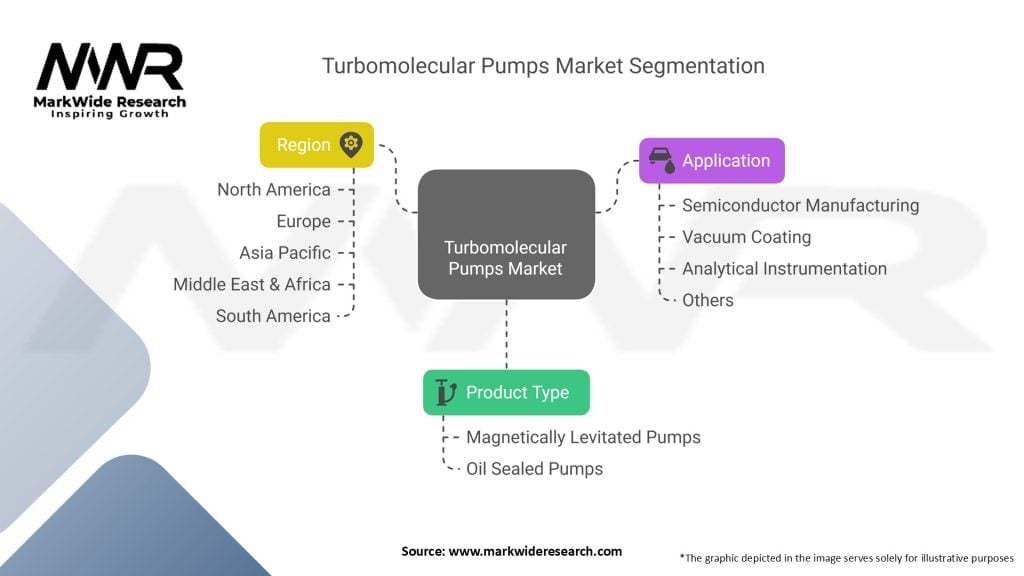

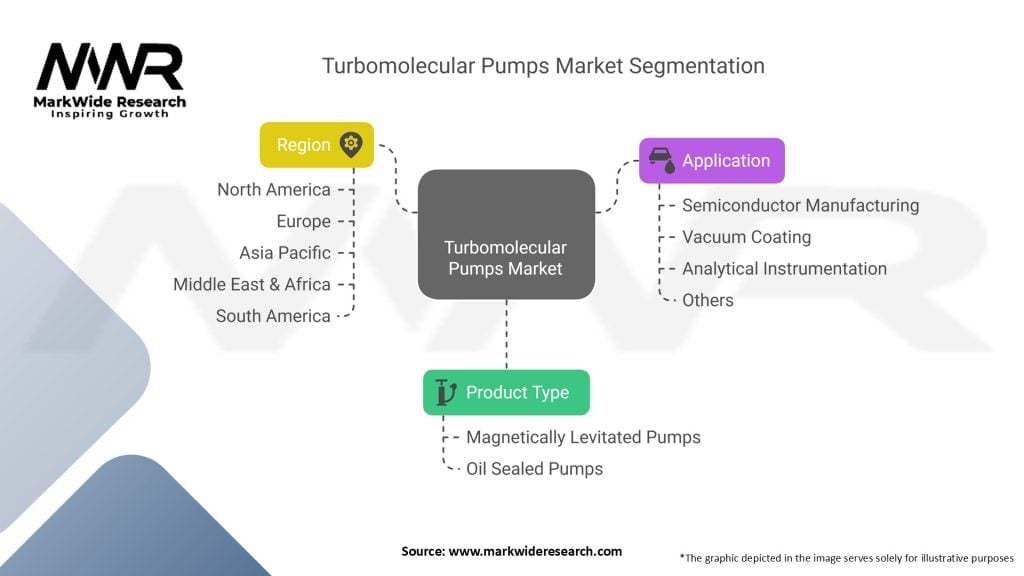

Segmentation

The turbomolecular pumps market can be segmented based on:

- By Type:

- By Application:

- Semiconductor Manufacturing

- Pharmaceuticals

- Research Laboratories

- Industrial Applications

- By Region:

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Category-wise Insights

- Magnetically Levitated Pumps: Magnetically levitated turbomolecular pumps offer advantages such as reduced maintenance requirements, higher reliability, and lower power consumption. They are gaining popularity in industries that require clean and reliable vacuum solutions, such as semiconductor manufacturing and analytical instrumentation.

- Oil-Sealed Pumps: Oil-sealed turbomolecular pumps, although less common than magnetically levitated pumps, are still used in specific applications. Their main advantage is their ability to handle a wide range of gases and particulate matter, making them suitable for various industries and research applications.

Key Benefits for Industry Participants and Stakeholders

- Enhanced manufacturing efficiency and productivity through the use of reliable and high-performance turbomolecular pumps.

- Improved product quality and consistency, particularly in the semiconductor industry, due to the elimination of contaminants and precise vacuum control.

- Cost savings and reduced downtime through the adoption of advanced pump technologies, such as intelligent control systems and predictive maintenance.

- Compliance with regulatory requirements regarding emissions and workplace safety, ensuring a safe and sustainable working environment.

- Access to emerging opportunities in developing regions and new applications, expanding market reach and potential revenue streams.

SWOT Analysis

Strengths:

- Turbomolecular pumps offer high pumping speeds, low ultimate pressures, and clean operation, providing a competitive advantage in demanding applications.

- Technological advancements have led to improved performance, reliability, and energy efficiency, enhancing the value proposition of turbomolecular pumps.

- Strong demand from industries such as semiconductor manufacturing, analytical instrumentation, and research laboratories drives market growth.

Weaknesses:

- High initial costs and the need for skilled technicians for installation and maintenance may limit market penetration, particularly among smaller enterprises.

- The occasional risk of pump contamination due to backstreaming necessitates additional precautions and maintenance efforts.

Opportunities:

- Growing opportunities in emerging economies and untapped applications offer significant market potential.

- Integration of advanced control systems and automation in turbomolecular pumps presents opportunities for efficiency gains and remote monitoring.

- Collaborations and partnerships for research and development can drive innovation and the development of next-generation turbomolecular pumps.

Threats:

- Intense competition among global and regional players in the turbomolecular pumps market poses a threat to market share and profitability.

- Volatility in raw material prices, particularly for critical components, may impact production costs and margins.

Market Key Trends

- Adoption of Oil-Free Turbomolecular Pumps: The market is witnessing a shift towards oil-free turbomolecular pumps due to their environmental benefits, lower maintenance requirements, and reduced risk of contamination.

- Intelligent Control Systems and Automation: Turbomolecular pump manufacturers are focusing on integrating advanced control systems and automation features, enabling remote monitoring, predictive maintenance, and improved performance.

- Increasing Demand from Additive Manufacturing: The growing adoption of additive manufacturing, or 3D printing, has created a demand for turbomolecular pumps in applications such as metal powder sintering and vacuum casting.

- Sustainability and Energy Efficiency: The market is witnessing a trend towards sustainable vacuum solutions, with turbomolecular pumps offering energy-efficient operation and lower environmental impact.

- Customization and Application-Specific Solutions: Manufacturers are offering customized turbomolecular pump solutions to cater to specific applications, providing enhanced performance and efficiency.

Covid-19 Impact

The Covid-19 pandemic has had mixed effects on the turbomolecular pumps market. While certain industries, such as semiconductor manufacturing and research laboratories, experienced disruptions due to lockdowns and restrictions, the demand for analytical instrumentation in healthcare and pharmaceutical applications increased significantly. The market witnessed a temporary slowdown in terms of installations and investments, but as economies recover and industries resume operations, the turbomolecular pumps market is expected to regain momentum. Moreover, the pandemic has highlighted the importance of clean and contamination-free processes, which further emphasizes the value of turbomolecular pumps in critical industries.

Key Industry Developments

- Product Innovations: Ongoing advancements in turbomolecular pump designs and materials are enhancing performance and efficiency.

- Strategic Collaborations: Partnerships between manufacturers and end-users are fostering innovation and improving product offerings.

- Focus on Regulatory Compliance: Increased attention to meeting regulatory standards is driving improvements in product safety and effectiveness.

Analyst Suggestions

- Focus on Research and Development: Manufacturers should invest in research and development activities to enhance the performance, reliability, and energy efficiency of turbomolecular pumps.

- Develop Partnerships and Collaborations: Collaborations with research institutions, end-users, and industry stakeholders can drive innovation and help develop tailored solutions for specific applications.

- Embrace Digitalization and Automation: Integrating advanced control systems, automation features, and remote monitoring capabilities can provide a competitive advantage and improve overall customer experience.

- Address Cost and Maintenance Concerns: Manufacturers should explore strategies to reduce the initial costs associated with turbomolecular pumps and offer comprehensive maintenance services to ease adoption for small and medium-sized enterprises.

Future Outlook

The turbomolecular pumps market is expected to witness steady growth in the coming years, driven by the increasing demand for high-precision vacuum solutions in industries such as semiconductor manufacturing, analytical instrumentation, and research laboratories. Technological advancements, including the integration of intelligent control systems and the development of oil-free pumps, will continue to shape the market. Additionally, emerging opportunities in developing regions and new applications, such as additive manufacturing, are expected to contribute to market expansion. However, manufacturers need to address challenges related to cost, maintenance, and market competition to capitalize on the market’s growth potential.

Conclusion

The turbomolecular pumps market is poised for growth, driven by the demand for clean and efficient vacuum solutions in various industries. Technological advancements, expanding end-use industries, and increasing investments in research and development activities are key factors shaping the market.

While challenges such as high initial costs and the need for skilled technicians exist, the market offers significant opportunities for manufacturers to innovate, expand their presence in emerging economies, and cater to new applications. By focusing on technological advancements, customization, and partnerships, turbomolecular pump manufacturers can position themselves for success in this dynamic market.

Turbomolecular Pumps Market

| Segmentation |

Details |

| Product Type |

Magnetically Levitated Pumps, Oil Sealed Pumps |

| Application |

Semiconductor Manufacturing, Vacuum Coating, Analytical Instrumentation, Others |

| Region |

North America, Europe, Asia Pacific, Middle East & Africa, South America |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Turbomolecular Pumps Market:

- Edwards Vacuum LLC

- Pfeiffer Vacuum GmbH

- Shimadzu Corporation

- Osaka Vacuum Ltd.

- ULVAC Technologies, Inc.

- Agilent Technologies, Inc.

- Atlas Copco AB

- KYKY Technology Development Ltd.

- Osaka Vacuum, Ltd.

- Leybold GmbH

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA