444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview: The Tucking Needle market serves as an integral component within the textile industry, offering specialized tools for knitting and weaving processes. Tucking needles play a crucial role in textile manufacturing, facilitating the creation of intricate patterns, designs, and textures in knitted fabrics. These needles are engineered with precision and durability to withstand the rigors of industrial knitting machines, enabling efficient production of a wide range of textiles, including apparel, home furnishings, and technical fabrics. The Tucking Needle market experiences steady demand from textile manufacturers worldwide, driven by evolving fashion trends, consumer preferences, and technological advancements in textile production.

Meaning: Tucking needles are specialized knitting machine components used to create tuck stitches in knitted fabrics. These needles feature unique designs with latch mechanisms that allow them to hold yarn temporarily, creating loops and textures in the fabric. Tuck stitches add visual interest, depth, and elasticity to knitted fabrics, enhancing their aesthetic appeal and functional properties. Tucking needles come in various sizes, gauges, and configurations to accommodate different knitting machine types, yarn weights, and fabric structures. They are essential tools for textile manufacturers, enabling the production of diverse fabric designs and styles for various applications.

Executive Summary: The Tucking Needle market serves as a vital segment within the textile industry, providing essential tools for knitting and weaving processes. The market benefits from strong demand driven by the global textile manufacturing sector, which relies on tucking needles for creating intricate patterns and textures in knitted fabrics. While the market offers lucrative opportunities for manufacturers, distributors, and retailers, it also faces challenges such as competition, technological advancements, and fluctuating raw material costs. Success in the Tucking Needle market requires innovation, quality, and responsiveness to evolving market trends and customer needs.

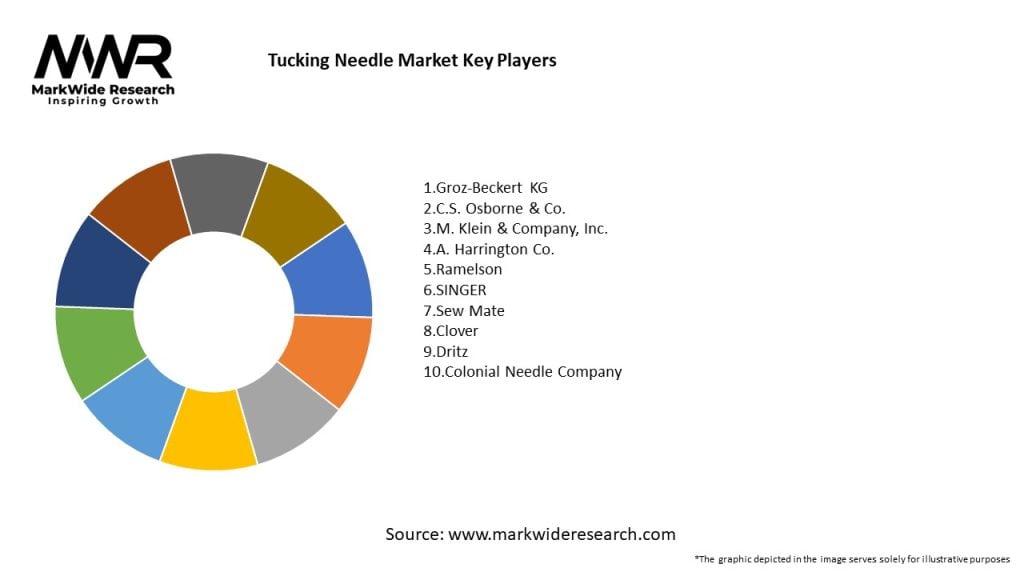

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics: The Tucking Needle market operates within a dynamic ecosystem influenced by factors such as fashion trends, technological advancements, global supply chain dynamics, and regulatory compliance requirements. These dynamics shape market demand, product innovation, pricing strategies, and competitive landscape, requiring market participants to adapt and evolve to stay competitive and meet customer needs effectively. Understanding the market dynamics is essential for tucking needle manufacturers, distributors, and retailers to identify opportunities, mitigate risks, and make informed strategic decisions to drive business growth and profitability.

Regional Analysis: The Tucking Needle market exhibits regional variations influenced by factors such as textile manufacturing infrastructure, labor costs, consumer preferences, and regulatory environments. Key regions for the Tucking Needle market include:

Competitive Landscape:

Leading Companies in the Tucking Needle Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

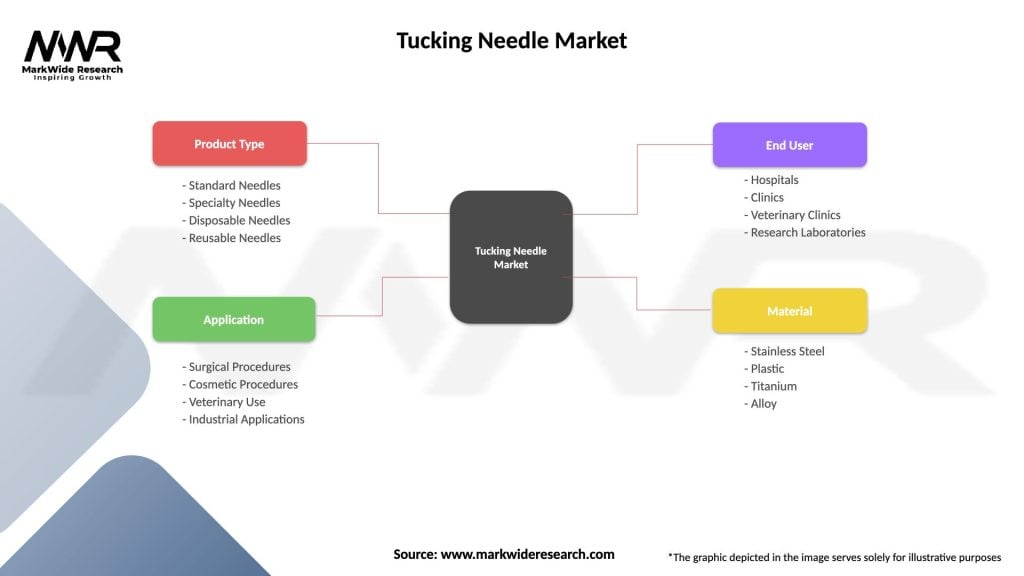

Segmentation: The Tucking Needle market can be segmented based on various factors such as:

Segmentation provides a comprehensive understanding of the Tucking Needle market, enabling suppliers to tailor products, services, and marketing strategies to specific customer segments and market opportunities effectively.

Category-wise Insights:

Key Benefits for Industry Participants and Stakeholders:

SWOT Analysis:

Market Key Trends:

Covid-19 Impact:

Key Industry Developments:

Analyst Suggestions:

Future Outlook:

The Tucking Needle market is poised for continued growth and evolution, driven by factors such as technological advancements, sustainability initiatives, customization trends, and demand for technical textiles. As the textile industry embraces digitalization, automation, and sustainability, tucking needle manufacturers have opportunities to innovate, differentiate, and capture market share by offering high-quality, versatile, and eco-friendly products and solutions. By staying agile, responsive, and proactive, tucking needle suppliers can navigate market dynamics, capitalize on emerging opportunities, and contribute to the ongoing transformation and resilience of the textile industry.

Conclusion:

The Tucking Needle market plays a vital role in the textile industry, providing essential tools for creating intricate patterns, textures, and designs in knitted fabrics. Despite challenges such as competition, technology disruptions, and regulatory compliance, the market offers opportunities for innovation, growth, and sustainability. By embracing digitalization, customization, sustainability, and collaboration, tucking needle manufacturers can meet evolving market needs, drive product innovation, and strengthen their position in the global textile supply chain. As the textile industry evolves, tucking needle suppliers must remain adaptable, resilient, and customer-focused to thrive in a dynamic and competitive market landscape.

What is Tucking Needle?

A tucking needle is a specialized sewing tool used primarily in the textile and garment industry for tucking fabric layers together. It is designed to create precise folds and tucks, enhancing the aesthetic and structural quality of garments.

What are the key players in the Tucking Needle Market?

Key players in the Tucking Needle Market include companies like Schmetz, Organ Needles, and Groz-Beckert, which are known for their high-quality needle products. These companies compete on innovation, product range, and customer service, among others.

What are the growth factors driving the Tucking Needle Market?

The growth of the Tucking Needle Market is driven by the increasing demand for high-quality textiles and the expansion of the fashion industry. Additionally, advancements in needle technology and the rise of DIY sewing trends contribute to market growth.

What challenges does the Tucking Needle Market face?

The Tucking Needle Market faces challenges such as the availability of counterfeit products and fluctuating raw material prices. These issues can affect product quality and pricing strategies for manufacturers.

What opportunities exist in the Tucking Needle Market?

Opportunities in the Tucking Needle Market include the growing trend of sustainable fashion and the increasing popularity of home sewing. Manufacturers can capitalize on these trends by developing eco-friendly needle options and expanding their product lines.

What trends are shaping the Tucking Needle Market?

Current trends in the Tucking Needle Market include the development of specialized needles for various fabric types and the integration of technology in needle design. Innovations such as ergonomic designs and enhanced durability are also gaining traction.

Tucking Needle Market

| Segmentation Details | Description |

|---|---|

| Product Type | Standard Needles, Specialty Needles, Disposable Needles, Reusable Needles |

| Application | Surgical Procedures, Cosmetic Procedures, Veterinary Use, Industrial Applications |

| End User | Hospitals, Clinics, Veterinary Clinics, Research Laboratories |

| Material | Stainless Steel, Plastic, Titanium, Alloy |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Tucking Needle Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at