444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The triaxial testing machine market serves as a cornerstone in the geotechnical and materials testing industry, facilitating comprehensive analysis of soil and rock mechanics properties. Triaxial testing machines are indispensable tools for evaluating the mechanical behavior, shear strength, and deformation characteristics of soils and rocks under varying stress and environmental conditions. As essential instruments in geotechnical engineering, construction materials testing, and research laboratories, triaxial testing machines play a pivotal role in ensuring structural integrity, safety, and performance across diverse civil engineering and infrastructure projects.

Meaning

Triaxial testing machines are sophisticated laboratory apparatus designed to subject soil and rock specimens to controlled axial and radial stresses, simulating in-situ conditions encountered in geological formations and engineering structures. These machines enable researchers, engineers, and materials scientists to analyze critical parameters such as shear strength, stress-strain relationships, permeability, and consolidation characteristics, thereby informing design, construction, and maintenance practices in civil engineering, geotechnical exploration, and construction materials manufacturing.

Executive Summary

The triaxial testing machine market experiences steady growth, driven by burgeoning infrastructure development, urbanization trends, and investments in geotechnical research and development. Industry participants must capitalize on key market insights, technological advancements, and emerging application trends to foster innovation, enhance product offerings, and cater to evolving customer requirements across diverse sectors.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The triaxial testing machine market operates within a dynamic ecosystem shaped by technological advancements, regulatory landscapes, industry collaborations, and market globalization trends. Navigating these dynamics requires market players to exhibit agility, innovation, and strategic foresight to capitalize on emergent opportunities, mitigate risks, and sustain competitive advantage in a rapidly evolving marketplace.

Regional Analysis

The triaxial testing machine market exhibits regional variations influenced by factors such as infrastructure investment trends, regulatory frameworks, academic research funding, and industry maturity levels. A comprehensive regional analysis enables market segmentation, customer targeting, and localized market strategies to optimize market penetration and revenue generation.

Competitive Landscape

Leading Companies in the Triaxial Testing Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

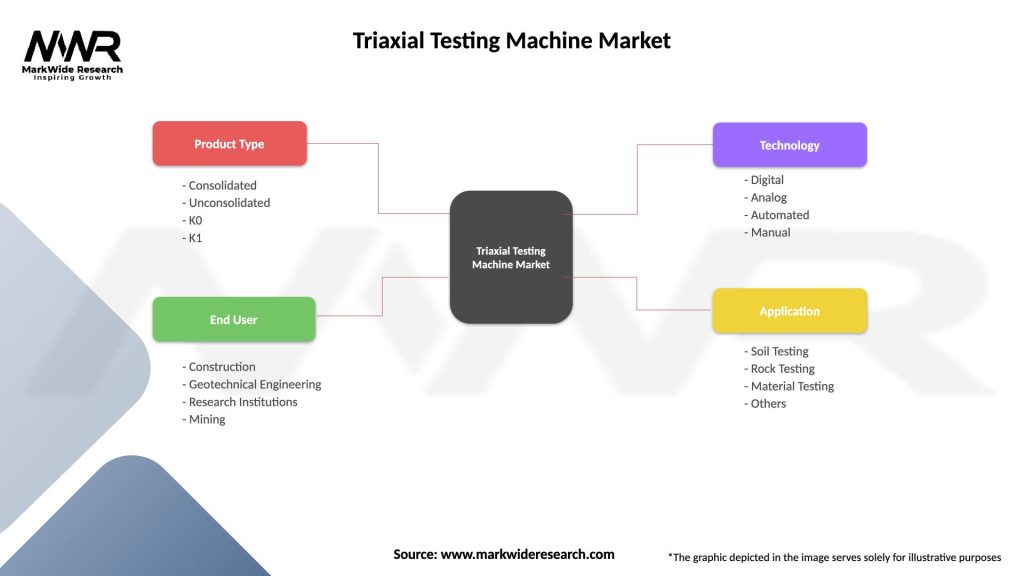

Segmentation

The triaxial testing machine market can be segmented based on various parameters, including:

Segmentation enables market players to tailor product offerings, marketing strategies, and customer support services to specific industry verticals, geographic regions, and application requirements, fostering market penetration and customer satisfaction.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has catalyzed transformative shifts within the triaxial testing machine market, characterized by:

Key Industry Developments

Analyst Suggestions

Future Outlook

The triaxial testing machine market exhibits robust growth prospects, buoyed by escalating demand for infrastructure development, geotechnical exploration, and construction materials testing applications. Industry stakeholders must leverage technological advancements, sustainability imperatives, and emerging market opportunities to sustain competitive advantage, foster innovation, and drive market growth amidst evolving industry dynamics.

Conclusion

The triaxial testing machine market assumes pivotal significance in the geotechnical and materials testing landscape, serving as essential instruments for evaluating soil and rock mechanics properties. Amidst escalating demand for infrastructure development, construction materials testing, and geotechnical research initiatives, market players must exhibit agility, innovation, and strategic foresight to capitalize on emergent opportunities, mitigate risks, and sustain competitive advantage in a rapidly evolving marketplace. By fostering digitalization, embracing sustainability imperatives, and prioritizing customer-centricity, triaxial testing machine providers can navigate market dynamics, fortify market positioning, and contribute substantively to industry advancement and infrastructure resilience.

What is Triaxial Testing Machine?

A Triaxial Testing Machine is a device used to determine the mechanical properties of soil and other materials under controlled conditions. It applies pressure in three dimensions to simulate real-world conditions, allowing for the assessment of strength, compressibility, and other critical parameters.

What are the key players in the Triaxial Testing Machine Market?

Key players in the Triaxial Testing Machine Market include GDS Instruments, Geotechnical Testing Equipment, and ELE International, among others. These companies are known for their innovative solutions and contributions to soil testing technologies.

What are the growth factors driving the Triaxial Testing Machine Market?

The growth of the Triaxial Testing Machine Market is driven by increasing construction activities, the need for soil stability assessments, and advancements in testing technologies. Additionally, the rising demand for infrastructure development in emerging economies contributes to market expansion.

What challenges does the Triaxial Testing Machine Market face?

The Triaxial Testing Machine Market faces challenges such as high initial investment costs and the need for skilled personnel to operate the equipment. Furthermore, the availability of alternative testing methods may hinder market growth.

What opportunities exist in the Triaxial Testing Machine Market?

Opportunities in the Triaxial Testing Machine Market include the development of automated testing solutions and the integration of advanced data analysis software. These innovations can enhance testing accuracy and efficiency, appealing to a broader range of industries.

What trends are shaping the Triaxial Testing Machine Market?

Trends in the Triaxial Testing Machine Market include the increasing adoption of digital technologies and the focus on sustainability in construction practices. Additionally, there is a growing emphasis on real-time data collection and analysis to improve testing outcomes.

Triaxial Testing Machine Market

| Segmentation Details | Description |

|---|---|

| Product Type | Consolidated, Unconsolidated, K0, K1 |

| End User | Construction, Geotechnical Engineering, Research Institutions, Mining |

| Technology | Digital, Analog, Automated, Manual |

| Application | Soil Testing, Rock Testing, Material Testing, Others |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Triaxial Testing Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at