444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The track rail slider market plays a crucial role in the smooth functioning and operation of various industries that rely on track systems for transportation or movement. Track rail sliders are components designed to facilitate the movement of objects along a track, ensuring stability, precision, and efficiency. They are widely used in industries such as automotive, aerospace, manufacturing, and logistics, among others. The market for track rail sliders has witnessed significant growth due to the increasing demand for improved transportation systems, automation, and efficient material handling processes.

Meaning

Track rail sliders, also known as rail slides or linear slides, are mechanical devices used to enable smooth linear motion along a track. They consist of a sliding mechanism, usually incorporating bearings or rollers, that glide along a rail or track system. Track rail sliders are designed to minimize friction, provide stability, and ensure precise movement of objects or equipment in various applications.

Executive Summary

The track rail slider market has experienced steady growth in recent years, driven by the increasing need for efficient material handling systems, automation in industrial processes, and advancements in transportation and logistics. The market is characterized by the presence of numerous players offering a wide range of track rail slider solutions to cater to diverse industry requirements. Key factors influencing market growth include technological advancements, the demand for enhanced precision and stability in motion control, and the emphasis on optimizing operational efficiency in industries.

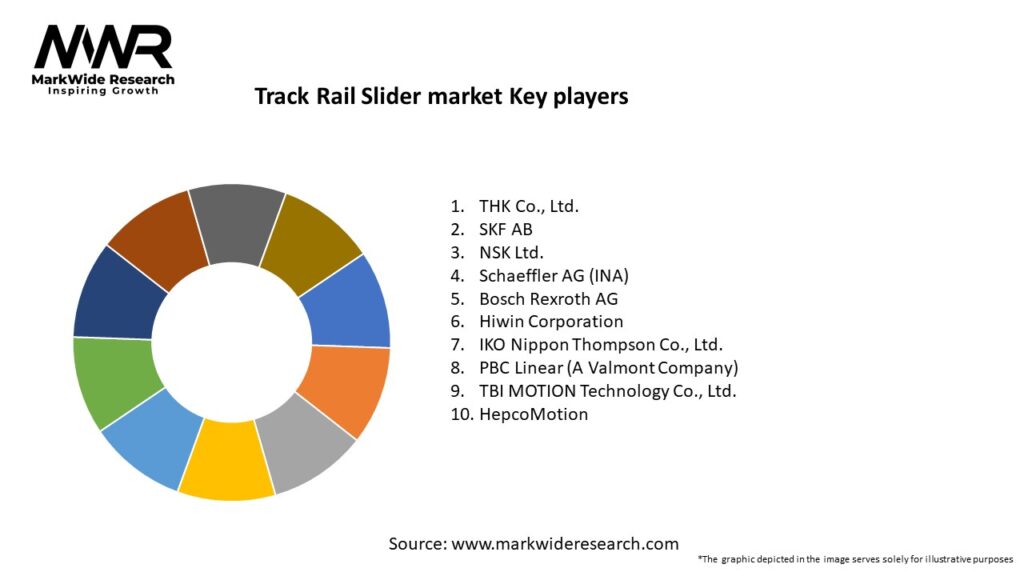

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The track rail slider market is driven by several dynamics, including technological advancements, industry trends, and the evolving needs of end-users. The market is highly competitive, with key players continuously investing in research and development to enhance product performance, reliability, and efficiency. Collaborations between manufacturers, distributors, and end-users play a vital role in driving innovation and expanding market reach.

Regional Analysis

The track rail slider market’s growth is influenced by regional factors, such as industrial development, infrastructure projects, and manufacturing activities. Developed regions, including North America and Europe, have a strong presence of established players and advanced manufacturing capabilities. Asia Pacific is witnessing rapid industrial growth and investments in infrastructure, contributing to the market’s expansion in the region.

Competitive Landscape

Leading Companies in Track Rail Slider Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

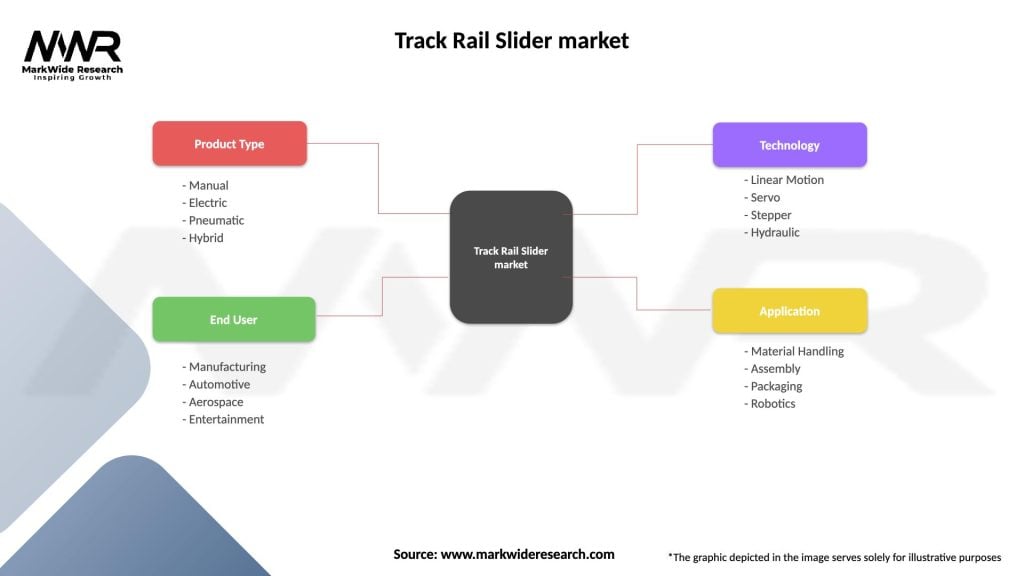

Segmentation

The track rail slider market can be segmented based on various factors, including type, load capacity, application, and end-user industry. Types of track rail sliders include ball bearing slides, roller slides, and linear guide systems. Load capacity categories range from light-duty to heavy-duty, catering to different weight requirements. Applications span industries such as automotive, aerospace, electronics, logistics, and more.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had both positive and negative impacts on the track rail slider market. The disruption in global supply chains and manufacturing activities initially affected the market’s growth. However, the increasing demand for automation, contactless operations, and efficient material handling systems amid the pandemic has provided opportunities for track rail slider manufacturers. The market is expected to rebound as industries prioritize operational resilience and invest in automation to mitigate future disruptions.

Key Industry Developments

Analyst Suggestions

Future Outlook

The track rail slider market is expected to witness significant growth in the coming years, driven by the increasing demand for automation, efficient material handling systems, and precise motion control in various industries. Technological advancements, such as the integration of sensors and feedback systems, miniaturization, and sustainable design practices, will shape the future of the market. Collaborations and partnerships among manufacturers, system integrators, and end-users will drive innovation and foster the development of customized track rail slider solutions. Despite challenges such as high initial costs and maintenance requirements, the market’s future outlook remains positive, with opportunities for growth, expansion, and advancements in track rail slider technology.

Conclusion

The track rail slider market plays a critical role in enabling smooth and precise linear motion in various industries. With increasing demand for automation, precise motion control, and efficient material handling systems, track rail sliders have gained prominence. The market offers a wide range of solutions, including ball bearing slides and roller slides, to cater to different load capacities and application requirements. Technological advancements, such as sensor integration, compact designs, and sustainability initiatives, drive market growth and innovation. The Covid-19 pandemic has accelerated the adoption of automation and contactless operations, providing opportunities for track rail slider manufacturers. However, challenges related to initial costs and maintenance requirements should be addressed. The market’s future outlook is optimistic, with opportunities for collaboration, technological advancements, and customized solutions to meet industry-specific needs.

What is Track Rail Slider?

Track Rail Slider refers to a mechanical device used in various applications, including photography and videography, to enable smooth and controlled movement along a track. It is commonly utilized in camera systems to achieve dynamic shots and stable footage.

What are the key players in the Track Rail Slider market?

Key players in the Track Rail Slider market include companies like Manfrotto, Kessler Crane, and Rhino Camera Gear, which are known for their innovative products and solutions in the field of camera equipment and accessories, among others.

What are the growth factors driving the Track Rail Slider market?

The growth of the Track Rail Slider market is driven by the increasing demand for high-quality video production in industries such as film, advertising, and social media. Additionally, advancements in technology and the rise of content creation among influencers contribute to this growth.

What challenges does the Track Rail Slider market face?

The Track Rail Slider market faces challenges such as the high cost of advanced equipment and the need for skilled operators to effectively use these tools. Furthermore, competition from alternative stabilization technologies can impact market growth.

What opportunities exist in the Track Rail Slider market?

Opportunities in the Track Rail Slider market include the expansion of e-commerce platforms for easier access to products and the growing trend of live streaming, which increases the demand for professional-grade equipment. Additionally, innovations in materials and design can enhance product offerings.

What trends are shaping the Track Rail Slider market?

Trends in the Track Rail Slider market include the integration of smart technology for automated movements and the development of lightweight, portable designs that cater to on-the-go content creators. There is also a growing interest in modular systems that allow for customization based on user needs.

Track Rail Slider market

| Segmentation Details | Description |

|---|---|

| Product Type | Manual, Electric, Pneumatic, Hybrid |

| End User | Manufacturing, Automotive, Aerospace, Entertainment |

| Technology | Linear Motion, Servo, Stepper, Hydraulic |

| Application | Material Handling, Assembly, Packaging, Robotics |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in Track Rail Slider Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at