444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Top hammer drill bits are essential tools used in construction and mining operations for drilling holes in rock formations. These drill bits are designed to withstand high-impact forces and provide efficient drilling performance in various geological conditions. The top hammer drilling method, characterized by its percussive action and use of pneumatic or hydraulic hammers, offers advantages such as fast drilling rates, precise hole accuracy, and minimal deviation. The top hammer drill bits for construction market plays a crucial role in infrastructure development, mining exploration, and quarrying activities, driving demand for high-quality and durable drilling tools.

Meaning

Top hammer drill bits for construction are specialized tools used in top hammer drilling rigs to penetrate rock formations and create boreholes for various applications. These drill bits feature a carbide button or insert at the tip, which delivers impact energy to the rock surface, breaking it into small fragments. The percussive action of the top hammer drill, combined with rotation, enables efficient drilling in hard rock formations, making it a preferred method for construction, mining, and civil engineering projects.

Executive Summary

The top hammer drill bits for construction market is witnessing steady growth, fueled by increasing infrastructure investments, urbanization, and mining activities worldwide. Market players are focusing on product innovation, material advancements, and performance enhancements to meet evolving customer demands and industry standards. However, challenges such as intense competition, raw material costs, and regulatory compliance pose significant hurdles for market participants. Understanding key market insights, trends, and dynamics is essential for stakeholders to capitalize on growth opportunities and maintain competitiveness in the global market.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The top hammer drill bits for construction market operates in a dynamic environment influenced by factors such as economic conditions, technological advancements, regulatory changes, and competitive forces. These dynamics shape market trends, customer preferences, and industry developments, requiring agility and adaptability among market participants. Understanding market dynamics is essential for stakeholders to identify opportunities, mitigate risks, and formulate effective strategies in a rapidly evolving market landscape.

Regional Analysis

The top hammer drill bits for construction market exhibits regional variations in demand, adoption, and market dynamics due to differences in construction activity, mining resources, regulatory environments, and economic factors. Key regions such as North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa present diverse market opportunities and challenges for drill bit manufacturers. Analyzing regional trends and market dynamics enables companies to tailor their strategies and offerings to specific regional needs and preferences.

Competitive Landscape

Leading Companies in the Top Hammer Drill Bits for Construction Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

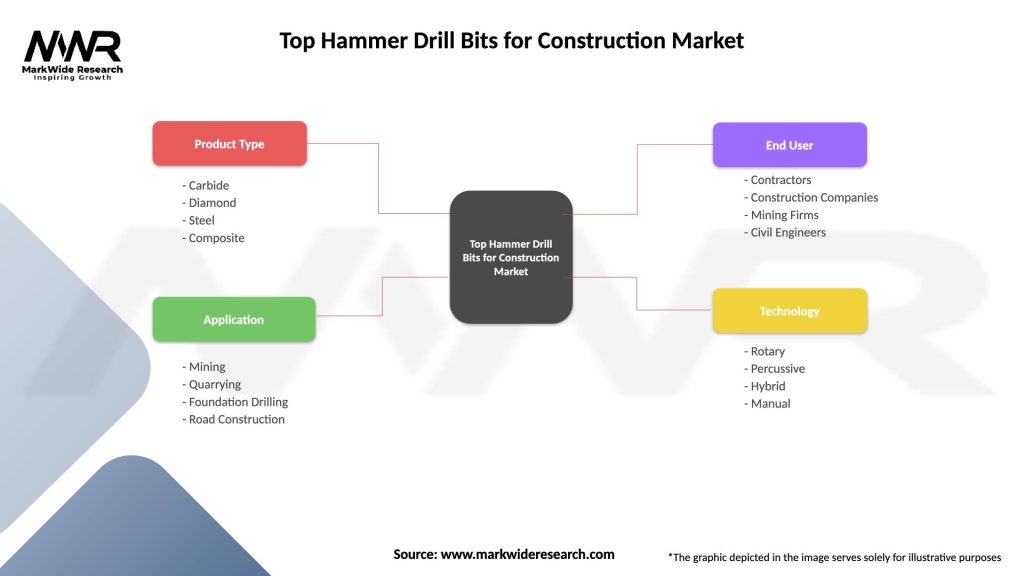

Segmentation

The top hammer drill bits for construction market can be segmented based on various factors such as product type, application, end-use industry, and geography. Common product types include button bits, cross bits, reaming bits, and DTH (Down-the-Hole) bits, each designed for specific drilling conditions and rock formations. Applications span a wide range of construction and mining activities, including foundation drilling, blasthole drilling, tunneling, and exploration drilling. End-use industries include infrastructure, mining, oil and gas, and geothermal energy, among others. Segmenting the market provides insights into customer needs, preferences, and buying behavior, enabling manufacturers to target specific segments and tailor their offerings accordingly.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The top hammer drill bits for construction market offer several benefits for industry participants and stakeholders, including improved drilling efficiency, increased productivity, reduced downtime, and enhanced safety. High-quality and reliable drill bits enable faster penetration rates, longer bit life, and higher drilling accuracy, resulting in cost savings and operational performance improvements. By investing in premium drill bits, construction contractors, mining companies, and drilling operators can achieve higher project profitability, better resource utilization, and competitive advantages in the market.

SWOT Analysis

Strengths

• The top hammer drill bits market benefits from advanced manufacturing technologies that enhance performance and durability, catering to the demanding needs of the construction industry.

• A strong reputation for reliability and efficiency in drilling applications positions top hammer drill bits as a preferred choice among contractors and construction firms.

• The availability of a wide range of sizes and specifications allows for customization, enabling users to select the most suitable drill bits for various geological conditions.

• Established distribution networks ensure that top hammer drill bits are readily accessible, facilitating quick procurement and minimizing project downtime for construction companies.

Weaknesses

• High production costs associated with premium materials and advanced technologies can limit the price competitiveness of top hammer drill bits in the market.

• The reliance on specialized equipment and expertise for effective use may deter smaller construction firms with limited resources from adopting top hammer drilling solutions.

• Limited brand differentiation in a saturated market can lead to consumer confusion, making it challenging for manufacturers to establish a unique market presence.

• The potential for rapid wear and tear in harsh drilling environments may result in increased maintenance costs and reduced operational efficiency for users.

Opportunities

• The growing trend towards sustainable construction practices presents an opportunity for manufacturers to innovate eco-friendly drill bit materials and processes.

• Increasing investments in infrastructure development and mining projects globally create a rising demand for efficient drilling solutions, boosting the top hammer drill bits market.

• The advent of smart drilling technologies and IoT integration can enhance operational efficiency, offering manufacturers a chance to differentiate their products through advanced features.

• Expanding into emerging markets with developing construction sectors provides a significant opportunity for growth and increased market penetration for top hammer drill bit manufacturers.

Threats

• Intense competition from alternative drilling technologies, such as rotary and percussive drilling, poses a risk to market share for top hammer drill bits.

• Fluctuations in raw material prices can adversely impact production costs, potentially leading to increased prices for end-users and reduced demand.

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has had mixed effects on the top hammer drill bits for construction market. While construction and mining activities faced disruptions and project delays due to lockdowns, supply chain disruptions, and workforce shortages, the pandemic also highlighted the importance of resilient and adaptable drilling solutions. Increased focus on health, safety, and operational efficiency led to the adoption of remote monitoring, contactless drilling, and digital collaboration tools, driving demand for smart and connected drill bit technologies.

Key Industry Developments

Key industry developments in the top hammer drill bits for construction market include advancements in drill bit design and materials, introduction of smart drilling technologies, expansion into new markets, and strategic partnerships and acquisitions. Manufacturers are investing in research and development to improve drilling performance, durability, and sustainability, addressing customer needs and market demands. Collaborative innovation initiatives and industry consortia are driving technology adoption and market growth, shaping the future of drilling solutions in the construction and mining sectors.

Analyst Suggestions

Analyst suggestions for industry participants in the top hammer drill bits for construction market include investing in research and development to drive innovation and product differentiation, expanding market presence in emerging economies, enhancing aftermarket services and support offerings, and leveraging digital technologies for predictive maintenance and remote monitoring. By aligning strategies with market trends and customer needs, companies can navigate market dynamics and capitalize on growth opportunities in the global top hammer drill bits for construction market.

Future Outlook

The future outlook for the top hammer drill bits for construction market is optimistic, with continued growth expected driven by factors such as increasing infrastructure investments, mining activities, technological advancements, and sustainability initiatives. Industry players that focus on innovation, sustainability, and customer-centric solutions are well-positioned to capitalize on emerging opportunities and maintain competitiveness in a dynamic and evolving market landscape.

Conclusion

In conclusion, the top hammer drill bits for construction market plays a critical role in enabling efficient and productive drilling operations in construction, mining, and civil engineering projects. With increasing infrastructure investments, urbanization, and mining activities worldwide, the demand for high-quality and durable drill bits is on the rise. By understanding key market insights, trends, and dynamics, industry participants can capitalize on growth opportunities, address challenges, and navigate market uncertainties to achieve long-term success in the global top hammer drill bits for construction market.

What is Top Hammer Drill Bits for Construction?

Top hammer drill bits for construction are specialized tools designed for drilling into hard materials like concrete and rock. They utilize a percussive action to break through tough surfaces, making them essential for construction and mining applications.

What are the leading companies in the Top Hammer Drill Bits for Construction Market?

Key players in the top hammer drill bits for construction market include Hilti, Atlas Copco, and Bosch, among others. These companies are known for their innovative products and extensive range of drill bits tailored for various construction needs.

What are the growth factors driving the Top Hammer Drill Bits for Construction Market?

The growth of the top hammer drill bits for construction market is driven by the increasing demand for infrastructure development and urbanization. Additionally, advancements in drilling technology and the rising need for efficient construction tools contribute to market expansion.

What challenges does the Top Hammer Drill Bits for Construction Market face?

The top hammer drill bits for construction market faces challenges such as fluctuating raw material prices and competition from alternative drilling technologies. Moreover, the need for regular maintenance and replacement of drill bits can impact operational costs for users.

What opportunities exist in the Top Hammer Drill Bits for Construction Market?

Opportunities in the top hammer drill bits for construction market include the development of eco-friendly drill bits and the expansion into emerging markets. Additionally, the growing trend of automation in construction processes presents new avenues for innovation.

What trends are shaping the Top Hammer Drill Bits for Construction Market?

Current trends in the top hammer drill bits for construction market include the increasing use of high-performance materials and coatings to enhance durability. Furthermore, the integration of smart technology in drilling equipment is becoming more prevalent, improving efficiency and precision.

Top Hammer Drill Bits for Construction Market

| Segmentation Details | Description |

|---|---|

| Product Type | Carbide, Diamond, Steel, Composite |

| Application | Mining, Quarrying, Foundation Drilling, Road Construction |

| End User | Contractors, Construction Companies, Mining Firms, Civil Engineers |

| Technology | Rotary, Percussive, Hybrid, Manual |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Top Hammer Drill Bits for Construction Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at