444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The Thailand plastic bottles market represents a dynamic and rapidly evolving sector within Southeast Asia’s packaging industry. Thailand’s strategic position as a manufacturing hub and its robust consumer goods sector have positioned the country as a significant player in plastic bottle production and consumption. The market encompasses various applications including beverages, personal care products, pharmaceuticals, and household chemicals, with beverage packaging commanding the largest market share at approximately 45% of total consumption.

Market dynamics in Thailand reflect the country’s economic growth and changing consumer preferences toward convenient packaging solutions. The industry has experienced consistent expansion driven by urbanization, rising disposable incomes, and increased demand for packaged goods. Manufacturing capabilities have advanced significantly, with local producers adopting international quality standards and sustainable production practices. The market demonstrates strong growth potential with projected expansion at a compound annual growth rate (CAGR) of 6.2% through the forecast period.

Regional distribution shows concentration in major industrial zones including Bangkok, Rayong, and Chonburi provinces, where established manufacturing facilities and proximity to raw material suppliers create competitive advantages. The market benefits from Thailand’s well-developed infrastructure and favorable government policies supporting the packaging industry’s growth and modernization initiatives.

The Thailand plastic bottles market refers to the comprehensive ecosystem encompassing the production, distribution, and consumption of plastic bottle containers within Thailand’s borders. This market includes various bottle types manufactured from different plastic resins such as polyethylene terephthalate (PET), high-density polyethylene (HDPE), and polypropylene (PP), serving diverse end-use industries including food and beverages, personal care, pharmaceuticals, and industrial applications.

Market scope extends beyond simple container manufacturing to include value-added services such as custom design, labeling, and specialized packaging solutions. The industry encompasses both domestic consumption and export activities, with Thailand serving as a regional manufacturing base for multinational companies seeking cost-effective production capabilities combined with quality assurance.

Stakeholder involvement includes raw material suppliers, bottle manufacturers, brand owners, distributors, and recycling companies, creating an integrated value chain that supports Thailand’s broader packaging industry objectives and sustainability goals.

Thailand’s plastic bottles market demonstrates remarkable resilience and growth potential, driven by strong domestic demand and expanding export opportunities. The market benefits from Thailand’s established position as the “Detroit of Southeast Asia” for manufacturing, with advanced production capabilities and skilled workforce supporting industry expansion. Key growth drivers include increasing urbanization rates, rising consumer spending on packaged goods, and growing health consciousness leading to higher bottled water consumption.

Technological advancement plays a crucial role in market development, with manufacturers investing in advanced blow molding equipment, automation systems, and quality control technologies. The industry shows strong commitment to sustainability, with recycling rates improving by 15% annually and increased adoption of eco-friendly materials and production processes.

Market challenges include raw material price volatility, environmental regulations, and increasing competition from alternative packaging materials. However, strategic initiatives focusing on innovation, sustainability, and market diversification position Thai manufacturers favorably for continued growth and market leadership in the region.

Strategic market positioning reveals several critical insights that define Thailand’s plastic bottles market landscape:

Market intelligence indicates strong correlation between economic growth and plastic bottle consumption, with premium segment products showing particularly robust demand growth in urban markets.

Economic prosperity serves as the primary catalyst driving Thailand’s plastic bottles market expansion. Rising disposable incomes and improved living standards have increased consumer spending on packaged goods, particularly in urban areas where convenience and product safety are prioritized. GDP growth correlation shows direct relationship between economic expansion and packaging demand, with middle-class expansion creating sustained market growth momentum.

Demographic trends significantly influence market dynamics, with Thailand’s young population demonstrating strong preference for convenient packaging solutions. Urbanization rates continue climbing, creating concentrated demand centers and supporting efficient distribution networks. Lifestyle changes including increased mobility, longer working hours, and health consciousness drive demand for portable beverage containers and personal care products.

Industrial development in key sectors including food processing, pharmaceuticals, and cosmetics creates substantial demand for specialized plastic bottle solutions. Thailand’s position as a regional manufacturing hub attracts multinational companies seeking reliable packaging suppliers, generating consistent demand for high-quality bottle products.

Government initiatives supporting industrial development and export promotion provide favorable operating environment for plastic bottle manufacturers. Infrastructure investments and trade facilitation measures enhance market accessibility and reduce operational costs for industry participants.

Environmental concerns represent the most significant challenge facing Thailand’s plastic bottles market. Increasing awareness of plastic pollution and its environmental impact has led to stricter regulations and consumer preference shifts toward sustainable alternatives. Government policies targeting single-use plastics and promoting circular economy principles create compliance costs and operational challenges for manufacturers.

Raw material volatility poses ongoing challenges, with petroleum-based resin prices subject to global oil market fluctuations. Supply chain disruptions and geopolitical tensions can significantly impact production costs and profit margins. Currency fluctuations affect both raw material imports and export competitiveness, creating financial planning complexities for market participants.

Competition intensity from both domestic and international players pressures pricing strategies and market share retention. Low-cost imports from neighboring countries and alternative packaging materials including glass, metal, and biodegradable options create competitive pressures requiring continuous innovation and cost optimization.

Regulatory compliance costs associated with food safety standards, environmental regulations, and quality certifications increase operational expenses and complexity. Changing regulations require ongoing investments in technology upgrades and process modifications to maintain market access and competitiveness.

Sustainability transformation presents significant opportunities for forward-thinking manufacturers willing to invest in eco-friendly technologies and materials. Growing consumer demand for recycled content bottles and biodegradable alternatives creates premium market segments with higher profit margins. Circular economy initiatives supported by government policies offer competitive advantages for companies developing comprehensive recycling and reuse programs.

Export expansion opportunities exist throughout ASEAN markets where Thailand’s manufacturing expertise and cost competitiveness provide strategic advantages. Regional trade agreements and improved logistics infrastructure facilitate market access and reduce export barriers. Value-added services including custom design, private labeling, and integrated packaging solutions offer differentiation opportunities and higher margins.

Technology integration including smart packaging, IoT-enabled tracking, and advanced materials science creates new product categories and applications. Digital transformation initiatives can improve operational efficiency, reduce costs, and enhance customer service capabilities. Industry 4.0 adoption offers opportunities for process optimization and quality improvement.

Niche market development in specialized applications including pharmaceuticals, cosmetics, and industrial chemicals provides growth opportunities with less price sensitivity and higher technical requirements. Premium positioning strategies can capture value from quality-conscious consumers and brand owners seeking differentiated packaging solutions.

Supply chain integration characterizes Thailand’s plastic bottles market, with vertical integration strategies becoming increasingly common among major manufacturers. Companies are investing in upstream capabilities including resin production and downstream services such as filling and distribution to capture additional value and improve cost competitiveness. Strategic partnerships between bottle manufacturers and brand owners create stable demand relationships and collaborative innovation opportunities.

Innovation cycles drive continuous market evolution, with manufacturers investing heavily in research and development to create lighter, stronger, and more sustainable bottle designs. Material science advances enable development of specialized bottles with enhanced barrier properties, extended shelf life, and improved recyclability. Technology adoption rates show acceleration in automation and quality control systems.

Market consolidation trends reflect economies of scale advantages and capital intensity requirements in modern manufacturing. Smaller players face pressure to specialize in niche markets or consider strategic partnerships with larger manufacturers. Foreign investment continues flowing into Thailand’s packaging sector, bringing advanced technologies and international market access.

Regulatory evolution shapes market dynamics through environmental standards, food safety requirements, and trade policies. Industry adaptation to changing regulations requires ongoing investment in compliance systems and process modifications, creating both challenges and opportunities for market differentiation.

Comprehensive market analysis employs multiple research methodologies to ensure accuracy and reliability of findings. Primary research includes extensive interviews with industry executives, manufacturers, suppliers, and end-users across Thailand’s major industrial regions. Survey methodologies capture quantitative data on production volumes, capacity utilization, pricing trends, and market share distributions.

Secondary research incorporates analysis of government statistics, industry association reports, trade data, and regulatory filings to establish market baselines and validate primary research findings. Data triangulation techniques ensure consistency across multiple information sources and identify potential discrepancies requiring further investigation.

Market modeling utilizes econometric analysis to establish relationships between key variables including economic indicators, demographic trends, and market performance metrics. Forecasting models incorporate multiple scenarios to account for uncertainty and provide robust projections for strategic planning purposes.

Quality assurance protocols include peer review processes, data validation checks, and expert panel consultations to ensure research findings meet professional standards and provide actionable insights for market participants and stakeholders.

Bangkok Metropolitan Region dominates Thailand’s plastic bottles market, accounting for approximately 35% of total consumption driven by high population density and concentrated commercial activity. The region serves as the primary distribution hub and houses major brand owners’ headquarters, creating substantial demand for diverse bottle types and sizes. Manufacturing presence includes several major facilities serving both domestic and export markets.

Eastern Economic Corridor represents Thailand’s manufacturing powerhouse, with provinces including Chonburi, Rayong, and Chachoengsao hosting significant production capacity. The region benefits from excellent infrastructure, port access, and government incentives supporting industrial development. Export-oriented production facilities in this region serve regional markets and global supply chains.

Central Region including Ayutthaya and Pathum Thani provinces combines manufacturing capabilities with agricultural processing industries, creating demand for specialized bottle applications. The region’s strategic location provides cost-effective access to both Bangkok markets and northern provinces.

Northern and Southern regions show growing market potential driven by tourism industry development and regional economic growth. These markets demonstrate increasing demand for premium bottled products and specialized applications, though production capacity remains concentrated in central regions.

Cross-border trade dynamics influence regional market patterns, with border provinces serving as gateways for export activities to neighboring countries including Myanmar, Laos, and Cambodia.

Market leadership in Thailand’s plastic bottles sector reflects a combination of domestic champions and international players, each bringing distinct competitive advantages and market strategies:

Competitive strategies emphasize technology leadership, sustainability initiatives, and customer service excellence. Market leaders invest heavily in automation, quality systems, and environmental compliance to maintain competitive advantages and meet evolving customer requirements.

By Material Type:

By Application:

By Capacity Range:

Beverage packaging represents the most dynamic category within Thailand’s plastic bottles market, driven by health consciousness trends and convenience preferences. Water bottles dominate this segment with consistent growth supported by quality concerns about tap water and active lifestyle adoption. Premium water brands command higher margins through innovative bottle designs and sustainable materials.

Personal care applications show strong growth potential with premiumization trends driving demand for sophisticated packaging solutions. Thai consumers increasingly value product presentation and brand differentiation through packaging design. Cosmetics packaging requires specialized materials and manufacturing processes, creating opportunities for value-added services.

Pharmaceutical packaging demands highest quality standards and regulatory compliance, creating barriers to entry but offering stable margins and long-term customer relationships. Child-resistant closures and tamper-evident features add complexity and value to pharmaceutical bottle applications.

Industrial applications provide steady demand with less price sensitivity, though requiring specialized materials and certifications. Chemical compatibility and performance requirements create technical challenges but offer differentiation opportunities for capable manufacturers.

Export categories focus on standardized products with competitive pricing, while domestic premium segments emphasize customization and service quality. Market segmentation strategies increasingly target specific applications with tailored solutions rather than commodity approaches.

Manufacturers benefit from Thailand’s competitive manufacturing environment including skilled workforce, established supply chains, and government support for industrial development. Cost advantages compared to developed markets enable competitive pricing while maintaining quality standards. Access to regional markets through ASEAN trade agreements provides export growth opportunities.

Brand owners gain access to reliable, high-quality packaging solutions with flexible manufacturing capabilities and responsive customer service. Local sourcing reduces supply chain risks and transportation costs while supporting sustainability objectives. Technical expertise and innovation capabilities enable custom packaging development.

Consumers benefit from improved product safety, convenience, and quality through advanced packaging technologies. Sustainable packaging options address environmental concerns while maintaining product integrity. Competitive market dynamics ensure reasonable pricing and continuous innovation.

Government stakeholders benefit from industrial development, employment creation, and export revenue generation. Technology transfer and skills development contribute to Thailand’s industrial competitiveness and economic diversification objectives.

Environmental stakeholders benefit from industry initiatives promoting recycling, waste reduction, and sustainable materials adoption. Circular economy development creates new business opportunities while addressing environmental challenges.

Strengths:

Weaknesses:

Opportunities:

Threats:

Sustainability transformation dominates current market trends, with manufacturers investing heavily in recycled content integration, biodegradable materials research, and circular economy initiatives. Consumer awareness of environmental issues drives demand for eco-friendly packaging solutions, creating competitive advantages for early adopters of sustainable technologies.

Lightweighting innovations continue advancing through improved design techniques and advanced materials, reducing material consumption while maintaining structural integrity. Manufacturing efficiency improvements through automation and process optimization enable cost reduction and quality enhancement simultaneously.

Customization trends reflect brand owners’ desire for differentiated packaging solutions that enhance product appeal and consumer engagement. Digital printing technologies enable cost-effective short-run customization and rapid design changes supporting marketing flexibility.

Smart packaging integration incorporates IoT sensors, QR codes, and interactive features creating new value propositions for brand owners and consumers. Supply chain transparency initiatives utilize blockchain and tracking technologies to provide product authenticity and sustainability verification.

Regional consolidation trends see larger manufacturers acquiring smaller players to achieve economies of scale and expand market coverage. Vertical integration strategies include backward integration into raw materials and forward integration into filling and distribution services.

Technology investments by major manufacturers focus on advanced blow molding equipment, automation systems, and quality control technologies. MarkWide Research indicates significant capital expenditure increases as companies modernize facilities to meet growing demand and quality requirements. Recent facility expansions in the Eastern Economic Corridor demonstrate industry confidence in long-term growth prospects.

Sustainability initiatives include major recycling facility investments and partnerships with waste management companies to develop closed-loop systems. Industry collaborations with government agencies and NGOs address plastic waste challenges through comprehensive recycling programs and consumer education initiatives.

Market consolidation activities include strategic acquisitions and joint ventures aimed at expanding production capacity and market reach. International partnerships bring advanced technologies and global market access while strengthening competitive positioning in regional markets.

Regulatory compliance investments address evolving environmental standards and food safety requirements. Certification programs including ISO standards and industry-specific quality systems ensure market access and customer confidence in product quality and safety.

Innovation partnerships with research institutions and technology providers accelerate development of next-generation packaging solutions including biodegradable materials and smart packaging technologies.

Strategic positioning recommendations emphasize sustainability leadership as a key differentiator in increasingly competitive markets. Companies should invest in recycling technologies, sustainable materials research, and circular economy initiatives to capture premium market segments and meet evolving regulatory requirements. Early adoption of eco-friendly technologies provides competitive advantages and supports long-term market positioning.

Market diversification strategies should reduce dependence on beverage applications through expansion into personal care, pharmaceuticals, and industrial segments. Value-added services including custom design, integrated packaging solutions, and supply chain services offer higher margins and stronger customer relationships.

Technology investment priorities should focus on automation, quality systems, and digital transformation initiatives that improve efficiency and reduce costs. Industry 4.0 adoption enables data-driven decision making and predictive maintenance capabilities supporting operational excellence.

Regional expansion opportunities in ASEAN markets require strategic partnerships and local market knowledge to navigate regulatory requirements and cultural preferences. Export strategies should leverage Thailand’s manufacturing competitiveness while building strong distribution networks in target markets.

Talent development initiatives should address skills gaps in advanced manufacturing, sustainability, and digital technologies. Workforce training programs ensure companies can effectively utilize new technologies and maintain quality standards as operations expand.

Long-term growth prospects for Thailand’s plastic bottles market remain positive despite environmental challenges and regulatory pressures. MWR projections indicate sustained demand growth driven by economic development, urbanization, and regional market expansion. The industry’s adaptation to sustainability requirements through innovation and technology adoption positions Thailand favorably for continued market leadership in Southeast Asia.

Technology evolution will reshape market dynamics through advanced materials, smart packaging, and automated manufacturing systems. Sustainability integration becomes increasingly critical for market access and competitive positioning, with companies investing heavily in recycling capabilities and eco-friendly materials development.

Market structure evolution toward greater consolidation and specialization creates opportunities for companies with clear strategic positioning and competitive advantages. Export growth potential remains strong as regional trade integration advances and Thai manufacturers build stronger international market presence.

Regulatory landscape will continue evolving toward stricter environmental standards and circular economy requirements, creating both challenges and opportunities for industry participants. Innovation capabilities become increasingly important for maintaining competitiveness and meeting evolving customer requirements.

Investment opportunities exist in sustainable technologies, automation systems, and regional market expansion initiatives. Companies with strong financial positions and strategic vision can capitalize on market consolidation opportunities and technology advancement requirements.

Thailand’s plastic bottles market demonstrates remarkable resilience and growth potential despite facing significant environmental and competitive challenges. The industry’s strategic advantages including manufacturing excellence, competitive costs, and regional market access position Thailand as a continued leader in Southeast Asian packaging markets. Sustainability transformation represents both the greatest challenge and opportunity, requiring significant investments but offering competitive differentiation and premium market access.

Market dynamics favor companies with strong innovation capabilities, sustainability leadership, and diversified market positioning. The industry’s evolution toward higher value-added applications and services creates opportunities for margin improvement and competitive advantage development. Regional expansion potential through ASEAN integration provides additional growth avenues for well-positioned manufacturers.

Future success in Thailand’s plastic bottles market will depend on companies’ ability to balance cost competitiveness with sustainability requirements while maintaining quality standards and customer service excellence. Strategic investments in technology, sustainability, and market diversification will determine long-term competitive positioning and growth potential in this dynamic and evolving market landscape.

What is Plastic Bottles?

Plastic bottles are containers made from various types of plastic, commonly used for packaging liquids such as beverages, cleaning products, and personal care items. They are lightweight, durable, and can be produced in various shapes and sizes to meet consumer needs.

What are the key players in the Thailand Plastic Bottles Market?

Key players in the Thailand Plastic Bottles Market include companies like SCG Packaging, Thai Plastic and Chemicals, and Indorama Ventures, which are known for their extensive production capabilities and innovative packaging solutions, among others.

What are the growth factors driving the Thailand Plastic Bottles Market?

The growth of the Thailand Plastic Bottles Market is driven by increasing consumer demand for packaged beverages, the rise of e-commerce, and a growing focus on convenience in packaging. Additionally, the expansion of the food and beverage industry contributes significantly to market growth.

What challenges does the Thailand Plastic Bottles Market face?

The Thailand Plastic Bottles Market faces challenges such as environmental concerns regarding plastic waste, regulatory pressures for sustainable packaging, and competition from alternative materials like glass and biodegradable options. These factors can impact production and consumer preferences.

What opportunities exist in the Thailand Plastic Bottles Market?

Opportunities in the Thailand Plastic Bottles Market include the development of eco-friendly packaging solutions, innovations in recycling technologies, and the potential for growth in the personal care and pharmaceutical sectors. Companies are increasingly focusing on sustainability to attract environmentally conscious consumers.

What trends are shaping the Thailand Plastic Bottles Market?

Trends in the Thailand Plastic Bottles Market include the shift towards lightweight and recyclable materials, the adoption of smart packaging technologies, and increasing consumer awareness about sustainability. These trends are influencing product design and manufacturing processes.

Thailand Plastic Bottles Market

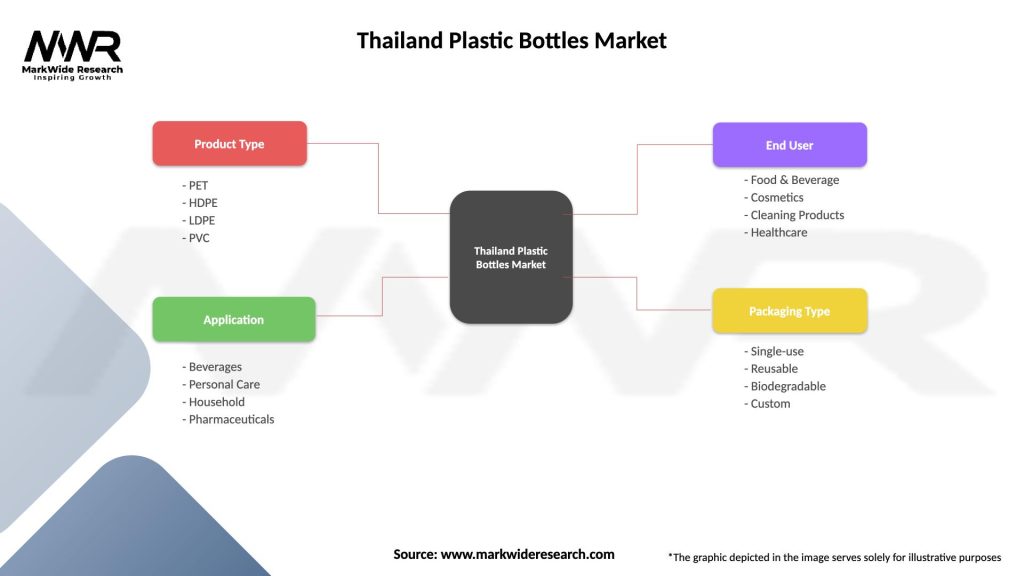

| Segmentation Details | Description |

|---|---|

| Product Type | PET, HDPE, LDPE, PVC |

| Application | Beverages, Personal Care, Household, Pharmaceuticals |

| End User | Food & Beverage, Cosmetics, Cleaning Products, Healthcare |

| Packaging Type | Single-use, Reusable, Biodegradable, Custom |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Thailand Plastic Bottles Market

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at