444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The temperature controlled packaging solutions for the pharmaceuticals market play a crucial role in ensuring the integrity and safety of temperature-sensitive pharmaceutical products during storage and transportation. These solutions are designed to maintain the required temperature range and protect the products from any temperature excursions that could compromise their efficacy. With the growing demand for biopharmaceuticals, vaccines, and other temperature-sensitive drugs, the market for temperature controlled packaging solutions has witnessed significant growth in recent years.

Meaning

Temperature controlled packaging solutions refer to specialized packaging systems and materials used to maintain a specific temperature range for pharmaceutical products throughout the supply chain. These solutions are essential for preserving the efficacy and stability of temperature-sensitive drugs, as even slight deviations from the recommended temperature can lead to product degradation or loss of potency. By providing insulation, temperature control, and protection against external factors, such as temperature fluctuations, light exposure, and moisture, these packaging solutions ensure the quality and effectiveness of pharmaceutical products.

Executive Summary

The temperature controlled packaging solutions for pharmaceuticals market has experienced substantial growth in recent years, driven by the increasing demand for temperature-sensitive drugs, stringent regulatory requirements, and the expansion of the pharmaceutical industry. This report provides comprehensive insights into the market, including key market trends, drivers, restraints, opportunities, and regional analysis. It also offers a competitive landscape, segmentation analysis, SWOT analysis, and future outlook to help industry participants and stakeholders make informed decisions.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The temperature controlled packaging solutions for pharmaceuticals market is driven by a combination of factors, including the increasing demand for temperature-sensitive drugs, regulatory requirements, technological advancements, and globalization of the pharmaceutical supply chain. The market presents significant growth opportunities, but it also faces challenges such as high costs, regulatory complexities, and environmental concerns. Industry participants need to navigate these dynamics and capitalize on the emerging trends and opportunities to stay competitive in the market.

Regional Analysis

The temperature controlled packaging solutions for pharmaceuticals market can be analyzed based on various regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Each region has its own unique market characteristics, regulatory landscape, and demand drivers. It is essential to understand the regional dynamics and tailor temperature controlled packaging solutions accordingly to meet the specific requirements and challenges of each market.

Competitive Landscape

Leading Companies in the Temperature Controlled Packaging Solutions for Pharmaceuticals Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

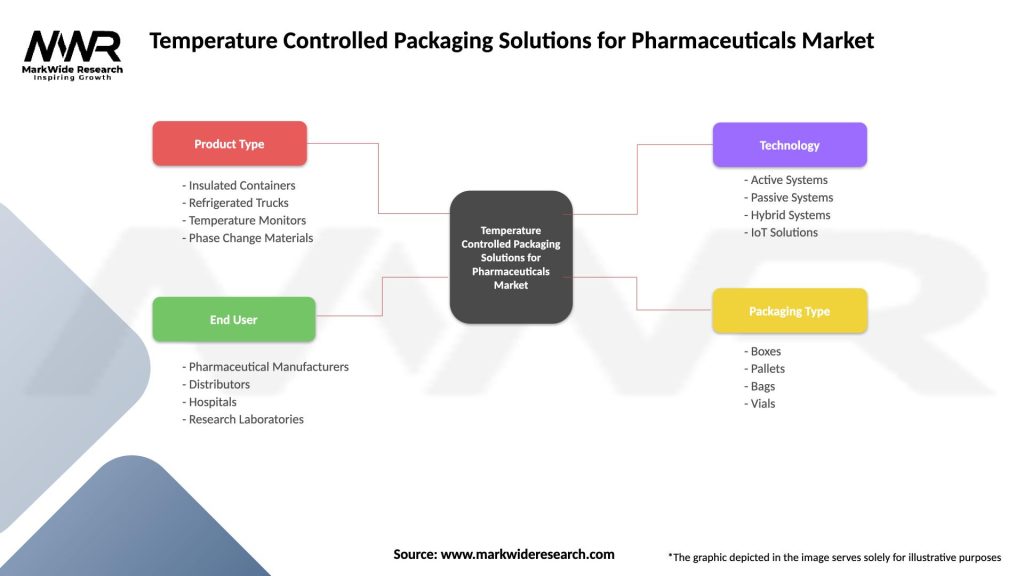

Segmentation

The temperature controlled packaging solutions for pharmaceuticals market can be segmented based on product type, temperature range, end-user, and geography. By product type, the market includes insulated shippers, insulated containers, refrigerants, phase change materials (PCMs), and temperature monitoring devices. Based on the temperature range, the market can be categorized into refrigerated packaging and controlled room temperature packaging. The end-users of these solutions include pharmaceutical manufacturers, distributors, and logistics providers.

Category-wise Insights

Insulated shippers: Insulated shippers are widely used in the pharmaceutical industry for transporting temperature-sensitive drugs. These shippers provide thermal insulation and are available in various sizes and configurations to accommodate different shipment volumes. They are designed to maintain the required temperature range for a specified duration, typically ranging from a few hours to several days.

Insulated Containers: Insulated containers are larger packaging solutions used for the transportation of bulk quantities of pharmaceutical products. These containers offer superior insulation properties and can maintain temperature control for an extended period, making them suitable for long-distance shipments. Insulated containers are available in various sizes and can be customized to meet specific temperature requirements.

Refrigerants: Refrigerants, such as gel packs and dry ice, are commonly used in temperature controlled packaging to provide additional cooling during transportation. Gel packs are reusable and environmentally friendly, while dry ice offers extremely low temperatures for deep freezing applications. Refrigerants play a crucial role in maintaining the desired temperature inside the packaging and preventing temperature excursions.

Phase Change Materials (PCMs): Phase change materials are substances that can absorb or release thermal energy during the phase transition process. These materials are used in temperature controlled packaging to stabilize the internal temperature by absorbing or releasing heat. PCMs offer advantages such as high energy storage capacity, long-lasting temperature control, and reduced reliance on external refrigerants.

Temperature Monitoring Devices: Temperature monitoring devices, such as data loggers and real-time tracking systems, are essential for ensuring temperature control and compliance throughout the supply chain. These devices provide accurate temperature readings and alerts in case of temperature excursions. They enable real-time monitoring, data analysis, and documentation of temperature conditions, facilitating regulatory compliance and quality assurance.

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic had a significant impact on the temperature controlled packaging solutions for pharmaceuticals market. The global distribution of Covid-19 vaccines required the efficient transportation of large volumes of temperature-sensitive vaccines, driving the demand for specialized packaging solutions. The pandemic also highlighted the importance of robust cold chain infrastructure and temperature control in ensuring the efficacy of vaccines and other essential pharmaceutical products.

Key Industry Developments

Analyst Suggestions

Future Outlook

The temperature controlled packaging solutions for pharmaceuticals market is poised for substantial growth in the coming years. Factors such as the increasing demand for temperature-sensitive drugs, stringent regulatory requirements, and advancements in packaging technologies will continue to drive market expansion. The integration of IoT, blockchain, and sustainable materials will shape the future of temperature controlled packaging, ensuring the safe and efficient transportation of pharmaceutical products while minimizing environmental impact.

Conclusion

The temperature controlled packaging solutions for pharmaceuticals market plays a critical role in preserving the efficacy and safety of temperature-sensitive drugs throughout the supply chain. The market offers significant growth opportunities driven by the increasing demand for biopharmaceuticals, stringent regulatory guidelines, and technological advancements. Industry participants need to stay abreast of key market trends, invest in research and development, and collaborate to develop innovative and sustainable solutions. By addressing the challenges and leveraging emerging opportunities, stakeholders can ensure the integrity and quality of pharmaceutical products while meeting the evolving needs of the global healthcare industry.

What is Temperature Controlled Packaging Solutions for Pharmaceuticals?

Temperature Controlled Packaging Solutions for Pharmaceuticals refer to specialized packaging systems designed to maintain specific temperature ranges for pharmaceutical products during storage and transportation. These solutions are crucial for preserving the efficacy and safety of temperature-sensitive medications, vaccines, and biologics.

What are the key players in the Temperature Controlled Packaging Solutions for Pharmaceuticals Market?

Key players in the Temperature Controlled Packaging Solutions for Pharmaceuticals Market include companies like Sonoco Products Company, Cold Chain Technologies, and Pelican BioThermal, among others. These companies provide innovative packaging solutions that ensure the integrity of pharmaceutical products throughout the supply chain.

What are the main drivers of growth in the Temperature Controlled Packaging Solutions for Pharmaceuticals Market?

The main drivers of growth in the Temperature Controlled Packaging Solutions for Pharmaceuticals Market include the increasing demand for biologics and biosimilars, the rise in global vaccine distribution, and the growing emphasis on regulatory compliance for temperature-sensitive products.

What challenges does the Temperature Controlled Packaging Solutions for Pharmaceuticals Market face?

Challenges in the Temperature Controlled Packaging Solutions for Pharmaceuticals Market include the high costs associated with advanced packaging technologies, the complexity of maintaining temperature control during transit, and the need for stringent regulatory compliance across different regions.

What opportunities exist in the Temperature Controlled Packaging Solutions for Pharmaceuticals Market?

Opportunities in the Temperature Controlled Packaging Solutions for Pharmaceuticals Market include the development of smart packaging technologies that provide real-time temperature monitoring, the expansion of e-commerce in pharmaceuticals, and the increasing focus on sustainable packaging solutions.

What trends are shaping the Temperature Controlled Packaging Solutions for Pharmaceuticals Market?

Trends shaping the Temperature Controlled Packaging Solutions for Pharmaceuticals Market include the adoption of eco-friendly materials, advancements in IoT technology for better tracking and monitoring, and the growing integration of automation in packaging processes to enhance efficiency.

Temperature Controlled Packaging Solutions for Pharmaceuticals Market

| Segmentation Details | Description |

|---|---|

| Product Type | Insulated Containers, Refrigerated Trucks, Temperature Monitors, Phase Change Materials |

| End User | Pharmaceutical Manufacturers, Distributors, Hospitals, Research Laboratories |

| Technology | Active Systems, Passive Systems, Hybrid Systems, IoT Solutions |

| Packaging Type | Boxes, Pallets, Bags, Vials |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Temperature Controlled Packaging Solutions for Pharmaceuticals Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at