444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

Tamper-evident banding machines are specialized packaging equipment designed to securely seal and protect products, ensuring their integrity throughout the supply chain. These machines are widely used in various industries, including food and beverage, pharmaceuticals, cosmetics, and consumer goods. Tamper-evident banding provides an additional layer of security by visually indicating if a package has been tampered with, thus safeguarding the product and assuring consumers of its authenticity.

Meaning

Tamper-evident banding machines utilize bands made of various materials, such as shrink film, tear tape, or adhesive labels, which are applied tightly around the packaging to create a seal. This seal is designed in a way that any attempt to remove or tamper with it will result in clear and visible signs of interference. This ensures that consumers can easily identify if a product has been opened or compromised, enhancing trust and reducing the risk of counterfeiting or contamination.

Executive Summary

The tamper-evident banding machine market is experiencing significant growth due to the rising need for product protection, increasing consumer awareness about product safety, and stringent regulations imposed by regulatory authorities. The market is witnessing the introduction of advanced banding machines equipped with innovative features, such as high-speed operation, precise banding, and integration with other packaging systems.

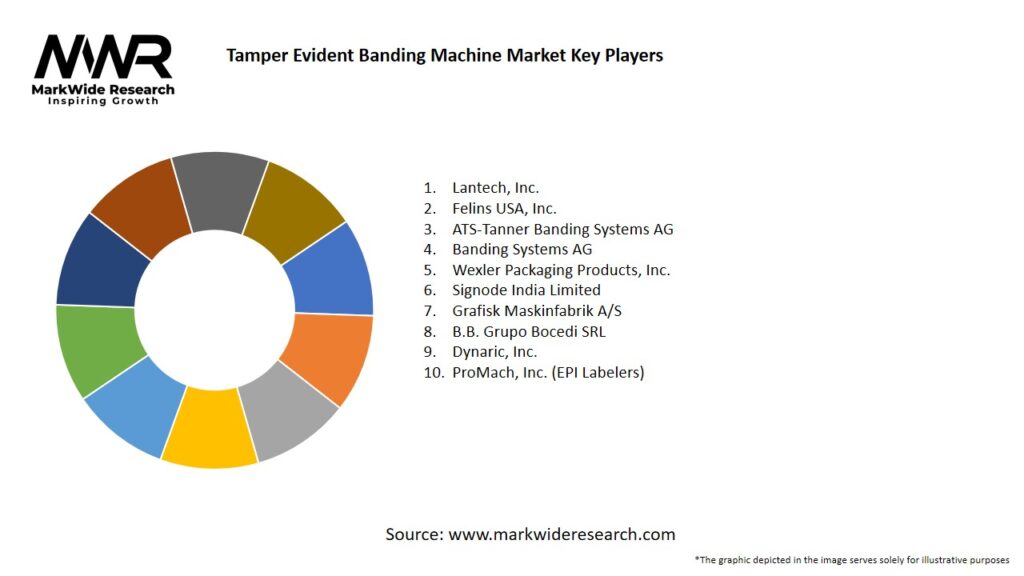

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The tamper-evident banding machine market is driven by several factors, including the increasing need for product safety, stringent regulations, advancements in technology, and rising consumer awareness. However, certain challenges, such as high costs and limited adoption in some regions, pose restraints to market growth. Nonetheless, the market offers significant opportunities for expansion through market penetration in emerging economies, collaborations, customization, and integration with smart packaging technologies.

Regional Analysis

The tamper-evident banding machine market is geographically segmented into North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. North America and Europe dominate the market due to strict regulatory standards and the presence of established industries. Asia Pacific is expected to witness substantial growth, driven by rapid industrialization, increasing consumer awareness, and government initiatives to combat counterfeiting.

Competitive Landscape

Leading Companies in the Tamper Evident Banding Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

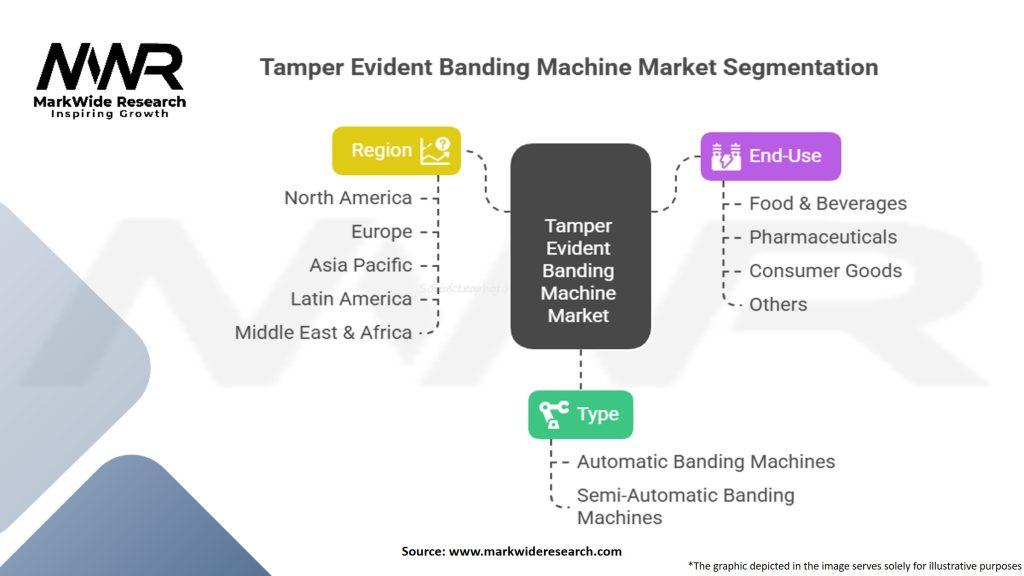

Segmentation

The tamper-evident banding machine market can be segmented based on machine type, packaging material, end-use industry, and geography. By machine type, the market can be categorized into automatic banding machines, semi-automatic banding machines, and manual banding machines. Based on packaging material, the market can be divided into shrink film banding, tear tape banding, and adhesive label banding. The end-use industries for tamper-evident banding machines include food and beverage, pharmaceuticals, cosmetics, consumer goods, and others.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The COVID-19 pandemic has had mixed effects on the tamper-evident banding machine market. While certain industries, such as food and pharmaceuticals, experienced increased demand for tamper-evident packaging solutions due to heightened consumer concerns, others, such as cosmetics and luxury goods, faced challenges due to reduced consumer spending and disrupted supply chains. However, the overall impact on the market was relatively moderate, with the industry displaying resilience and adapting to the changing market dynamics.

Key Industry Developments

Analyst Suggestions

Future Outlook

The tamper-evident banding machine market is expected to witness steady growth in the coming years. Factors such as increasing consumer awareness, stringent regulations, technological advancements, and the need for product safety and brand protection will drive market expansion. Collaboration, customization, and integration with smart packaging technologies are likely to emerge as key strategies for industry players. Furthermore, sustainability and eco-friendly packaging solutions will gain prominence, presenting opportunities for innovation and growth in the tamper-evident banding machine market.

Conclusion

The tamper-evident banding machine market is experiencing significant growth driven by the need for product integrity, consumer safety, and regulatory compliance. Technological advancements, such as automation and integration with smart packaging technologies, are reshaping the industry. While challenges exist in terms of costs and limited adoption in certain regions, opportunities lie in emerging markets, partnerships, customization, and sustainability. The market’s future looks promising as manufacturers continue to innovate and cater to the evolving needs of industries seeking reliable and tamper-evident packaging solutions.

What is Tamper evident banding machine?

A tamper evident banding machine is a device used to apply tamper-evident bands around products to ensure their integrity and safety. These machines are commonly used in industries such as food and beverage, pharmaceuticals, and cosmetics to prevent unauthorized access and ensure product authenticity.

What are the key players in the Tamper evident banding machine Market?

Key players in the tamper evident banding machine market include companies like Aetna Group, ACG Worldwide, and A.B. Sealer, among others. These companies are known for their innovative solutions and advanced technologies in packaging machinery.

What are the growth factors driving the Tamper evident banding machine Market?

The growth of the tamper evident banding machine market is driven by increasing consumer demand for product safety and security, stringent regulations in packaging, and the rising prevalence of counterfeiting in various industries. Additionally, the expansion of e-commerce is boosting the need for secure packaging solutions.

What challenges does the Tamper evident banding machine Market face?

Challenges in the tamper evident banding machine market include high initial investment costs and the need for regular maintenance. Furthermore, the rapid pace of technological advancements can make it difficult for companies to keep up with the latest innovations.

What opportunities exist in the Tamper evident banding machine Market?

Opportunities in the tamper evident banding machine market include the development of smart packaging solutions and the integration of automation technologies. As industries continue to prioritize sustainability, there is also potential for eco-friendly tamper evident solutions.

What trends are shaping the Tamper evident banding machine Market?

Current trends in the tamper evident banding machine market include the increasing adoption of digital printing technologies and the demand for customizable packaging solutions. Additionally, there is a growing focus on enhancing user experience through improved machine interfaces and automation.

Tamper Evident Banding Machine Market

| Segmentation | Details |

|---|---|

| Type | Automatic Banding Machines, Semi-Automatic Banding Machines |

| End-Use | Food & Beverages, Pharmaceuticals, Consumer Goods, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Tamper Evident Banding Machine Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at