444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The Sweden data center cooling market represents a critical component of the nation’s rapidly expanding digital infrastructure ecosystem. As Sweden continues to establish itself as a leading destination for hyperscale data centers and cloud computing facilities, the demand for advanced cooling solutions has experienced unprecedented growth. The market encompasses various cooling technologies including air-based systems, liquid cooling solutions, and innovative hybrid approaches designed to optimize energy efficiency while maintaining optimal operating temperatures.

Market dynamics in Sweden are particularly influenced by the country’s favorable climate conditions, abundant renewable energy resources, and progressive environmental policies. The Nordic climate provides natural cooling advantages, enabling data center operators to achieve 30-40% energy savings compared to facilities in warmer regions. This geographical advantage, combined with Sweden’s commitment to carbon neutrality by 2045, has attracted major technology companies to establish significant data center operations throughout the country.

Growth trajectories indicate that the Swedish data center cooling market is expanding at a robust 12.5% CAGR, driven by increasing digitalization, cloud adoption, and the proliferation of edge computing infrastructure. The market benefits from Sweden’s stable political environment, advanced telecommunications infrastructure, and strategic location serving both European and global markets. MarkWide Research analysis reveals that liquid cooling technologies are gaining particular traction, representing approximately 25% market share and growing rapidly due to their superior efficiency in high-density computing environments.

The Sweden data center cooling market refers to the comprehensive ecosystem of technologies, systems, and services designed to maintain optimal operating temperatures within data center facilities across Sweden. This market encompasses traditional air conditioning systems, advanced liquid cooling solutions, free cooling technologies, and innovative hybrid approaches that leverage Sweden’s natural climate advantages to minimize energy consumption while ensuring reliable equipment operation.

Cooling solutions in this context include computer room air conditioning (CRAC) units, computer room air handlers (CRAH), in-row cooling systems, rear-door heat exchangers, immersion cooling technologies, and direct-to-chip liquid cooling systems. The market also incorporates supporting infrastructure such as cooling towers, chillers, pumps, heat exchangers, and sophisticated monitoring and control systems that optimize cooling efficiency based on real-time demand and environmental conditions.

Strategic positioning of Sweden’s data center cooling market reflects the country’s emergence as a premier destination for sustainable digital infrastructure. The market demonstrates exceptional growth potential driven by increasing data consumption, cloud migration trends, and the deployment of next-generation technologies requiring advanced cooling capabilities. Sweden’s unique combination of cold climate, renewable energy abundance, and progressive environmental regulations creates an ideal environment for innovative cooling solutions.

Key market characteristics include the dominance of energy-efficient cooling technologies, with free cooling systems accounting for approximately 45% adoption rate among major facilities. The market shows strong preference for solutions that maximize the utilization of ambient air cooling, reducing reliance on mechanical refrigeration systems. Liquid cooling technologies are experiencing accelerated adoption, particularly in high-performance computing and artificial intelligence applications where traditional air cooling proves insufficient.

Investment patterns reveal significant capital allocation toward next-generation cooling infrastructure, with particular emphasis on solutions that support higher rack densities and improved power usage effectiveness (PUE) ratios. The market benefits from strong government support for sustainable technology initiatives and favorable regulatory frameworks that encourage energy-efficient data center operations.

Fundamental market insights reveal several critical trends shaping the Sweden data center cooling landscape:

Primary growth drivers propelling the Sweden data center cooling market include the accelerating digital transformation across industries, increasing cloud adoption, and the proliferation of data-intensive applications. The surge in remote work, streaming services, and digital commerce has created unprecedented demand for data processing capabilities, directly translating to increased cooling requirements in Swedish data centers.

Environmental regulations serve as a significant market catalyst, with Sweden’s ambitious climate goals driving adoption of energy-efficient cooling technologies. The country’s carbon tax policies and environmental compliance requirements incentivize data center operators to invest in advanced cooling solutions that minimize environmental impact while maintaining operational efficiency.

Technological advancement in artificial intelligence, machine learning, and high-performance computing creates substantial cooling challenges that traditional air-based systems cannot adequately address. These applications generate intense heat loads requiring innovative cooling approaches, driving demand for liquid cooling and hybrid solutions that can handle higher power densities effectively.

Geographic advantages continue to attract international data center investments, with Sweden’s cold climate providing natural cooling benefits that reduce operational costs. The availability of abundant renewable energy resources, particularly hydroelectric power, enables sustainable cooling operations that align with corporate environmental commitments and regulatory requirements.

Capital investment requirements represent a significant barrier to market expansion, particularly for advanced cooling technologies such as liquid cooling systems. The high upfront costs associated with implementing sophisticated cooling infrastructure can deter smaller operators and limit market penetration, especially in price-sensitive segments where traditional air cooling remains economically attractive.

Technical complexity of modern cooling systems creates operational challenges that require specialized expertise and training. The integration of advanced cooling technologies with existing data center infrastructure often involves complex engineering considerations, potential compatibility issues, and the need for skilled technicians capable of maintaining sophisticated cooling equipment.

Seasonal variations in Sweden’s climate, while generally favorable for cooling, can create operational challenges during warmer summer months when free cooling effectiveness diminishes. Data center operators must design systems capable of handling peak cooling loads during these periods, potentially requiring backup mechanical cooling systems that increase complexity and costs.

Supply chain constraints for specialized cooling equipment can impact project timelines and costs, particularly for custom-designed solutions required in unique data center environments. Global supply chain disruptions and component shortages have affected the availability of critical cooling system components, creating potential delays in facility deployments and upgrades.

Emerging opportunities in the Sweden data center cooling market center around the growing demand for edge computing infrastructure, which requires distributed cooling solutions optimized for smaller facilities and remote locations. The proliferation of 5G networks, Internet of Things applications, and autonomous systems creates substantial opportunities for innovative cooling technologies designed for edge environments.

Sustainability initiatives present significant growth opportunities as organizations increasingly prioritize environmental responsibility in their data center operations. The development of carbon-neutral cooling solutions, waste heat recovery systems, and circular economy approaches to cooling infrastructure creates new market segments and revenue streams for innovative technology providers.

Artificial intelligence integration offers opportunities for smart cooling systems that optimize energy consumption through predictive analytics, machine learning algorithms, and automated control systems. These intelligent cooling solutions can significantly improve efficiency while reducing operational costs, creating compelling value propositions for data center operators.

International expansion opportunities exist as Swedish cooling technology expertise and climate-optimized solutions gain recognition in other Nordic countries and similar climate regions. The export potential for Swedish cooling innovations and consulting services represents a substantial growth avenue for market participants.

Dynamic market forces shaping the Sweden data center cooling landscape reflect the interplay between technological innovation, regulatory requirements, and economic considerations. The market demonstrates strong momentum driven by increasing data center capacity deployments, with cooling requirements growing proportionally to computing infrastructure expansion.

Competitive dynamics reveal a market characterized by both established international cooling technology providers and emerging Swedish companies developing climate-specific solutions. The competitive landscape encourages continuous innovation, with companies investing heavily in research and development to create more efficient, sustainable, and cost-effective cooling technologies.

Technology evolution continues to reshape market dynamics, with liquid cooling technologies gaining market share at the expense of traditional air-based systems in high-density applications. The transition toward higher rack densities and more powerful computing equipment drives demand for advanced cooling solutions capable of handling increased heat loads efficiently.

Economic factors including energy costs, carbon pricing, and operational efficiency requirements influence cooling technology selection decisions. The favorable economics of free cooling in Sweden’s climate create unique market dynamics that differentiate the Swedish market from other regions with less favorable environmental conditions.

Comprehensive research methodology employed in analyzing the Sweden data center cooling market incorporates multiple data collection and analysis techniques to ensure accuracy and reliability of market insights. The research approach combines primary research through industry interviews, surveys, and expert consultations with secondary research utilizing industry reports, government publications, and technical documentation.

Primary research activities include structured interviews with data center operators, cooling technology vendors, system integrators, and industry consultants operating in the Swedish market. These interviews provide valuable insights into market trends, technology preferences, investment patterns, and future growth projections from industry participants with direct market experience.

Secondary research sources encompass industry publications, government statistics, regulatory documents, company financial reports, and technical specifications from cooling equipment manufacturers. This comprehensive data collection approach ensures broad market coverage and validates primary research findings through multiple independent sources.

Analytical frameworks applied include market sizing methodologies, competitive analysis techniques, trend identification processes, and forecasting models that account for various market drivers and constraints. The research methodology incorporates both quantitative analysis of market data and qualitative assessment of industry trends and technological developments.

Stockholm region dominates the Sweden data center cooling market, accounting for approximately 40% of total market activity due to its concentration of major data center facilities and proximity to international connectivity infrastructure. The region benefits from excellent transportation links, skilled workforce availability, and established technology ecosystem that supports advanced cooling technology deployment and maintenance.

Gothenburg area represents the second-largest regional market, with significant data center investments driven by its strategic location for serving European markets and excellent renewable energy access. The region’s industrial heritage provides a strong foundation for cooling technology manufacturing and system integration capabilities, supporting both domestic and export market opportunities.

Northern Sweden emerges as a rapidly growing market segment, with regions like Luleå and Boden attracting major hyperscale data center investments due to extremely favorable cooling conditions and abundant renewable energy resources. These locations offer optimal conditions for free cooling systems, enabling data centers to achieve exceptional energy efficiency ratios.

Regional distribution patterns show increasing decentralization as edge computing requirements drive cooling technology deployment across smaller cities and rural areas. This geographic expansion creates opportunities for distributed cooling solutions and local service providers capable of supporting cooling infrastructure in diverse locations throughout Sweden.

Market leadership in the Sweden data center cooling sector includes both international technology providers and specialized regional companies offering climate-optimized solutions. The competitive environment encourages innovation and specialization, with companies developing unique approaches to leverage Sweden’s natural cooling advantages.

Technology-based segmentation reveals distinct market categories based on cooling approaches and methodologies:

Air-Based Cooling Systems:

Liquid Cooling Solutions:

Application-based segmentation includes enterprise data centers, colocation facilities, hyperscale operations, edge computing sites, and high-performance computing installations, each with distinct cooling requirements and technology preferences.

Enterprise Data Centers represent a significant market category characterized by moderate cooling requirements and emphasis on reliability and cost-effectiveness. These facilities typically utilize traditional air-based cooling systems with increasing adoption of free cooling technologies to reduce operational costs. Energy efficiency considerations drive technology selection, with many enterprises upgrading to more efficient cooling systems to meet sustainability goals.

Colocation Facilities demonstrate diverse cooling requirements serving multiple tenants with varying density and performance needs. These facilities increasingly deploy flexible cooling architectures capable of supporting different customer requirements while maintaining overall efficiency. Scalability and modularity are key considerations in cooling system design for colocation environments.

Hyperscale Data Centers represent the most demanding category in terms of cooling capacity and efficiency requirements. These facilities drive innovation in cooling technologies, with significant investments in advanced liquid cooling systems and sophisticated environmental control systems. Operational efficiency and sustainability are paramount concerns influencing cooling technology selection.

Edge Computing Facilities create unique cooling challenges due to their distributed nature and often unmanned operation requirements. These facilities require reliable, low-maintenance cooling solutions optimized for smaller footprints and remote monitoring capabilities. Automation and remote management features are essential for edge cooling systems.

Data Center Operators benefit from advanced cooling technologies through reduced operational costs, improved energy efficiency, and enhanced equipment reliability. Modern cooling solutions enable higher rack densities, supporting increased computing capacity within existing facility footprints while maintaining optimal operating conditions for critical IT equipment.

Technology Vendors gain opportunities to develop and deploy innovative cooling solutions tailored to Sweden’s unique climate conditions and regulatory environment. The market provides a testing ground for next-generation cooling technologies and creates export opportunities for successful solutions to other Nordic and cold-climate regions.

Environmental Stakeholders benefit from the adoption of energy-efficient cooling technologies that reduce carbon emissions and support Sweden’s climate goals. Advanced cooling systems contribute to overall data center sustainability and demonstrate the feasibility of environmentally responsible digital infrastructure operations.

Economic Development benefits include job creation in high-technology sectors, attraction of international investment, and development of specialized expertise in sustainable data center technologies. The cooling market supports a broader ecosystem of technology providers, service companies, and research institutions contributing to Sweden’s digital economy.

Strengths:

Weaknesses:

Opportunities:

Threats:

Liquid cooling adoption represents the most significant trend transforming the Sweden data center cooling market, with immersion cooling and direct-to-chip solutions gaining substantial traction in high-density computing environments. This trend is driven by increasing rack densities, AI workloads, and the limitations of traditional air cooling in handling extreme heat loads generated by modern computing equipment.

Artificial intelligence integration in cooling systems enables predictive maintenance, optimized energy consumption, and automated environmental control. Smart cooling systems utilize machine learning algorithms to anticipate cooling requirements, adjust system parameters in real-time, and identify potential issues before they impact operations, significantly improving overall efficiency and reliability.

Sustainability focus continues to intensify, with data center operators prioritizing cooling solutions that minimize environmental impact and support carbon neutrality goals. This trend drives adoption of renewable energy-powered cooling systems, waste heat recovery technologies, and circular economy approaches to cooling infrastructure lifecycle management.

Modular cooling architectures gain popularity as they provide flexibility to scale cooling capacity in alignment with computing infrastructure growth. These systems enable data centers to deploy cooling resources incrementally, reducing initial capital requirements while maintaining the ability to expand cooling capacity as demand increases.

Recent industry developments highlight the dynamic nature of the Sweden data center cooling market, with several major announcements and technological breakthroughs shaping the competitive landscape. MWR analysis indicates that liquid cooling technology deployments have accelerated significantly, with multiple hyperscale operators announcing large-scale immersion cooling implementations.

Partnership formations between international cooling technology providers and Swedish system integrators have strengthened local market capabilities and accelerated technology transfer. These collaborations combine global cooling expertise with local climate knowledge and regulatory understanding, creating more effective solutions for Swedish data center environments.

Government initiatives supporting sustainable data center development have provided additional momentum for advanced cooling technology adoption. Recent policy announcements include incentives for energy-efficient cooling systems and research funding for innovative cooling technology development, demonstrating strong governmental support for the sector.

Technology breakthroughs in areas such as two-phase immersion cooling, advanced heat exchanger designs, and AI-driven cooling optimization have created new possibilities for improving cooling efficiency and reducing environmental impact. These developments position Sweden as a testing ground for next-generation cooling technologies.

Strategic recommendations for market participants include prioritizing investment in liquid cooling technologies, particularly for facilities supporting high-performance computing and artificial intelligence applications. The superior cooling efficiency and density support capabilities of liquid cooling systems position them as essential technologies for future data center operations in Sweden.

Partnership development with local system integrators and service providers is crucial for international cooling technology vendors seeking to establish strong market presence. Local partnerships provide valuable market knowledge, regulatory expertise, and customer relationships that accelerate market penetration and reduce operational risks.

Sustainability integration should be a central consideration in all cooling system designs and implementations, with emphasis on renewable energy utilization, waste heat recovery, and circular economy principles. Data center operators that prioritize environmental responsibility will gain competitive advantages and align with Sweden’s climate goals.

Innovation investment in areas such as AI-driven cooling optimization, advanced materials, and hybrid cooling architectures will create differentiation opportunities and support long-term market success. Companies that invest in research and development will be better positioned to address evolving market requirements and technological challenges.

Long-term projections for the Sweden data center cooling market indicate continued robust growth driven by increasing digitalization, cloud adoption, and emerging technologies requiring advanced cooling capabilities. The market is expected to maintain strong growth momentum with projected annual growth rates exceeding 10% over the next five years, supported by favorable regulatory environment and continued international investment in Swedish data center infrastructure.

Technology evolution will likely favor liquid cooling solutions, with immersion cooling and direct-to-chip systems gaining substantial market share in high-density applications. Traditional air cooling will remain relevant for lower-density applications but will increasingly incorporate free cooling and hybrid approaches to improve efficiency and reduce environmental impact.

Market consolidation may occur as smaller cooling technology providers seek partnerships or acquisition opportunities with larger companies possessing greater resources and market reach. This consolidation could accelerate technology development and improve market efficiency while maintaining competitive dynamics that drive innovation.

International expansion opportunities will likely emerge as Swedish cooling technology expertise gains recognition in other cold-climate regions and countries prioritizing sustainable data center operations. The export potential for Swedish cooling innovations represents a significant growth opportunity for established market participants.

Market assessment reveals that the Sweden data center cooling market represents a dynamic and rapidly evolving sector characterized by strong growth potential, technological innovation, and favorable environmental conditions. The unique combination of cold climate, abundant renewable energy, and progressive regulatory framework creates an ideal environment for advanced cooling technology development and deployment.

Strategic positioning of Sweden as a leading destination for sustainable data center operations continues to attract international investment and drive demand for innovative cooling solutions. The market benefits from strong fundamentals including growing data consumption, cloud migration trends, and increasing adoption of high-performance computing applications that require advanced cooling capabilities.

Future success in the Sweden data center cooling market will depend on the ability to leverage natural climate advantages while incorporating cutting-edge technologies such as liquid cooling, artificial intelligence, and sustainable energy systems. Companies that can effectively combine environmental responsibility with operational efficiency will be best positioned to capitalize on the substantial growth opportunities in this evolving market landscape.

What is Data Center Cooling?

Data Center Cooling refers to the methods and technologies used to maintain optimal temperature and humidity levels in data centers, ensuring the efficient operation of servers and IT equipment. Effective cooling is crucial for preventing overheating and ensuring reliability in data center operations.

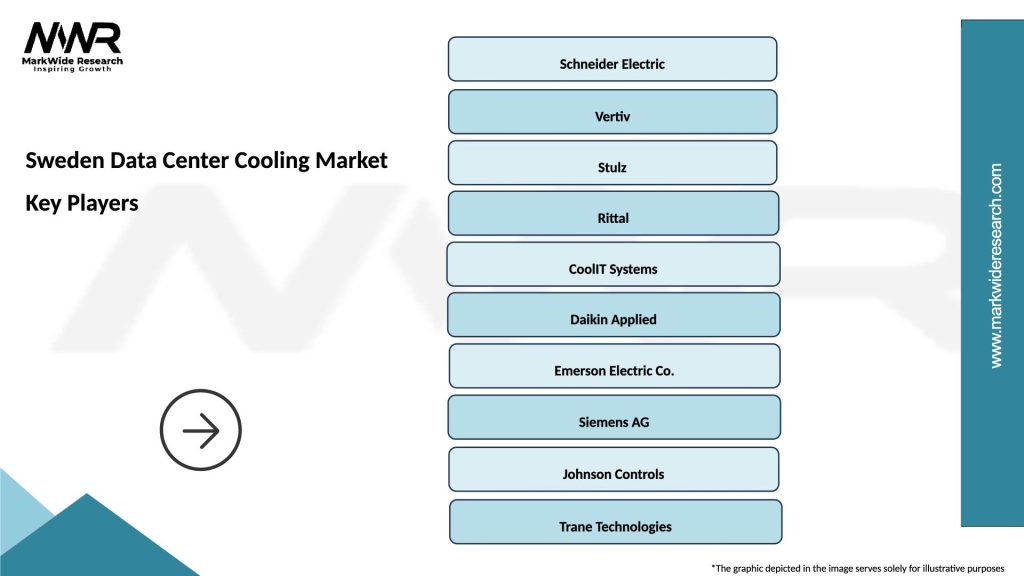

What are the key players in the Sweden Data Center Cooling Market?

Key players in the Sweden Data Center Cooling Market include companies like Schneider Electric, Vertiv, and Stulz, which provide innovative cooling solutions tailored for data centers. These companies focus on energy efficiency and advanced cooling technologies, among others.

What are the main drivers of the Sweden Data Center Cooling Market?

The main drivers of the Sweden Data Center Cooling Market include the increasing demand for data storage and processing, the growth of cloud computing, and the need for energy-efficient cooling solutions. Additionally, the rise in digital transformation across various industries contributes to market growth.

What challenges does the Sweden Data Center Cooling Market face?

Challenges in the Sweden Data Center Cooling Market include the high initial costs of advanced cooling systems and the complexity of integrating new technologies with existing infrastructure. Additionally, regulatory compliance regarding energy efficiency can pose challenges for data center operators.

What opportunities exist in the Sweden Data Center Cooling Market?

Opportunities in the Sweden Data Center Cooling Market include the development of sustainable cooling technologies and the increasing adoption of artificial intelligence for optimizing cooling processes. Furthermore, the expansion of edge computing presents new avenues for innovative cooling solutions.

What trends are shaping the Sweden Data Center Cooling Market?

Trends shaping the Sweden Data Center Cooling Market include the shift towards liquid cooling solutions and the integration of renewable energy sources in cooling systems. Additionally, the focus on modular data center designs is influencing cooling strategies to enhance efficiency.

Sweden Data Center Cooling Market

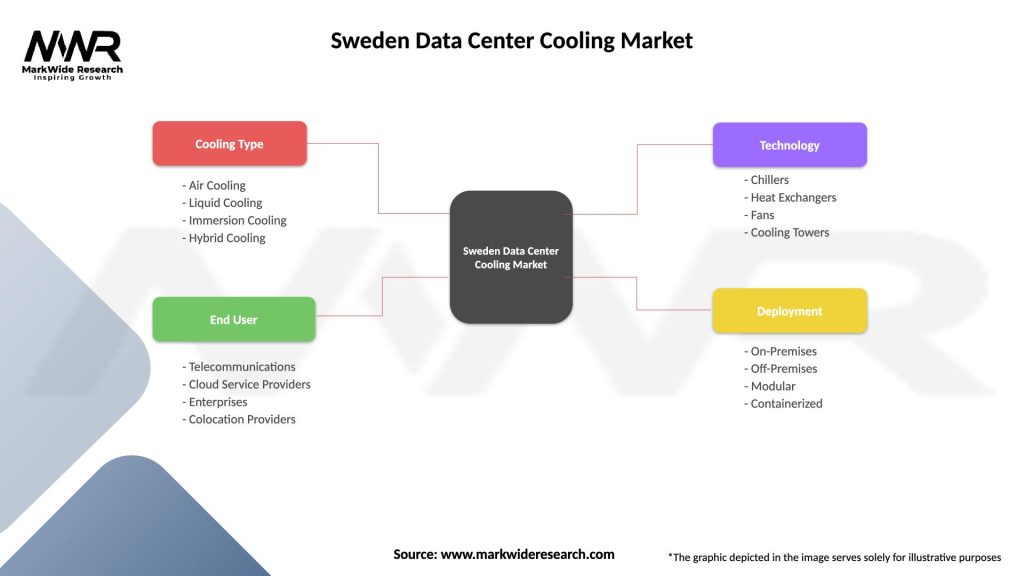

| Segmentation Details | Description |

|---|---|

| Cooling Type | Air Cooling, Liquid Cooling, Immersion Cooling, Hybrid Cooling |

| End User | Telecommunications, Cloud Service Providers, Enterprises, Colocation Providers |

| Technology | Chillers, Heat Exchangers, Fans, Cooling Towers |

| Deployment | On-Premises, Off-Premises, Modular, Containerized |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Sweden Data Center Cooling Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at