444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

The Sweden container glass market represents a vital segment of the Nordic packaging industry, characterized by robust demand across multiple sectors including food and beverage, pharmaceuticals, and cosmetics. Sweden’s commitment to environmental sustainability has positioned the container glass market as a cornerstone of circular economy initiatives, with glass packaging offering unparalleled recyclability and environmental benefits. The market demonstrates steady growth driven by increasing consumer preference for sustainable packaging solutions and stringent environmental regulations.

Market dynamics in Sweden reflect a sophisticated understanding of packaging requirements, with manufacturers focusing on lightweight glass solutions that maintain durability while reducing transportation costs. The Swedish container glass industry benefits from advanced manufacturing technologies and strong integration with European supply chains. Growth projections indicate a compound annual growth rate of 4.2% through 2030, supported by expanding applications in premium beverage packaging and pharmaceutical containers.

Regional characteristics of the Swedish market include high recycling rates exceeding 90% for glass containers, making it one of Europe’s most sustainable packaging markets. The market’s evolution reflects Sweden’s position as a leader in environmental stewardship, with container glass playing a crucial role in achieving national sustainability targets. Innovation trends focus on enhanced barrier properties, reduced weight formulations, and improved aesthetic appeal to meet evolving consumer preferences.

The Sweden container glass market refers to the comprehensive ecosystem encompassing the production, distribution, and utilization of glass containers across various industries within Sweden’s borders. This market includes bottles, jars, vials, and specialized glass packaging solutions designed for food preservation, beverage storage, pharmaceutical applications, and cosmetic products. Container glass represents a critical packaging medium that combines functional performance with environmental sustainability, offering superior product protection while maintaining complete recyclability.

Market scope extends beyond simple manufacturing to include recycling infrastructure, design innovation, and supply chain optimization. The Swedish container glass market operates within a framework of strict environmental regulations and consumer expectations for sustainable packaging solutions. Industry participants range from large-scale glass manufacturers to specialized packaging companies, recycling facilities, and end-user industries that depend on glass containers for product integrity and brand positioning.

Sweden’s container glass market demonstrates remarkable resilience and growth potential, driven by increasing environmental consciousness and regulatory support for sustainable packaging solutions. The market benefits from strong domestic demand across food and beverage sectors, with particular strength in premium alcoholic beverages and organic food products. Technological advancement in glass manufacturing has enabled Swedish producers to offer innovative solutions that meet both performance and sustainability requirements.

Key market drivers include Sweden’s ambitious climate goals, consumer preference for recyclable packaging, and growing demand from the pharmaceutical sector. The market shows consistent expansion with beverage applications accounting for approximately 65% of total demand, followed by food packaging and pharmaceutical containers. Competitive landscape features both international glass manufacturers and domestic specialists, creating a dynamic market environment focused on innovation and sustainability.

Future prospects remain positive, with anticipated growth in premium packaging applications and continued investment in recycling infrastructure. The market’s alignment with Sweden’s circular economy objectives positions it favorably for long-term expansion, supported by technological innovations and evolving consumer preferences toward environmentally responsible packaging solutions.

Strategic insights reveal several critical factors shaping the Swedish container glass market landscape:

Environmental regulations serve as the primary catalyst for container glass market expansion in Sweden, with government policies increasingly favoring sustainable packaging solutions. Sweden’s commitment to carbon neutrality by 2045 creates strong incentives for industries to adopt recyclable packaging materials, positioning glass containers as preferred alternatives to single-use plastics. The regulatory framework includes extended producer responsibility programs that make glass packaging economically attractive through reduced waste management costs.

Consumer behavior shifts toward environmentally conscious purchasing decisions significantly impact market demand, with Swedish consumers demonstrating willingness to pay premium prices for sustainable packaging. Brand positioning strategies increasingly emphasize environmental responsibility, driving companies to select glass containers that align with sustainability messaging. The growing organic food market in Sweden particularly benefits glass packaging, as consumers associate glass with product purity and quality preservation.

Technological advancement in glass manufacturing enables production of lighter, stronger containers that reduce transportation costs while maintaining protective properties. Innovation in glass chemistry has produced specialized formulations for pharmaceutical applications, expanding market opportunities beyond traditional food and beverage sectors. Advanced recycling technologies further enhance the economic viability of glass packaging by improving collection efficiency and reducing processing costs.

High initial costs associated with glass container production and specialized manufacturing equipment create barriers for new market entrants and limit rapid capacity expansion. Energy-intensive production processes require significant investment in efficient furnace technology and sustainable energy sources, impacting overall cost competitiveness compared to alternative packaging materials. The capital requirements for establishing glass manufacturing facilities often exceed those needed for plastic or metal packaging production.

Transportation challenges arise from the weight and fragility of glass containers, resulting in higher logistics costs and increased risk of product damage during distribution. Handling complexities throughout the supply chain require specialized equipment and trained personnel, adding operational expenses for manufacturers and end-users. These factors particularly impact cost-sensitive market segments where packaging expenses significantly influence product pricing strategies.

Competition from alternatives including lightweight plastics, flexible packaging, and aluminum containers presents ongoing challenges for glass market share retention. Technological improvements in alternative materials continue to narrow performance gaps while maintaining cost advantages, requiring glass manufacturers to continuously innovate and demonstrate superior value propositions. Market segments with extreme weight sensitivity or cost constraints may shift toward alternative packaging solutions despite environmental considerations.

Pharmaceutical sector expansion presents significant growth opportunities for specialized glass containers, with increasing demand for high-quality vials, ampoules, and bottles for drug storage and delivery. Sweden’s strong pharmaceutical industry and focus on biotechnology create domestic demand for precision glass containers that meet stringent regulatory requirements. The growing trend toward personalized medicine and biologics requires specialized glass packaging solutions with enhanced barrier properties and chemical resistance.

Premium beverage markets offer substantial opportunities for innovative glass container designs that enhance brand differentiation and consumer appeal. Craft brewing industry growth in Sweden drives demand for unique bottle designs and specialized glass formulations that preserve flavor integrity. The expanding wine and spirits market similarly benefits from glass packaging that maintains product quality while supporting premium brand positioning strategies.

Circular economy initiatives create opportunities for integrated recycling solutions and closed-loop packaging systems that maximize glass container value retention. Digital technology integration enables smart packaging solutions with embedded sensors and tracking capabilities, opening new market segments in logistics and consumer engagement. Export opportunities to neighboring Nordic countries and broader European markets leverage Sweden’s reputation for high-quality, sustainable manufacturing practices.

Supply chain integration characterizes the Swedish container glass market, with strong relationships between raw material suppliers, manufacturers, and end-users creating efficient value chains. Vertical integration strategies enable glass manufacturers to control quality and costs throughout production processes while ensuring consistent supply to key customers. The market benefits from Sweden’s abundant silica sand resources and access to renewable energy sources that support sustainable manufacturing operations.

Demand fluctuations reflect seasonal patterns in beverage consumption and food packaging requirements, with manufacturers adapting production schedules to optimize capacity utilization. Market consolidation trends have created larger, more efficient operations capable of serving diverse customer needs while maintaining competitive pricing structures. According to MarkWide Research analysis, market efficiency improvements have reached 15% over the past five years through operational optimization and technology upgrades.

Innovation cycles drive continuous product development, with manufacturers investing approximately 8% of revenue in research and development activities focused on performance enhancement and cost reduction. Collaborative partnerships between glass manufacturers and end-users facilitate customized solutions that address specific packaging requirements while supporting long-term business relationships. The market’s responsiveness to changing consumer preferences and regulatory requirements demonstrates strong adaptive capacity and growth resilience.

Comprehensive market analysis employs multiple research methodologies to ensure accurate and reliable insights into the Swedish container glass market landscape. Primary research includes structured interviews with industry executives, manufacturers, distributors, and end-users to gather firsthand perspectives on market trends, challenges, and opportunities. Survey methodologies capture quantitative data on market preferences, purchasing patterns, and growth projections across different industry segments.

Secondary research incorporates analysis of industry reports, government statistics, trade publications, and company financial statements to validate primary findings and provide comprehensive market context. Data triangulation techniques ensure consistency across multiple information sources while identifying potential discrepancies that require additional investigation. Market modeling approaches utilize statistical analysis and forecasting methods to project future trends and growth scenarios.

Industry expert consultations provide specialized knowledge on technical aspects of glass manufacturing, regulatory requirements, and emerging technologies that influence market development. Competitive intelligence gathering includes analysis of company strategies, product portfolios, and market positioning to understand competitive dynamics and identify strategic opportunities. The research methodology ensures comprehensive coverage of market factors while maintaining objectivity and analytical rigor throughout the investigation process.

Stockholm region dominates the Swedish container glass market, accounting for approximately 35% of total consumption due to high concentration of beverage manufacturers, pharmaceutical companies, and packaging distributors. Industrial infrastructure in the Stockholm area supports efficient distribution networks and provides access to skilled workforce and research institutions that drive innovation in glass packaging applications. The region’s proximity to major ports facilitates both raw material imports and finished product exports.

Gothenburg area represents another significant market center, with strong presence in food processing and beverage production that drives demand for glass containers. Manufacturing capabilities in the western region benefit from excellent transportation links and established supply chain relationships with European markets. The region shows particular strength in specialty glass applications for pharmaceutical and cosmetic industries, supported by local manufacturing expertise and quality standards.

Northern Sweden demonstrates growing market potential, driven by expanding food processing industries and increasing focus on sustainable packaging solutions. Regional development initiatives support glass recycling infrastructure and promote circular economy practices that enhance market sustainability. The distribution of market demand across Sweden’s regions reflects the country’s balanced economic development and widespread adoption of glass packaging across diverse industries and applications.

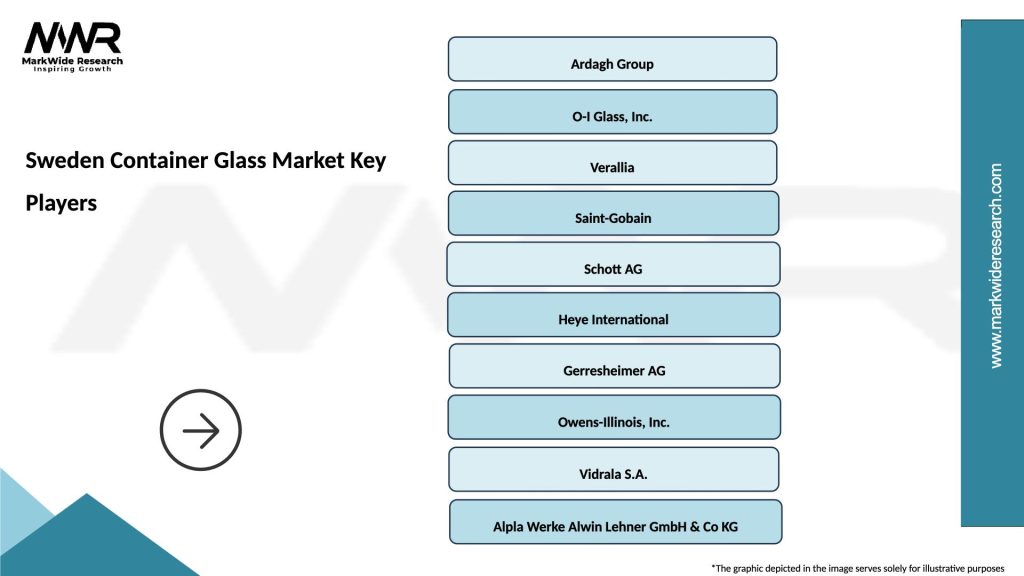

Market leadership in Sweden’s container glass sector features a combination of international manufacturers and specialized domestic producers, creating a competitive environment focused on innovation and customer service excellence:

Competitive strategies emphasize sustainability credentials, technological innovation, and customer partnership development to maintain market position and drive growth. Market differentiation occurs through specialized product offerings, superior quality standards, and comprehensive service capabilities that address specific customer requirements across diverse industry segments.

By Application:

By Glass Type:

Beverage applications represent the largest segment of Sweden’s container glass market, driven by strong domestic brewing industry and growing wine consumption. Premium positioning of Swedish craft beers and imported wines creates demand for distinctive glass bottle designs that enhance brand recognition and consumer appeal. The segment benefits from seasonal demand patterns that align with summer consumption peaks and holiday celebrations, requiring flexible manufacturing capacity and inventory management strategies.

Food packaging segment demonstrates steady growth supported by increasing consumer preference for preserved and specialty food products packaged in glass containers. Organic food trends particularly favor glass packaging due to consumer perception of purity and chemical-free storage. The segment shows innovation in jar designs and closure systems that improve convenience while maintaining the traditional appeal of glass food packaging.

Pharmaceutical applications exhibit the highest growth rates within the Swedish container glass market, reflecting expansion of the domestic pharmaceutical industry and increasing regulatory requirements for drug packaging. Specialized glass formulations address specific pharmaceutical needs including chemical compatibility, barrier properties, and sterilization requirements. The segment commands premium pricing due to stringent quality standards and specialized manufacturing processes required for pharmaceutical-grade glass containers.

Manufacturers benefit from Sweden’s strong environmental regulatory framework that creates competitive advantages for glass packaging over alternative materials. Operational efficiency improvements through advanced manufacturing technologies and recycling integration reduce production costs while enhancing sustainability credentials. The market’s stability and growth prospects provide attractive investment opportunities for capacity expansion and technology upgrades that support long-term profitability.

End-users gain access to high-quality glass containers that enhance product preservation, brand positioning, and consumer appeal across diverse applications. Supply chain reliability in the Swedish market ensures consistent availability of glass packaging solutions while supporting sustainability objectives and regulatory compliance requirements. Cost predictability through long-term supply agreements enables effective budget planning and pricing strategies for end-user companies.

Environmental stakeholders benefit from glass packaging’s contribution to circular economy objectives and waste reduction initiatives throughout Sweden. Recycling infrastructure development creates economic opportunities while supporting national sustainability goals and carbon emission reduction targets. The market’s alignment with environmental priorities demonstrates industry commitment to responsible manufacturing and packaging practices that benefit society as a whole.

Strengths:

Weaknesses:

Opportunities:

Threats:

Lightweight glass technology represents a major trend transforming the Swedish container glass market, with manufacturers developing thinner-walled containers that maintain strength while reducing material usage and transportation costs. Advanced glass chemistry enables production of bottles and jars that weigh 20-30% less than traditional designs without compromising durability or barrier properties. This trend addresses cost concerns while maintaining glass packaging’s environmental and performance advantages.

Smart packaging integration introduces digital capabilities to glass containers through embedded sensors, QR codes, and NFC technology that enhance consumer engagement and supply chain visibility. Brand differentiation increasingly relies on interactive packaging features that provide product information, authenticity verification, and promotional content. These technological enhancements position glass containers as premium packaging solutions that combine traditional benefits with modern digital functionality.

Circular economy optimization drives development of closed-loop recycling systems that maximize glass container value retention and minimize waste generation. MWR data indicates that advanced recycling programs achieve glass recovery rates exceeding 95% in leading Swedish municipalities, creating sustainable supply chains that reduce raw material requirements and environmental impact. This trend supports both cost reduction and sustainability objectives while strengthening glass packaging’s competitive position.

Manufacturing modernization initiatives across Sweden’s container glass industry focus on energy efficiency improvements and production automation that enhance competitiveness while reducing environmental impact. Furnace technology upgrades incorporate renewable energy sources and waste heat recovery systems that significantly reduce carbon emissions and operating costs. These developments position Swedish glass manufacturers as leaders in sustainable production practices.

Strategic partnerships between glass manufacturers and major beverage brands create collaborative product development programs that result in innovative container designs and improved supply chain efficiency. Long-term supply agreements provide stability for manufacturers while ensuring consistent quality and availability for brand owners. These partnerships demonstrate the industry’s commitment to customer-focused innovation and relationship building.

Recycling infrastructure expansion includes new collection systems, processing facilities, and quality improvement technologies that enhance the efficiency and effectiveness of glass recycling programs throughout Sweden. Investment initiatives supported by government incentives and industry collaboration create comprehensive recycling networks that support circular economy objectives while reducing raw material costs for manufacturers.

Market participants should prioritize investment in lightweight glass technologies and energy-efficient manufacturing processes to maintain competitiveness while addressing cost and environmental concerns. Strategic focus on premium market segments including pharmaceuticals, craft beverages, and luxury cosmetics offers higher margins and growth potential compared to commodity packaging applications. Companies should develop specialized capabilities and customer relationships in these high-value segments.

Sustainability initiatives require comprehensive integration throughout operations, from raw material sourcing to end-of-life recycling, to maximize competitive advantages and meet evolving regulatory requirements. Collaboration strategies with recycling partners, customers, and technology providers can accelerate innovation and market development while sharing investment risks and costs. These partnerships are essential for developing next-generation glass packaging solutions.

Technology adoption in areas such as smart packaging, advanced manufacturing, and digital supply chain management will differentiate successful companies from competitors while creating new revenue opportunities. Market expansion strategies should consider export opportunities to neighboring countries and specialized applications that leverage Sweden’s reputation for quality and sustainability. Companies should balance growth ambitions with operational efficiency and financial stability.

Long-term prospects for Sweden’s container glass market remain positive, supported by strengthening environmental regulations, growing consumer sustainability awareness, and continued innovation in glass packaging technologies. Market evolution will likely favor companies that successfully integrate sustainability, technology, and customer service excellence while maintaining cost competitiveness. The industry’s alignment with Sweden’s circular economy objectives provides a strong foundation for sustained growth.

Growth projections indicate continued expansion across key application segments, with pharmaceutical and premium beverage markets showing particularly strong potential. MarkWide Research forecasts suggest that technological advancement and sustainability initiatives will drive market growth at approximately 4.5% annually through the next decade. This growth trajectory reflects both domestic market expansion and increasing export opportunities for Swedish glass manufacturers.

Innovation trends will likely focus on enhanced functionality, reduced environmental impact, and improved cost-effectiveness that address evolving market requirements and competitive pressures. Industry consolidation may continue as companies seek scale advantages and technological capabilities necessary for long-term success. The market’s future development will depend on successful adaptation to changing consumer preferences, regulatory requirements, and competitive dynamics while maintaining Sweden’s leadership in sustainable packaging solutions.

Sweden’s container glass market demonstrates remarkable strength and growth potential, driven by the country’s commitment to environmental sustainability and strong demand across diverse application segments. Market fundamentals including high recycling rates, advanced manufacturing capabilities, and supportive regulatory framework create competitive advantages that position Swedish glass manufacturers for continued success. The industry’s focus on innovation, quality, and sustainability aligns perfectly with evolving market requirements and consumer preferences.

Strategic opportunities in pharmaceutical packaging, premium beverages, and smart packaging applications offer significant growth potential for companies that invest in appropriate technologies and customer relationships. Market challenges related to cost competitiveness and alternative materials require ongoing attention and strategic responses, but the fundamental value proposition of glass packaging remains strong. The industry’s collaborative approach to sustainability and innovation creates a positive environment for long-term market development and success in Sweden’s container glass sector.

What is Container Glass?

Container glass refers to glass products designed for packaging and storing various goods, including beverages, food, and pharmaceuticals. It is known for its durability, recyclability, and ability to preserve the quality of its contents.

What are the key players in the Sweden Container Glass Market?

Key players in the Sweden Container Glass Market include Ardagh Group, O-I Glass, and Vetropack Holding AG, among others. These companies are involved in the production and supply of container glass for various applications.

What are the growth factors driving the Sweden Container Glass Market?

The Sweden Container Glass Market is driven by increasing consumer demand for sustainable packaging solutions, the rise in the beverage industry, and the growing trend of eco-friendly products. Additionally, the shift towards glass over plastic for health and environmental reasons contributes to market growth.

What challenges does the Sweden Container Glass Market face?

The Sweden Container Glass Market faces challenges such as high production costs, competition from alternative packaging materials, and the need for advanced recycling technologies. These factors can impact the profitability and sustainability of container glass production.

What opportunities exist in the Sweden Container Glass Market?

Opportunities in the Sweden Container Glass Market include the expansion of the e-commerce sector, which increases demand for packaging, and innovations in glass manufacturing processes. Additionally, the growing focus on reducing carbon footprints presents avenues for growth.

What trends are shaping the Sweden Container Glass Market?

Trends in the Sweden Container Glass Market include the increasing use of lightweight glass containers, advancements in design for enhanced consumer appeal, and a focus on circular economy practices. These trends reflect a broader shift towards sustainability in packaging.

Sweden Container Glass Market

| Segmentation Details | Description |

|---|---|

| Product Type | Bottles, Jars, Jugs, Vials |

| End User | Food & Beverage, Pharmaceuticals, Cosmetics, Household |

| Grade | Recycled, Virgin, Specialty, High-Strength |

| Packaging Type | Bulk, Retail, Custom, Standard |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading companies in the Sweden Container Glass Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at