Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

-

Versatility Advantage: Specialty PS’s wide-ranging formulations enable rapid customization for nearly any application requiring rigidity, clarity, or toughness.

-

Cost‑Performance Balance: Lower cost than engineering plastics (ABS, PC) while delivering targeted performance boosts its appeal in price‑sensitive markets.

-

Sustainability Push: Development of PS grades with renewable content or enhanced recyclability aligns with global circular‑economy goals.

-

Emerging Applications: Growth in additive manufacturing and consumer electronics miniaturization opens new markets for specialty PS.

-

Regulatory Landscape: Stricter flammability and food‑contact regulations drive demand for compliant flame‑retardant and food‑grade PS grades.

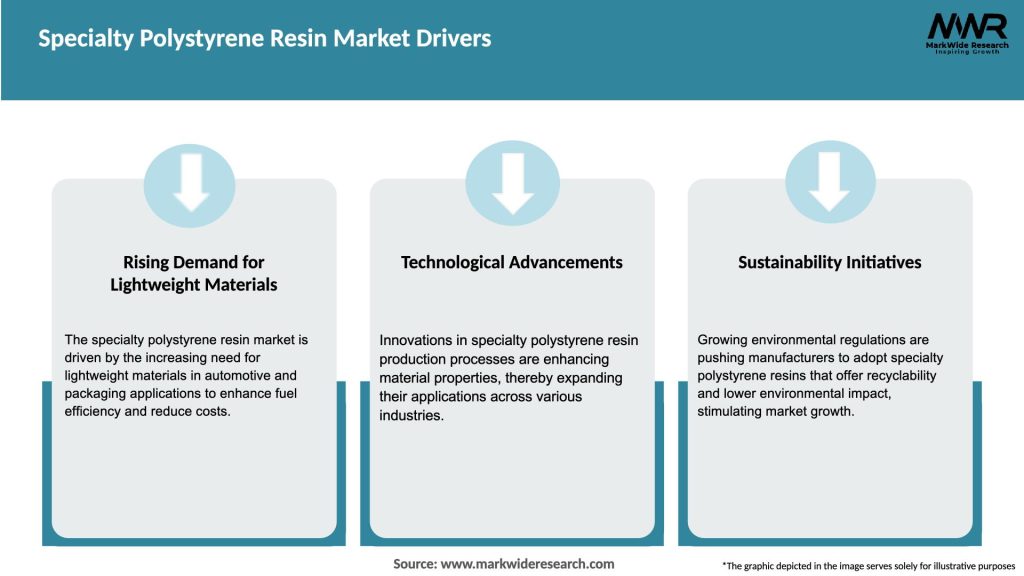

Market Drivers

-

Packaging Industry Surge: Demand for clear, rigid, and protective packaging (e.g., bakery trays, clamshells) fuels OPS and HIPS growth.

-

Electronics & Electrical Demand: Safety and performance standards in appliances and consumer electronics promote flame‑retardant and antistatic PS.

-

Medical & Healthcare Expansion: Single‑use medical trays, diagnostic kits, and housings leverage HIPS impact resistance and sterilization compatibility.

-

Lightweighting Trends: Automotive and consumer goods industries adopt HIPS to reduce weight and cost relative to traditional engineering plastics.

-

Technological Innovation: Advancements in polymer blending, nanocomposites, and reactive extrusions expand specialty PS capabilities.

Market Restraints

-

Volatile Raw Material Prices: Fluctuations in styrene monomer costs impact margins, particularly for commodity PS derivatives.

-

Environmental Concerns: Regulatory scrutiny over single‑use plastics and polystyrene foam disposal may restrict certain applications.

-

Competition from Alternatives: Engineering thermoplastics (ABS, PC) and biodegradable polymers vie for market share in high‑performance segments.

-

Recycling Challenges: Low recycling rates and contamination in post‑consumer PS waste streams hinder circular‑economy aspirations.

-

Processing Limitations: Poor heat resistance of standard PS grades requires additives or blending, increasing formulation complexity and cost.

Market Opportunities

-

Bio‑Based Styrene: Development of styrene monomers from renewable feedstocks can yield “green” PS grades, appealing to eco‑conscious brands.

-

PS Foam Recycling: Advanced chemical and mechanical recycling technologies for expanded PS (EPS) and PET‑PS blends open new value streams.

-

Additive Manufacturing: Specialty PS filaments for 3D printing offer high dimensional accuracy and post‑processing ease.

-

High‑Value Niche Applications: PS foams and specialty grades for oil‑spill cleanup, thermal storage (phase‑change materials), and filtration media.

-

Enhanced Barrier Coatings: PS composites with nanoclay or laminates for superior moisture, oxygen, and aroma barriers in food packaging.

Market Dynamics

-

Supply Side: Investments in integrated styrene‑PS production complexes enhance feedstock security and cost control.

-

Demand Side: Surge in e‑commerce packaging and medical device consumption drives specialty PS requirements.

-

Economic Factors: GDP growth in Asia‑Pacific and Latin America correlates strongly with increased PS consumption across end‑use verticals.

-

Regulatory Factors: REACH and FDA approvals influence which specialty PS grades can be sold in Europe and North America.

Regional Analysis

-

Asia‑Pacific: Largest regional market—driven by packaging, electronics manufacturing in China, India, and Southeast Asia; rapid industrialization.

-

North America: Mature market with high adoption of flame‑retardant and antistatic grades; strong focus on healthcare and automotive sectors.

-

Europe: Stringent environmental regulations spur bio‑PS development; robust food‑grade and specialty packaging demand.

-

Latin America: Growing consumer markets and automotive production hubs fuel steady specialty PS growth despite infrastructure challenges.

-

Middle East & Africa: Emerging petrochemical capacities and construction booms present nascent opportunity for EPS insulation and specialty PS composites.

Competitive Landscape

Leading Companies in the Specialty Polystyrene Resin Market:

- TotalEnergies SE

- Trinseo

- INEOS Styrolution Group GmbH

- SABIC

- Versalis S.p.A.

- Atlas EPS

- Alpek S.A.B. de C.V.

- Formosa Plastics Corporation

- Synthos S.A.

- Techno Polymer Co., Ltd.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

-

By Type: HIPS, OPS/GPPS blends, flame‑retardant PS, antistatic PS, PS foam (EPS/XPS).

-

By Application: Food packaging, electronic housings, medical devices, automotive interiors, building insulation, consumer goods.

-

By End‑User Industry: Packaging, electrical & electronics, healthcare, construction, automotive, consumer appliances.

-

By Sales Channel: Direct sales, distributors, online B2B platforms.

-

By Region: Asia‑Pacific, North America, Europe, Latin America, Middle East & Africa.

Category-wise Insights

-

Food Packaging: OPS and GPPS blends offer clarity and rigidity; HIPS used for thermoformed trays; emerging barrier‑coated PS for fresh food.

-

Electronics & Appliances: Flame‑retardant PS grades meet UL and IEC standards; antistatic PS protects against ESD in electronic packaging.

-

Medical Devices: Biocompatible HIPS resins serve in disposable trays, housings, and diagnostic cartridges; sterilizable and low-leach formulations.

-

Construction & Insulation: EPS and XPS specialty PS foams dominate thermal insulation in walls, roofs, and cold‑chain logistics.

-

Automotive Interiors: Lightweight HIPS composites used in dash panels, door trims, and non‑structural components—balancing cost and durability.

Key Benefits for Industry Participants and Stakeholders

-

Customization: Tailorable resin formulations meet exact performance, regulatory, and processing requirements.

-

Cost Advantage: Lower-cost alternative to engineering polymers, with targeted property enhancements minimizing material over‑engineering.

-

Operational Efficiency: Ease of processing (injection molding, thermoforming, extrusion) reduces cycle times and energy consumption.

-

Regulatory Compliance: Food‑grade and medical‑grade specialty PS grades meet global standards (FDA, EU directives, ISO).

-

Sustainability: Innovations in bio‑PS and PS foam recycling support corporate ESG goals and circular‑economy commitments.

SWOT Analysis

-

Strengths: Versatility across applications; low cost; established processing infrastructure; continuous innovation.

-

Weaknesses: Environmental scrutiny over single‑use PS; limited heat resistance vs. engineering plastics; recycling challenges.

-

Opportunities: Bio‑based monomers; chemical recycling of PS foams; 3D‑printing market; high‑value niche applications (phase‑change, filtration).

-

Threats: Stringent single‑use plastic bans; competition from biodegradable polymers and emerging engineering resins; feedstock volatility.

Market Key Trends

-

Bio‑PS Development: Commercial launches of partial‑renewable polystyrene grades from bioethanol/styrene.

-

Expanded PS Foam Recycling: Chemical depolymerization and closed‑loop systems for EPS and XPS.

-

Lightweight Automotive Design: Increased incorporation of HIPS in interior applications to reduce vehicle mass.

-

Advanced Antimicrobial and Barrier Coatings: Specialty PS with integrated antimicrobial additives for food safety.

-

Digital Manufacturing: Growth of PS‑based 3D printing filaments for prototyping and low‑volume production.

Covid‑19 Impact

-

Supply Chain Disruptions: Temporary styrene monomer shortages affected specialty resin availability in early 2020.

-

Surge in Medical Packaging: Spike in demand for medical device trays and diagnostic disposables drove HIPS consumption.

-

Accelerated E‑commerce: Increased need for protective PS cold‑chain packaging and disposable foam coolers.

-

Shift to Local Sourcing: Regionalized production investments to mitigate global logistics risks.

-

Sustainability Focus: Heightened awareness of waste management accelerated R&D in PS recycling.

Key Industry Developments

-

Strategic Capacity Expansions: Major producers adding PS foam recycling lines and new specialty resin reactors in Asia.

-

Partnerships for Bio‑Monomer Production: Collaborations between styrene producers and bioethanol suppliers.

-

Technology Licensing: Licensing of advanced compatibilizer and impact‑modification technologies to global converters.

-

Digital Quality Monitoring: Implementation of Industry 4.0 solutions for real‑time resin quality control.

-

Sustainability Certifications: Adoption of ISCC and RedCert EU certifications for bio‑PS grades.

Analyst Suggestions

-

Accelerate Bio‑PS Adoption: Fast‑track development and commercialization of renewable‑content polystyrene to pre‑empt regulatory pressures.

-

Invest in Closed‑Loop Recycling: Partner with recyclers to develop scalable chemical recycling for EPS/XPS outputs.

-

Target High‑Value Niches: Focus on 3D‑printing filaments, phase‑change thermal storage packs, and antimicrobial food packaging.

-

Enhance Digital Integration: Deploy real‑time process analytics and IoT‑enabled tracer systems to optimize specialty resin production.

-

Strengthen Regulatory Engagement: Work with industry associations to shape pragmatic single‑use plastic policies that recognize PS recyclability.

Future Outlook

The Specialty Polystyrene Resin Market is poised for steady growth, driven by sustainable innovations, emerging high‑value applications, and continued demand for cost‑efficient, high‑performance polymers. Key future developments include:

-

Commercial scale‑up of bio‑styrene routes, reducing carbon footprint and meeting circular‑economy mandates.

-

Widespread implementation of PS foam chemical recycling, providing a sustainable end‑of‑life solution.

-

Integration of smart manufacturing—using AI and predictive analytics for consistent resin quality.

-

Expansion into advanced packaging (active, intelligent, biodegradable barrier coatings).

-

Greater penetration in additive manufacturing, leveraging PS’s ease of extrusion and post‑processing.

Conclusion

The global Specialty Polystyrene Resin Market is set to transform traditional polystyrene use, offering tailored performance, enhanced sustainability, and new business models driven by recycling and bio‑monomers. Stakeholders—from resin producers and converters to brand‑owners and recyclers—must collaborate on innovation, infrastructure, and policy to fully realize specialty PS’s potential. Balancing cost, performance, and environmental impact will be paramount in navigating regulatory shifts, capturing emerging opportunities, and delivering the next generation of specialty polystyrene solutions.