444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The sound insulation felt market is a niche segment within the construction and automotive industries, focused on providing acoustic insulation solutions to reduce noise transmission and improve sound quality in buildings, vehicles, and industrial environments. Sound insulation felt, also known as acoustic felt or soundproofing felt, is a specialized material designed to absorb, dampen, or block sound waves, thereby minimizing noise pollution and creating quieter environments.

Meaning

Sound insulation felt is a composite material typically composed of fibers, foam, rubber, or other sound-absorbing materials, engineered to attenuate airborne and impact noise. It is used in various applications such as wall panels, ceiling tiles, flooring underlayment, automotive interiors, machinery enclosures, and HVAC ducts to enhance acoustical comfort and compliance with noise regulations.

Executive Summary

The sound insulation felt market has witnessed steady growth driven by increasing awareness of noise pollution, stringent regulatory standards, and the growing emphasis on occupant comfort and productivity. As industries and consumers prioritize sound control measures, the demand for high-performance sound insulation felts is expected to rise, presenting opportunities for manufacturers and suppliers.

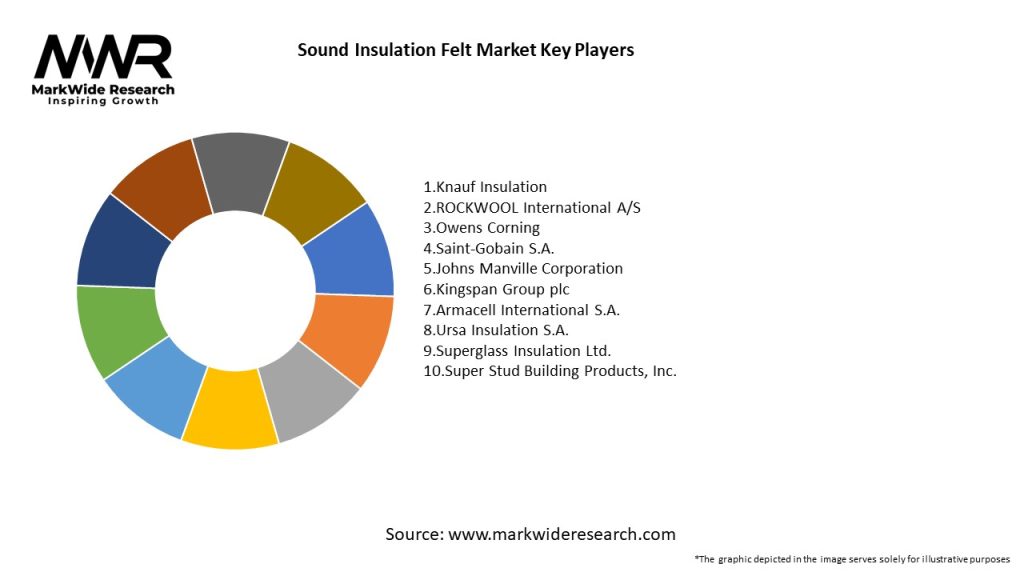

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The sound insulation felt market operates in a dynamic environment influenced by factors such as technological innovation, regulatory changes, economic trends, and customer preferences. Understanding and adapting to these market dynamics are essential for manufacturers, suppliers, and end-users to navigate challenges and capitalize on opportunities.

Regional Analysis

The demand for sound insulation felts varies regionally based on factors such as population density, urbanization rates, industrial activities, transportation infrastructure, and regulatory frameworks. Key regions such as North America, Europe, Asia Pacific, and Latin America exhibit distinct market dynamics and growth drivers for sound insulation felt products.

Competitive Landscape

Leading Companies in Sound Insulation Felt Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The sound insulation felt market can be segmented based on factors such as material type, product form, application, end-user industry, and geographic region. Segmentation enables manufacturers and suppliers to target specific market segments, tailor their product offerings, and address the unique needs of different customers and applications.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The adoption of sound insulation felts offers several benefits for industry participants and stakeholders, including:

SWOT Analysis

Strengths

• Excellent acoustic absorption and vibration dampening properties.

• Lightweight, flexible, and easy-to-install material suitable for multiple applications.

• Growing usage across construction, automotive, and industrial sectors.

Weaknesses

• Susceptibility to moisture and degradation in humid environments.

• Limited fire resistance in certain felt compositions.

• High dependency on raw material availability and quality consistency.

Opportunities

• Increasing demand for noise reduction in residential and commercial buildings.

• Technological advancements leading to eco-friendly and recyclable insulation materials.

• Expanding adoption in electric vehicles and public transport for cabin noise control.

Threats

• Price competition from alternative insulation materials such as foams and fiberglass.

• Stringent environmental regulations on synthetic fiber-based products.

• Fluctuating construction activity and economic downturns impacting market demand.

Market Key Trends

Systems-Based Specs: Tested wall/floor assemblies replacing single-product callouts.

High-Recycled PET: Recycled content exceeding 60% in leading SKUs.

Thin Premium Builds: Sub-10 mm felts achieving IIC +15 in floating floors.

Moisture-Tolerant Felts: Bituminous hybrids with ~25% better retention in humid sites.

Data-Driven Proof: On-site acoustic verification driving repeat specs.

Key Industry Developments

Launch of multilayer hybrid felts combining PET, rubber-crumb, and mineral layers for +18 IIC uplift at thin build-ups.

Expansion of factory-applied felts on modular wall panels, cutting site labor by ~15%.

New low-VOC binders achieving stringent indoor air quality labels across commercial lines.

Roll-format optimization (wider rolls, lighter cores) improving logistics and waste reduction by ~8%.

MarkWide Research notes rising demand for assemblies with documented field test deltas (design vs. as-built).

Analyst Suggestions

Future Outlook

The sound insulation felt market is poised for steady growth driven by increasing demand for noise control solutions in construction, automotive, industrial, and entertainment sectors. Technological advancements, regulatory mandates, sustainability initiatives, and demographic shifts are expected to shape the future trajectory of the market, presenting opportunities and challenges for industry participants.

Conclusion

The sound insulation felt market plays a vital role in enhancing acoustic comfort, reducing noise pollution, and improving quality of life in diverse applications and industries. As demand for noise control solutions continues to rise, manufacturers, suppliers, and end-users must collaborate to innovate products, optimize performance, and ensure regulatory compliance in a rapidly evolving market landscape. By leveraging technological advancements, embracing sustainability, and addressing customer needs, the sound insulation felt industry can achieve sustainable growth and contribute to creating quieter, more harmonious environments for people around the world.

What is Sound Insulation Felt?

Sound insulation felt is a material designed to reduce sound transmission between spaces. It is commonly used in construction and renovation projects to enhance acoustic comfort in residential and commercial buildings.

What are the key players in the Sound Insulation Felt Market?

Key players in the Sound Insulation Felt Market include companies like Rockwool International, Owens Corning, and Knauf Insulation, among others. These companies are known for their innovative products and solutions in soundproofing materials.

What are the growth factors driving the Sound Insulation Felt Market?

The Sound Insulation Felt Market is driven by increasing urbanization, rising awareness of noise pollution, and the growing demand for acoustic solutions in residential and commercial spaces. Additionally, stringent building regulations regarding sound insulation are contributing to market growth.

What challenges does the Sound Insulation Felt Market face?

Challenges in the Sound Insulation Felt Market include the high cost of advanced materials and competition from alternative soundproofing solutions. Additionally, fluctuating raw material prices can impact production costs.

What opportunities exist in the Sound Insulation Felt Market?

Opportunities in the Sound Insulation Felt Market include the development of eco-friendly materials and the expansion of applications in the automotive and aerospace industries. The increasing focus on sustainable building practices also presents growth potential.

What trends are shaping the Sound Insulation Felt Market?

Trends in the Sound Insulation Felt Market include the rise of smart building technologies and the integration of sound insulation materials in modular construction. Additionally, there is a growing emphasis on aesthetic designs that incorporate soundproofing solutions.

Sound Insulation Felt Market

| Segmentation Details | Description |

|---|---|

| Product Type | Acoustic Felt, Foam Panels, Mass Loaded Vinyl, Soundproofing Blankets |

| Application | Residential, Commercial, Industrial, Automotive |

| Material | Fiberglass, Polyester, Rubber, Mineral Wool |

| Installation Method | Adhesive, Staple, Mechanical Fasteners, Loose Lay |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in Sound Insulation Felt Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at