444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Solder flux is a type of chemical compound that is used to facilitate the soldering process by cleaning the metal surfaces and reducing oxidation. Soldering is a process of joining two or more metal surfaces by melting a filler metal or solder and then allowing it to cool and solidify. Solder flux is used to reduce the surface tension of the molten solder and allow it to flow more easily, ensuring a strong bond between the metal surfaces.

The solder flux market has been growing steadily over the past few years, driven by the increasing demand for electronic devices and the rising popularity of lead-free solders. According to a recent report by MarketsandMarkets, the global solder flux market is projected to reach $213.1 million by 2025, growing at a CAGR of 3.3% from 2020 to 2025.

Solder flux is an essential component of the soldering process, helping to clean and prepare the metal surfaces for soldering. The flux works by removing any oxidation, dirt, or other contaminants from the metal surfaces and protecting them from further oxidation during the soldering process.

There are several types of solder flux available, including rosin-based fluxes, water-soluble fluxes, and no-clean fluxes. Each type of flux has its own advantages and disadvantages, depending on the specific application and the materials being soldered.

Executive Summary:

The global solder flux market is expected to grow at a steady pace over the next few years, driven by the increasing demand for electronic devices and the growing popularity of lead-free soldering. Key market drivers include the growth of the electronics industry, the rise of the electric vehicle market, and the increasing use of renewable energy sources.

However, the market also faces several challenges, including the rising cost of raw materials and the need for constant innovation to keep up with changing technologies. Despite these challenges, the solder flux market presents significant opportunities for growth, particularly in emerging markets such as Asia-Pacific and Latin America.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Market Drivers:

The growth of the electronics industry is one of the key drivers of the solder flux market. With the increasing demand for electronic devices such as smartphones, laptops, and tablets, the demand for solder flux is also growing. Solder flux is used extensively in the production of printed circuit boards (PCBs), which are essential components of most electronic devices.

Another major driver of the market is the rise of the electric vehicle (EV) market. As more countries push towards reducing their carbon footprint, the demand for EVs is expected to grow significantly in the coming years. Solder flux is a critical component of EV batteries, and as the market for EVs grows, so too will the demand for solder flux.

Finally, the increasing use of renewable energy sources such as solar and wind power is also driving the demand for solder flux. Solder flux is used extensively in the production of solar panels and wind turbines, which are essential components of renewable energy systems.

Market Restraints:

Despite the growing demand for solder flux, the market also faces several challenges. One of the biggest challenges is the rising cost of raw materials such as tin and copper. These materials are essential components of solder flux, and any fluctuations in their prices can significantly impact the cost of production.

Another challenge facing the market is the need for constant innovation. With the rapid pace of technological change, solder flux manufacturers must continually adapt and improve their products to keep up with changing technologies and materials.

Market Opportunities:

Despite these challenges, the solder flux market presents significant opportunities for growth, particularly in emerging markets such as Asia-Pacific and Latin America. With the growing demand for electronic devices and the rise of the electric vehicle and renewable energy markets, these regions present significant growth opportunities for solder flux manufacturers.

In addition, the increasing use of advanced manufacturing techniques such as 3D printing and the Internet of Things (IoT) is also expected to drive the demand for solder flux. These technologies require advanced electronic components and soldering techniques, which in turn require high-quality solder flux.

Market Dynamics:

The solder flux market is highly competitive, with several players operating in the market. Key players in the market include Henkel AG & Co. KGaA, Kester, Indium Corporation, Alpha Assembly Solutions, and Heraeus Holding GmbH.

The market is also highly fragmented, with a large number of small and medium-sized players operating in various regions. These players often specialize in specific types of solder flux or serve niche markets, such as aerospace or medical devices.

Regional Analysis:

The Asia-Pacific region is expected to dominate the solder flux market over the next few years, driven by the growing demand for electronic devices and the increasing use of renewable energy sources in countries such as China, India, and Japan.

North America and Europe are also significant markets for solder flux, with a large number of manufacturers operating in these regions. The demand for solder flux in these regions is driven by the growth of the electronics industry and the increasing use of advanced manufacturing techniques such as 3D printing.

Competitive Landscape:

Leading Companies in the Solder Flux Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

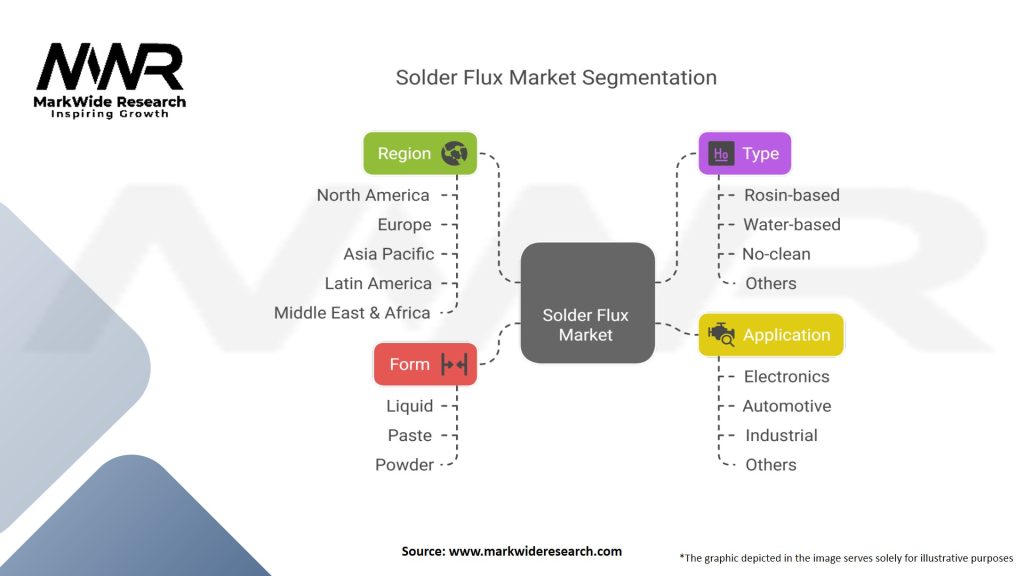

Segmentation:

The solder flux market can be segmented on the basis of type, application, and region. By type, the market can be divided into rosin-based fluxes, water-soluble fluxes, and no-clean fluxes. By application, the market can be segmented into PCB assembly, semiconductor packaging, and others.

Category-wise Insights:

The PCB assembly segment is expected to dominate the solder flux market over the next few years, driven by the increasing demand for electronic devices and the growing popularity of lead-free soldering. The semiconductor packaging segment is also expected to grow at a steady pace, driven by the increasing demand for high-performance semiconductors and advanced packaging techniques.

Key Benefits for Industry Participants and Stakeholders:

The solder flux market presents significant opportunities for growth and innovation, particularly in emerging markets such as Asia-Pacific and Latin America. By developing high-quality, environmentally-friendly, and cost-effective solder fluxes, manufacturers can meet the growing demand for sustainable manufacturing practices and advanced manufacturing techniques.

SWOT Analysis:

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends:

Some of the key trends in the solder flux market include:

Covid-19 Impact:

The Covid-19 pandemic has had a significant impact on the solder flux market, with disruptions to global supply chains and reduced demand for electronic devices in some regions.

However, the market has also seen increased demand for electronic devices and components, particularly for remote work and education purposes. This has helped to offset some of the negative impacts of the pandemic on the market.

Key Industry Developments:

Some of the key industry developments in the solder flux market include:

Analyst Suggestions:

To succeed in the solder flux market, manufacturers should focus on developing high-quality, environmentally-friendly, and cost-effective products that meet the specific needs of their target markets. They should also focus on building strong partnerships with customers and suppliers to ensure a reliable supply chain and maximize growth opportunities.

Future Outlook:

The solder flux market is expected to continue growing steadily over the next few years, driven by the increasing demand for electronic devices, the rise of the electric vehicle and renewable energy markets, and the adoption of advanced manufacturing techniques.

However, the market also faces several challenges, including the rising cost of raw materials and the need for constant innovation to keep up with changing technologies. Despite these challenges, the solder flux market presents significant opportunities for growth and innovation, particularly in emerging markets such as Asia-Pacific and Latin America.

Conclusion:

In conclusion, the solder flux market is a dynamic and highly competitive industry that presents significant opportunities for growth and innovation. By developing high-quality, environmentally-friendly, and cost-effective products, manufacturers can meet the growing demand for sustainable manufacturing practices and advanced manufacturing techniques.

However, they must also be prepared to navigate the challenges of rising raw material costs and changing technologies to stay competitive in the global market.As the electronics industry continues to expand, the demand for solder flux is expected to grow steadily in the coming years. With the increasing adoption of advanced manufacturing techniques such as 3D printing and IoT, the demand for high-quality solder fluxes is expected to increase as well.

What is solder flux?

Solder flux is a chemical agent used in the soldering process to facilitate the flow of solder and improve the quality of the joint. It helps to remove oxidation from the surfaces being soldered, ensuring a strong and reliable connection in electronic components and circuit boards.

What are the key players in the solder flux market?

Key players in the solder flux market include Kester, Alpha Assembly Solutions, and Henkel, among others. These companies are known for their innovative products and extensive distribution networks in the electronics manufacturing sector.

What are the growth factors driving the solder flux market?

The solder flux market is driven by the increasing demand for electronic devices, advancements in soldering technologies, and the growing trend of miniaturization in electronics. Additionally, the rise in automation and smart manufacturing practices is contributing to market growth.

What challenges does the solder flux market face?

The solder flux market faces challenges such as stringent environmental regulations and the need for compliance with RoHS standards. Additionally, the volatility in raw material prices can impact production costs and availability.

What opportunities exist in the solder flux market?

Opportunities in the solder flux market include the development of eco-friendly flux formulations and the expansion into emerging markets. The increasing adoption of electric vehicles and renewable energy technologies also presents new avenues for growth.

What trends are shaping the solder flux market?

Trends in the solder flux market include the shift towards water-soluble fluxes and the integration of advanced materials for better performance. Additionally, the rise of Industry Four Point Zero is influencing the adoption of automated soldering processes.

Solder Flux Market

| Segmentation Details | Details |

|---|---|

| Form | Liquid, Paste, Powder |

| Type | Rosin-based, Water-based, No-clean, Others |

| Application | Electronics, Automotive, Industrial, Others |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Solder Flux Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at