444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Shotcrete/Sprayed Concrete market is a rapidly growing sector within the construction industry. Shotcrete, also known as sprayed concrete, is a versatile and efficient method of placing concrete that offers numerous advantages over traditional casting techniques. It involves the use of a pneumatic or hydraulic pump to spray a pre-mixed concrete mixture onto a surface at high velocity.

Meaning

Shotcrete, derived from the words “shot” and “concrete,” refers to the process of applying concrete through a nozzle under high pressure. It is commonly used in construction projects for a variety of applications, including structural repairs, tunnel linings, swimming pool construction, and ground stabilization. The technique allows for better concrete compaction and bonding, resulting in improved durability and strength.

Executive Summary

The Shotcrete/Sprayed Concrete market has witnessed significant growth in recent years, driven by the increasing demand for efficient and cost-effective construction methods. The market is characterized by the presence of numerous players offering a wide range of products and services. Key market participants include manufacturers, contractors, and suppliers of shotcrete equipment and materials.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

The global Shotcrete/Sprayed Concrete market is valued at over USD 7 billion and is anticipated to grow steadily, driven by infrastructure renovation and new build projects.

Wet-mix shotcrete accounts for the larger share due to its ease of mix control and higher throughput, while dry-mix remains prevalent in remote and underground applications.

Fiber-reinforced shotcrete (steel, synthetic, glass fibers) is gaining traction, improving crack resistance, toughness, and reducing rebound waste.

Robotic and semi-automated spraying systems enhance application precision, minimize labor intensity, and improve on-site safety.

Environmental regulations prompt adoption of low-alkali, low-carbon shotcrete formulations and incorporation of supplementary cementitious materials (SCMs) such as fly ash and slag.

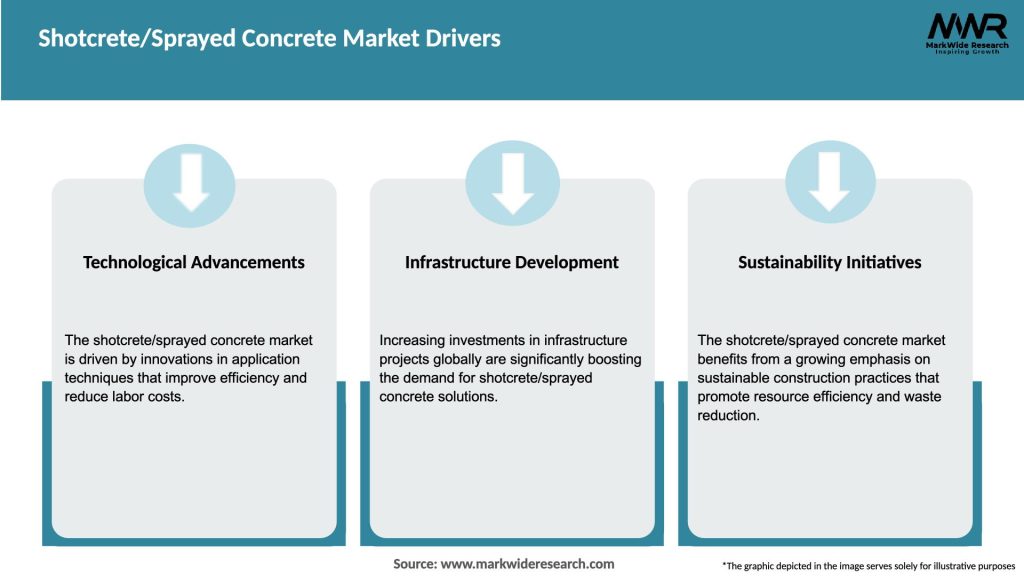

Market Drivers

Infrastructure Renewal: Aging bridges, tunnels, and parking structures require rapid repair solutions; shotcrete enables quick rehabilitation with minimal traffic disruption.

Tunneling & Mining Growth: Expansion of metro, rail, and mining projects demands robust ground support; shotcrete provides immediate reinforcement and water sealing.

Labor Efficiency: Skilled labor shortages and high labor costs drive adoption of mechanized spraying equipment to accelerate application and reduce manpower.

Performance Enhancement: Innovations in admixtures (accelerators, waterproofers) and fiber additions boost early strength development and long-term durability.

Sustainability Focus: Use of SCMs and recycled aggregates in shotcrete aligns with green construction mandates and reduces carbon footprint.

Market Restraints

High Equipment Costs: Initial investment in shotcrete pumps, mixing units, and robotic sprayers can be prohibitive for small contractors.

Technical Expertise: Effective shotcrete application requires trained operators to control nozzle technique, mixture consistency, and layer thickness.

Rebound and Waste: Dry-mix shotcrete can generate significant rebound (25–50%), leading to material waste and clean-up challenges.

Quality Control: Ensuring uniform mixing and proper placement in wet-mix processes demands rigorous on-site testing and monitoring.

Environmental Constraints: Spraying in enclosed or urban areas can produce dust and overspray, requiring containment and ventilation measures.

Market Opportunities

Automation & Robotics: Further development of autonomous shotcrete robots can lower labor dependency, improve quality, and enable 24/7 operations.

Ultra-High-Performance Shotcrete: Specialty formulations offering compressive strengths above 100 MPa for critical structural and rehabilitation projects.

Modular Rehabilitation Systems: Precast shotcrete panel solutions for rapid bridge and tunnel lining replacement minimize downtime.

Digital Twins & BIM Integration: Coupling shotcrete application plans with Building Information Modeling (BIM) improves planning accuracy and material optimization.

Emerging Markets: Infrastructure expansion in APAC and Latin America presents untapped demand, particularly in metro rail and hydropower projects.

Market Dynamics

Technological Evolution: Adoption of improved admixtures (e.g., hydrophobic agents) and fiber blends enhances shotcrete performance under aggressive environmental conditions.

Regulatory Standards: Evolving codes (e.g., ASTM C1140 for wet-mix, C1322 for dry-mix) drive consistency in shotcrete material and application protocols.

Collaborative Ecosystems: Partnerships between equipment OEMs, admixture suppliers, and contractors foster integrated solution offerings and training programs.

Cost Competition: Contractors balance shotcrete’s higher unit price against long-term savings from reduced formwork and shorter project durations.

Digital Monitoring: Real-time sensor-based monitoring of layer thickness, moisture, and temperature enables proactive quality assurance.

Regional Analysis

North America: Largest regional market, driven by infrastructure stimulus packages, highway repairs, and mine backfill operations.

Europe: Strong demand in tunneling (Alpine base tunnels, metro expansions) and structural rehabilitation in historic urban centers.

Asia-Pacific: Rapid urbanization and large-scale hydroelectric and subway projects in China and India fuel wet-mix shotcrete growth.

Latin America: Growing opportunity in mining reinforcement and water management structures, although adoption of high-end admixtures remains limited.

Middle East & Africa: Infrastructure modernization—particularly in Gulf Cooperation Council (GCC) countries—presents niche shotcrete rehabilitation needs.

Competitive Landscape

Leading Companies in the Shotcrete/Sprayed Concrete Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

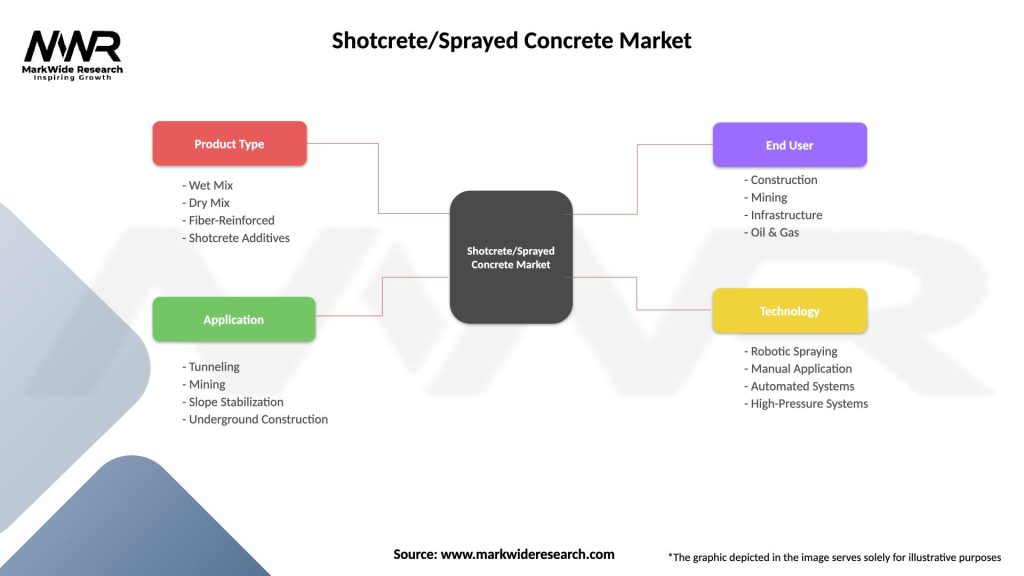

Segmentation

Process Type: Dry-Mix Shotcrete, Wet-Mix Shotcrete.

Application: Tunneling & Mining, Structural Rehabilitation, Slope Stabilization, Swimming Pools & Water Tanks, Civil Infrastructure, Precast Panel Repair.

End-User: Construction Contractors, Mining Companies, Municipal Authorities, Utilities, Swimming Pool Contractors.

Region: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa.

Category-wise Insights

Dry-Mix Shotcrete: Preferred for remote and underground sites due to portability of dry materials; limited by higher rebound and variable water content at nozzle.

Wet-Mix Shotcrete: Favored for high-volume civil works; offers better control of water–cement ratio, reduced rebound, and higher throughput rates.

Fiber-Reinforced Systems: Steel and synthetic fibers reduce crack propagation and improve tensile strength, enabling thinner linings and faster application.

Accelerated Formulations: Calcium aluminate and alkali-free accelerators enable rapid setting in cold climates and wet environments, reducing formwork time.

Key Benefits for Industry Participants and Stakeholders

Reduced Formwork Costs: Shotcrete eliminates the need for traditional formwork, lowering material and labor expenses.

Accelerated Schedules: High-velocity application allows rapid layer build-up—up to several meters per shift—shortening project timelines.

Enhanced Durability: Dense, low-permeability shotcrete linings improve waterproofing and longevity, reducing maintenance costs.

Flexibility: Suitable for complex geometries and overhead repairs where conventional concrete placement is impractical.

Safety Improvements: Remote-controlled spraying equipment minimizes operator exposure to dust and rebound hazards.

SWOT Analysis

Strengths:

Versatile application across vertical, overhead, and complex surfaces.

Strong track record in ground support and rapid repair scenarios.

Continual innovation in admixtures and robotic application.

Weaknesses:

Higher initial equipment and training costs compared to cast-in-place concrete.

Quality variability in dry-mix processes due to operator technique.

Dust generation and rebound management challenges.

Opportunities:

Growth of automated shotcrete robots for enhanced consistency and reduced labor.

Development of eco-friendly shotcrete mixes with lower embodied carbon.

Integration of IoT sensors for real-time process monitoring and quality assurance.

Threats:

Competition from alternative support methods (e.g., steel ribs, sprayed mortar).

Volatility in cement and admixture raw material prices.

Regulatory changes dictating stricter health and environmental controls on spraying operations.

Market Key Trends

Robotic Spraying Solutions: Increased deployment of automated shotcrete robots to boost application speed, consistency, and worker safety.

High-Performance Mixes: Ultra-high-strength shotcrete formulations (over 100 MPa) for critical structural linings and high-pressure water containment.

Sustainable Shotcrete: Use of recycled aggregates, SCMs, and low-carbon cements to meet green building certifications.

Digital Integration: Adoption of BIM-linked shotcrete planning and sensor-based thickness measurement to optimize material usage.

Hybrid Support Systems: Combining shotcrete with fiber-reinforced polymer (FRP) liners and mesh for enhanced ground control in tunneling.

Covid-19 Impact

The Covid-19 pandemic led to delays in construction starts but accelerated on-site automation to reduce workforce density. Remote training programs for shotcrete application and virtual equipment commissioning became widespread. As projects resumed, emphasis on rapid repair of transportation infrastructure to support economic recovery reinforced shotcrete demand in bridge girder repairs and tunnel maintenance.

Key Industry Developments

Furukawa’s QRO-5 Robot Launch: Introduction of a new autonomous shotcrete robot featuring programmable path control and integrated thickness sensors.

BASF’s CarbonCure Integration: Collaboration to incorporate captured CO₂ into shotcrete mixes, reducing carbon footprint and improving early strength.

Slipform Modular Panels: Development of precast shotcrete panel systems for rapid installation in tunnel linings, minimizing on-site spraying.

Analyst Suggestions

Embrace Automation: Contractors should pilot robotic shotcrete systems to evaluate ROI in labor savings and quality improvements.

Invest in Sustainable Mixes: Early adoption of low-carbon shotcrete formulations will position firms favorably under tightening environmental regulations.

Strengthen Training Programs: Comprehensive operator certification and refresher courses will ensure consistent application quality and safety compliance.

Leverage Data Analytics: Utilize sensor data to refine mix designs, predict maintenance requirements, and optimize material consumption.

Future Outlook

The Shotcrete/Sprayed Concrete market is poised for steady growth as global infrastructure renewal and new subsurface projects expand. Advances in robotics, admixture technology, and digital process controls will enhance efficiency, reduce waste, and improve safety. Sustainable shotcrete formulations and modular linings will gain traction in green construction initiatives. Contractors and suppliers that invest in end-to-end solutions—combining high-performance mixes, automated equipment, and data-driven quality assurance—will lead the industry toward faster, smarter, and more sustainable applications.

Conclusion

In conclusion, shotcrete and sprayed concrete remain indispensable for rapid, durable construction and repair across diverse civil and mining applications. By harnessing innovations in fiber reinforcement, accelerators, automation, and digital monitoring, stakeholders can deliver projects with reduced costs, shorter schedules, and superior long-term performance. As sustainability and labor efficiency become paramount, the market will increasingly favor integrated solution providers that offer advanced materials, equipment, and services underpinned by robust training and technical support.

What is Shotcrete/Sprayed Concrete?

Shotcrete, also known as sprayed concrete, is a method of applying concrete that involves spraying a mixture of cement, aggregates, and water onto a surface. This technique is commonly used in construction for applications such as tunnel linings, slope stabilization, and swimming pool construction.

What are the key players in the Shotcrete/Sprayed Concrete Market?

Key players in the Shotcrete/Sprayed Concrete Market include companies like BASF SE, Sika AG, and CEMEX, which provide a range of products and services related to sprayed concrete applications. These companies are known for their innovative solutions and extensive industry experience, among others.

What are the main drivers of growth in the Shotcrete/Sprayed Concrete Market?

The growth of the Shotcrete/Sprayed Concrete Market is driven by increasing urbanization, the need for rapid construction methods, and the rising demand for durable and sustainable building materials. Additionally, the expansion of infrastructure projects globally contributes to market growth.

What challenges does the Shotcrete/Sprayed Concrete Market face?

Challenges in the Shotcrete/Sprayed Concrete Market include issues related to the quality control of materials, the need for skilled labor, and environmental concerns regarding dust and waste management during application. These factors can impact project timelines and costs.

What opportunities exist in the Shotcrete/Sprayed Concrete Market?

Opportunities in the Shotcrete/Sprayed Concrete Market include advancements in technology that improve application techniques and material properties. Additionally, the growing focus on sustainable construction practices presents avenues for innovation in eco-friendly shotcrete solutions.

What trends are shaping the Shotcrete/Sprayed Concrete Market?

Current trends in the Shotcrete/Sprayed Concrete Market include the increasing use of robotic spraying technologies and the development of high-performance shotcrete mixtures. These innovations aim to enhance efficiency, reduce labor costs, and improve the overall quality of concrete applications.

Shotcrete/Sprayed Concrete Market

| Segmentation Details | Description |

|---|---|

| Product Type | Wet Mix, Dry Mix, Fiber-Reinforced, Shotcrete Additives |

| Application | Tunneling, Mining, Slope Stabilization, Underground Construction |

| End User | Construction, Mining, Infrastructure, Oil & Gas |

| Technology | Robotic Spraying, Manual Application, Automated Systems, High-Pressure Systems |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Shotcrete/Sprayed Concrete Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at