444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The Separator for Sodium-ion Battery market is experiencing rapid growth, driven by the increasing demand for sodium-ion batteries as a cost-effective and sustainable energy storage solution. Separators play a crucial role in sodium-ion battery technology by facilitating ion transport between the cathode and anode while preventing electrical short circuits. With the growing focus on renewable energy integration, electric vehicles, and grid-scale energy storage, the demand for high-performance separators for sodium-ion batteries is expected to surge, supporting the development of efficient and reliable energy storage systems worldwide.

Meaning

Separators for sodium-ion batteries are thin, porous membranes placed between the cathode and anode of the battery cell to facilitate the passage of sodium ions while preventing the direct contact between the electrodes. These separators are typically made of polymer or ceramic materials with high porosity, mechanical strength, and chemical stability to ensure efficient ion transport, electrolyte retention, and thermal management in sodium-ion battery systems. By controlling ion flow and preventing short circuits, separators contribute to the safety, performance, and lifespan of sodium-ion batteries in various applications, including portable electronics, electric vehicles, and stationary energy storage systems.

Executive Summary

The Separator for Sodium-ion Battery market is witnessing robust growth, fueled by the expanding adoption of sodium-ion battery technology in renewable energy storage, electric vehicles, and portable electronics. This comprehensive report provides insights into the market landscape, key trends, drivers, challenges, and opportunities shaping the industry’s growth trajectory. It offers valuable information for stakeholders, including battery manufacturers, material suppliers, investors, and policymakers, to navigate the evolving dynamics of the Separator for Sodium-ion Battery market and capitalize on emerging opportunities.

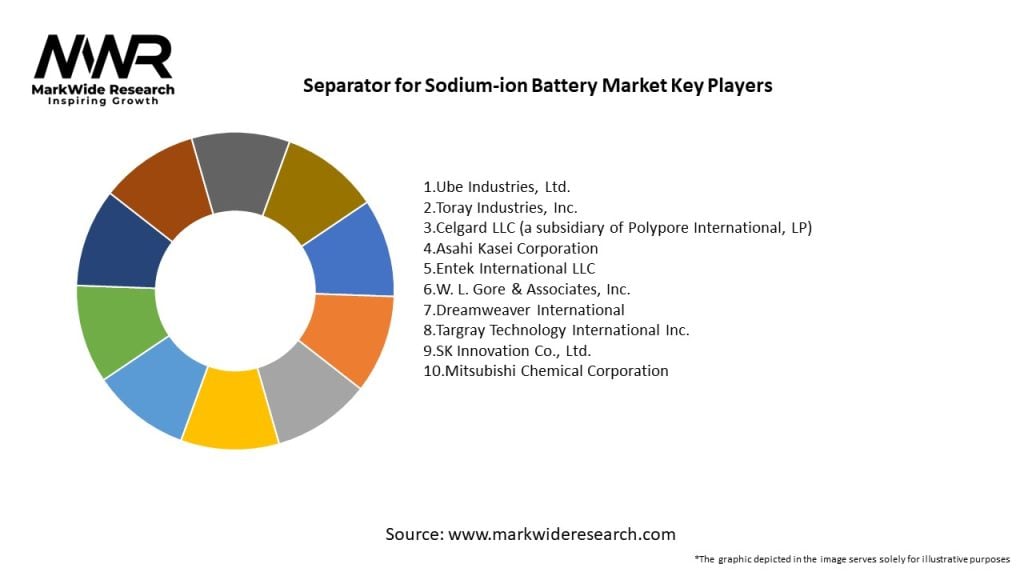

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The Separator for Sodium-ion Battery market is characterized by dynamic market dynamics, including technological innovation, regulatory developments, market competition, and industry collaboration, shaping the demand, supply, and pricing of separators for sodium-ion batteries. Market participants, including battery manufacturers, material suppliers, equipment vendors, and end-users, must navigate these dynamics to seize opportunities, mitigate risks, and drive sustainable growth in the Separator for Sodium-ion Battery market.

Regional Analysis

The Separator for Sodium-ion Battery market exhibits regional variations in demand, influenced by factors such as government policies, investment incentives, market maturity, and industrial infrastructure. Regions with significant investments in renewable energy, electric vehicles, and energy storage infrastructure, such as Asia Pacific, Europe, and North America, represent key markets for separators for sodium-ion batteries. Emerging economies in Latin America, Africa, and the Middle East are also witnessing increasing investments in sodium-ion battery technology, driving demand for separators and related components.

Competitive Landscape

Leading Companies in the Separator for Sodium-ion Battery Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

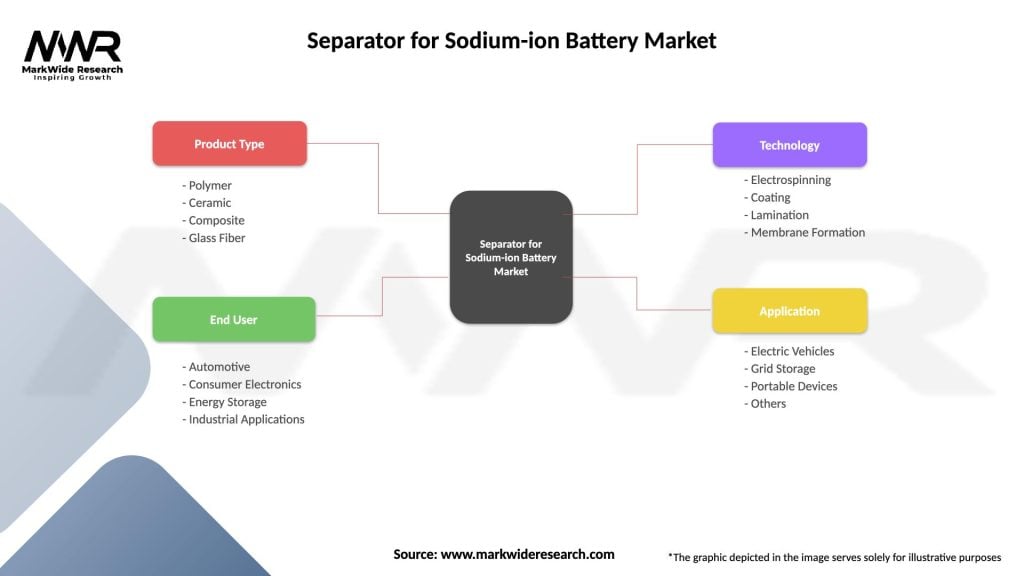

Segmentation

The Separator for Sodium-ion Battery market can be segmented based on material type, technology, application, and end-user industry. By material type, separators include polymer-based separators, ceramic-based separators, and composite separators tailored to the specific requirements of sodium-ion battery applications. By technology, separators utilize various manufacturing processes, coating techniques, and surface modifications to enhance performance, safety, and reliability in sodium-ion battery systems. By application, separators are used in portable electronics, electric vehicles, stationary energy storage systems, and other emerging applications requiring high-performance battery solutions. By end-user industry, separators are supplied to battery manufacturers, equipment integrators, and end-users involved in sodium-ion battery production, assembly, and integration into various devices and systems.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had a mixed impact on the Separator for Sodium-ion Battery market, with disruptions to global supply chains, manufacturing operations, and demand for energy storage solutions affecting market dynamics. While the pandemic has led to short-term challenges such as supply chain disruptions, project delays, and economic uncertainties, it has also underscored the importance of energy resilience, grid stability, and renewable energy integration, driving long-term demand for sodium-ion batteries and separators in diverse applications.

Key Industry Developments

Analyst Suggestions

Future Outlook

The Separator for Sodium-ion Battery market is poised for rapid growth and innovation in the coming years, driven by the increasing adoption of sodium-ion battery technology in electric vehicles, renewable energy storage, and grid-scale applications. As the industry focuses on sustainability, performance, and cost-effectiveness, demand for high-performance separators for sodium-ion batteries is expected to rise, supporting the development of efficient and reliable energy storage solutions worldwide.

Conclusion

In conclusion, the Separator for Sodium-ion Battery market presents significant opportunities for stakeholders seeking to capitalize on the growing demand for sodium-ion battery technology in renewable energy storage, electric vehicles, and grid-scale applications. By investing in innovation, collaboration, and sustainability, players in the separator supply chain can address market challenges, drive technological advancement, and support the transition to clean, sustainable, and resilient energy systems. As the world seeks to decarbonize transportation, enhance energy security, and mitigate climate change, sodium-ion batteries and separators will play a crucial role in enabling the widespread adoption of renewable energy and advancing the transition to a low-carbon future.

What is Separator for Sodium-ion Battery?

A separator for sodium-ion battery is a critical component that prevents short circuits between the anode and cathode while allowing the flow of ions. It plays a vital role in the overall performance, safety, and efficiency of sodium-ion batteries used in various applications such as electric vehicles and renewable energy storage.

What are the key companies in the Separator for Sodium-ion Battery Market?

Key companies in the separator for sodium-ion battery market include Asahi Kasei, Toray Industries, and Mitsubishi Chemical, among others. These companies are involved in the development and production of advanced separator materials that enhance battery performance.

What are the growth factors driving the Separator for Sodium-ion Battery Market?

The growth of the separator for sodium-ion battery market is driven by the increasing demand for energy storage solutions, advancements in battery technology, and the rising adoption of electric vehicles. Additionally, the need for sustainable and cost-effective alternatives to lithium-ion batteries is propelling market expansion.

What challenges does the Separator for Sodium-ion Battery Market face?

The separator for sodium-ion battery market faces challenges such as the limited availability of high-performance materials and competition from established lithium-ion battery technologies. Additionally, concerns regarding the scalability of sodium-ion battery production can hinder market growth.

What opportunities exist in the Separator for Sodium-ion Battery Market?

Opportunities in the separator for sodium-ion battery market include the potential for innovation in separator materials and designs, as well as the growing interest in renewable energy applications. The increasing focus on reducing reliance on lithium resources also presents a favorable environment for sodium-ion battery technologies.

What trends are shaping the Separator for Sodium-ion Battery Market?

Trends shaping the separator for sodium-ion battery market include the development of advanced polymer separators, improvements in manufacturing processes, and a shift towards more sustainable materials. Additionally, research into enhancing the electrochemical performance of sodium-ion batteries is gaining momentum.

Separator for Sodium-ion Battery Market

| Segmentation Details | Description |

|---|---|

| Product Type | Polymer, Ceramic, Composite, Glass Fiber |

| End User | Automotive, Consumer Electronics, Energy Storage, Industrial Applications |

| Technology | Electrospinning, Coating, Lamination, Membrane Formation |

| Application | Electric Vehicles, Grid Storage, Portable Devices, Others |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Separator for Sodium-ion Battery Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at