Market Overview

The semiconductor test socket market encompasses a crucial component in the semiconductor testing process, facilitating the connection between the integrated circuit (IC) package and the testing equipment. These sockets play a vital role in ensuring the functionality, reliability, and performance of semiconductor devices before they are integrated into end products. As the semiconductor industry continues to advance, driven by technological innovations and increasing demand for electronic devices, the demand for high-quality test sockets is expected to grow significantly.

Meaning

Semiconductor test sockets serve as interfaces between semiconductor devices, such as microprocessors, memory chips, and integrated circuits, and the testing equipment used to evaluate their performance and functionality. These sockets provide a secure and reliable connection while allowing for rapid testing and analysis of semiconductor devices during various stages of the manufacturing process. Test sockets come in different designs, configurations, and specifications to accommodate the diverse requirements of semiconductor manufacturers, ensuring accurate and efficient testing procedures.

Executive Summary

The semiconductor test socket market is witnessing steady growth, driven by factors such as the rising demand for semiconductor devices across various industries, the proliferation of consumer electronics, and the increasing complexity of semiconductor designs. Key market players focus on developing innovative test socket solutions that offer enhanced performance, reliability, and compatibility with advanced semiconductor technologies. With the continuous evolution of semiconductor manufacturing processes and the emergence of new testing requirements, the semiconductor test socket market presents lucrative opportunities for expansion and technological advancement.

Key Market Insights

- The semiconductor test socket market is characterized by the growing adoption of advanced semiconductor technologies, such as System-on-Chip (SoC), 5G connectivity, artificial intelligence (AI), and Internet of Things (IoT), driving the demand for high-performance test socket solutions.

- Customization and flexibility are essential factors driving the market, with semiconductor manufacturers seeking test socket solutions tailored to their specific device designs, packaging technologies, and testing requirements.

- Technological advancements, including the development of innovative materials, contact technologies, and thermal management solutions, enhance the performance, durability, and reliability of test sockets, addressing the challenges posed by high-speed, high-density, and high-temperature semiconductor applications.

- The market is segmented based on factors such as socket type, application, end-user industry, and geographic region, catering to the diverse needs and preferences of semiconductor manufacturers and testing professionals.

Market Drivers

Several factors are driving the growth of the semiconductor test socket market:

- Increasing Demand for Semiconductor Devices: The growing adoption of semiconductor devices in automotive, industrial, consumer electronics, telecommunications, and other sectors fuels the demand for semiconductor test sockets to ensure the quality and reliability of these components.

- Advancements in Semiconductor Manufacturing: Technological advancements, such as miniaturization, heterogeneous integration, and 3D packaging, drive the need for advanced test socket solutions capable of accommodating complex semiconductor designs and configurations.

- Rising Complexity of Testing Requirements: The increasing complexity of semiconductor devices, including higher speeds, greater integration, and stricter performance criteria, necessitates the use of sophisticated test socket solutions capable of meeting stringent testing requirements.

- Demand for High-Speed and High-Density Testing: The emergence of applications requiring high-speed data transmission, high-density interconnects, and advanced packaging technologies drives the demand for test sockets capable of supporting ultra-fast testing protocols and high-frequency signals.

- Focus on Quality and Reliability Assurance: Semiconductor manufacturers prioritize quality assurance and reliability testing to meet industry standards and customer expectations, driving the adoption of reliable and high-performance test socket solutions.

Market Restraints

Despite the positive growth prospects, the semiconductor test socket market faces several challenges:

- Complexity of Semiconductor Designs: The increasing complexity of semiconductor designs, including smaller form factors, higher pin counts, and diverse packaging technologies, poses challenges for test socket manufacturers in developing compatible and reliable solutions.

- Cost and Pricing Pressures: Semiconductor manufacturers face cost pressures and pricing constraints, demanding cost-effective test socket solutions without compromising performance, reliability, or compatibility with advanced semiconductor technologies.

- Technical Limitations and Compatibility Issues: Technical limitations such as signal integrity issues, thermal management challenges, and compatibility issues with emerging semiconductor technologies may hinder the adoption of test socket solutions for specific applications or device configurations.

- Long Development Cycles and Time-to-Market Constraints: The development cycles for semiconductor test socket solutions are often long and complex, requiring extensive testing, validation, and customization to meet the unique requirements of semiconductor manufacturers, resulting in delays in time-to-market and revenue generation.

- Global Supply Chain Disruptions: Disruptions in the global semiconductor supply chain, including shortages of raw materials, components, and manufacturing equipment, may impact the production, availability, and delivery of test socket solutions, leading to delays and supply shortages.

Market Opportunities

Despite the challenges, the semiconductor test socket market presents several opportunities for growth:

- Development of Advanced Test Socket Solutions: Continued investment in research and development (R&D) enables test socket manufacturers to develop advanced solutions capable of addressing the evolving needs and challenges of semiconductor testing, including higher speeds, greater densities, and increased functionality.

- Expansion into Emerging Applications: The proliferation of emerging applications such as autonomous vehicles, augmented reality (AR), virtual reality (VR), and edge computing creates new opportunities for test socket manufacturers to provide specialized solutions tailored to the requirements of these applications, driving market expansion and revenue growth.

- Partnerships and Collaborations: Collaboration with semiconductor manufacturers, testing laboratories, equipment suppliers, and industry consortia facilitates the development of customized test socket solutions, accelerates product innovation, and enhances market competitiveness.

- Focus on Reliability and Performance: Test socket manufacturers can differentiate their products by focusing on reliability, performance, and quality assurance, offering solutions that meet or exceed industry standards and customer expectations for semiconductor testing.

- Geographic Expansion and Market Penetration: Expanding into new geographic regions and emerging markets with growing semiconductor industries, such as Asia-Pacific, Latin America, and the Middle East, allows test socket manufacturers to diversify their customer base, increase market share, and capitalize on untapped opportunities.

Market Dynamics

The semiconductor test socket market is influenced by dynamic trends and factors such as technological advancements, market competition, industry regulations, and macroeconomic conditions. Key market players must stay abreast of these dynamics and adapt their strategies accordingly to maintain a competitive edge and capitalize on emerging opportunities.

Regional Analysis

The semiconductor test socket market exhibits varying trends and dynamics across different regions:

- North America: North America is a leading market for semiconductor test sockets, driven by factors such as the presence of major semiconductor manufacturers, technological innovation, and demand for high-performance testing solutions across various industries.

- Europe: Europe has a mature semiconductor market characterized by stringent quality standards, regulatory requirements, and investments in semiconductor research and development, driving the demand for reliable and high-quality test socket solutions.

- Asia-Pacific: Asia-Pacific is a rapidly growing market for semiconductor test sockets, fueled by factors such as the expansion of the semiconductor industry, increasing semiconductor manufacturing capabilities, and growing demand for electronic devices in countries such as China, Japan, South Korea, and Taiwan.

Competitive Landscape

The semiconductor test socket market is highly competitive, with numerous global and regional players competing for market share. Key players in the market include:

- Yamaichi Electronics: Yamaichi Electronics is a leading manufacturer of semiconductor test sockets, offering a wide range of solutions for various semiconductor packages and testing applications.

- Enplas Corporation: Enplas Corporation specializes in the design and manufacture of test sockets, handlers, and related equipment for semiconductor testing, serving customers in the automotive, consumer electronics, and telecommunications industries.

- Feinmetall GmbH: Feinmetall GmbH is a renowned provider of high-precision test contacts and test sockets for semiconductor testing, focusing on innovative solutions for high-speed, high-density, and high-reliability applications.

- Meritronics: Meritronics is a leading supplier of semiconductor test sockets and interconnect solutions, offering customized solutions tailored to the specific requirements of semiconductor manufacturers and testing professionals.

- Smiths Interconnect: Smiths Interconnect offers a comprehensive portfolio of test socket solutions for semiconductor testing, including advanced contact technologies, thermal management solutions, and application-specific designs for diverse semiconductor packages and testing environments.

Segmentation

The semiconductor test socket market can be segmented based on various factors, including:

- Socket Type: Vertical, Horizontal, Cantilever, Vertical Probe, Kelvin, Radio Frequency (RF)

- Application: Logic, Memory, Mixed-Signal, Power Management, RF, Automotive, Industrial, Consumer Electronics, Telecommunications, Aerospace & Defense

- End-User Industry: Semiconductor Manufacturing, Integrated Device Manufacturers (IDMs), Fabless Semiconductor Companies, Testing Laboratories, Research Institutes

- Geography: North America, Europe, Asia-Pacific, Latin America, Middle East & Africa

Category-wise Insights

Each category of semiconductor test sockets offers unique features, benefits, and applications tailored to different semiconductor testing requirements:

- Vertical Test Sockets: Vertical test sockets are commonly used for testing semiconductor devices with vertical package configurations, providing reliable and high-speed connectivity for a wide range of applications.

- Horizontal Test Sockets: Horizontal test sockets are ideal for testing semiconductor devices with horizontal package configurations, offering enhanced thermal management, signal integrity, and reliability for demanding testing applications.

- Cantilever Test Sockets: Cantilever test sockets are designed for testing semiconductor devices with cantilevered or spring-loaded contacts, providing superior electrical performance, contact force, and reliability for high-speed and high-frequency testing.

- Vertical Probe Test Sockets: Vertical probe test sockets utilize vertical probe technology to establish contact with semiconductor devices, offering excellent signal integrity, impedance control, and ease of use for testing applications requiring precise electrical measurements.

- Kelvin Test Sockets: Kelvin test sockets feature separate current and voltage contacts to minimize contact resistance and ensure accurate measurements of semiconductor devices’ electrical characteristics, making them suitable for high-precision testing of power management, analog, and mixed-signal devices.

- Radio Frequency (RF) Test Sockets: RF test sockets are optimized for testing semiconductor devices operating at radio frequencies, offering low insertion loss, high isolation, and excellent impedance matching for RF and wireless communication applications.

Key Benefits for Industry Participants and Stakeholders

The semiconductor test socket market offers several benefits for manufacturers, testing professionals, and end-users:

- Enhanced Testing Efficiency: Test sockets enable rapid and efficient testing of semiconductor devices, reducing test times, increasing throughput, and improving overall testing efficiency for semiconductor manufacturers and testing laboratories.

- Quality Assurance and Reliability: High-quality test sockets ensure accurate and reliable testing results, allowing semiconductor manufacturers to identify defects, faults, and performance issues early in the manufacturing process, leading to improved product quality and reliability.

- Flexibility and Customization: Test socket solutions can be customized to meet specific semiconductor device designs, package configurations, and testing requirements, providing flexibility and versatility for diverse applications and testing environments.

- Cost Savings and Time-to-Market: Efficient testing processes facilitated by test sockets help semiconductor manufacturers reduce production costs, minimize time-to-market, and accelerate product development cycles, enabling faster delivery of high-quality semiconductor devices to customers.

- Compatibility and Interoperability: Test sockets are designed to be compatible with various semiconductor packages, testing equipment, and testing protocols, ensuring interoperability and ease of integration into existing testing workflows and manufacturing processes.

SWOT Analysis

Strengths:

- Essential component in semiconductor testing process, facilitating efficient and reliable connectivity between semiconductor devices and testing equipment.

- Technological advancements enable the development of high-performance test socket solutions capable of meeting the evolving needs and challenges of semiconductor testing.

- Customization options and flexibility allow test socket manufacturers to tailor solutions to the specific requirements of semiconductor manufacturers and testing professionals.

Weaknesses:

- Technical limitations such as signal integrity issues, thermal management challenges, and compatibility issues may hinder the adoption of test socket solutions for certain semiconductor applications or device configurations.

- Development cycles for test socket solutions are often long and complex, requiring extensive testing, validation, and customization, leading to delays in time-to-market and revenue generation.

- Cost pressures and pricing constraints may limit market accessibility and affordability for some semiconductor manufacturers, especially those operating in cost-sensitive market segments.

Opportunities:

- Continued advancements in semiconductor technologies drive the demand for high-performance test socket solutions capable of supporting complex semiconductor designs, configurations, and testing requirements.

- Emerging applications such as autonomous vehicles, augmented reality (AR), virtual reality (VR), and edge computing create new opportunities for specialized test socket solutions tailored to the requirements of these applications.

- Collaboration with semiconductor manufacturers, testing laboratories, and industry consortia facilitates the development of customized test socket solutions, accelerates product innovation, and enhances market competitiveness.

Threats:

- Competition from alternative testing solutions, such as wafer-level testing, probe cards, and automated test equipment (ATE), may challenge market share and differentiation for test socket manufacturers.

- Global supply chain disruptions, including shortages of raw materials, components, and manufacturing equipment, may impact the production, availability, and delivery of test socket solutions, leading to delays and supply shortages.

- Regulatory changes, industry standards, and compliance requirements may pose challenges for test socket manufacturers in ensuring product quality, reliability, and safety while meeting customer expectations and regulatory obligations.

Market Key Trends

Several key trends are shaping the semiconductor test socket market:

- Advancements in Semiconductor Packaging: Technological advancements in semiconductor packaging, such as System-in-Package (SiP), fan-out wafer-level packaging (FOWLP), and 2.5D/3D integration, drive the demand for advanced test socket solutions capable of accommodating complex package configurations and heterogeneous integration.

- Miniaturization and High-Density Interconnects: The trend towards smaller form factors, higher pin counts, and greater integration density in semiconductor devices requires test socket solutions capable of supporting high-density interconnects, fine-pitch contacts, and miniaturized package designs.

- High-Speed and High-Frequency Testing: The emergence of applications requiring high-speed data transmission, high-frequency signals, and advanced modulation schemes demands test socket solutions with superior signal integrity, impedance control, and frequency response for accurate testing of RF, wireless, and high-speed digital devices.

- Thermal Management Solutions: Thermal management is a critical consideration in semiconductor testing, with test socket manufacturers focusing on innovative thermal solutions such as heat sinks, thermal pads, and liquid cooling systems to dissipate heat effectively and maintain device reliability during testing.

- Industry 4.0 and Smart Manufacturing: The adoption of Industry 4.0 principles and smart manufacturing technologies, such as Internet of Things (IoT) sensors, artificial intelligence (AI), and data analytics, enables real-time monitoring, predictive maintenance, and optimization of semiconductor testing processes, enhancing efficiency, productivity, and yield.

Covid-19 Impact

The Covid-19 pandemic has had a mixed impact on the semiconductor test socket market:

- Disruptions in Supply Chain: Global supply chain disruptions, including shortages of raw materials, components, and manufacturing equipment, have impacted the production, availability, and delivery of test socket solutions, leading to delays and supply shortages.

- Shifts in Demand: Changes in consumer behavior, work-from-home arrangements, and remote learning initiatives have driven demand for consumer electronics, networking equipment, and telecommunication devices, increasing the need for semiconductor testing solutions.

- Remote Testing Solutions: The pandemic has accelerated the adoption of remote testing solutions, cloud-based testing platforms, and virtual collaboration tools, enabling semiconductor manufacturers to conduct testing remotely, minimize physical contact, and maintain business continuity during lockdowns and travel restrictions.

- Focus on Health and Safety: Semiconductor manufacturers prioritize health and safety measures in testing facilities, implementing social distancing protocols, sanitization procedures, and remote monitoring solutions to protect workers and ensure continuity of operations.

Key Industry Developments

- Technological Advancements: Test socket manufacturers continue to innovate in materials, contact technologies, and thermal management solutions to address the evolving needs and challenges of semiconductor testing, offering solutions that support higher speeds, greater densities, and increased reliability.

- Customization and Flexibility: Customization options and flexibility are key focus areas for test socket manufacturers, enabling them to develop solutions tailored to the specific requirements of semiconductor manufacturers, testing laboratories, and equipment suppliers.

- Collaborative Partnerships: Collaboration between test socket manufacturers, semiconductor manufacturers, and testing equipment suppliers facilitates the development of interoperable solutions, accelerates product innovation, and enhances market competitiveness.

- Sustainability Initiatives: Test socket manufacturers are increasingly focusing on sustainability initiatives, such as eco-friendly materials, energy-efficient manufacturing processes, and waste reduction strategies, to minimize their environmental footprint and appeal to environmentally conscious customers.

- Digitalization and Automation: Digitalization and automation play a significant role in semiconductor testing, with test socket manufacturers leveraging digital technologies such as artificial intelligence (AI), machine learning (ML), and robotics to optimize testing processes, improve efficiency, and reduce time-to-market.

Analyst Suggestions

Based on market trends and developments, analysts suggest the following strategies for industry participants:

- Investment in R&D: Continued investment in research and development (R&D) enables test socket manufacturers to develop advanced solutions capable of meeting the evolving needs and challenges of semiconductor testing, driving market differentiation and competitive advantage.

- Focus on Innovation and Differentiation: Test socket manufacturers should focus on innovation, differentiation, and customization to develop solutions that address the unique requirements of semiconductor manufacturers, testing laboratories, and equipment suppliers, offering value-added features, performance enhancements, and compatibility with emerging semiconductor technologies.

- Collaborative Partnerships: Collaboration with semiconductor manufacturers, testing laboratories, equipment suppliers, and industry consortia facilitates the development of customized test socket solutions, accelerates product innovation, and enhances market competitiveness, enabling industry participants to deliver cutting-edge solutions that meet customer needs and market demands.

- Market Diversification and Geographic Expansion: Diversification of product offerings and expansion into new geographic regions and emerging markets enable test socket manufacturers to diversify their customer base, increase market share, and capitalize on untapped opportunities, reducing dependency on specific market segments or regions.

- Sustainability and Corporate Social Responsibility (CSR): Emphasis on sustainability initiatives, eco-friendly materials, and ethical manufacturing practices enables test socket manufacturers to minimize their environmental footprint, enhance brand reputation, and appeal to environmentally conscious customers, aligning with corporate social responsibility (CSR) objectives and industry sustainability goals.

Future Outlook

The future outlook for the semiconductor test socket market is optimistic, with continued growth and innovation expected in the coming years. As semiconductor technologies continue to advance, driven by factors such as artificial intelligence (AI), 5G connectivity, Internet of Things (IoT), and autonomous vehicles, the demand for high-performance test socket solutions is expected to increase, creating new opportunities for market expansion and technological advancement. Test socket manufacturers that prioritize innovation, customization, and collaboration are well-positioned to capitalize on this growing market opportunity and drive the next wave of semiconductor testing innovation.

Conclusion

In conclusion, the semiconductor test socket market plays a critical role in semiconductor testing, ensuring the functionality, reliability, and performance of semiconductor devices across various industries. Despite challenges such as technical limitations, cost pressures, and supply chain disruptions, the market continues to grow and evolve, driven by advancements in semiconductor technologies, increasing demand for electronic devices, and the proliferation of emerging applications. By focusing on innovation, customization, and collaboration, test socket manufacturers can differentiate their products, address customer needs, and unlock the full potential of the semiconductor test socket market.

Semiconductor Test Socket Market

| Segmentation Details |

Description |

| Product Type |

Burn-in Sockets, Probe Sockets, Test Sockets, Adapters |

| Technology |

Mechanical, Electrical, Optical, Hybrid |

| End User |

Semiconductor Manufacturers, Test Labs, Research Institutions, Electronics Companies |

| Application |

Consumer Electronics, Automotive, Telecommunications, Industrial |

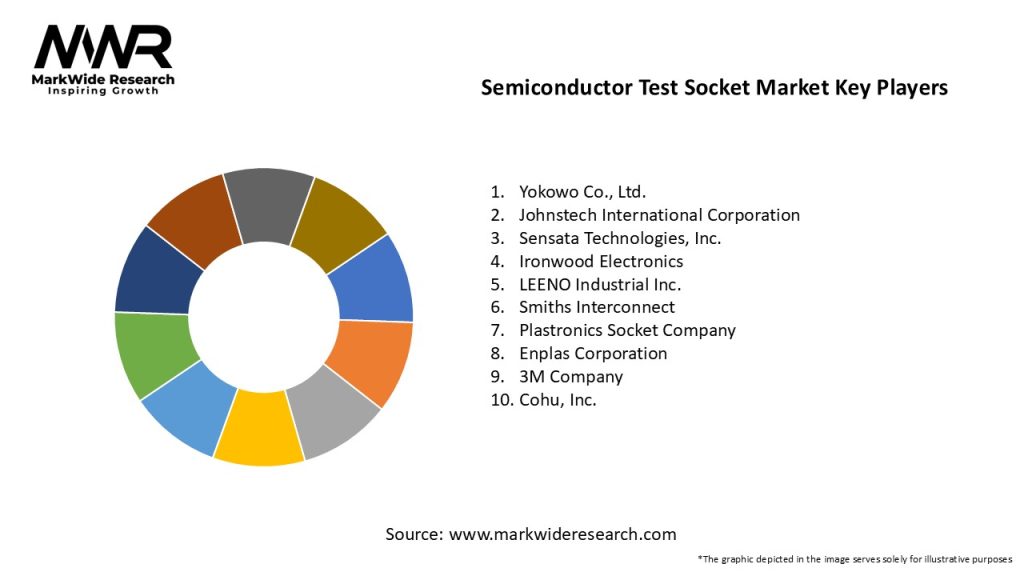

Leading Companies in the Semiconductor Test Socket Market:

- Yokowo Co., Ltd.

- Johnstech International Corporation

- Sensata Technologies, Inc.

- Ironwood Electronics

- LEENO Industrial Inc.

- Smiths Interconnect

- Plastronics Socket Company

- Enplas Corporation

- 3M Company

- Cohu, Inc.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

![]()