444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The seed industry processing equipment market plays a crucial role in ensuring the efficiency and quality of seed processing operations. Seed processing involves various activities such as cleaning, grading, treating, and packaging, which are essential for producing high-quality seeds. The market for seed industry processing equipment has witnessed significant growth in recent years due to the increasing demand for improved crop yields and the adoption of advanced technologies in the agriculture sector.

Meaning

Seed industry processing equipment refers to the machinery and tools used in the processing of seeds to enhance their quality and germination potential. It encompasses a wide range of equipment, including seed cleaners, graders, treaters, dryers, and packaging machines. These equipment are designed to remove impurities, separate seeds based on size and weight, treat seeds with pesticides or fungicides, and package them for distribution. The aim is to ensure that only high-quality seeds reach farmers, leading to better crop yields and overall agricultural productivity.

Executive Summary

The seed industry processing equipment market is experiencing steady growth due to the increasing demand for quality seeds and the adoption of advanced technologies in the agriculture sector. The market offers a wide range of equipment designed to facilitate efficient seed processing operations. Factors such as rising global population, shrinking arable land, and the need for sustainable agriculture are driving the demand for improved crop yields. This, in turn, fuels the demand for seed industry processing equipment to enhance seed quality and optimize production processes.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

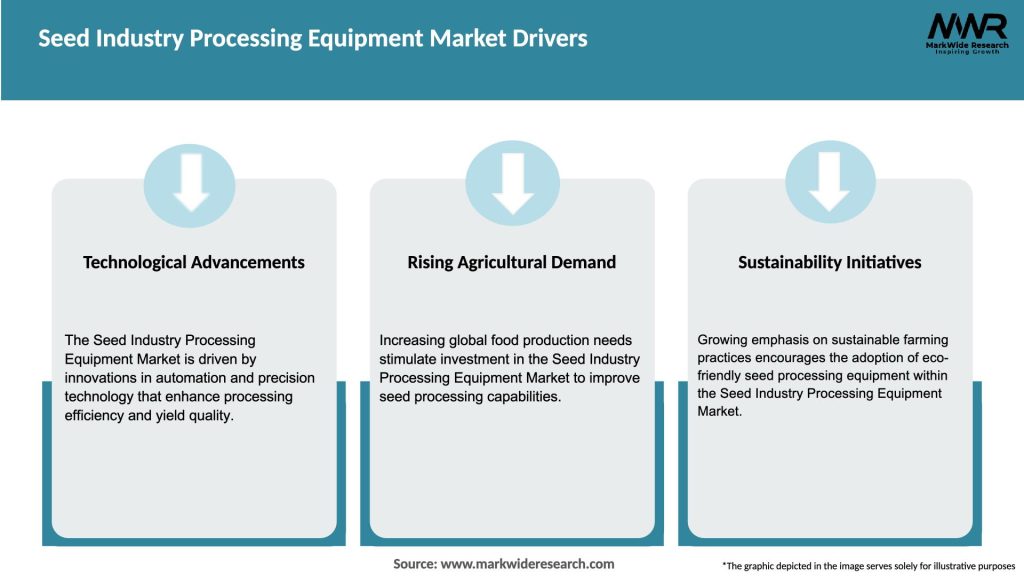

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The seed industry processing equipment market is influenced by various dynamic factors, including technological advancements, regulatory policies, market competition, and consumer preferences. Understanding these dynamics is crucial for stakeholders to make informed decisions and capitalize on market opportunities.

Technological advancements play a significant role in shaping the market landscape. Manufacturers are continuously investing in research and development to introduce innovative solutions that enhance the efficiency, accuracy, and automation of seed processing equipment. Integrated systems, digital solutions, and precision technologies are gaining prominence, enabling seamless seed processing operations and improved quality control.

Regulatory policies and government support impact the market by setting quality standards and providing incentives for the adoption of high-quality seeds. Compliance with regulatory requirements is essential for seed industry processing equipment manufacturers to ensure the market acceptance of their products. Government support, such as subsidies and grants, can also influence the purchasing decisions of farmers and agricultural enterprises.

Market competition is intense, with several established players and new entrants vying for market share. To stay competitive, manufacturers focus on product differentiation, cost optimization, and after-sales services. Customization of equipment to meet specific regional or crop-specific requirements is also a key strategy employed by market players.

Consumer preferences are evolving, with an increasing emphasis on sustainability, organic farming, and non-GMO products. This shift in consumer demand impacts the type of seeds produced and the processing equipment required. Manufacturers need to align their product offerings with these preferences to cater to the changing market dynamics.

Regional Analysis

The seed industry processing equipment market can be analyzed based on regional segmentation, considering factors such as market size, growth rate, and market dynamics in each region.

North America: North America has a well-established agriculture sector, characterized by the adoption of advanced technologies and precision farming practices. The region has a high demand for high-quality seeds, which drives the need for efficient seed processing equipment. Technological innovations and the presence of major market players contribute to the growth of the seed industry processing equipment market in this region.

Europe: Europe has a diverse agricultural landscape, with varying crop types and farming practices. The region focuses on sustainable agriculture and has stringent regulations regarding seed quality and processing. Seed industry processing equipment manufacturers in Europe emphasize the development of environmentally friendly and energy-efficient equipment to cater to the market demand. Collaboration between equipment manufacturers, seed companies, and research institutions is common in this region.

Asia Pacific: Asia Pacific is a key market for seed industry processing equipment due to the significant presence of agricultural economies such as China and India. The region experiences rapid urbanization and a growing demand for food. To meet this demand, farmers are increasingly adopting advanced seed processing technologies. The market in Asia Pacific is characterized by the presence of both domestic and international equipment manufacturers, offering a wide range of equipment options to cater to diverse market requirements.

Latin America: Latin America is a major agricultural region with a focus on crop production such as corn, soybeans, and sugarcane. The region experiences a growing demand for high-quality seeds to optimize crop yields. Seed industry processing equipment manufacturers in Latin America emphasize cost-effective solutions that cater to the needs of small-scale farmers and local agriculture practices. Collaborations with seed companies and the adoption of advanced technologies present growth opportunities in this region.

Middle East and Africa: The Middle East and Africa region have unique agriculture landscapes characterized by arid and semi-arid climates. The focus is on cultivating drought-tolerant crops and utilizing advanced irrigation techniques. The demand for seed industry processing equipment in this region is driven by the need for seeds suitable for arid conditions and the adoption of precision agriculture technologies. The market in this region is characterized by collaborations between international equipment manufacturers and local stakeholders to develop customized solutions.

Competitive Landscape

Leading Companies in the Seed Industry Processing Equipment Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The seed industry processing equipment market can be segmented based on equipment type, end-user, and region.

By Equipment Type:

By End-User:

By Region:

Segmentation allows for a more detailed analysis of the market, enabling stakeholders to identify specific market segments and target their offerings accordingly. It helps equipment manufacturers understand regional preferences, end-user requirements, and growth opportunities in different segments.

Category-wise Insights

Each category of seed industry processing equipment caters to specific stages of the seed processing workflow. Manufacturers focus on developing equipment that offers efficiency, accuracy, automation, and customization to meet the diverse requirements of end-users.

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

A SWOT analysis provides an evaluation of the strengths, weaknesses, opportunities, and threats in the seed industry processing equipment market.

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had both positive and negative impacts on the seed industry processing equipment market.

Positive impact:

Negative impact:

Despite the challenges faced during the pandemic, the seed industry processing equipment market demonstrated resilience and adaptability. The industry’s ability to respond to changing market dynamics and the increased recognition of the importance of the agriculture sector bode well for future growth.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the seed industry processing equipment market is promising. Factors such as increasing global population, the need for improved crop yields, technological advancements, and the emphasis on sustainable agriculture will continue to drive the demand for high-quality seeds and efficient seed processing equipment. Manufacturers will focus on developing advanced equipment that offers automation, digitization, customization, and sustainability. Integration of artificial intelligence, machine learning, and data analytics will become more prevalent, enabling optimized seed processing operations and enhanced quality control.

The expansion of agriculture in emerging economies, growing demand for organic and non-GMO seeds, and collaborations between equipment manufacturers and seed companies will present significant growth opportunities in the market. Manufacturers will continue to explore partnerships and collaborations to drive innovation, gain market share, and expand their geographical presence.

Conclusion

While challenges such as high initial investment costs and limited technical expertise exist, increased awareness, government support, and technological advancements will help overcome these obstacles. In conclusion, the seed industry processing equipment market is poised for growth, driven by the increasing demand for high-quality seeds, adoption of advanced technologies, and focus on sustainable agriculture. Manufacturers, end-users, and stakeholders must adapt to market trends, embrace innovation, and collaborate to capitalize on the opportunities and ensure a thriving seed industry.

What is Seed Industry Processing Equipment?

Seed Industry Processing Equipment refers to the machinery and tools used in the processing of seeds, including cleaning, sorting, and packaging. This equipment is essential for ensuring seed quality and efficiency in agricultural production.

What are the key players in the Seed Industry Processing Equipment Market?

Key players in the Seed Industry Processing Equipment Market include companies like AGI, Bühler Group, and Cimbria, which specialize in seed processing technologies and solutions. These companies provide a range of equipment for various seed types and processing needs, among others.

What are the growth factors driving the Seed Industry Processing Equipment Market?

The growth of the Seed Industry Processing Equipment Market is driven by increasing demand for high-quality seeds, advancements in processing technology, and the need for efficient agricultural practices. Additionally, the rise in organic farming and sustainable practices is contributing to market expansion.

What challenges does the Seed Industry Processing Equipment Market face?

Challenges in the Seed Industry Processing Equipment Market include high initial investment costs, the need for skilled labor to operate advanced machinery, and fluctuating raw material prices. These factors can hinder market growth and equipment adoption.

What opportunities exist in the Seed Industry Processing Equipment Market?

Opportunities in the Seed Industry Processing Equipment Market include the development of innovative processing technologies, increasing investments in agricultural automation, and the growing trend of precision farming. These factors are expected to enhance efficiency and productivity in seed processing.

What trends are shaping the Seed Industry Processing Equipment Market?

Trends in the Seed Industry Processing Equipment Market include the integration of IoT and automation technologies, a focus on sustainability, and the increasing use of data analytics for optimizing seed processing. These trends are transforming how seed processing is conducted and improving overall efficiency.

Seed Industry Processing Equipment Market

| Segmentation | Details |

|---|---|

| Equipment Type | Seed Cleaners, Seed Graders, Seed Treaters, Others |

| Crop Type | Cereals and Grains, Oilseeds and Pulses, Fruits and Vegetables, Others |

| Sales Channel | Direct Sales, Indirect Sales |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Seed Industry Processing Equipment Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at