444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$2450

Market Overview:

The Saudi Arabia Electrostatic Discharge (ESD) Packaging Market is a critical segment within the packaging industry, specializing in providing protective solutions against electrostatic discharge. As industries in Saudi Arabia embrace advanced technologies and electronic components, the demand for ESD packaging has witnessed a significant upsurge. This market plays a crucial role in safeguarding sensitive electronic devices during transportation, handling, and storage.

Meaning:

The Saudi Arabia Electrostatic Discharge (ESD) Packaging Market revolves around the creation and utilization of packaging materials designed to prevent electrostatic discharge events. ESD packaging is essential for industries dealing with sensitive electronic components, as it ensures that static electricity does not damage or compromise the functionality of these components.

Executive Summary:

The executive summary of the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market provides a comprehensive overview of key market trends, challenges, and opportunities. With a focus on the dynamic landscape of electronics manufacturing and distribution in Saudi Arabia, this summary outlines the strategic importance of ESD packaging in maintaining product integrity.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights:

Market Drivers:

Market Restraints:

Market Opportunities:

Market Dynamics

The dynamics of the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market are influenced by a range of factors, including technological advancements, regulatory developments, and consumer preferences. As industries increasingly prioritize quality and reliability in electronic components, the demand for effective ESD packaging solutions is expected to grow, prompting manufacturers to innovate continuously.

Regional Analysis

Saudi Arabia’s strategic location and ongoing investments in the electronics manufacturing sector position it as a key player in the ESD packaging market. The government’s focus on diversifying the economy and promoting technology-driven sectors, such as electronics and automotive, is driving demand for ESD packaging solutions.

The market is supported by various initiatives aimed at enhancing local manufacturing capabilities and attracting foreign investments in the technology sector. Key regions in Saudi Arabia, such as Riyadh, Jeddah, and Dammam, are witnessing increased construction of electronics manufacturing facilities, further boosting the demand for ESD packaging.

Competitive Landscape

Leading Companies in Saudi Arabia Electrostatic Discharge (ESD) Packaging Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

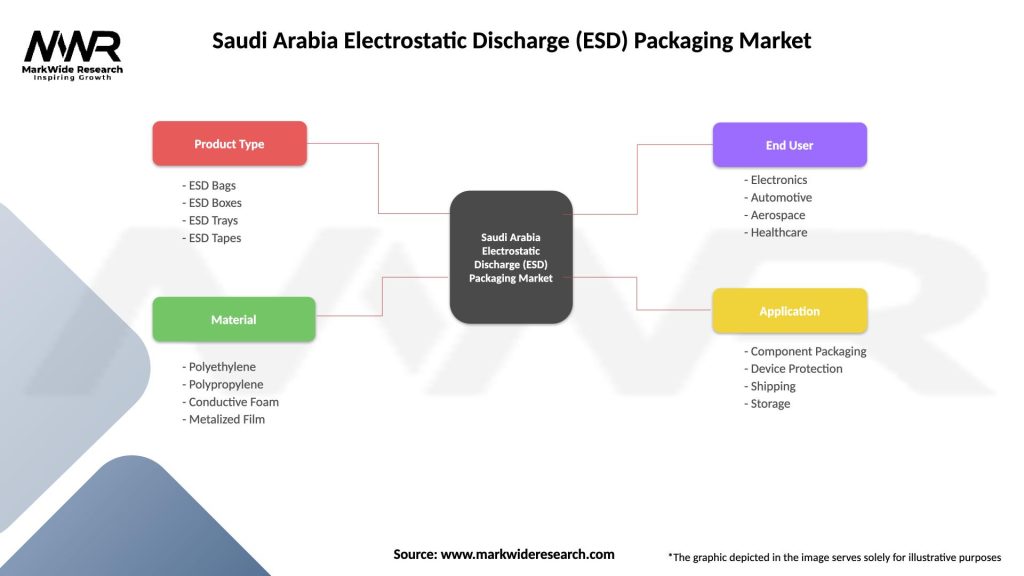

The Saudi Arabia Electrostatic Discharge (ESD) Packaging Market can be segmented based on various criteria:

Each segment offers unique opportunities and challenges, influencing overall market dynamics.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

The adoption of ESD packaging offers numerous benefits, including:

SWOT Analysis

Strengths: Growing electronics industry, increasing awareness of ESD risks, strong demand for reliable packaging solutions

Weaknesses: Higher initial costs, limited awareness in some sectors, competition from alternative packaging solutions

Opportunities: Emerging technologies, sustainable packaging trends, cross-industry applications

Threats: Economic fluctuations, regulatory changes, competition from established packaging alternatives

Market Key Trends

Several key trends are influencing the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market:

Covid-19 Impact

The Covid-19 pandemic has had a notable impact on the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market. While the initial phases of the pandemic led to disruptions in manufacturing and supply chains, the increased reliance on electronic devices during lockdowns drove demand for electronic components.

As the electronics industry adapts to post-pandemic realities, the emphasis on quality and reliability in ESD protection is expected to strengthen, ensuring sustained growth in the ESD packaging market.

Key Industry Developments

Analyst Suggestions

Analysts recommend that stakeholders in the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market focus on educating customers about the importance of ESD protection and the benefits of adopting specialized packaging solutions. Additionally, investing in research and development to create innovative and sustainable ESD packaging products can provide a competitive edge. Companies should also consider leveraging partnerships with key players in the electronics manufacturing sector to enhance market penetration.

Future Outlook

The future of the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market looks promising, with continued growth expected as the electronics manufacturing sector expands. The increasing focus on sustainability and regulatory compliance will drive demand for high-quality ESD packaging solutions. As the market evolves, stakeholders must remain agile and responsive to changing consumer needs and industry trends to capitalize on growth opportunities.

Conclusion

In conclusion, the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market is poised for significant growth, driven by the expanding electronics industry, increasing awareness of ESD risks, and advancements in packaging technology. By prioritizing innovation, sustainability, and education, stakeholders can contribute to a more resilient and effective ESD packaging landscape in Saudi Arabia. The ongoing commitment to quality and reliability will ensure that ESD packaging remains a critical component in protecting sensitive electronic components in the rapidly evolving technological landscape.

What is Electrostatic Discharge (ESD) Packaging?

Electrostatic Discharge (ESD) Packaging refers to materials and methods used to protect electronic components from electrostatic discharge, which can cause damage. This type of packaging is crucial in industries such as electronics manufacturing and semiconductor production.

What are the key players in the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market?

Key players in the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market include companies like Desco Industries, Inc., and 3M Company, which provide a range of ESD protective packaging solutions. Other notable companies include Aeco and Aven, among others.

What are the growth factors driving the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market?

The growth of the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market is driven by the increasing demand for electronic devices, advancements in semiconductor technology, and the rising awareness of ESD protection in manufacturing processes.

What challenges does the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market face?

Challenges in the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market include the high cost of advanced ESD packaging materials and the need for continuous innovation to keep up with rapidly evolving technology in electronics.

What opportunities exist in the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market?

Opportunities in the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market include the expansion of the electronics sector, increased investment in research and development, and the growing trend towards sustainable packaging solutions.

What trends are shaping the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market?

Trends in the Saudi Arabia Electrostatic Discharge (ESD) Packaging Market include the adoption of biodegradable ESD materials, the integration of smart packaging technologies, and the increasing focus on customized packaging solutions for specific electronic applications.

Saudi Arabia Electrostatic Discharge (ESD) Packaging Market

| Segmentation Details | Description |

|---|---|

| Product Type | ESD Bags, ESD Boxes, ESD Trays, ESD Tapes |

| Material | Polyethylene, Polypropylene, Conductive Foam, Metalized Film |

| End User | Electronics, Automotive, Aerospace, Healthcare |

| Application | Component Packaging, Device Protection, Shipping, Storage |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in Saudi Arabia Electrostatic Discharge (ESD) Packaging Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at