444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The rosin-free solder market is witnessing steady growth driven by increasing demand for environmentally friendly soldering solutions and regulatory restrictions on the use of hazardous substances in electronics manufacturing. Rosin-free solder, also known as no-clean solder, is formulated without the use of rosin flux, offering advantages such as reduced environmental impact, improved reliability, and enhanced solder joint performance.

Meaning

Rosin-free solder refers to solder alloys formulated without the use of rosin flux, a natural resin derived from pine trees traditionally used to facilitate soldering by removing oxides from metal surfaces. Instead, rosin-free solder uses synthetic flux formulations that do not leave behind residue after soldering, eliminating the need for cleaning operations and minimizing environmental impact.

Executive Summary

The rosin-free solder market is experiencing steady growth driven by increasing awareness of environmental issues, tightening regulations on hazardous substances, and growing adoption of lead-free soldering solutions in electronics manufacturing. Key factors driving market growth include advancements in soldering technology, expansion of electronics manufacturing industries, and adoption of sustainable manufacturing practices.

Key Market Insights

Market Drivers

Market Restraints

Market Opportunities

Market Dynamics

The rosin-free solder market is influenced by dynamic factors such as changing regulatory requirements, technological advancements, market demand, and competitive dynamics. Market players need to adapt to evolving market trends, anticipate customer needs, and invest in innovation and sustainability to maintain competitiveness and drive growth.

Regional Analysis

The rosin-free solder market is geographically diverse, with significant demand coming from regions with active electronics manufacturing industries, stringent regulatory frameworks for hazardous substances, and growing awareness of environmental issues. Key regional markets include North America, Europe, Asia Pacific, and Latin America, where rosin-free solder is gaining traction as a sustainable and compliant soldering solution.

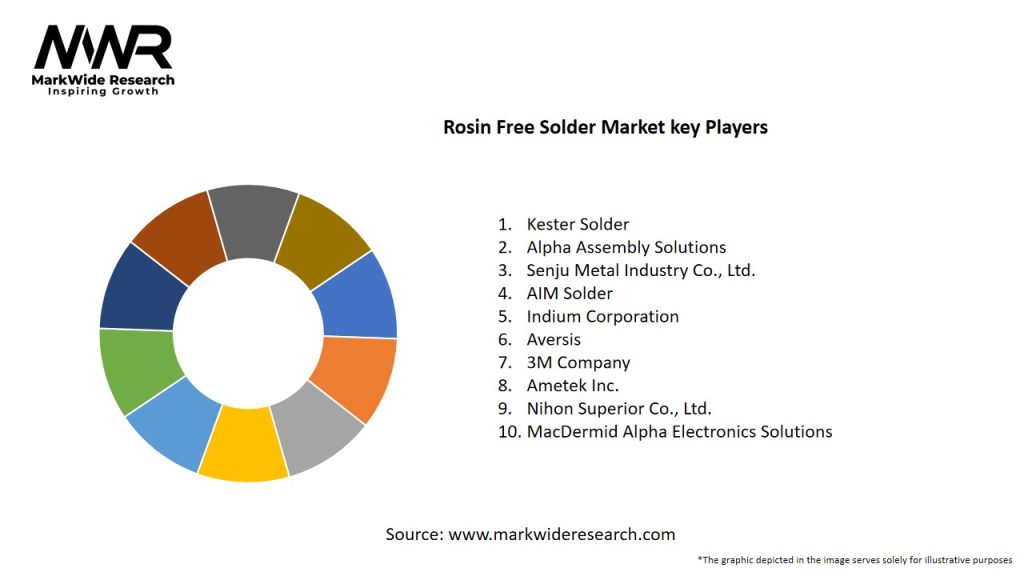

Competitive Landscape

The rosin-free solder market is competitive, with several global and regional players offering a wide range of solder alloys, flux formulations, and soldering consumables. Key market players include solder manufacturers, flux suppliers, equipment vendors, and service providers. Competition is based on factors such as product quality, performance, reliability, innovation, pricing, and customer service.

Segmentation

The rosin-free solder market can be segmented based on solder alloy type, flux formulation, application, end-use industry, and geography. Solder alloy types may include lead-free alloys such as SAC (tin-silver-copper) and SN100C, while flux formulations may include no-clean, low-residue, and water-soluble fluxes. Applications span electronics assembly, PCB assembly, rework and repair, and surface mount technology (SMT). End-use industries may include consumer electronics, automotive, aerospace, telecommunications, medical devices, and renewable energy.

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Market Key Trends

Covid-19 Impact

The Covid-19 pandemic has had mixed effects on the rosin-free solder market, with disruptions in global supply chains, manufacturing operations, and demand in certain industries such as automotive and aerospace, offset by increased demand for electronics, medical devices, and telecommunications equipment where rosin-free solder finds applications.

Key Industry Developments

Analyst Suggestions

Future Outlook

The future outlook for the rosin-free solder market is positive, driven by increasing demand for environmentally friendly soldering solutions, tightening regulations on hazardous substances, and advancements in soldering technology and materials. While challenges such as cost considerations, technical limitations, and regulatory uncertainties may persist, market players can capitalize on emerging trends, innovation opportunities, and collaboration initiatives to drive sustainable growth and market leadership in the dynamic rosin-free solder landscape.

Conclusion

In conclusion, the rosin-free solder market presents significant opportunities for industry participants to address growing demand for environmentally friendly soldering solutions, comply with regulatory requirements, and meet customer expectations for reliable and high-performance electronic assemblies. With advantages such as environmental sustainability, compliance with regulatory standards, and improved solder joint reliability, rosin-free solder offers attractive benefits for manufacturers, OEMs, and consumers seeking eco-friendly alternatives to traditional soldering materials. While challenges exist in terms of technical limitations, cost considerations, and regulatory uncertainties, strategic initiatives such as innovation, collaboration, and education can drive market adoption, foster sustainability, and position rosin-free solder as a leading solution for environmentally conscious industries and applications in the future.

Rosin Free Solder Market

| Segmentation Details | Description |

|---|---|

| Product Type | Lead-Free, Tin-Based, Silver-Based, Bismuth-Based |

| Application | Electronics, Automotive, Aerospace, Telecommunications |

| End User | Manufacturers, Repair Shops, DIY Enthusiasts, Contract Assemblers |

| Technology | Wave Soldering, Reflow Soldering, Hand Soldering, Selective Soldering |

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at