444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The robotic drilling market has experienced significant growth in recent years, driven by advancements in automation technology and increasing demand for efficient drilling processes. Robotic drilling involves the use of automated systems to perform drilling operations in various industries such as oil and gas, mining, and construction. These robotic systems offer improved accuracy, enhanced safety, and increased productivity compared to traditional drilling methods. This market overview provides a comprehensive analysis of the robotic drilling market, including key market insights, drivers, restraints, opportunities, and market dynamics.

Meaning

Robotic drilling refers to the use of automated systems and robots to carry out drilling operations. These systems are equipped with advanced sensors, computer algorithms, and control mechanisms that enable them to perform drilling tasks with precision and efficiency. Robotic drilling technology has revolutionized the drilling industry by reducing human intervention, improving drilling accuracy, and enhancing operational safety. These systems are widely used in the oil and gas industry, mining sector, and construction projects where precise and repetitive drilling tasks are required.

Executive Summary

The robotic drilling market has witnessed substantial growth in recent years, driven by the increasing demand for efficient drilling operations across various industries. The market is characterized by the adoption of advanced automation technologies and the integration of artificial intelligence (AI) and machine learning (ML) algorithms in drilling systems. This executive summary provides an overview of the key findings and trends in the robotic drilling market, including market size, growth rate, competitive landscape, and future outlook.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

Market Drivers

Several factors are driving the growth of the robotic drilling market:

Market Restraints

Despite the positive growth prospects, the robotic drilling market also faces certain challenges:

Market Opportunities

The robotic drilling market presents several opportunities for industry participants and stakeholders:

Market Dynamics

The robotic drilling market is driven by a combination of internal and external factors that influence its growth and development. Internal factors include technological advancements, product innovation, and market competition, while external factors encompass industry trends, government regulations, and economic conditions. Understanding the market dynamics is crucial for industry participants and stakeholders to make informed decisions and devise effective strategies for business growth in the robotic drilling market.

Regional Analysis

The robotic drilling market can be segmented into several regions, including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. Each region has its own unique characteristics and offers specific opportunities and challenges for the growth of the robotic drilling market. This regional analysis provides a detailed assessment of the market landscape, key players, market size, and growth prospects in each geographical segment.

Competitive Landscape

Leading Companies in the Robotic Drilling Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

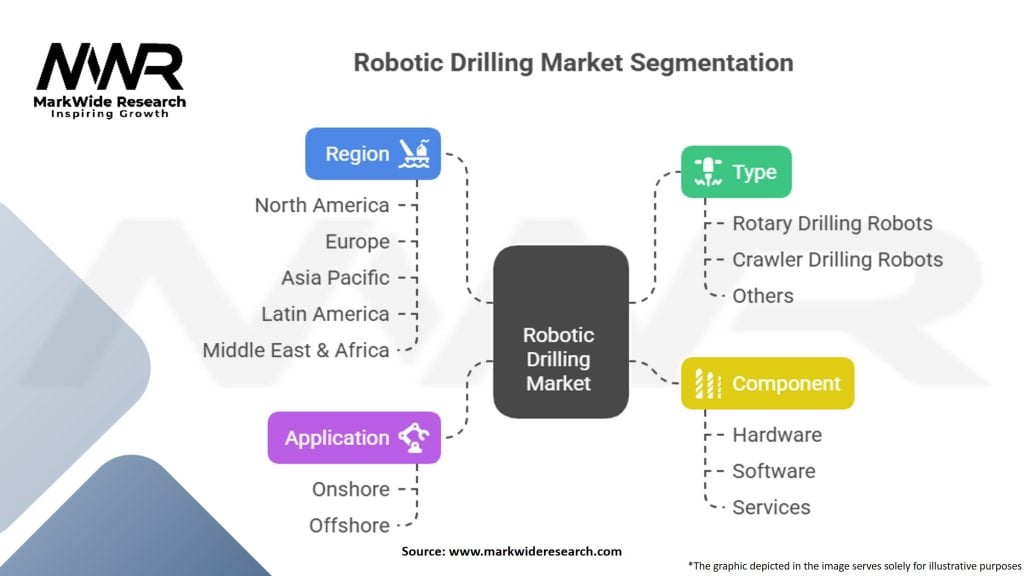

Segmentation

The robotic drilling market can be segmented based on various factors, including technology, application, end-user industry, and geography. This segmentation enables a deeper understanding of the market dynamics and allows industry participants to target specific customer segments and tailor their strategies accordingly. The segmentation analysis provides insights into the market size, growth rate, and trends for each segment, facilitating strategic decision-making.

Category-wise Insights

Different categories within the robotic drilling market offer distinct insights into market trends and opportunities. These categories include hardware components, software solutions, services, and aftermarket support. Hardware components include robotic arms, sensors, control systems, and drilling tools. Software solutions encompass control software, data analytics, and simulation tools. Services include installation, maintenance, and repair services, while aftermarket support includes spare parts and technical support. Analyzing the market trends and growth prospects for each category helps industry participants identify lucrative opportunities and devise appropriate strategies.

Key Benefits for Industry Participants and Stakeholders

Industry participants and stakeholders in the robotic drilling market can benefit in various ways:

SWOT Analysis

Strengths:

Enhanced Precision & Safety: Automated drilling robots reduce human error and exposure to hazardous conditions.

24/7 Operation: Unmanned systems can run continuously, boosting project throughput and reducing downtime.

Data‑Driven Optimization: Integrated sensors and analytics enable real‑time monitoring and process improvements.

Weaknesses:

High Capital Expenditure: Significant upfront investment in robotics hardware and integration infrastructure.

Technical Complexity: Requires specialized skills for programming, maintenance, and troubleshooting.

Dependency on Power & Connectivity: Remote or off‑grid sites may face reliability issues.

Opportunities:

Expansion in Oil & Gas and Mining: Growing focus on deep‑sea and underground operations where automation adds value.

Retrofit of Legacy Equipment: Upgrading existing rigs with robotic add‑ons can extend asset life and ROI.

Regulatory Push for Safety: Stricter safety standards drive adoption of non‑man entry drilling solutions.

Threats:

Commodity Price Volatility: Fluctuations in oil, gas, and mineral prices can delay capital projects.

Cybersecurity Risks: Increased connectivity exposes systems to hacking or data breaches.

Resistance to Change: Traditional operators may be slow to adopt unproven automation technologies.

Market Key Trends

The robotic drilling market is subject to several key trends that shape its growth and development:

Covid-19 Impact

The Covid-19 pandemic has had a significant impact on the global economy and various industries, including the robotic drilling market. The crisis has resulted in disruptions in the supply chain, project delays, and a decline in oil and gas prices. However, the pandemic has also accelerated the adoption of automation technologies and robotic systems, as they offer operational resilience and efficiency. The Covid-19 impact analysis assesses the short-term and long-term effects of the pandemic on the robotic drilling market and highlights the emerging trends and opportunities in the post-pandemic era.

Key Industry Developments

The robotic drilling market has witnessed several key industry developments that have shaped its growth trajectory:

Analyst Suggestions

Based on the market analysis and trends, analysts provide valuable suggestions for industry participants and stakeholders in the robotic drilling market. These suggestions aim to guide decision-making and strategy formulation for sustainable growth and competitive advantage. Analysts may recommend exploring emerging markets, investing in research and development, fostering collaborations, and embracing digitalization and data analytics capabilities.

Future Outlook

The future outlook for the robotic drilling market is highly promising, with substantial growth opportunities on the horizon. The market is expected to witness increased adoption of automation technologies, integration of AI and ML algorithms, and advancements in drilling systems. Key factors such as the expansion of oil and gas exploration activities, infrastructure development projects, and the growing focus on sustainable drilling practices will drive market growth. The future outlook provides a comprehensive assessment of the market’s growth potential, emerging trends, and strategic recommendations for industry participants.

Conclusion

The robotic drilling market is experiencing rapid growth and transformation, driven by advancements in automation technology and the increasing demand for efficient drilling operations. Robotic drilling systems offer enhanced accuracy, improved safety, and increased productivity compared to traditional drilling methods. The market presents lucrative opportunities for industry participants and stakeholders in various sectors, including oil and gas, mining, and construction. By embracing innovative technologies, fostering collaborations, and adapting to market trends, industry players can position themselves for success in the evolving robotic drilling market.

What is Robotic Drilling?

Robotic drilling refers to the use of automated systems and robots to perform drilling operations in various industries, including oil and gas, mining, and construction. These systems enhance precision, efficiency, and safety in drilling processes.

What are the key players in the Robotic Drilling Market?

Key players in the Robotic Drilling Market include companies like Halliburton, Schlumberger, and National Oilwell Varco. These companies are known for their innovative technologies and solutions in automated drilling systems, among others.

What are the main drivers of growth in the Robotic Drilling Market?

The main drivers of growth in the Robotic Drilling Market include the increasing demand for efficiency in drilling operations, advancements in automation technology, and the need for enhanced safety measures in hazardous environments. Additionally, the rising exploration activities in remote areas contribute to market expansion.

What challenges does the Robotic Drilling Market face?

The Robotic Drilling Market faces challenges such as high initial investment costs, technical complexities in integrating robotic systems, and the need for skilled personnel to operate and maintain these technologies. Additionally, regulatory hurdles can impact the adoption of robotic drilling solutions.

What opportunities exist in the Robotic Drilling Market?

Opportunities in the Robotic Drilling Market include the potential for innovation in drilling technologies, the expansion of applications in renewable energy sectors, and the increasing focus on sustainable drilling practices. These factors can lead to new market entrants and product developments.

What trends are shaping the Robotic Drilling Market?

Trends shaping the Robotic Drilling Market include the integration of artificial intelligence and machine learning for improved decision-making, the development of autonomous drilling rigs, and the growing emphasis on data analytics for optimizing drilling performance. These innovations are transforming traditional drilling methods.

Robotic Drilling Market

| Segmentation | Details |

|---|---|

| Type | Rotary Drilling Robots, Crawler Drilling Robots, Others |

| Application | Onshore, Offshore |

| Component | Hardware, Software, Services |

| Region | North America, Europe, Asia Pacific, Latin America, Middle East & Africa |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Leading Companies in the Robotic Drilling Market:

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at