444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview

The global Robot Grippers market is witnessing significant growth due to the increasing adoption of robots in various industries and the need for advanced gripping solutions to enhance their functionality. Robot grippers are essential components that enable robots to grasp, manipulate, and handle objects of different shapes, sizes, and materials. They play a crucial role in industries such as manufacturing, logistics, healthcare, and agriculture, where robots are deployed for tasks such as assembly, packaging, material handling, and pick-and-place operations. This comprehensive report provides insights into the market overview, meaning of robot grippers, executive summary, key market insights, market drivers, market restraints, market opportunities, market dynamics, regional analysis, competitive landscape, segmentation, category-wise insights, key benefits for industry participants and stakeholders, SWOT analysis, market key trends, the impact of Covid-19, key industry developments, analyst suggestions, future outlook, and a concluding summary.

Meaning

Robot grippers refer to the devices or end-effectors attached to robots that allow them to interact with objects in their environment. These grippers are designed to provide a secure and reliable grip on various types of objects, enabling robots to perform tasks that require picking, holding, releasing, or manipulating items. Robot grippers come in different types, including mechanical grippers, vacuum grippers, magnetic grippers, and servo-electric grippers, each suitable for specific applications and material handling requirements. They are crucial components in robotic systems, enabling robots to achieve precision, flexibility, and efficiency in their operations.

Executive Summary

The executive summary provides an overview of the global Robot Grippers market, highlighting its size, growth rate, key players, and notable market trends. It serves as a snapshot of the market’s current state and provides readers with a concise understanding of the key aspects and future prospects of the market.

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights

The Robot Grippers Market is characterized by several factors that are driving its growth:

Technological Advancements: The integration of AI, machine learning, and advanced materials is significantly enhancing the functionality of robot grippers, making them more versatile and capable of performing complex tasks.

Rise of Collaborative Robots (Cobots): The increasing use of cobots, which work alongside human operators, is driving the demand for flexible and adaptive robot grippers.

Industry Adoption: Industries such as automotive, logistics, manufacturing, and healthcare are rapidly adopting robot grippers to improve operational efficiency, reduce costs, and enhance safety.

Demand for Customization: The growing need for grippers tailored to specific tasks and industries, such as food handling or delicate product assembly, is leading to increased demand for specialized robot grippers.

Market Drivers

Several key factors are propelling the growth of the Robot Grippers Market:

Increased Automation in Manufacturing: The demand for robotic automation in manufacturing processes is driving the adoption of robot grippers. Grippers are critical for performing tasks such as assembly, material handling, and packaging.

Growth of E-commerce and Logistics: The expansion of e-commerce and logistics sectors has increased the need for automation in sorting, packaging, and fulfillment, driving the demand for robot grippers that can handle a wide range of products.

Advancements in Robotics and AI: The integration of artificial intelligence and machine learning with robotic systems enhances the capabilities of grippers, allowing them to handle more complex and varied tasks.

Rising Labor Costs: The increasing cost of labor, especially in countries with high wages, is encouraging companies to invest in automation technologies, including robot grippers, to reduce costs and improve efficiency.

Safety and Ergonomics: Robot grippers contribute to improving workplace safety by performing dangerous or repetitive tasks, reducing human exposure to hazards.

Market Restraints

Despite the growth potential, the Robot Grippers Market faces several challenges:

High Initial Costs: The cost of purchasing and integrating robot grippers can be a barrier, particularly for small and medium-sized enterprises (SMEs) with limited budgets.

Integration Complexities: The integration of robot grippers into existing robotic systems can be complex and time-consuming, especially in industries with older infrastructure.

Lack of Standardization: The absence of standardized gripper solutions across industries can result in difficulties in scaling and compatibility, hindering the market’s growth.

Maintenance and Repair Costs: Regular maintenance and the need for specialized technicians can add additional costs for companies adopting robotic grippers, limiting widespread adoption.

Market Opportunities

The Robot Grippers Market presents several opportunities for growth:

Innovation in Soft and Adaptive Grippers: As demand for flexible and adaptive solutions grows, particularly in industries like food handling and healthcare, there is a significant opportunity for companies to develop innovative soft grippers that can handle delicate objects with ease.

Development of Low-Cost Grippers: With the rise of automation in SMEs, there is a growing demand for affordable and cost-effective robot grippers that can be easily integrated into existing systems.

Expansion in Healthcare and Agriculture: The healthcare and agriculture sectors are increasingly adopting robotic automation for tasks like surgery and crop handling, creating opportunities for specialized robot grippers tailored to these industries.

Advancement of Collaborative Robotics: The demand for cobots is expected to grow, creating opportunities for grippers that can safely and efficiently work alongside human operators.

3D Printing and Customization: The rise of 3D printing technology allows for the rapid development of customized robot grippers, opening up new opportunities for tailored solutions.

Market Dynamics

The Robot Grippers Market is influenced by several factors:

Supply Side Factors:

Demand Side Factors:

Economic Factors:

Regional Analysis

The Robot Grippers Market shows varying growth patterns across regions:

North America:

Europe:

Asia-Pacific:

Latin America:

Middle East and Africa:

Competitive Landscape

Leading Companies in the Robot Grippers Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation

The Robot Grippers Market can be segmented as follows:

By Type:

By Application:

Category-wise Insights

Key Benefits for Industry Participants and Stakeholders

SWOT Analysis

Strengths:

Weaknesses:

Opportunities:

Threats:

Market Key Trends

Covid-19 Impact

The Covid-19 impact section evaluates the influence of the pandemic on the global Robot Grippers market. It discusses the challenges faced by the market during the pandemic, such as supply chain disruptions, reduced investments, and delayed projects. The section also examines the potential opportunities that emerged during the pandemic, such as the increased need for automation and contactless operations. It explores the accelerated adoption of robot grippers in industries such as e-commerce, healthcare, and logistics, driven by the demand for safer and more efficient operations. Furthermore, it discusses the potential long-term effects of the pandemic on the market, including the integration of grippers with remote operation capabilities and the focus on resilience and flexibility in robotic systems.

Key Industry Developments

The key industry developments section highlights recent advancements, initiatives, and collaborations in the global Robot Grippers market. It covers topics such as the launch of innovative gripper designs, strategic partnerships between gripper manufacturers and robot suppliers, and the development of grippers with advanced sensing and control capabilities. The section provides insights into the latest developments that are shaping the market landscape and driving innovation in Robot Grippers.

Analyst Suggestions

The analyst suggestions section offers recommendations and guidance for industry participants and stakeholders in the global Robot Grippers market. It provides insights into strategies for market entry and growth, such as investing in research and development, collaborating with robot manufacturers, and addressing the specific needs of end-user industries. The section emphasizes the importance of gripper versatility, ease of integration, and compatibility with different robot systems. It also suggests the need for continuous innovation, customer support, and training programs to stay competitive in the evolving market.

Future Outlook

The future outlook section provides a forward-looking perspective on the global Robot Grippers market. It discusses anticipated market trends, technological advancements, regulatory developments, and evolving customer requirements that are likely to shape the market in the coming years. The section highlights the potential for continued market growth, driven by the increasing adoption of robots and automation in various industries. It also emphasizes the need for grippers that can handle complex and delicate objects, the integration of artificial intelligence and machine learning algorithms in gripper design, and the opportunities for market expansion in emerging industries and regions.

Conclusion

In conclusion, the global Robot Grippers market is witnessing significant growth driven by the increasing adoption of robots and the need for advanced gripping solutions. Robot grippers play a crucial role in enabling robots to perform various tasks that require object handling and manipulation. The market is driven by factors such as the increasing demand for automation, the need for versatile and adaptable grippers, and the advancements in robotic technologies. However, challenges such as gripper customization and compatibility need to be addressed. The future outlook for the market is promising, with opportunities for innovation, market expansion, and improved operational efficiency. Strategic investments, collaborations, and continuous technological advancements will be key to success in the evolving landscape of the global Robot Grippers market.

What is Robot Grippers?

Robot grippers are mechanical devices used in automation to grasp and manipulate objects. They are essential components in robotic systems, enabling tasks such as assembly, packaging, and material handling across various industries.

Who are the key players in the Robot Grippers market?

Key players in the Robot Grippers market include companies like ABB, KUKA, and FANUC, which are known for their advanced robotic solutions. Other notable companies include Zimmer Group and Applied Robotics, among others.

What are the main drivers of growth in the Robot Grippers market?

The growth of the Robot Grippers market is driven by the increasing demand for automation in manufacturing, the rise of e-commerce requiring efficient packaging solutions, and advancements in robotics technology that enhance precision and efficiency.

What challenges does the Robot Grippers market face?

The Robot Grippers market faces challenges such as high initial investment costs for automation systems and the need for skilled labor to operate and maintain robotic systems. Additionally, the rapid pace of technological change can make it difficult for companies to keep up.

What opportunities exist in the Robot Grippers market?

Opportunities in the Robot Grippers market include the expansion of robotics in sectors like healthcare and agriculture, where automation can improve efficiency and safety. Furthermore, the development of smart grippers with AI capabilities presents new avenues for innovation.

What trends are shaping the Robot Grippers market?

Trends in the Robot Grippers market include the increasing adoption of collaborative robots (cobots) that work alongside humans, the integration of machine learning for enhanced grip control, and the growing focus on sustainability in manufacturing processes.

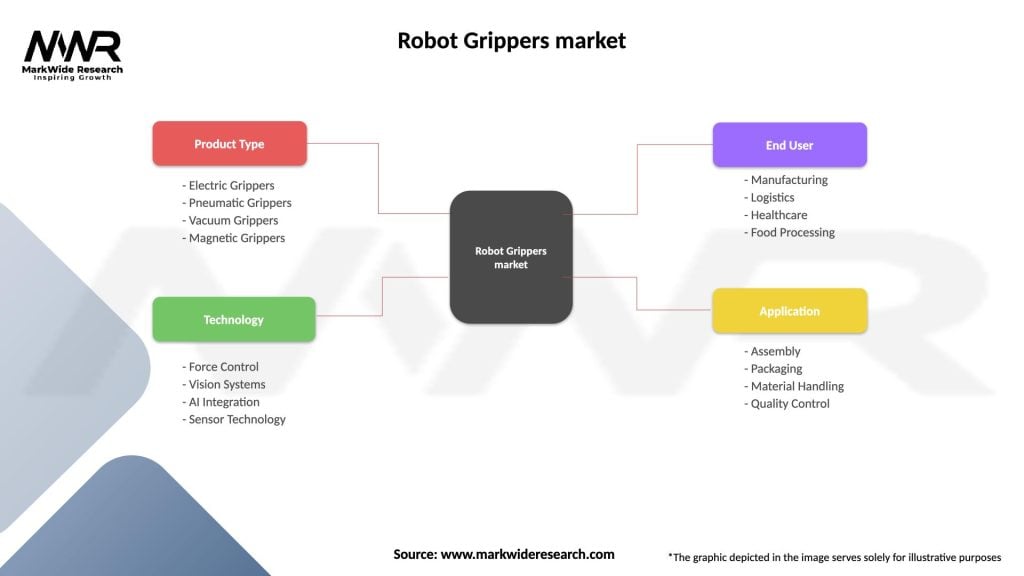

Robot Grippers market

| Segmentation Details | Description |

|---|---|

| Product Type | Electric Grippers, Pneumatic Grippers, Vacuum Grippers, Magnetic Grippers |

| Technology | Force Control, Vision Systems, AI Integration, Sensor Technology |

| End User | Manufacturing, Logistics, Healthcare, Food Processing |

| Application | Assembly, Packaging, Material Handling, Quality Control |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at