444 Alaska Avenue

Suite #BAA205 Torrance, CA 90503 USA

+1 424 999 9627

24/7 Customer Support

sales@markwideresearch.com

Email us at

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at

Corporate User License

Unlimited User Access, Post-Sale Support, Free Updates, Reports in English & Major Languages, and more

$3450

Market Overview: Precision in Connection

The riveting equipment market plays a pivotal role in various industries by providing tools that ensure precise and secure connections. Renowned for their ability to join materials through the process of riveting, these tools are essential for constructing robust structures. The riveting equipment market thrives on its contribution to reliable and durable connections in diverse applications.

Meaning: Tools of Secure Connection

Riveting equipment comprises tools and machinery designed to create permanent connections between materials through the insertion of rivets. Rivets are fasteners that hold materials together by expanding on the opposite side of the connection. The significance of riveting equipment lies in its role in creating connections that withstand various stresses and loads.

Executive Summary: Architects of Stability

The riveting equipment market stands as a cornerstone of stability and strength in construction and manufacturing. As tools that create secure connections, riveting equipment empowers industries to build robust structures and products. The market’s growth is rooted in its capacity to ensure the integrity of connections in diverse applications.

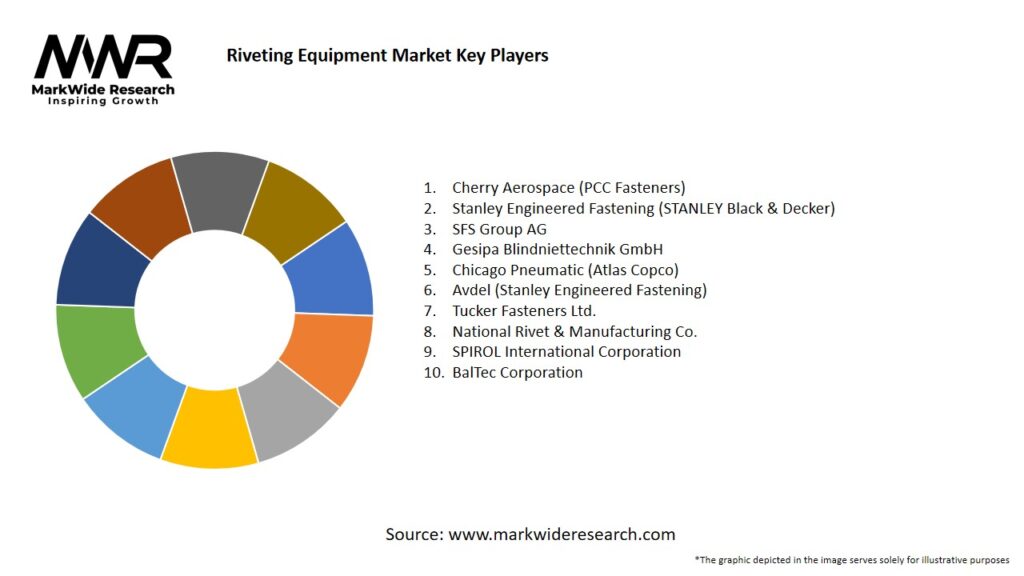

Important Note: The companies listed in the image above are for reference only. The final study will cover 18–20 key players in this market, and the list can be adjusted based on our client’s requirements.

Key Market Insights: Crafting Durable Bonds

The riveting equipment market experiences substantial growth due to its vital role in connecting materials securely. Industries seeking reliable and durable connections rely on riveting equipment to create bonds that withstand mechanical stress and environmental challenges. The market’s trajectory is shaped by the harmony between industrial needs and the precision of riveting equipment.

Market Drivers: Reinforcing Connections

Several factors drive the expansion of the riveting equipment market:

Market Restraints: Addressing Challenges in Connection

While the riveting equipment market displays strong potential, it faces certain challenges:

Market Opportunities: Innovating Connection Solutions

Within challenges lie opportunities for innovation and growth:

Market Dynamics: Forging Secure Pathways

The riveting equipment market dynamics are driven by evolving construction methods, industry demands, and the pursuit of reliable connections. As industries seek durable and secure bonds, riveting equipment stands as a guide to forging connections that withstand the test of time.

Regional Analysis: A Global Web of Connections

The riveting equipment market’s landscape varies across regions:

Competitive Landscape: Craftsmen of Precision

Leading Companies in the Riveting Equipment Market

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

Segmentation: Tailoring Connection Solutions

The market is segmented based on application, industry, and technology:

Category-wise Insights: Building Bonds with Precision

Key Benefits for Industry Participants and Stakeholders: Connecting with Confidence

SWOT Analysis: Evaluating Connection Dynamics

Market Key Trends: Precision Evolution

Covid-19 Impact: Adapting to Construction Needs

The pandemic reshaped construction practices, emphasizing the importance of reliable and durable structures. The demand for riveting equipment remained consistent as industries sought secure connections in their projects.

Key Industry Developments: Shaping Connection Methods

Analyst Suggestions: Navigating Precise Connections

Future Outlook: Precision in Connection

The riveting equipment market holds significant promise for the future. As industries continue to prioritize durable and secure connections, riveting equipment’s precision positions it as an indispensable tool. With a focus on automated assembly, sustainable practices, and technological advancements, the market is set to redefine the art of connection. Collaboration between manufacturers, developers, and end-users will be crucial in ensuring that the market continues to evolve in a sustainable and user-centric manner. In the coming years, a combination of strategic partnerships, ongoing research and development, and responsive adaptations to market dynamics will fuel the market’s growth trajectory, making it an exciting space to watch for both investors and industry participants.

Conclusion: Forging Bonds of Reliability

The riveting equipment market embodies the essence of reliability and precision in connections. As tools that create enduring bonds, riveting equipment enables industries to construct safe and robust structures, vehicles, and products. In a world where stability and durability are paramount, riveting equipment stands as a testament to precision, forging bonds that stand the test of time.

In conclusion, the Evolving Equipment Market stands on the precipice of remarkable growth and transformation. This analysis delved into the various dimensions of the market, shedding light on its current landscape, key trends, drivers, challenges, and future prospects. The market’s adaptability and innovation-driven nature are evident as it responds to changing consumer demands and technological advancements. As industries across the globe embrace automation and cutting-edge technologies, the Evolving Equipment Market is poised to play a pivotal role in shaping modern workflows and operational efficiencies.

What is Riveting Equipment?

Riveting Equipment refers to tools and machines used to join materials, typically metals, by deforming a rivet. This process is widely used in construction, automotive, and aerospace industries for creating strong, permanent joints.

What are the key players in the Riveting Equipment market?

Key players in the Riveting Equipment market include companies like Stanley Black & Decker, Atlas Copco, and Hilti, which provide a range of riveting solutions for various applications, among others.

What are the main drivers of growth in the Riveting Equipment market?

The growth of the Riveting Equipment market is driven by the increasing demand for lightweight materials in automotive and aerospace industries, as well as advancements in automation and manufacturing processes.

What challenges does the Riveting Equipment market face?

Challenges in the Riveting Equipment market include the high initial investment costs for advanced machinery and the need for skilled labor to operate complex riveting systems, which can hinder adoption in some sectors.

What opportunities exist in the Riveting Equipment market?

Opportunities in the Riveting Equipment market include the growing trend towards automation in manufacturing and the increasing use of riveting in renewable energy projects, such as wind turbine assembly.

What trends are shaping the Riveting Equipment market?

Trends in the Riveting Equipment market include the development of smart riveting technologies that integrate IoT for better monitoring and control, as well as a shift towards more sustainable materials and processes.

Riveting Equipment market

| Segmentation Details | Description |

|---|---|

| Product Type | Hydraulic Riveters, Pneumatic Riveters, Electric Riveters, Manual Riveters |

| End User | Aerospace, Automotive OEMs, Shipbuilding, Construction |

| Technology | Ultrasonic, Laser, Mechanical, Cold |

| Application | Metal Fabrication, Assembly Lines, Maintenance, Repair |

Please note: The segmentation can be entirely customized to align with our client’s needs.

Please note: This is a preliminary list; the final study will feature 18–20 leading companies in this market. The selection of companies in the final report can be customized based on our client’s specific requirements.

North America

o US

o Canada

o Mexico

Europe

o Germany

o Italy

o France

o UK

o Spain

o Denmark

o Sweden

o Austria

o Belgium

o Finland

o Turkey

o Poland

o Russia

o Greece

o Switzerland

o Netherlands

o Norway

o Portugal

o Rest of Europe

Asia Pacific

o China

o Japan

o India

o South Korea

o Indonesia

o Malaysia

o Kazakhstan

o Taiwan

o Vietnam

o Thailand

o Philippines

o Singapore

o Australia

o New Zealand

o Rest of Asia Pacific

South America

o Brazil

o Argentina

o Colombia

o Chile

o Peru

o Rest of South America

The Middle East & Africa

o Saudi Arabia

o UAE

o Qatar

o South Africa

o Israel

o Kuwait

o Oman

o North Africa

o West Africa

o Rest of MEA

Trusted by Global Leaders

Fortune 500 companies, SMEs, and top institutions rely on MWR’s insights to make informed decisions and drive growth.

ISO & IAF Certified

Our certifications reflect a commitment to accuracy, reliability, and high-quality market intelligence trusted worldwide.

Customized Insights

Every report is tailored to your business, offering actionable recommendations to boost growth and competitiveness.

Multi-Language Support

Final reports are delivered in English and major global languages including French, German, Spanish, Italian, Portuguese, Chinese, Japanese, Korean, Arabic, Russian, and more.

Unlimited User Access

Corporate License offers unrestricted access for your entire organization at no extra cost.

Free Company Inclusion

We add 3–4 extra companies of your choice for more relevant competitive analysis — free of charge.

Post-Sale Assistance

Dedicated account managers provide unlimited support, handling queries and customization even after delivery.

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

GET A FREE SAMPLE REPORT

This free sample study provides a complete overview of the report, including executive summary, market segments, competitive analysis, country level analysis and more.

ISO AND IAF CERTIFIED

Suite #BAA205 Torrance, CA 90503 USA

24/7 Customer Support

Email us at